Tractor and automobile chassis load running-in test bench and its running-in process

A technology for automobile chassis and tractor, applied in the field of electromechanical, can solve the problems of long test preparation time, increase cost, waste energy, etc., and achieve the effect of saving work preparation time, reducing running-in time, and improving the quality of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

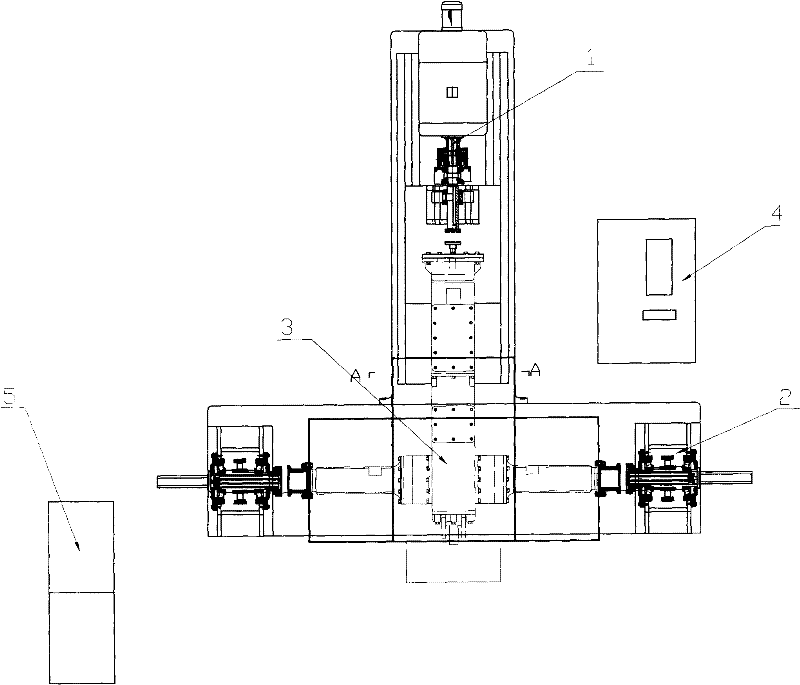

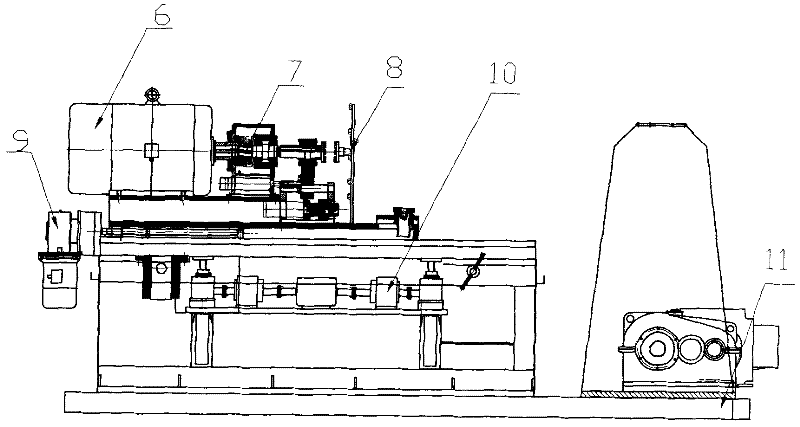

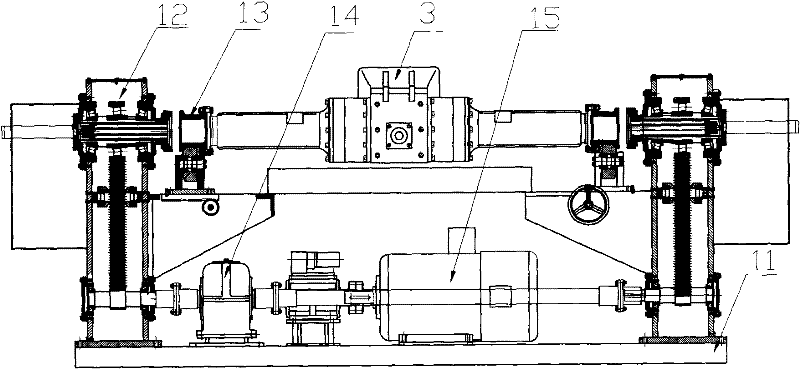

[0041] Such as figure 1 , 2 , shown in 3, tractor of the present invention and automobile chassis load run-in test bench, by input mechanism 1, elevating mechanism 10, output mechanism 2, loading mechanism (comprising loading speed-up box 14 and loading AC motor 15), base 11, hydraulic pressure Composed of purification system 4 and automatic control system 5;

[0042] The input mechanism 1 is located at one end of the base 11, and includes a traction motor 6, an input coupling mechanism 7, a front axle installation positioning mechanism 8 and a propulsion mechanism 9; the front axle installation positioning mechanism 8 is connected to the input on the traction motor 6 main shaft through a coupling The coupling mechanism 7 is connected; the traction motor 6 is connected with the lifting mechanism 10 installed on one end of the base 11 through the propulsion mechanism 9. The lifting mechanism 10 includes 4 lifters, 2 reducers, 1 lifting motor and 2 guide positioning Axle and e...

Embodiment 2

[0054] Such as figure 1 As shown, the running-in process of the tractor and automobile chassis load running-in test bench of the present invention is specifically: the tractor or the automobile chassis test piece 3 is installed on the tractor and the automobile chassis load running-in test bench, and the tractor and the automobile chassis load running-in test bench are started , the automatic control system 5 automatically loads and runs the chassis into stages, and starts the hydraulic purification system 4 at the same time, uses the purified oil to carry out the running-in purification on the tractor or the automobile chassis test piece 3 with a large flow pressure, and passes through the automatic control system during the running-in process. 5 Inspection and monitoring of the tractor or automobile chassis, the purified oil is recycled through the mesh filter and magnetic filter system, and the purified oil is composed of diesel oil, lubricating oil, and oily detergent in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com