Multifunctional following optical cable welding workbench

A multi-functional, workbench technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of increasing the labor burden of operators, reducing work efficiency, and inconvenient portability, so as to facilitate fault analysis and file establishment, and improve work efficiency , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

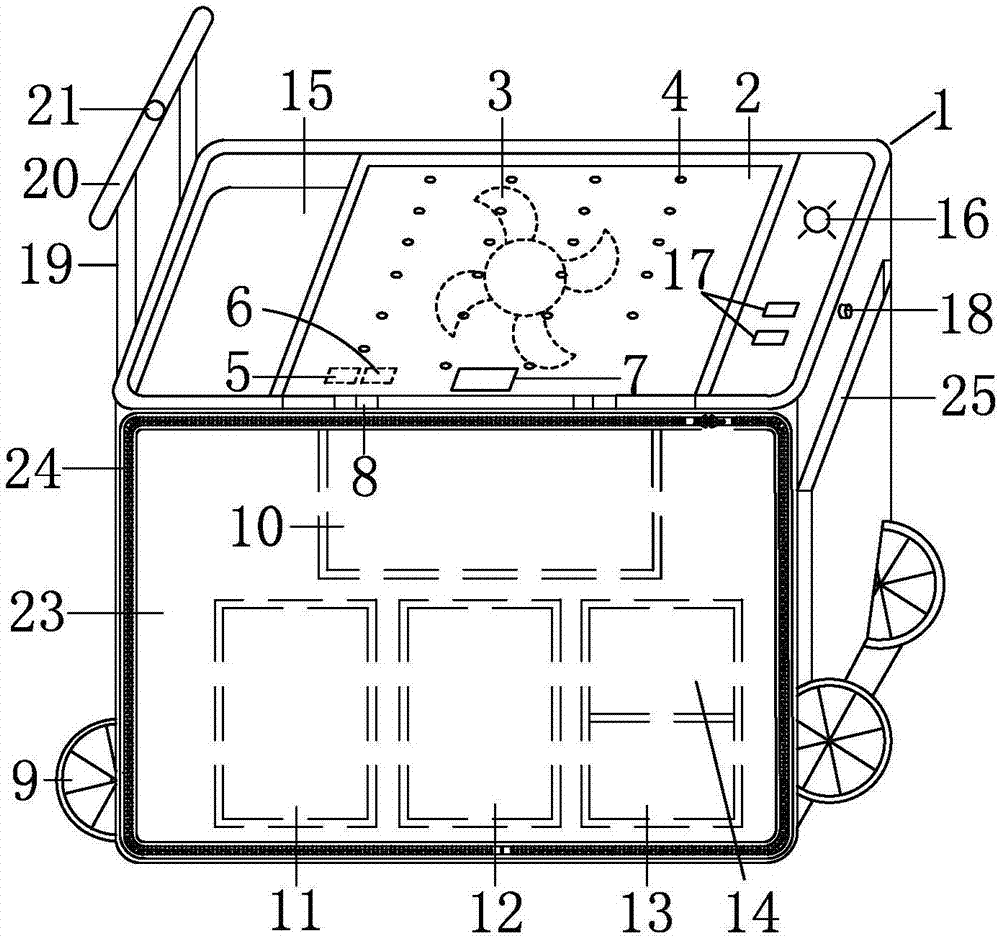

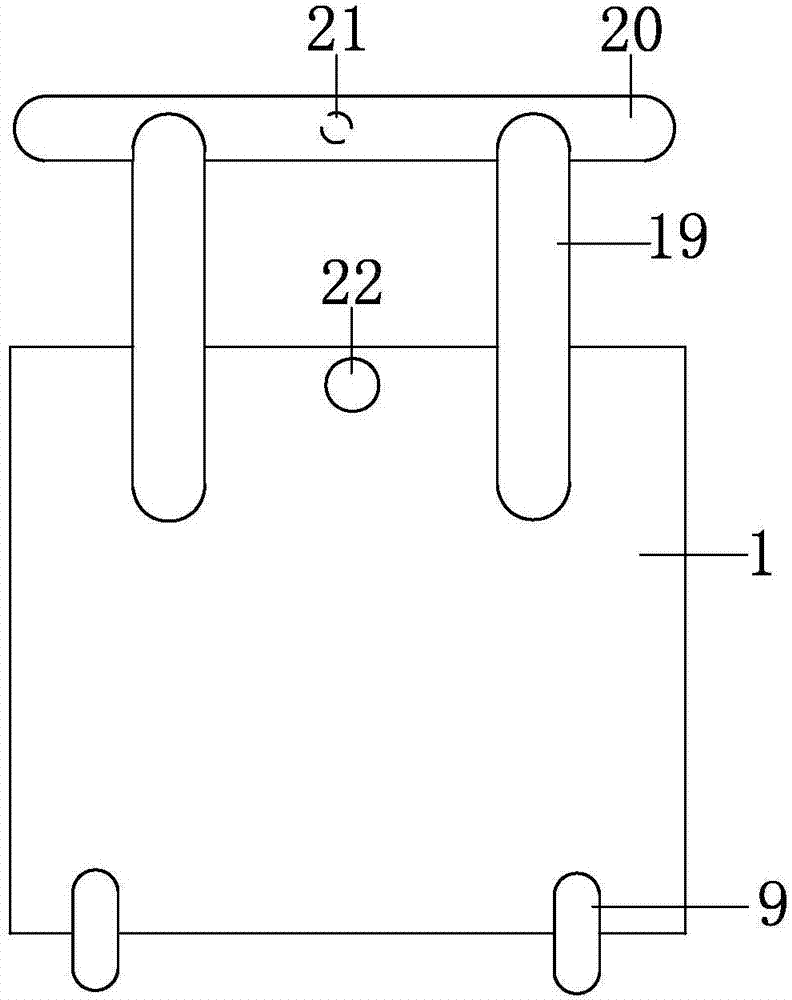

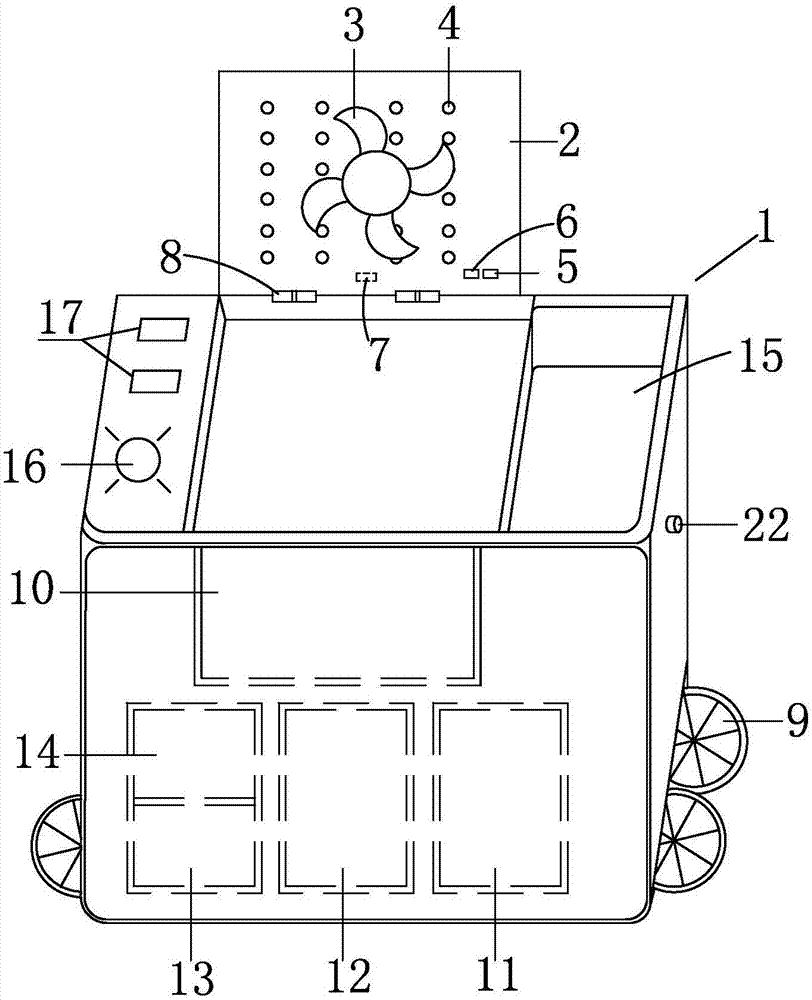

[0025] Such as Figure 1 to Figure 3 Shown: a multi-functional follow-up optical cable welding workbench, including a box body 1, the upper top surface of the box body 1 is provided with a work surface 2, and the work surface 2 is connected to the upper surface of the box body 1 through a damping hinge structure 8 The front and side edges of the top are connected, and the side of the worktable 2 facing the inside of the box body 1 is provided with a fan 3. The fan 3 is arranged in parallel with the worktop 2, and the side of the worktable 2 facing the inside of the box 1 is close to the fan. 3. A temperature sensor 5 and a temperature sensing controller 6 are also provided at the left front side. The temperature sensor 5 and the temperature sensing controller 6 are arranged horizontally. Connect with the temperature sensor 5, the temperature sensor 5 is connected with the temperature sensing controller 6 through the wire, the temperature sensing controller 6 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com