Pile prepressing method of four-pile-leg self-elevating platform

A self-elevating platform and pile leg technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of long operation preparation time and operation risks, shorten operation time, save operation preparation time, The effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

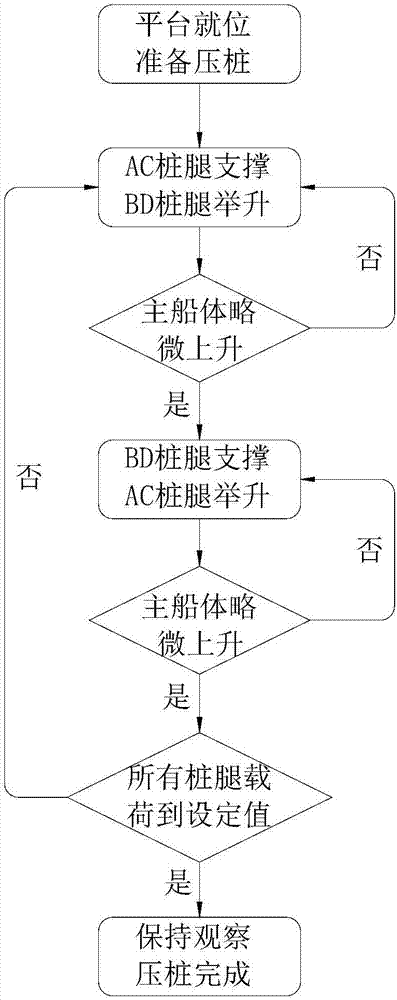

[0028] The invention provides a method for preloading piles of a self-elevating platform with four legs. The method mainly includes the following steps:

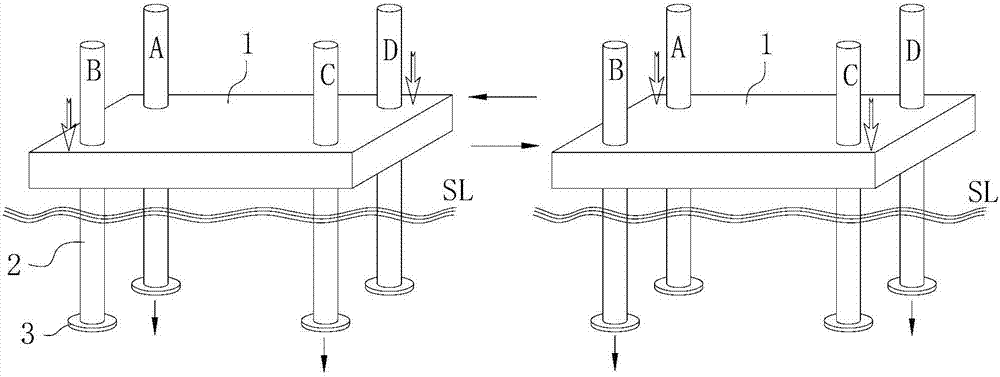

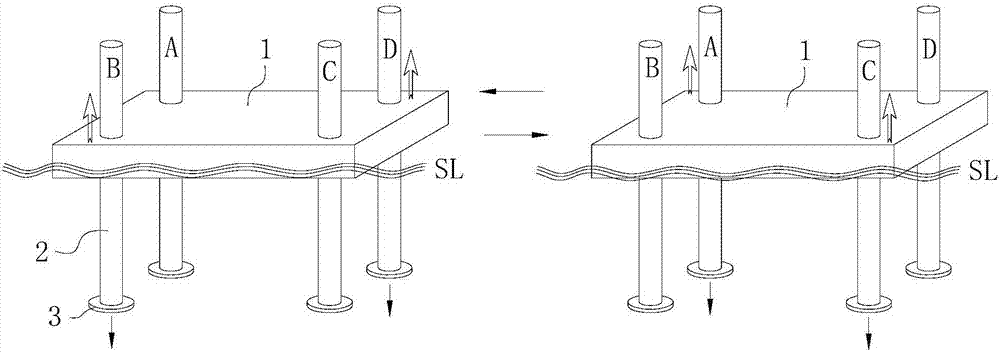

[0029] S10: platform stake positioning; combination figure 2 , in this step, make the platform reach the predetermined sea area, keep the main hull 1 of the platform floating in the sea water, and lower the four legs 2 of the platform until the spud cans 3 at the bottom of each leg 2 are positioned on the seabed.

[0030] S20: Keep the main hull 1 floating in the sea water, make the two legs 2 on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com