PVD nano composite ceramic coating screw and method for manufacturing same

A composite ceramic and screw technology, applied in the direction of coating, metal material coating technology, layered products, etc., to achieve good adhesion, overcome heavy metal pollution problems, and easy to promote on a large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

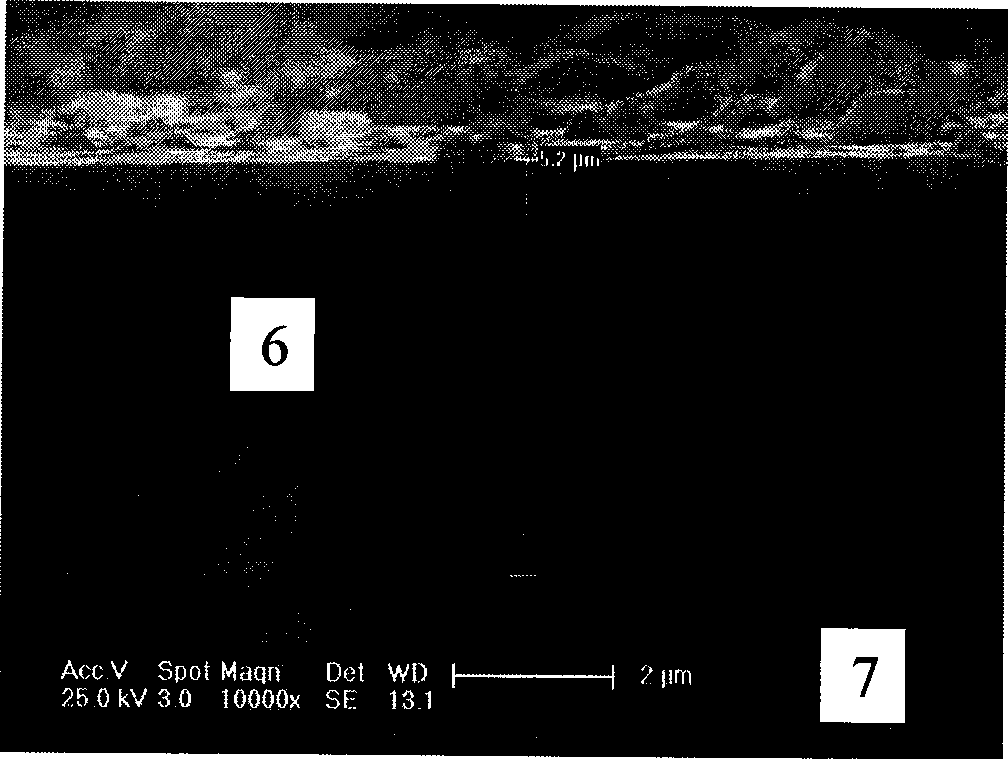

[0019] Example 1: Under the atmosphere of argon gas at 350°C, the nitriding-treated screw is glow-discharge cleaned, and the cleaning bias is -1000V; The transition metal Cr layer; then deposit 4 micron CrN / CN composite superhard coating under the conditions of 400°C, -200V bias, and 0.5Pa pressure; A 2-micron Cr-doped diamond-like carbon film was deposited under 0.5Pa air pressure; after the manufacture, it was naturally cooled to obtain a PVD composite ceramic-coated screw. The hardness of the surface coating of the ceramic coated screw was tested by the indentation method of the obtained screw, and the hardness of the surface coating of the ceramic coated screw was 42GPa. The thickness of the coating was measured by the optical interference method to be about 6 microns, and the coefficient of friction of the coating was tested by a friction and wear instrument to be 0.15.

Embodiment 2

[0020] Example 2: Under the environment of 400°C and argon gas, the nitriding-treated screw is glow-discharge cleaned, and the cleaning bias is -900V; The transition metal Ti layer; then deposit a 3-micron TiN / CN composite superhard coating under the conditions of 350°C, -150V bias, and 0.4Pa pressure, and the TiN crystal grain size is controlled below 10 nanometers; when the main wear-resistant layer is deposited, A 3-micron Ti-doped diamond-like carbon film was deposited under the conditions of 100°C, -80V bias voltage, and 0.4Pa air pressure; after the manufacturing was completed, it was cooled naturally to obtain a PVD composite ceramic-coated screw. The hardness of the ceramic coating screw surface coating is Hv greater than 45GPa, the coating thickness is about 6 microns, and the coating friction coefficient is 0.1.

Embodiment 3

[0021] Example 3: Under the environment of 400°C and argon gas, the nitriding-treated screw is glow-discharge cleaned, and the cleaning bias is -1200V; The transition metal Zr layer; then deposit a 3 micron ZrN / CN nanocomposite superhard coating under the conditions of 380°C, -200V bias, and 0.6Pa pressure; 1. Deposit 2 micron Ti-doped diamond-like carbon film under 0.3Pa air pressure condition; naturally cool after manufacturing, and obtain PVD composite ceramic coated screw. The hardness of the ceramic coating screw surface coating is Hv greater than 43GPa, the coating thickness is about 5 microns, and the coating friction coefficient is 0.18.

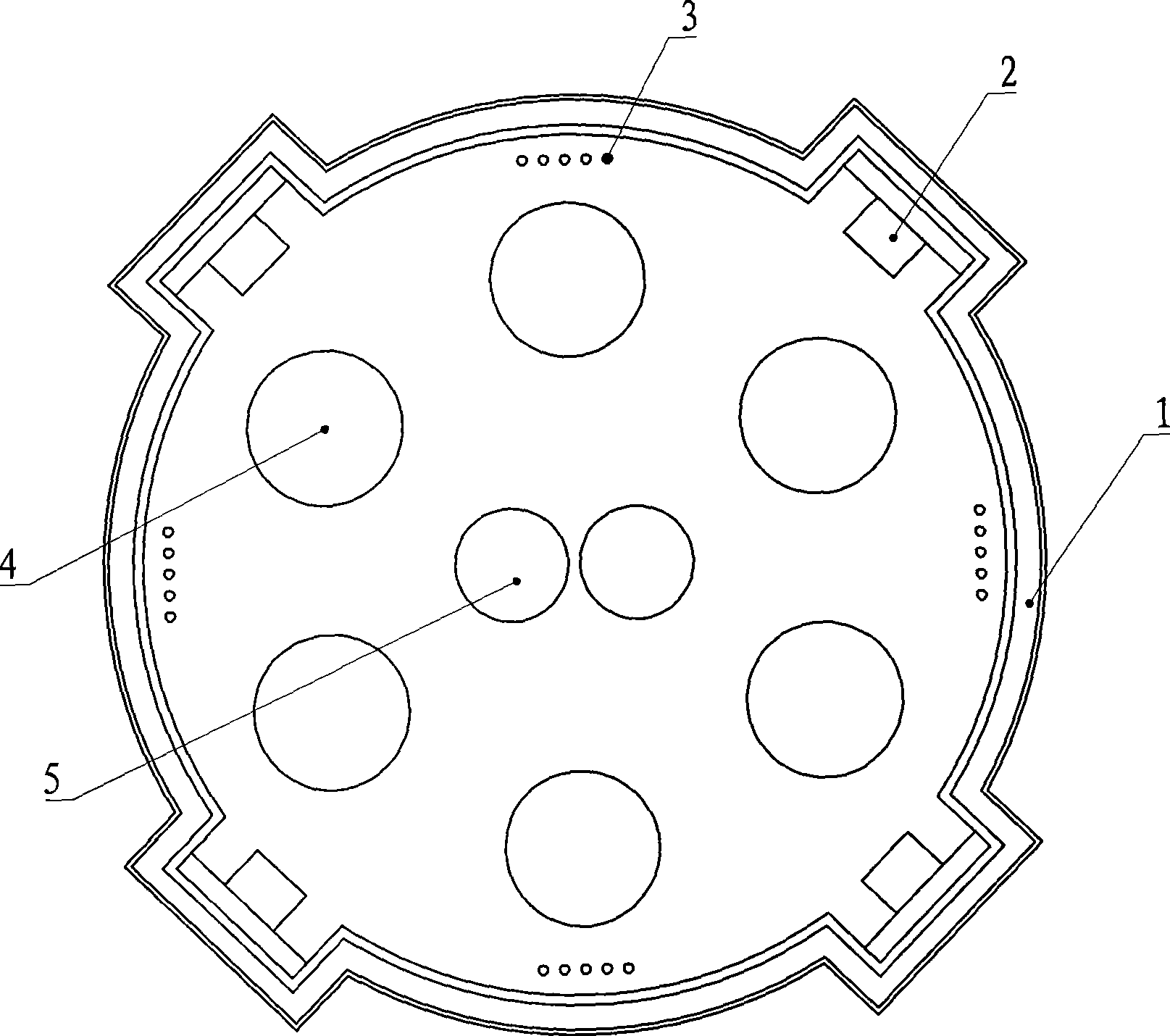

[0022] figure 1In order to implement the PVD equipment adopted in the present invention, the vacuum chamber 1 is surrounded by furnace walls, and the vacuum chamber is provided with a vacuum port and a working gas discharge port. An arc target 2 , a magnetron target 5 , a receipt device 3 and an independent workpiece holder 4 are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com