Patents

Literature

133results about How to "Reduce homework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washing machine

InactiveCN101328660AReduce frictionAvoid damageOther washing machinesControl devices for washing apparatusUser needsPulp and paper industry

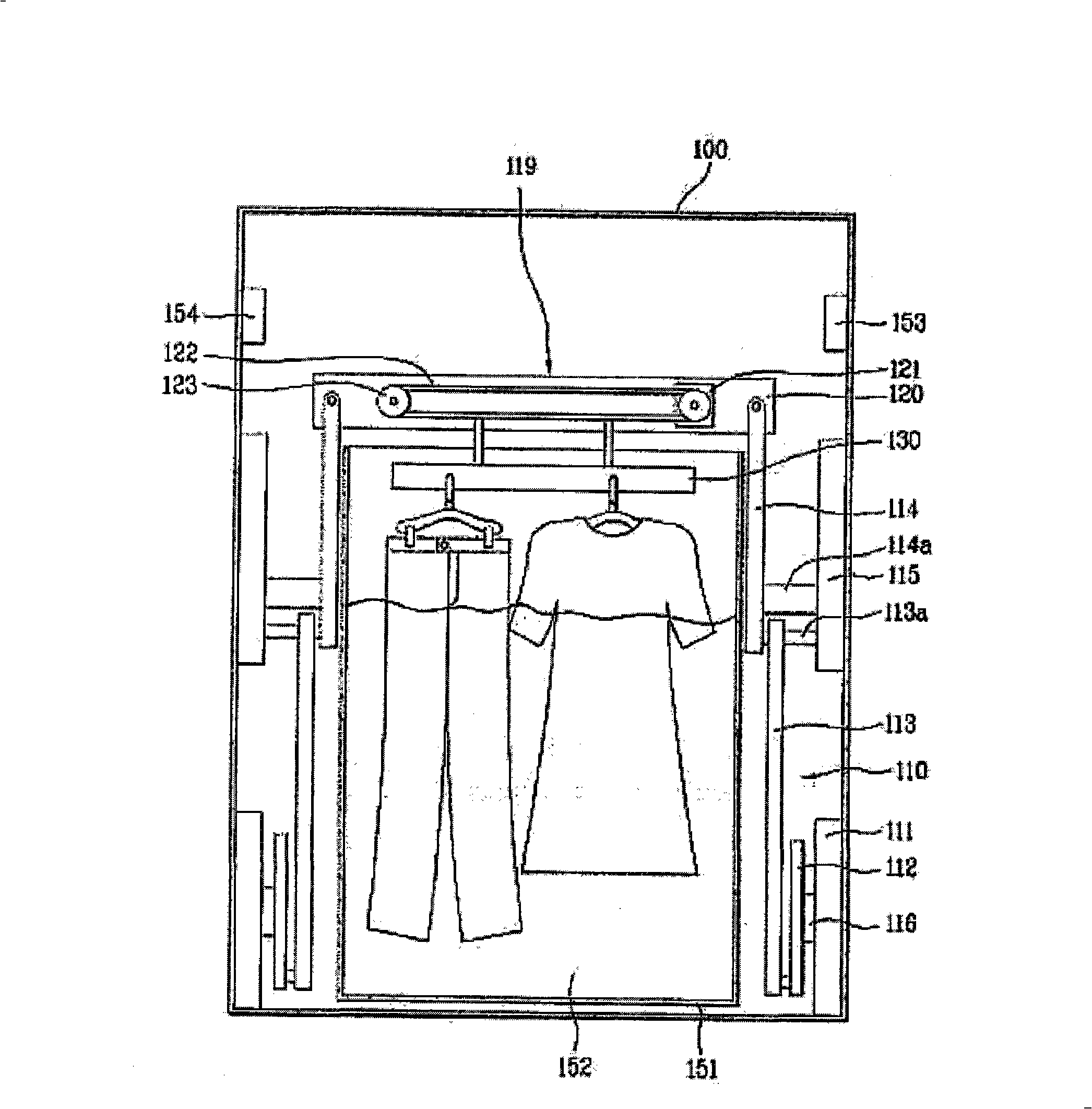

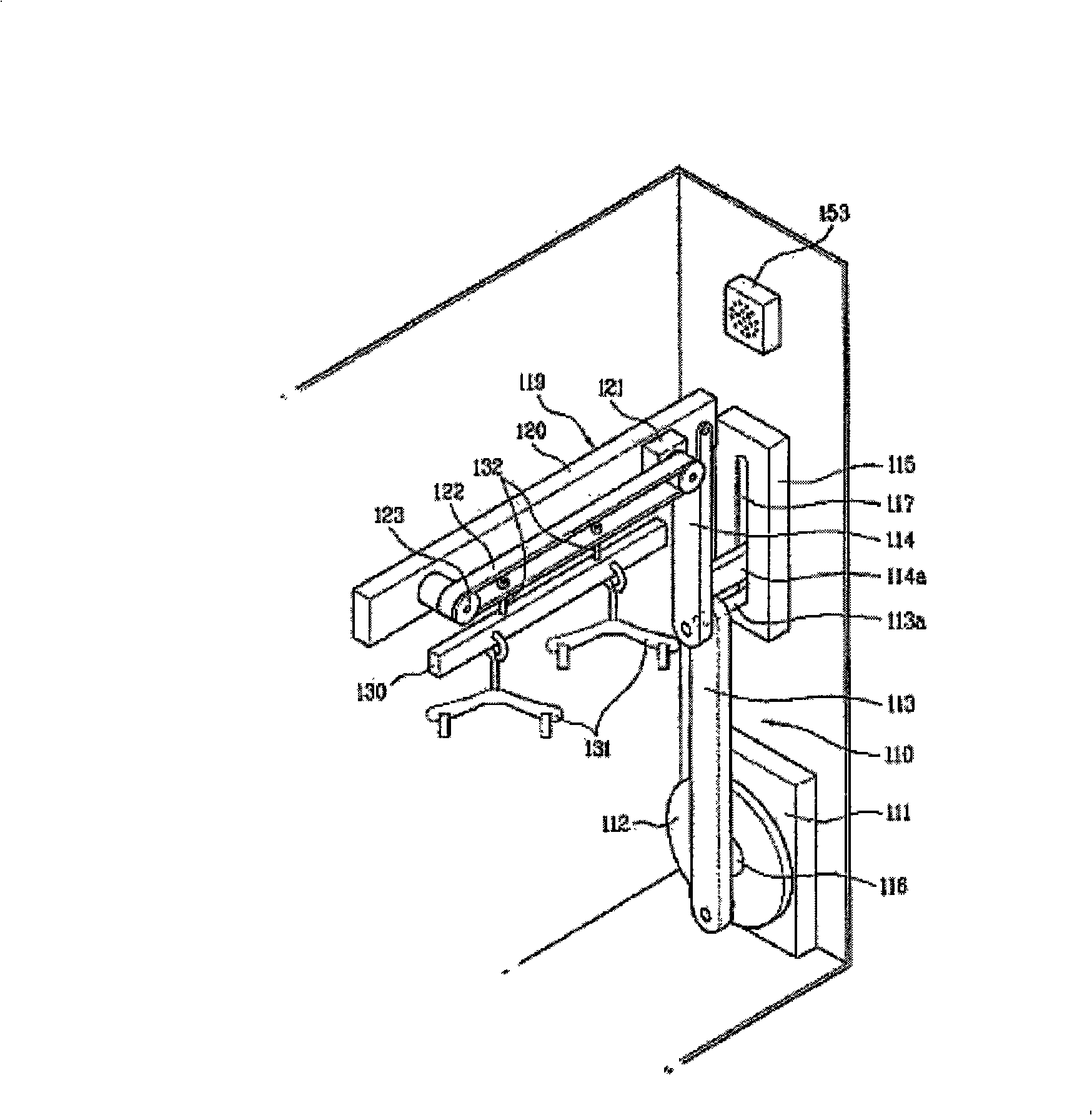

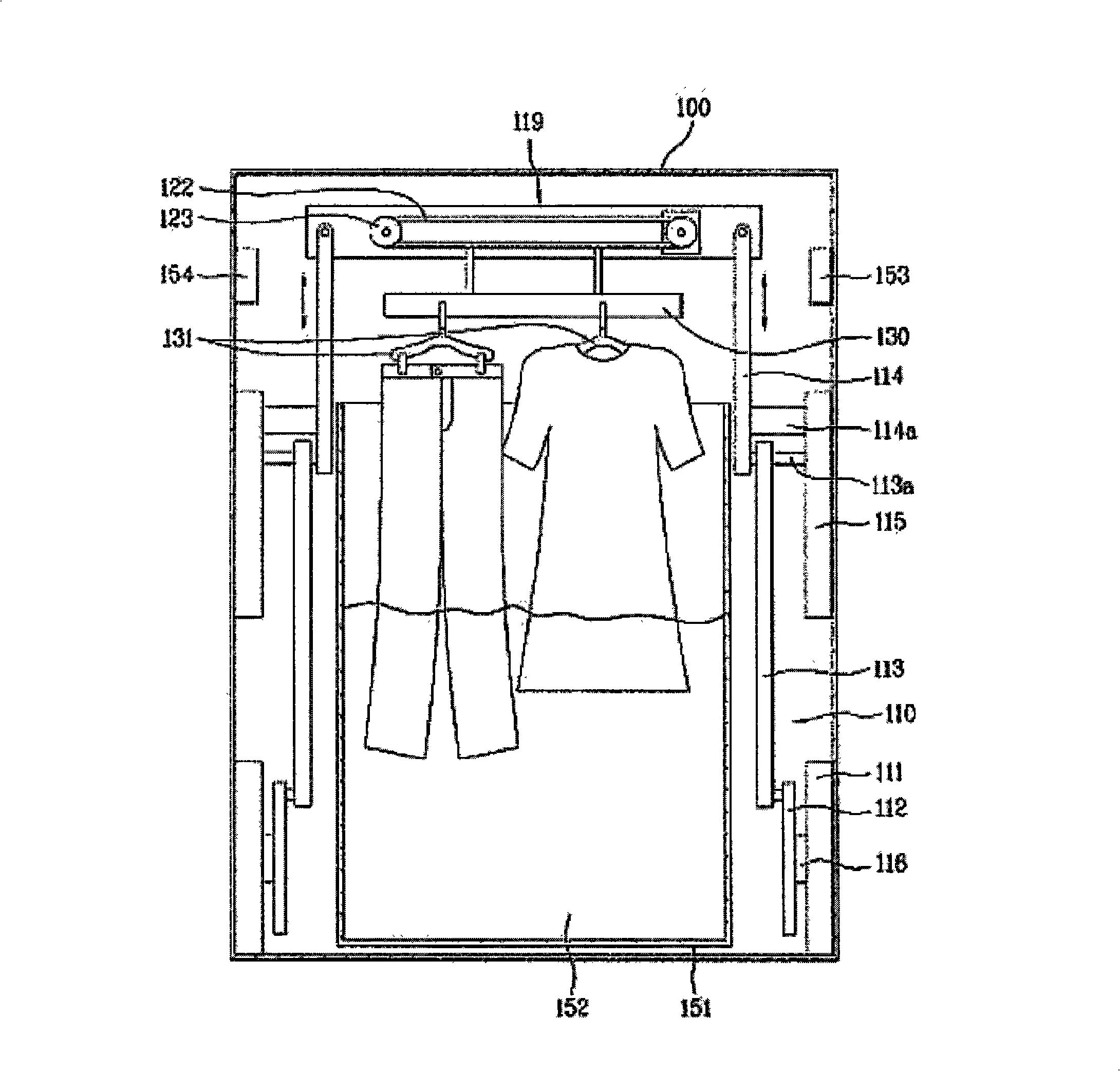

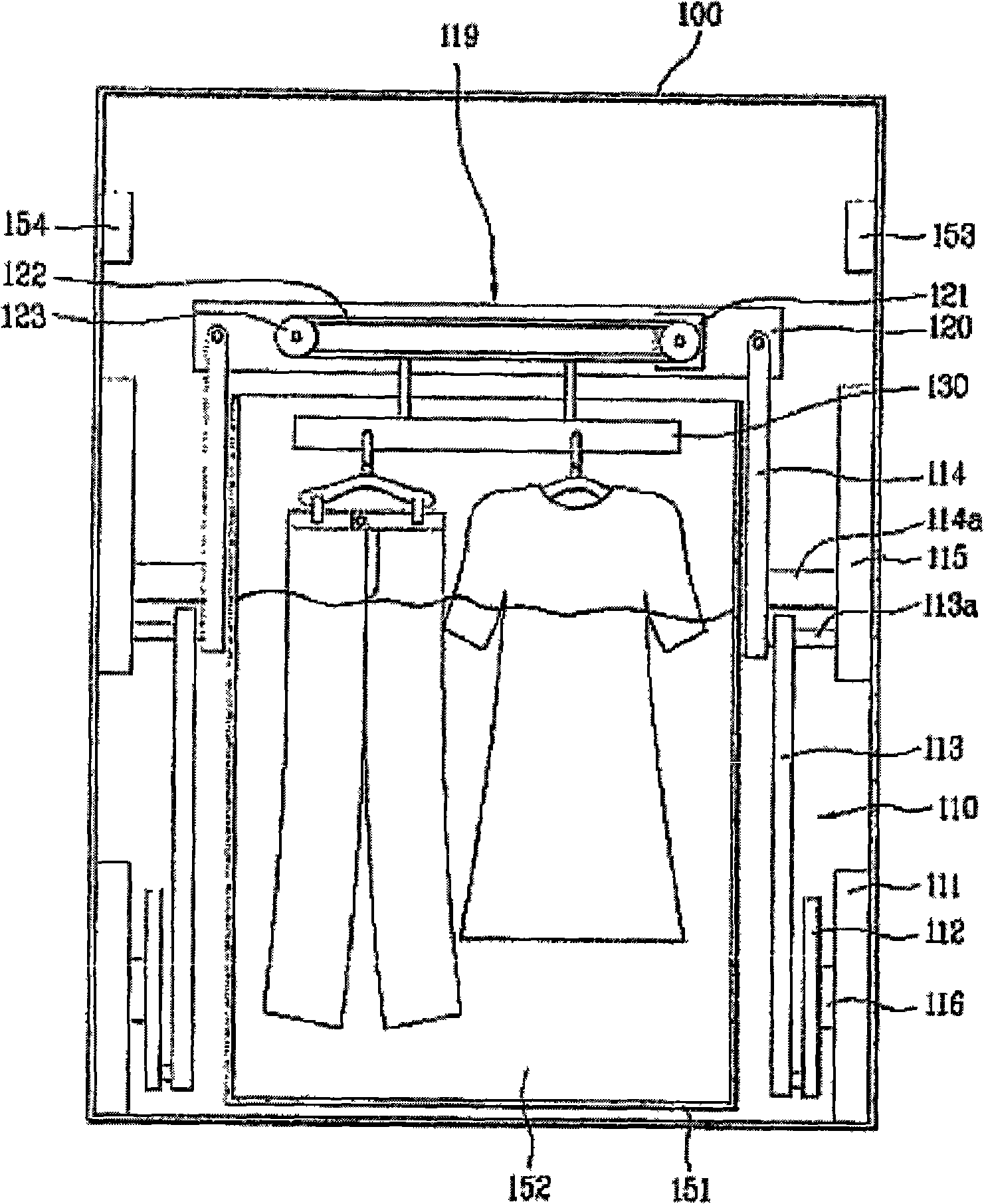

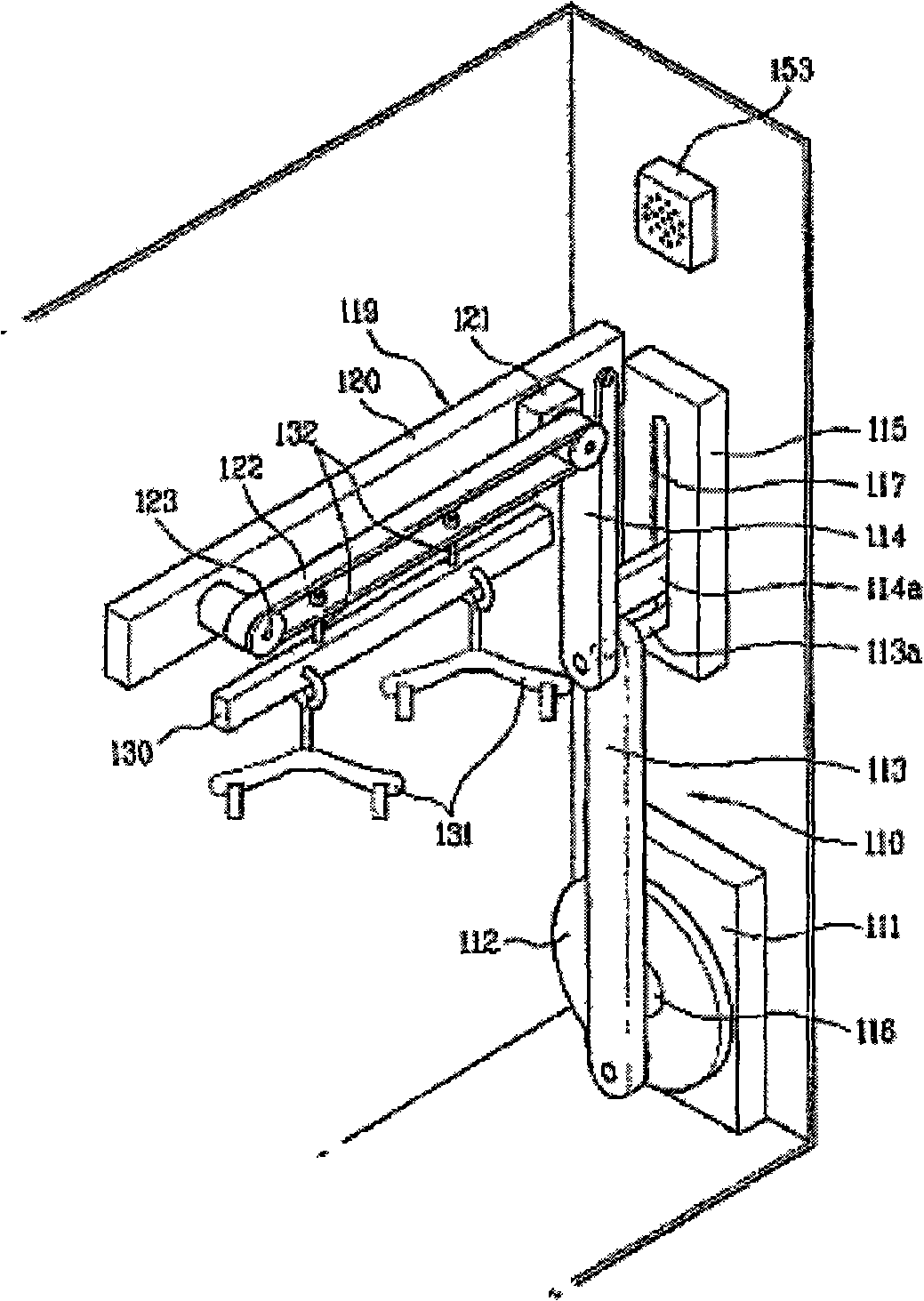

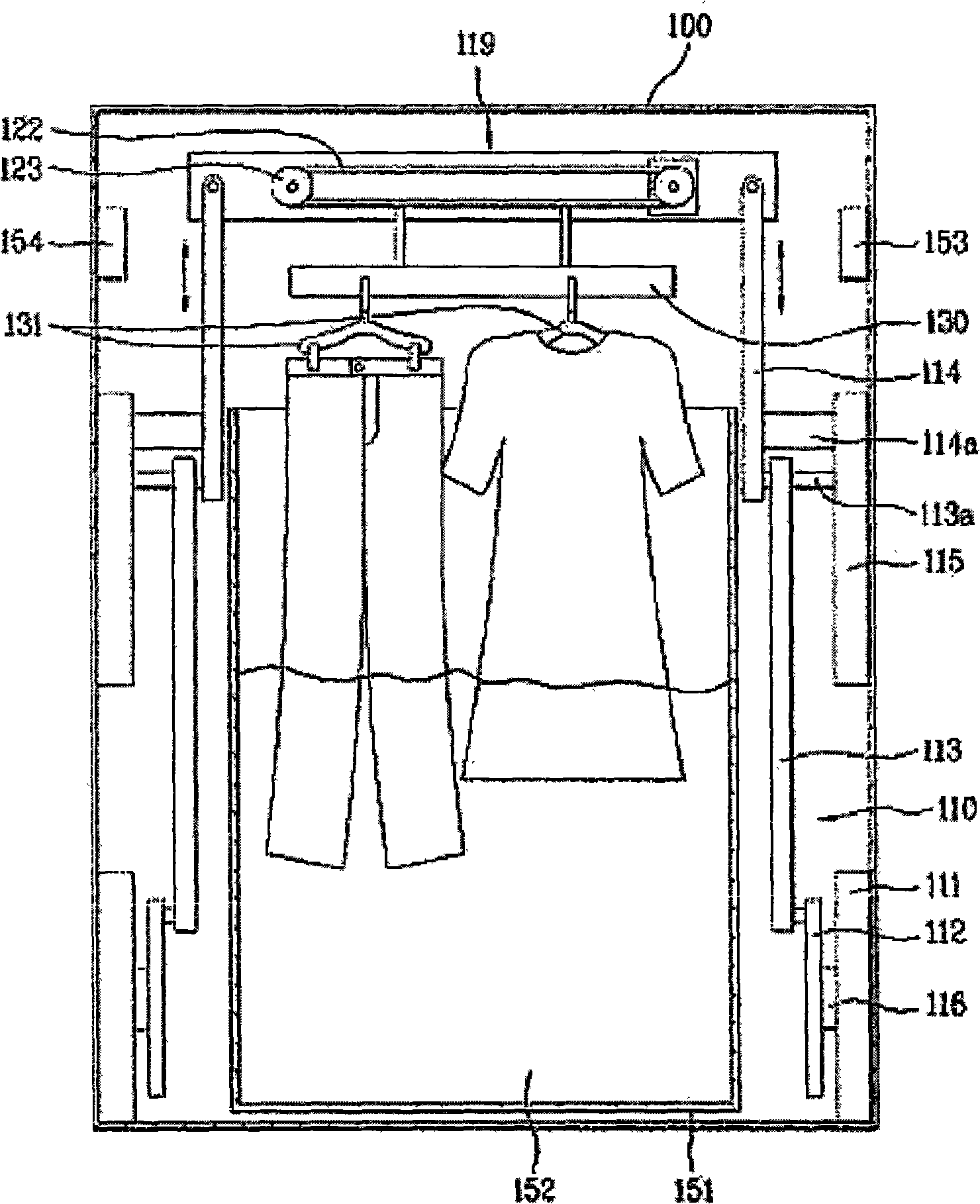

The invention discloses a washing machine, which can have a washing do linear movements in an up-down direction and carry out washing operation. The washing machine comprises a shell (100), a washing cylinder (151), a suspension device (130) and an up-down drive unit (110), wherein the shell forms the external appearance of the washing machine; the washing cylinder is positioned inside the shell (100) and is used for holding washing water; the suspension device moves the washing in the up-down direction to ensure that at least one side of the washing is soaked in the washing water (152) inside the washing cylinder (151); and the up-down drive unit (110) is used for driving the suspension device (130) in the up-down direction. When the washing machine is used for washing clothes, the washing cannot be intertwined, which can reduce inconvenient operation that users need to separate the washing and can reduce friction between the washing in the washing machine and a washing groove during rotation, so as to reduce the damage to the washed clothes.

Owner:NANJING LG PANDA APPLIANCES

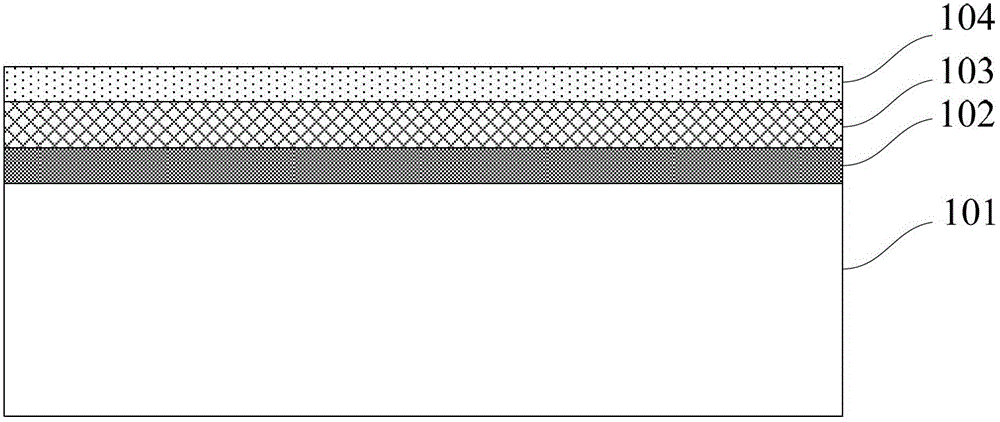

Method for cutting light emitting diode chip through deep etching

InactiveCN102881783AReduce homeworkAvoid chippingSemiconductor/solid-state device manufacturingSemiconductor devicesEtchingLaser cutting

The invention provides a method for cutting a light emitting diode chip through deep etching. The method comprises the following steps: firstly, forming a light emitting element comprising a plurality of light emitting units on the surface of a semiconductor substrate; then fabricating a protecting layer with etching windows formed at the connections between each of the light emitting units; etching from each of the etching windows to form sliver channels; next, filling each of the sliver channels with insulation material and thinning the semiconductor substrate from back until exposing the insulation material; and finally making a back coating, removing the insulation material in each of the sliver channel, and expanding the film to obtain independent light emitting units. According to the invention, by adopting the method of forming the sliver channels through deep etching, the cut grooves are deep into the sapphire substrate, thus avoiding laser cutting processing step, avoiding the problem of light absorption caused by laser ablation, and increasing light outgoing efficiency; and the deep etching depth is equivalent to the final thickness of the chip, and separated chip grains can be obtained by removing the filled SiO2, thus reducing sliver operation, avoiding broken sides and broken corners in the slivers, and increasing the yield.

Owner:施科特光电材料(昆山)有限公司

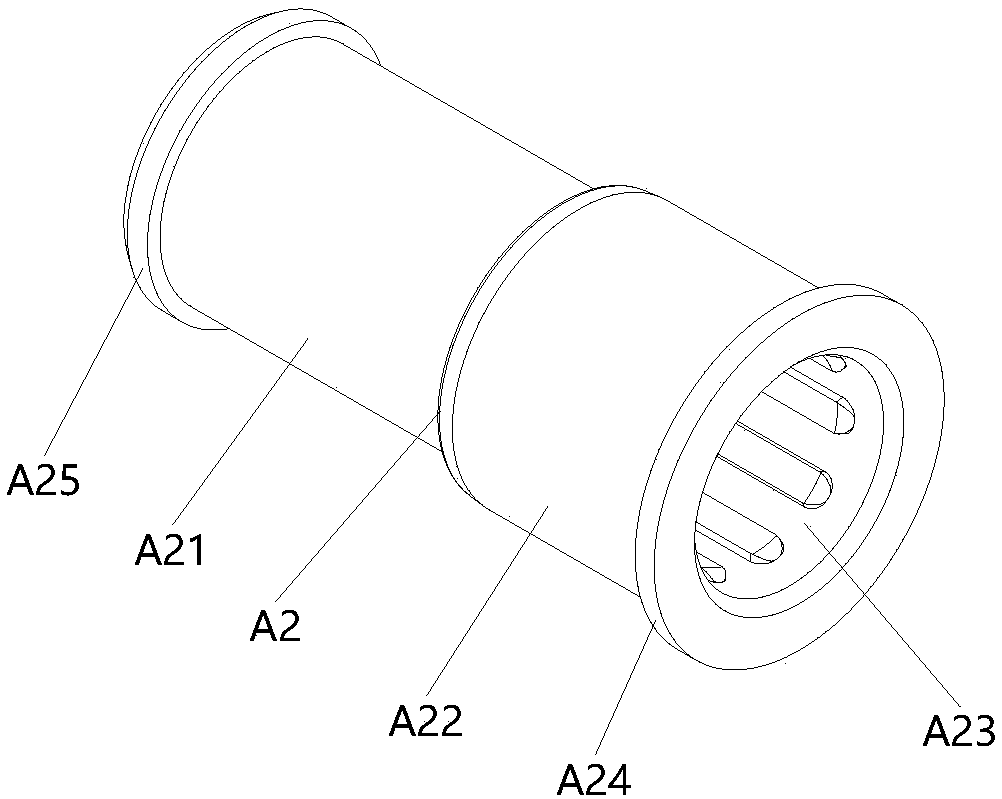

Rail gauge transformation component for gauge-changeable bogie

PendingCN107628055AImprove efficiencyReduce homeworkBogiesDifferent width rail tracksRail transportationBogie

The invention belongs to the technical field of railway rail devices, and particularly relates to a rail gauge transformation device which comprises a supporting rail, an unlocking rail and a guide rail. The supporting rail comprises a supporting preparing rail and a supporting continuing rail, the unlocking rail comprises an unlocking preparing rail and an unlocking continuing rail, the supporting preparing rail forms a supporting section, the supporting continuing rail and the unlocking preparing rail form an unlocking section, and the supporting continuing rail, the unlocking continuing rail and the guide rail form a guide section. The invention aims to provide a rail gauge transformation device to solve the problem of low efficiency of a rail gauge transformation mode of a bogie, so that the gauge-changeable bogie can automatically transform rail gauge specifications after passing the rail gauge conversion device. Railway transportation of a 'silk road economic belt' is implemented, the problem of non-uniform railway gauges needs to be solved, and the ground rail gauge transformation device is an essential device in a rail transformation link, so that design of the ground railgauge transformation device has quite important and profound significance.

Owner:SOUTHWEST JIAOTONG UNIV +1

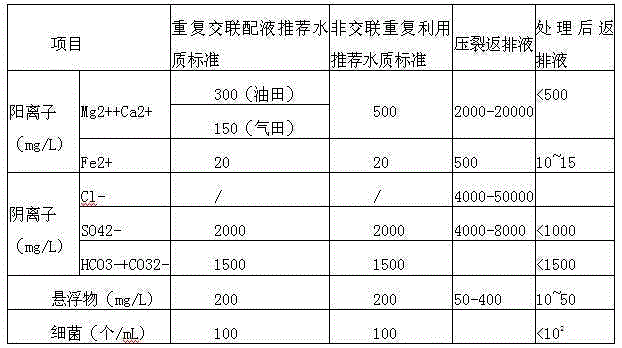

Oil and gas well fracturing flow-back fluid treatment method

The invention relates to an oil and gas well fracturing flow-back fluid treatment method. The method comprises the steps that fracturing flow-back fluid flowing back from an oil well mouth enters a buffer tank to be oxidized, a conditioning agent is added into the oxidized fracturing flow-back fluid, the PH of the oxidized fracturing flow-back fluid is adjusted to range from 7.5 to 9, the adjusted fracturing flow-back fluid is fed into a reactor through a lift pump, a treatment agent is added into the fracturing flow-back fluid in the reactor, sufficient mixing and reaction are achieved to generate floccule, the reacted mixture is pumped into a solid-liquid separation device for solid-liquid separation, solid phases obtained after separation are directly discharged out of the solid-liquid separation device, liquid phases obtained after separation enter a fine treatment device, and suspended matter, chromaticity and large-particle ions are removed further. Up-to-standard release and recycle of discharged water are achieved, the fracturing flow-back fluid is treated, flocculating settling, solid-liquid separation and filtering and clarification are efficiently and continuously achieved for oil and gas well fracturing flow-back fluid in an oil field, and the purposes of recycling, up-to-standard release and reinjection into a reservoir are achieved.

Owner:SHAANXI HAIMO OILFIELD SERVICE +2

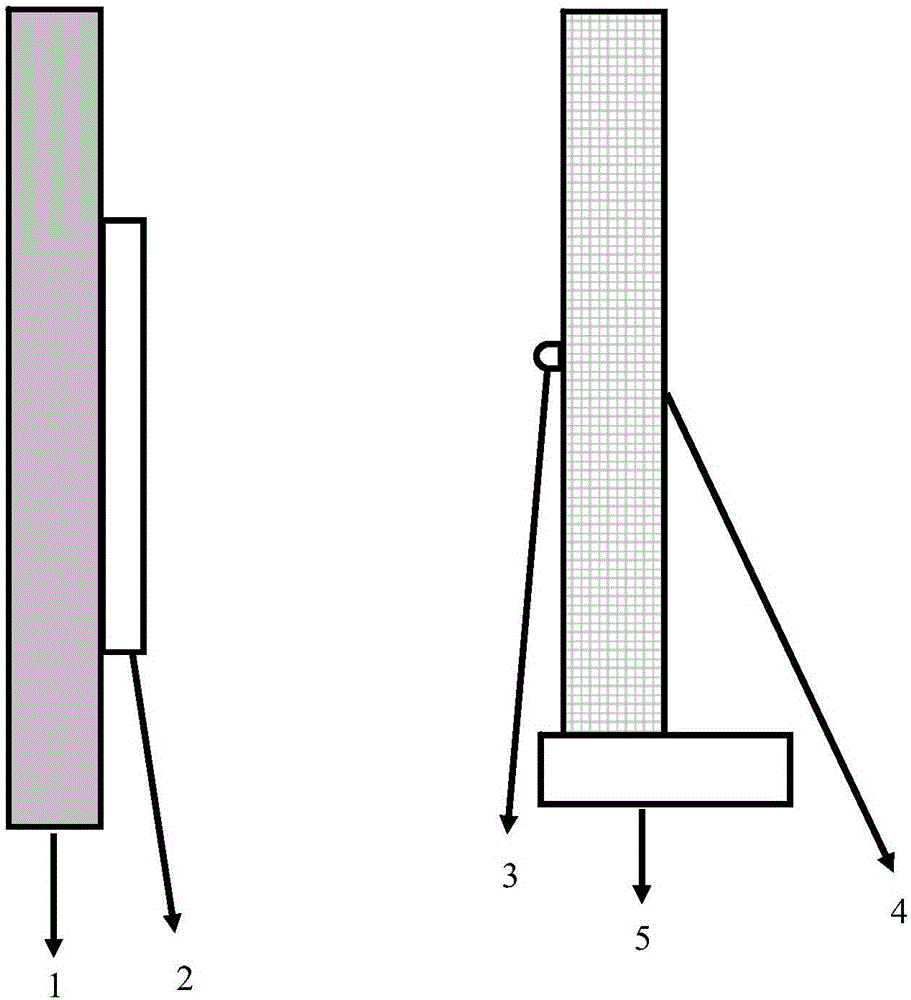

LED (light emitting diode) display light box

The invention discloses an LED (light emitting diode) display light box. The LED display light box comprises a diffuser and an advertising panel, wherein the bottom of the diffuser is connected with a rotating device, the rotating device is arranged in a cavity of a supporting device, the supporting device is used for supporting the diffuser above the supporting device, the advertising panel is arranged on the outer side of the diffuser, a plurality of LED (light emitting diode) light sources are arranged inside an area formed by the diffuser, and the LED light sources are uniformly arranged in parallel in the vertical direction. The LED lamps are arranged in the display light box to be used as the light sources, so that the consumption of the electric energy can be greatly reduced, and the electric energy can be reduced by more than 80 percent; meanwhile, since the service life of the LED lamp is long, the LED display light box can be used for a long time, the unnecessary operation and corresponding maintenance expense for disassembling the display light box caused by the damage of a bulb can be reduced; the rotating device is arranged below the integral light box, the display light box can be driven to rotate, the content on different advertising panels can be displayed, and the propaganda effect is better.

Owner:温宗峰

Washing machine

The invention discloses a washing machine that can make washing move up and down in a straight line and execute washing operation. The washing machine comprises: an outer casing that forming the appearance (100); a wash cylinder (151) inside the outer casing (100) and is used to contain washing water (151); a suspension device (130) that makes the washing move up and down and at least one side of the washing dip in the washing water (152) in the wash cylinder (151); and an up-down driving element (110) that drives the suspension device (130) up and down. When the washing machine of the invention is used in clothes washing, the washing does not twist together so that inconvenient operations needed to separate the washing by the user can be reduced; meanwhile, friction between the washing in the washing machine and the washing tank when revolving can also be reduced so as to avoid damage to the clothes washed.

Owner:NANJING LG PANDA APPLIANCES

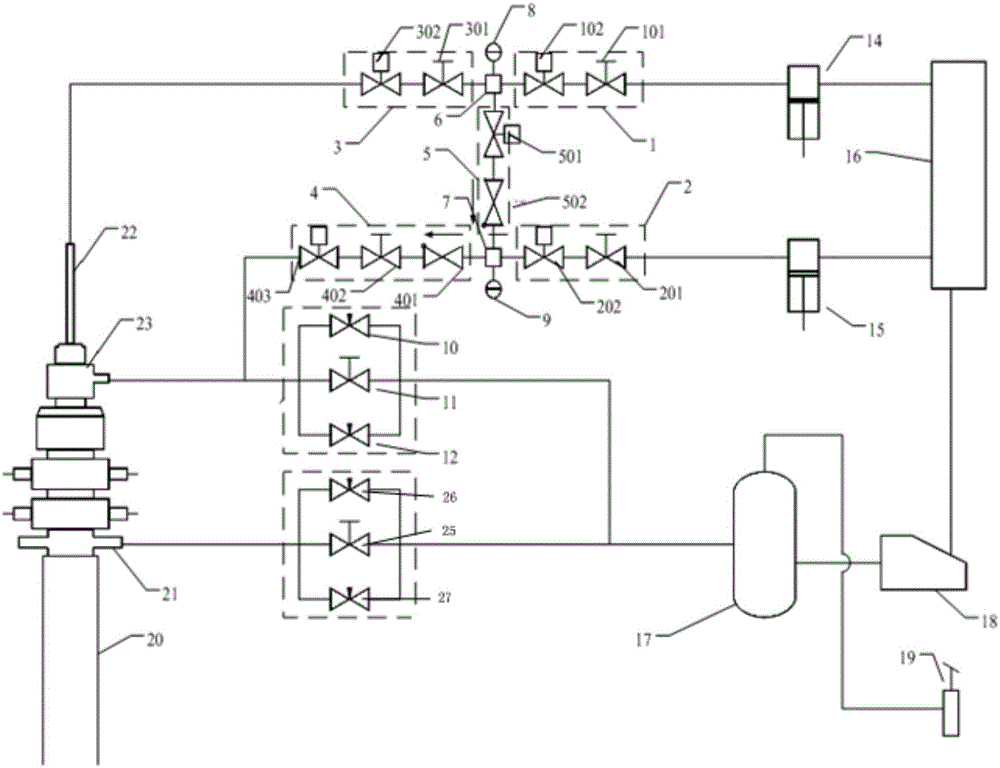

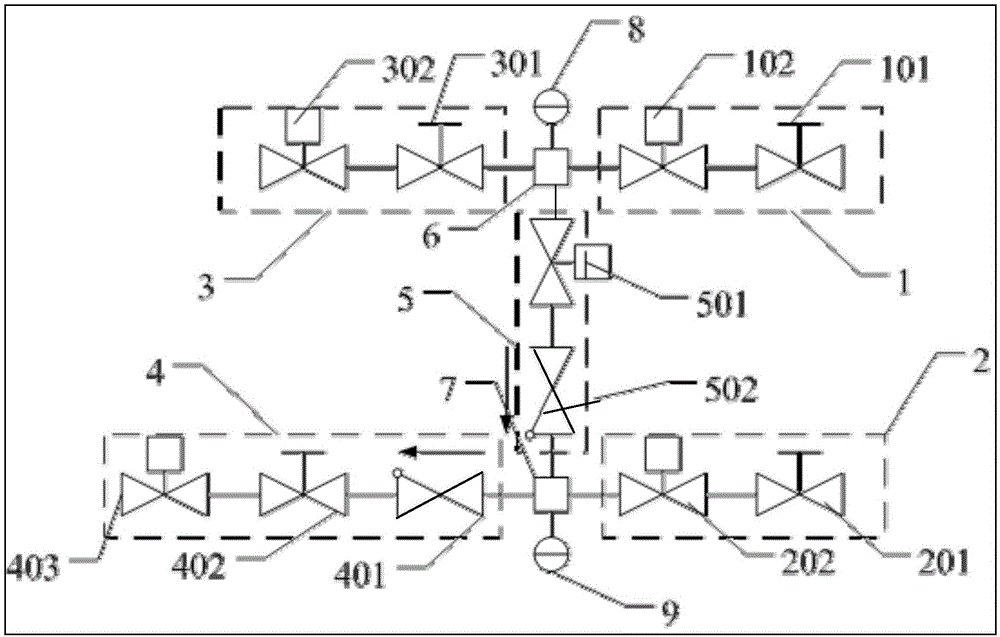

Pressure-control drilling system utilizing automatic shunt manifold for pressure-control drilling and pressure-control drilling method

ActiveCN106401512ASmall pressure fluctuationsImprove controlFlushingBottom hole pressureWell drilling

The invention discloses a pressure-control drilling system utilizing an automatic shunt manifold for pressure-control drilling and a corresponding pressure-control drilling method. The pressure-control drilling system comprises a drilling spool, a rotary control head, a drilling column, an automatic shunt manifold, an automatic throttle manifold and a throttle manifold; the drilling spool, the rotary control head and the drilling column are arranged at a wellhead at the upper part of a mineshaft; and the automatic shunt manifold, the automatic throttle manifold and the throttle manifold respectively communicate with the drilling column, a by-pass pipeline of the rotary control head and a by-pass pipeline in the blowout direction of the drilling spool. Due to the arrangement ways of all the manifolds and the mutual opening / closing matching between hydromatic valves and check valves arranged on all the manifolds and the utilization of a drilling fluid pump equipped for a drilling crew at present, the pressure-control drilling operation is realized; and through controlling the automatic shunt manifold for pressure-control drilling in connection making and tripping processes, the fluctuation of bottom hole pressure can be reduced, the control capacity for the bottom hole pressure can be improved, the no-drilling time can be shortened, the drilling cost can be reduced, and the operation incapability caused by a fault of a pressure return pump can be avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

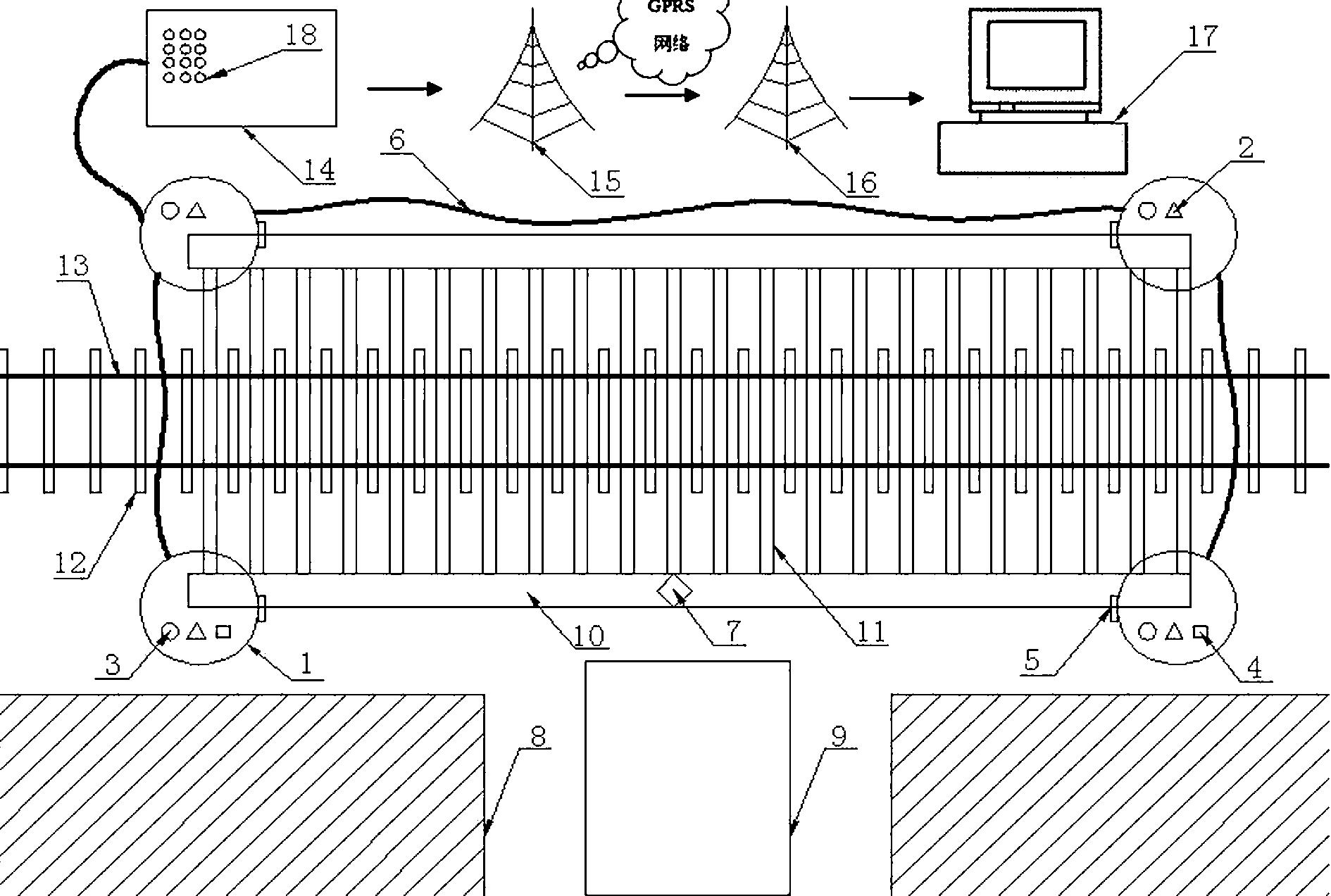

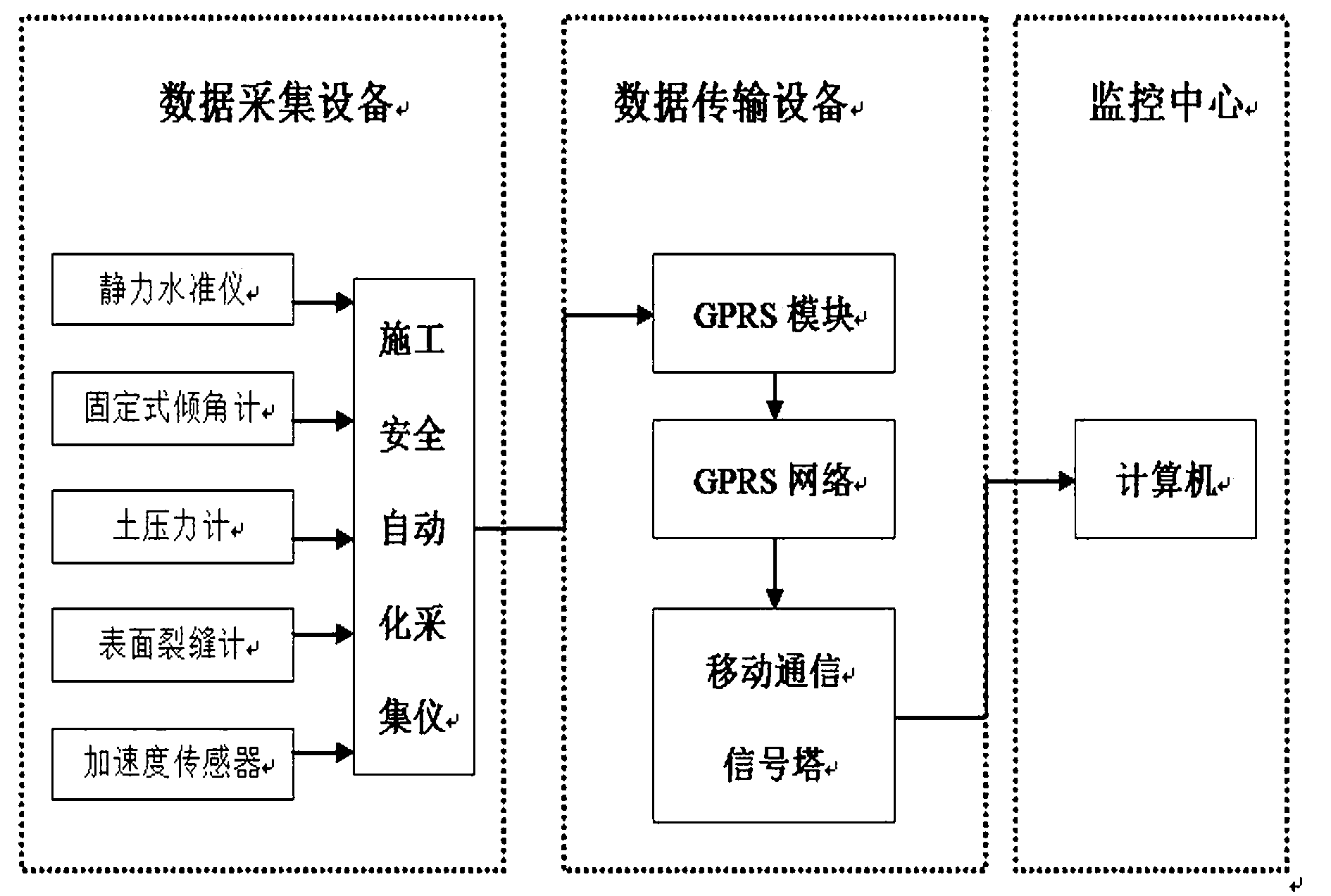

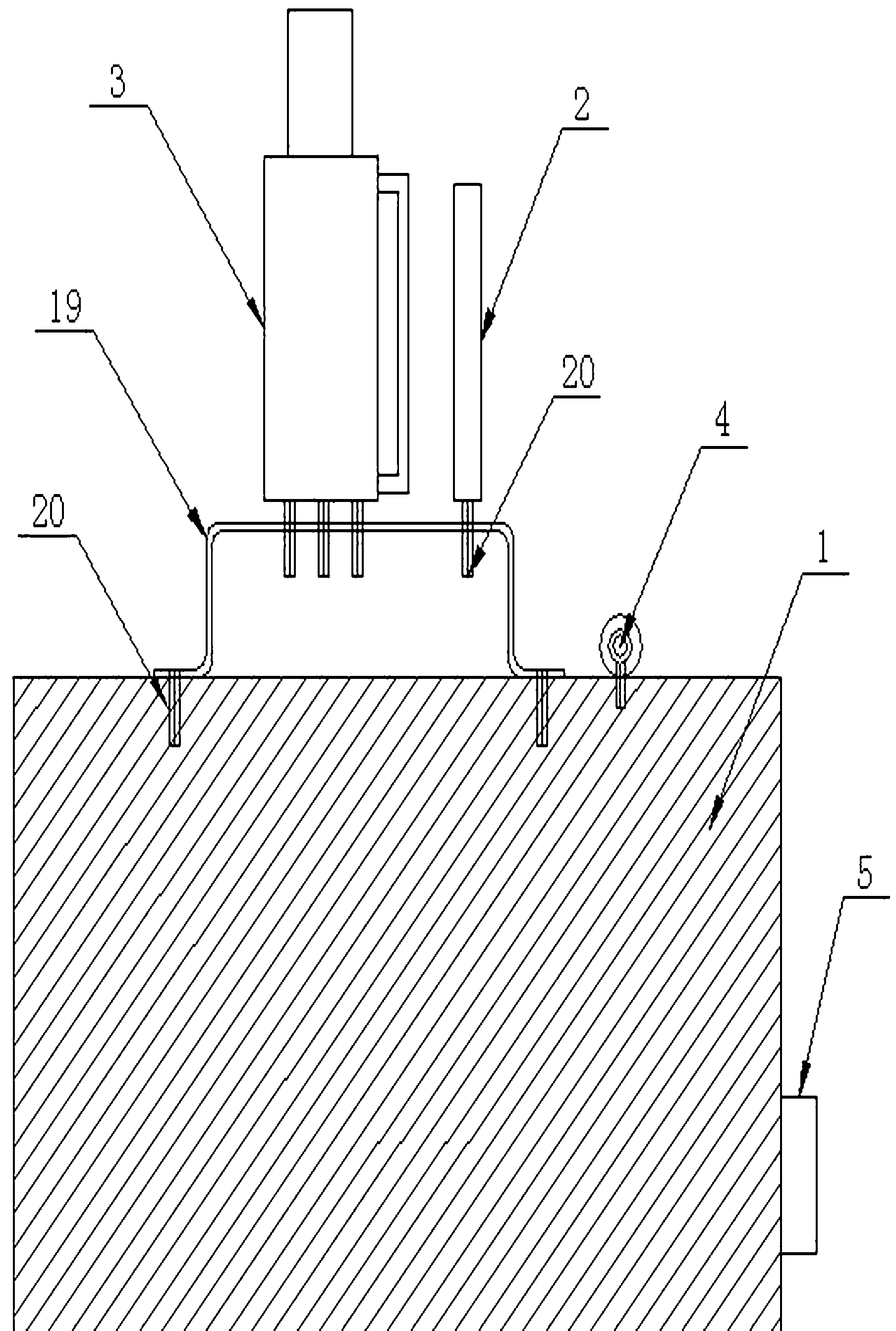

Multi-sensor real-time monitoring system for construction protection of bridges and culverts of business lines of railways

InactiveCN103017827ASafe drivingGuarantee smooth constructionMeasurement devicesData informationMonitoring system

The invention provides a multi-sensor real-time monitoring system for construction protection of bridges and culverts of business lines of railways and particularly relates to a LabVIEW-based multi-sensor real-time monitoring system for construction protection of bridges and culverts of business lines of railways. The system is composed of an automation monitoring device and a computer of a monitoring center, wherein the automation monitoring device is composed of a data collection device and a data transmission device, the data collection device is arranged at the construction site and is connected with the data transmission device through a cable, the data transmission device communicates with the computer through a wireless network, the data collection device obtains data information form the site and then transmits the data information to the data transmission device, and then the data transmission device transmits the data information to the computer through the wireless network. The multi-sensor real-time monitoring system can be recycled, is applicable to all-around real-time safety protection monitoring of major projects, overcomes a plurality of defects of traditional monitoring means and has the advantages of being high in precision, high in instantaneity, complete in monitored information and the like.

Owner:WUHAN UNIV OF TECH

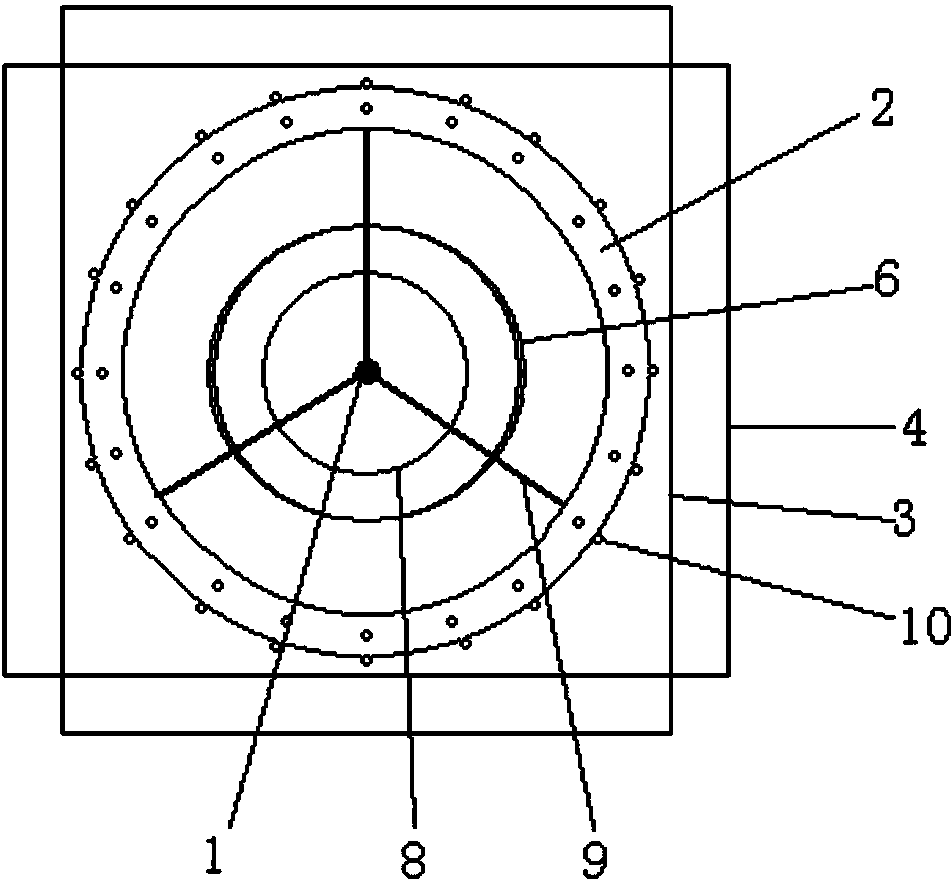

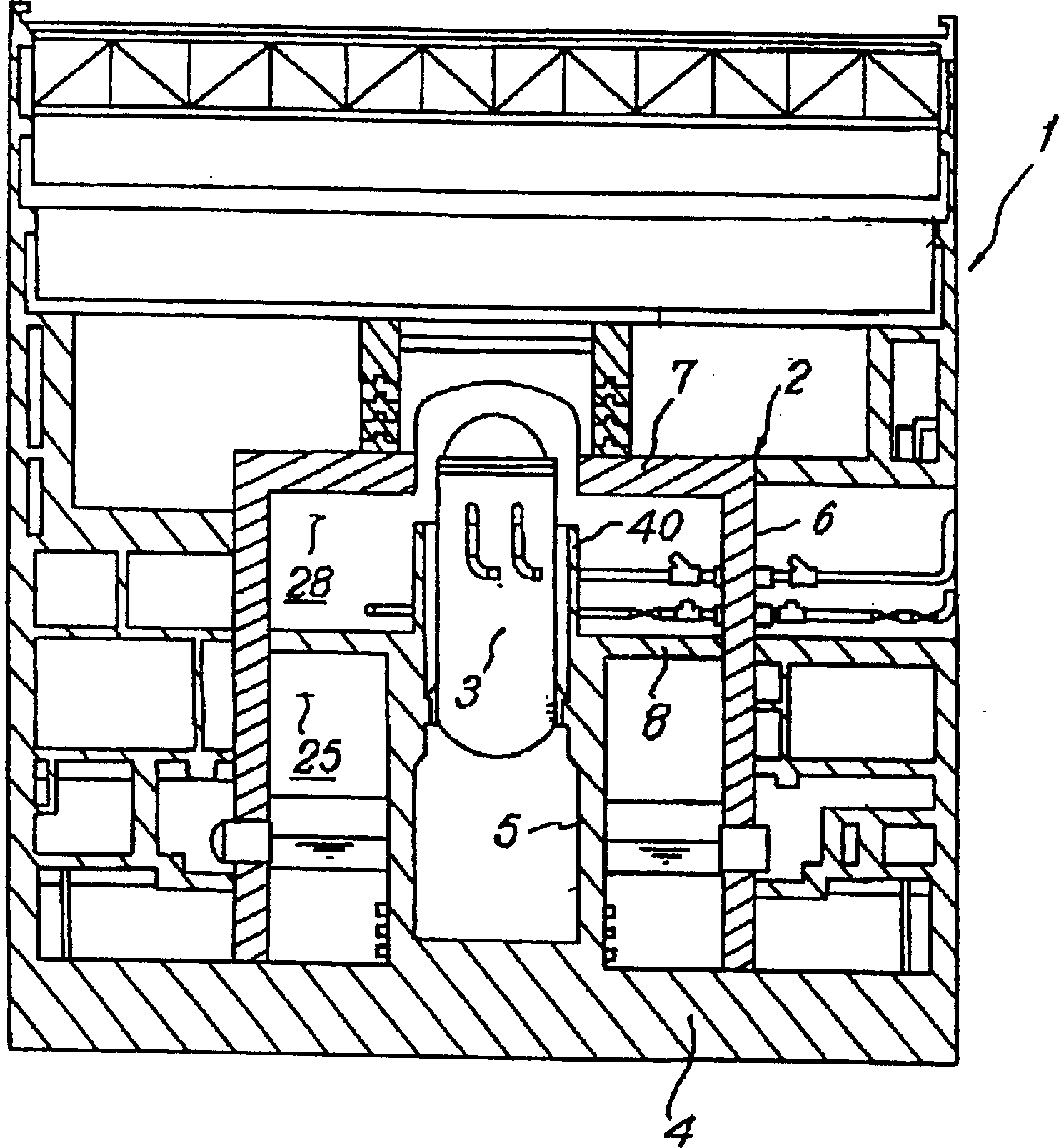

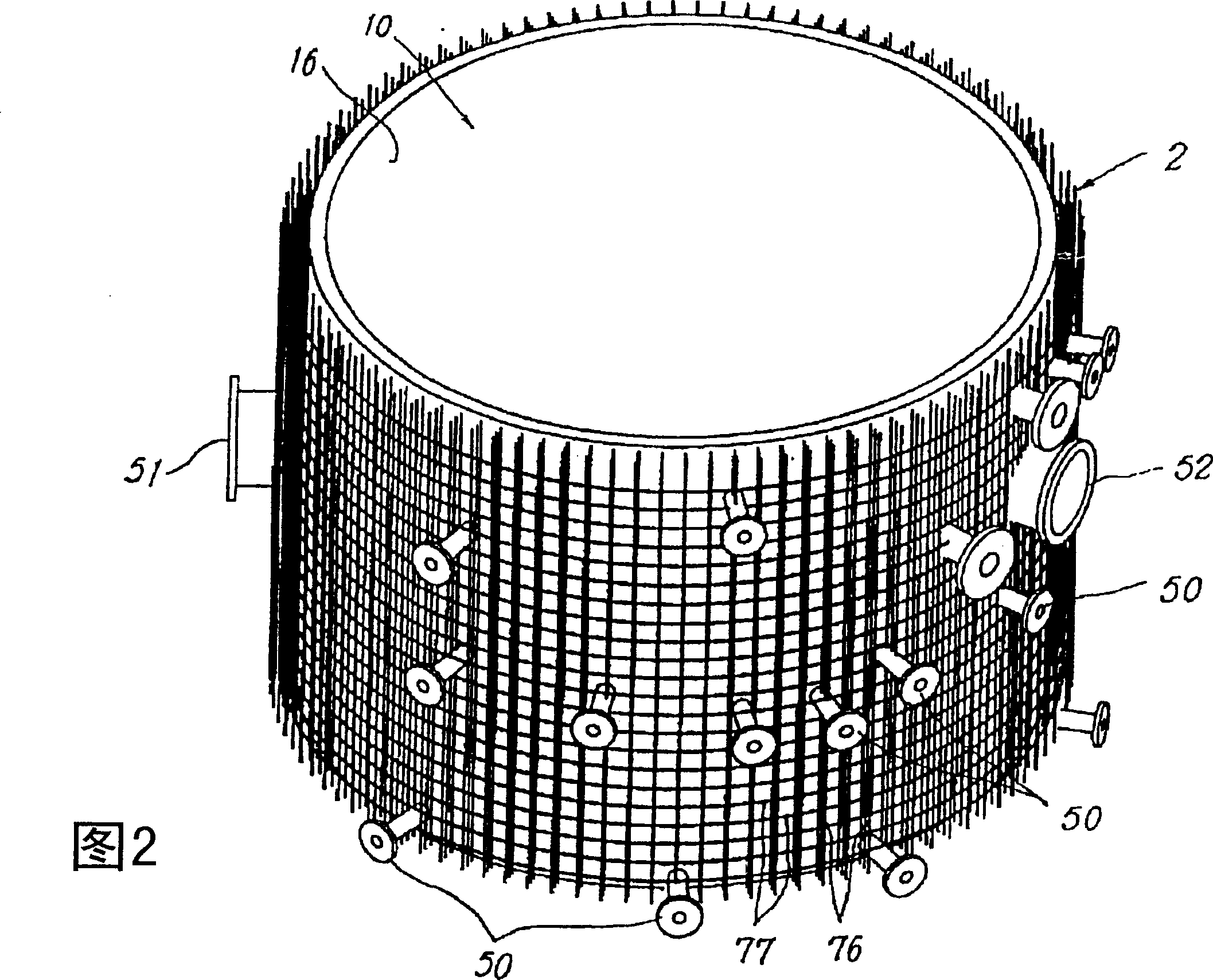

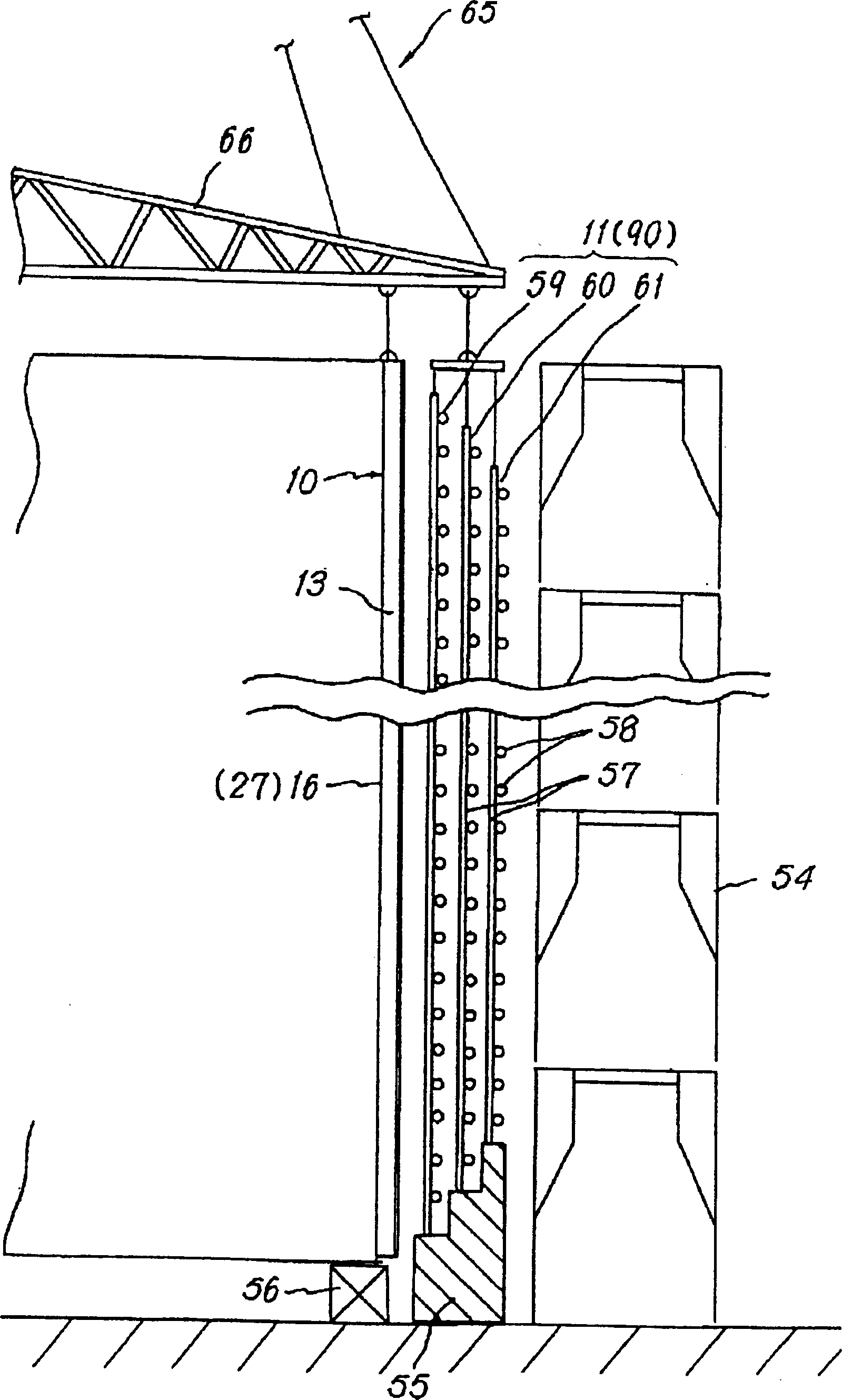

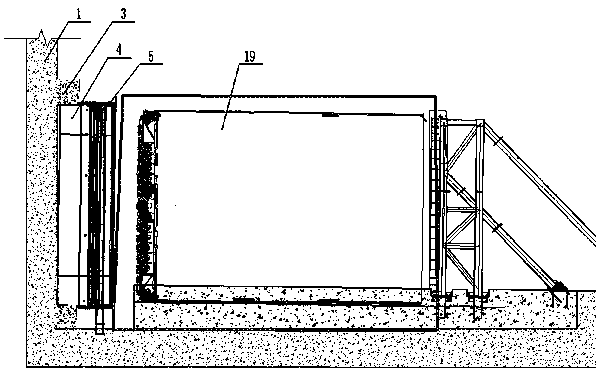

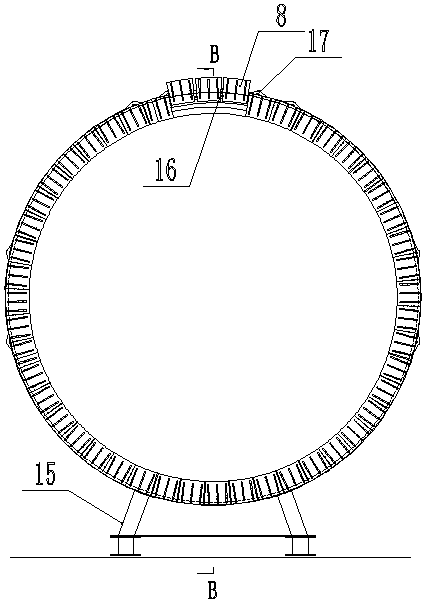

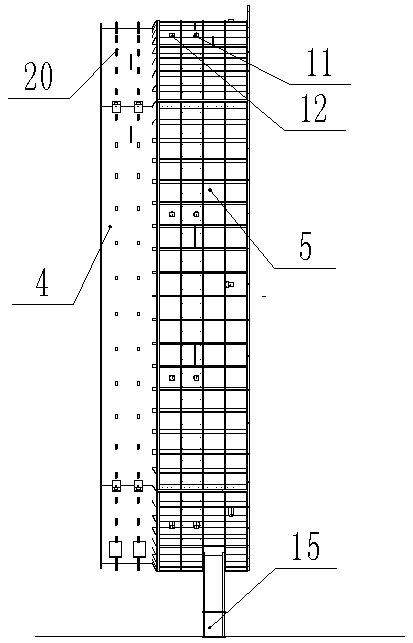

Reactor-containment vessel and its building method

InactiveCN1773630AReduce processEnsure safetyNuclear energy generationShieldingReinforced concreteNuclear reactor

PROBLEM TO BE SOLVED: To provide a reactor-containment vessel container that reduces work regarding RCCV (reinforced concrete reactor containment vessel) construction at a contruction site, to increase the efficiency of building work for improving safety, and greatly reduce the building period, and its building method. SOLUTION: A reactor-containment vessel 2 made of reinforced concrete is accommodated into a reactor building. A cylindrical part liner 10 for composing the reactor-containment vessel 2 and bar arrangements 11 and 90 inside an RCCV provided outside the liner 10 are assembled on the ground in advance for suspending and installing in a construction site. For a diaphragm floor 8 for dividing the reactor-containment vessels 2 and 10 into an upper dry well 28 and a lower pressure suppression room 25 and a top slab which is provided for covering the top part of the reactor-containment vessel 2, both of the diaphragm floor liner module and the top slab module that compose the diaphragm 8 and the top slab are assembled on the ground in advance as a one-piece structure for suspending and installing in a setting position at the construction site.

Owner:KK TOSHIBA

Method for online detection of warpage of glass cover plate

The invention discloses a method for online detection of warpage of a glass cover plate. An image deformation degree of a glass reflecting grating plate is collected through a camera on the basis of a grating plate, and quantized data of the warpage deformation degree of the glass plate is reflected through treatment of a computer information technology software system. The method is simple in design principle; the device is low in cost in comparison with that in other detection methods; software research and development are simple and feasible; the operation is simple and the efficiency is high; and above all, the targets of full detection of the warpage of a product and quantization of a warpage image can be achieved and the detection accuracy is high.

Owner:陕西彩虹电子玻璃有限公司

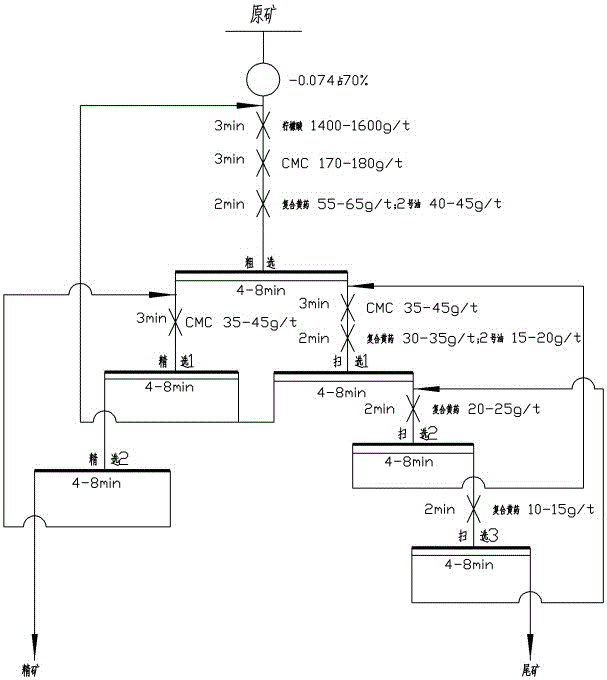

Nickel polymetallic ore separation technology

A nickel polymetallic ore separation technology includes the steps of crushing and screening raw ore with the granularity ranging from 300 mm to 500 mm so as to obtain fine ore with the granularity ranging from 10 mm to 15 mm; grinding the fine ore with the granularity ranging from 10 mm to 15 mm prior to classification so as to obtain ore pulp with 70% of -200-mesh ore; adding citric acid into the ore pulp with 70% of -200-mesh ore, adding CMC, composite xanthate and No.2 oil sequentially, stirring uniformly, performing rougher flotation, concentrating twice to obtain final concentrate, and scavenging for three times so as to obtain final tailings. The nickel polymetallic ore separation technology has the advantages of less operation, high recovery yield, high product indexes, less chemical consumption and higher economic benefit.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

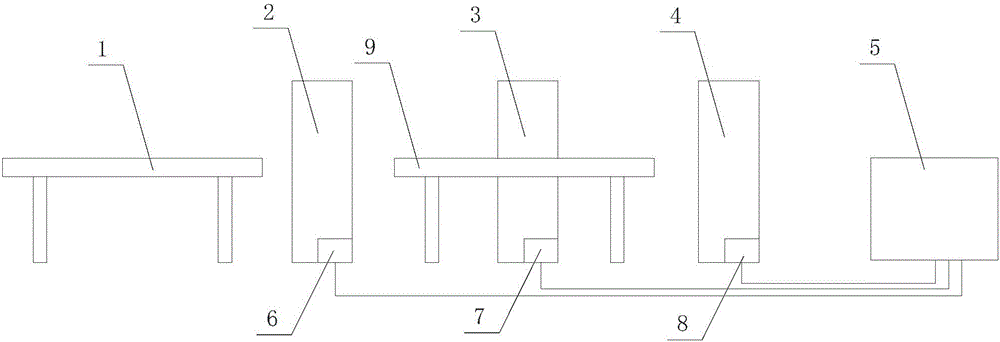

Glue injecting production line for loudspeaker

InactiveCN105872937AImprove automation performanceImprove work efficiencyElectrical transducersProduction lineAssembly line

The invention discloses a glue injecting production line for a loudspeaker. The glue injecting production line comprises a first working platform, a drying oven, a second working platform, a dispensing machine, a UV energy lamp and a control host computer which are arrayed in sequence. The dispensing machine is a double-cylinder dispensing machine, the first working platform and the second working platform are each provided with a positioning tool for fixing the loudspeaker, a temperature controller is arranged in the drying oven, a flow controller is arranged in the dispensing machine, a time controller is arranged on the UV energy lamp, and the signal input end of the temperature controller, the signal input end of the flow controller and the signal input end of the time controller are connected with the signal output end of the control hose computer. The glue injecting production line has the advantages that the temperature controller, the flow controller and the time controller are controlled by the host computer, the automatic performance of the whole production process is improved, double cylinders are simultaneously used for dispersing UV glue, the operation process of the assembly line is changed, the production cycle is shortened, 2-3 workers can be omitted for operation, operation efficiency is improved, and labor cost is reduced.

Owner:WUZHOU HENGSHENG ELECTRONICS

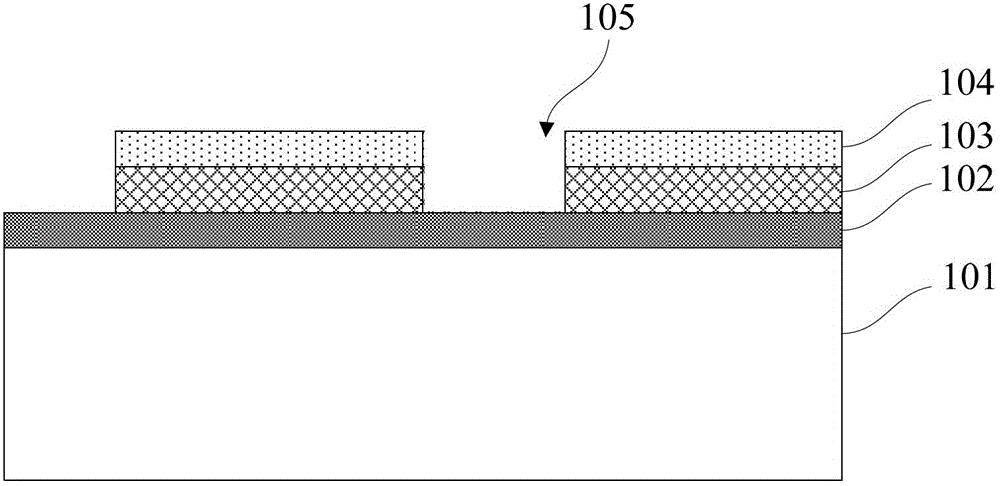

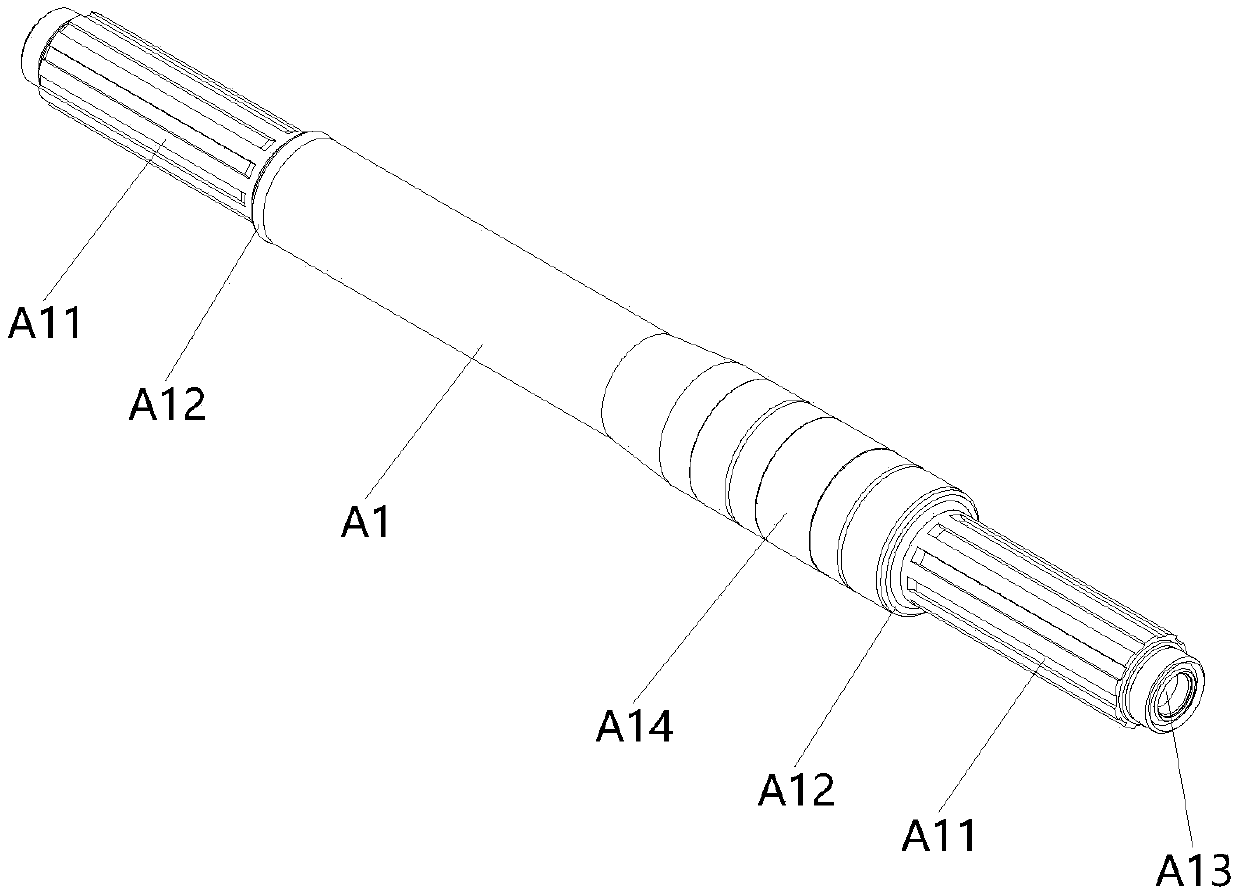

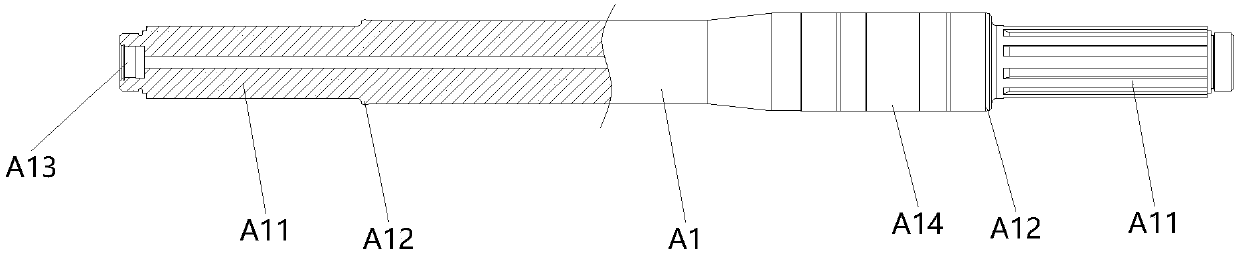

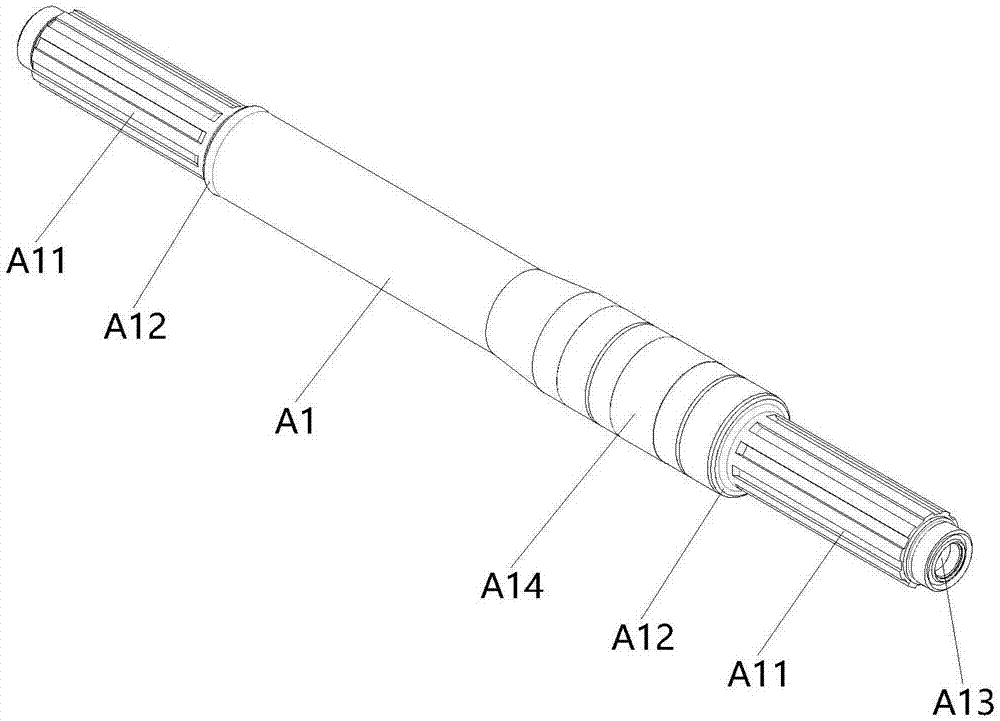

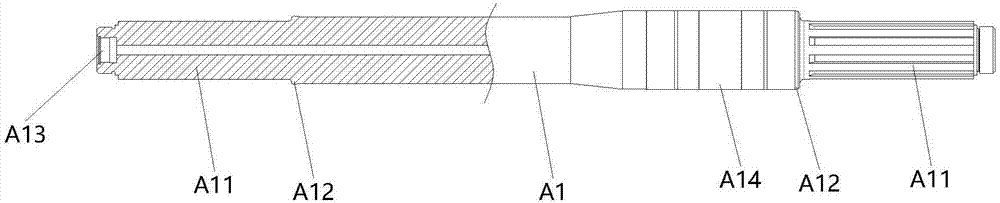

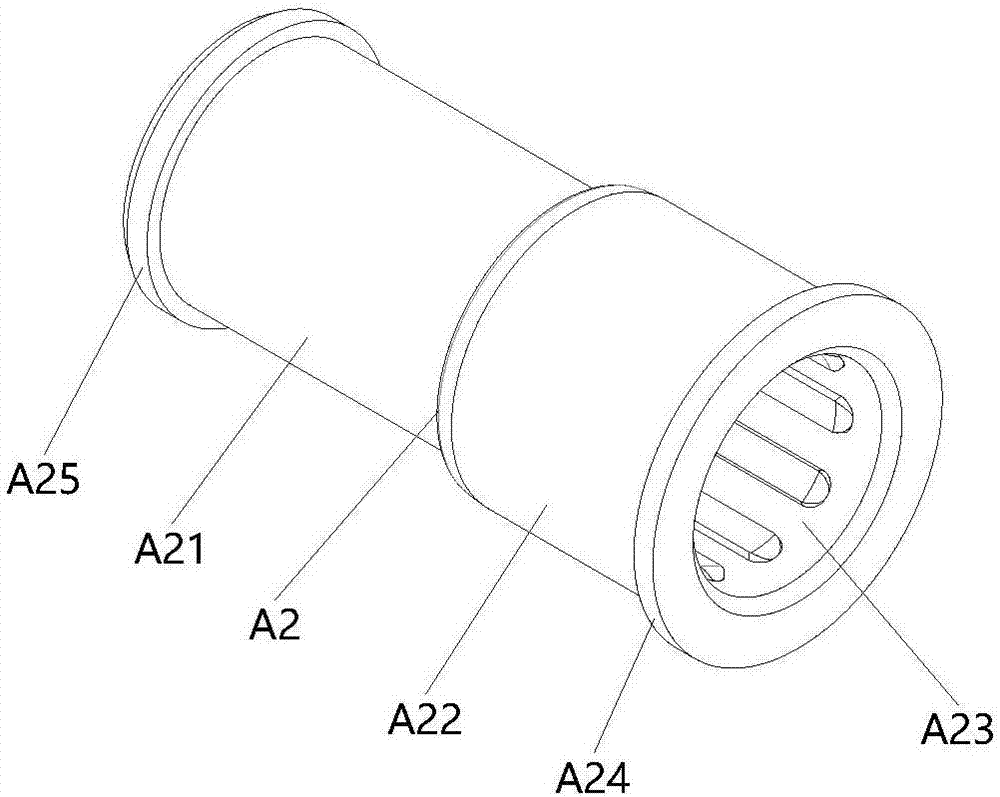

Axle assembly applied to variable-gauge bogie

InactiveCN107650936ALimited range of motionAvoid Interfering EffectsAxle-boxesDifferent width rail tracksBogieRail transportation

The invention belongs to the technical field of bogie systems and particularly relates to an axle assembly applied to a variable-gauge bogie. The axle assembly comprises an axle and a bearing and wheel integrated mounting seat. The positions of a wheel seat of the axle to the ends are moving pair connection parts. The bearing and wheel integrated mounting seat comprises bearing mounting seats andwheel mounting seats which are mutually connected and further comprises moving pair joint parts. The moving pair joint parts and the moving pair connection parts form axial moving pairs. The purposesof the axle assembly are that aiming at the problem that when a train passes through railways with different gauges, the transport efficiency is low, the axle assembly is provided and applied to the bogie, so that wheels can be adjusted in the axial direction relative to the axle, and thus the wheel distance of a wheel set of the bogie is converted to adapt to the railways with the different gauges. Railway transportation of 'Silk Road Economic Belt' is developed, thus the problem that the railway gauges are not uniform is faced, and therefore, quite important and profound significance is achieved on development of design of a variable-gauge bogie system.

Owner:CRRC TANGSHAN CO LTD +1

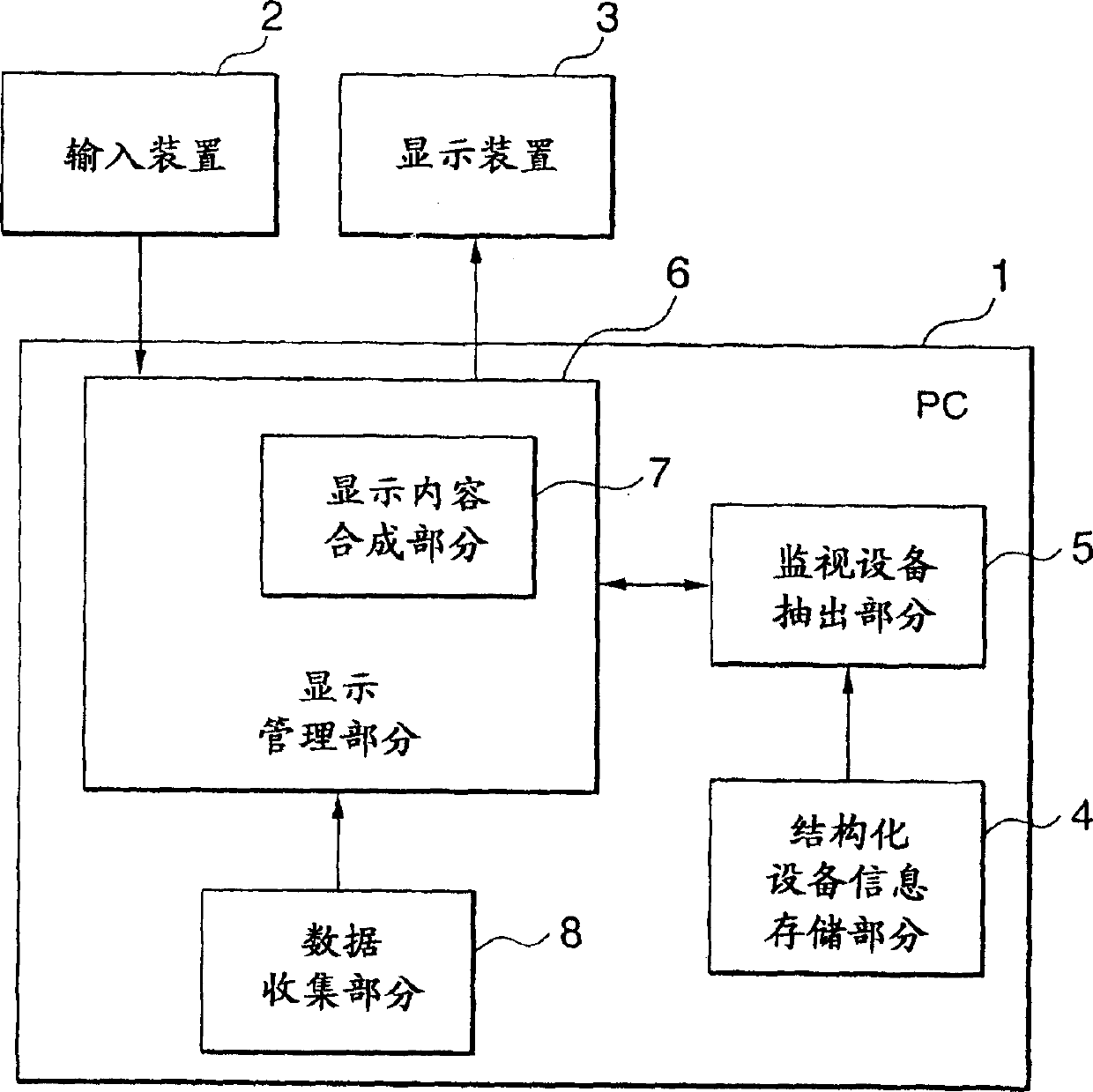

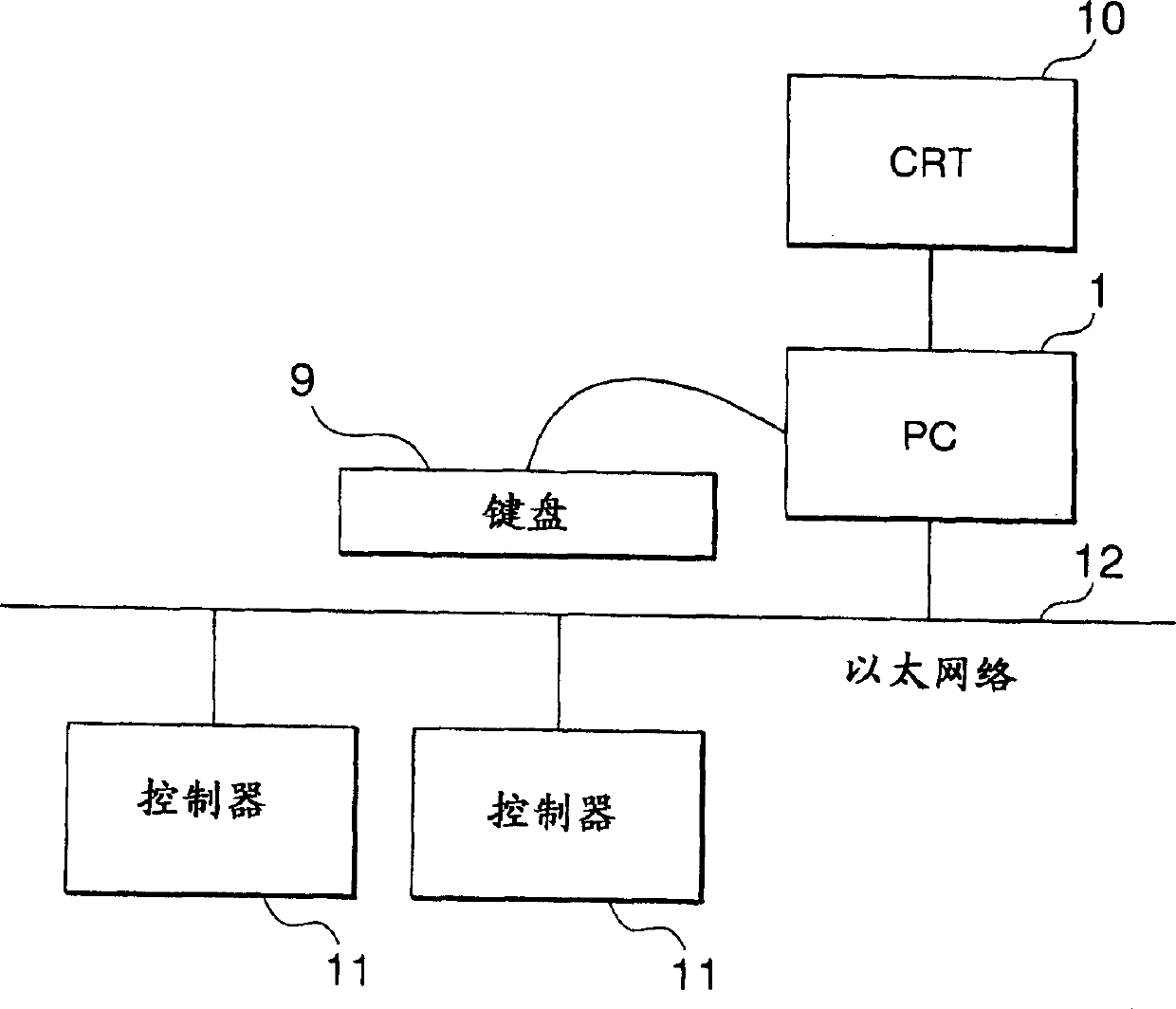

Monitoring system

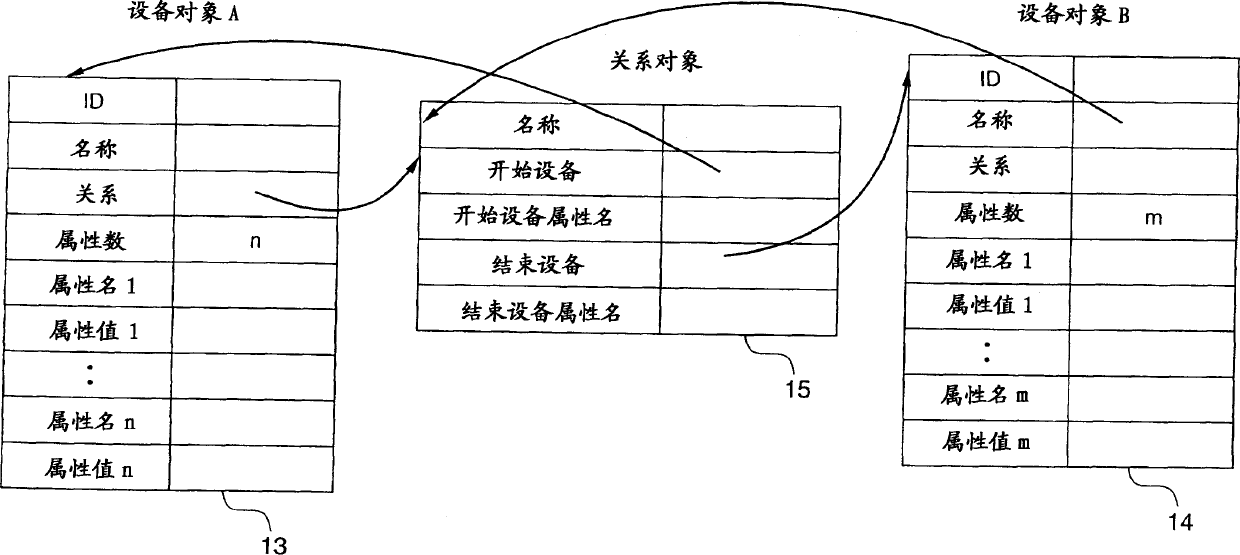

InactiveCN1403888AResilienceEasy to correspondNuclear energy generationDigital data processing detailsGraphical contentMonitoring system

A monitoring system indicating the condition of a plant at any time and from any place by particularly utilizing a small graphical content such as the display of a handy cellular phone. In particular, necessary equipment information can be quickly extracted from among many pieces of equipment to be monitored in a large-scale plant including a lot of monitored objects. The monitoring system includes a structured equipment information storage part for storing structured equipment information including equipment information on pieces of equipment and relational information describing relations among the pieces of equipment, and a monitored equipment extraction part for extracting a set of pieces of related equipment information associated with a piece of equipment of interest based on the structured equipment information with the equipment of interest, which is separately designated, being set as a base point of extraction.

Owner:MITSUBISHI ELECTRIC CORP

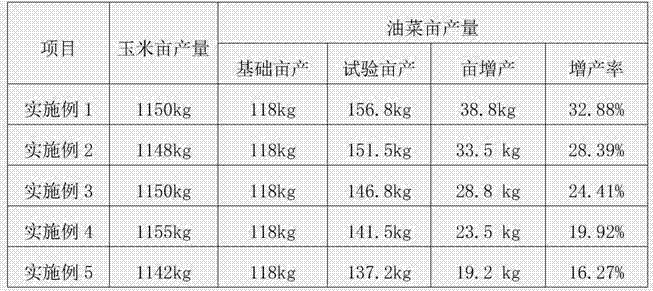

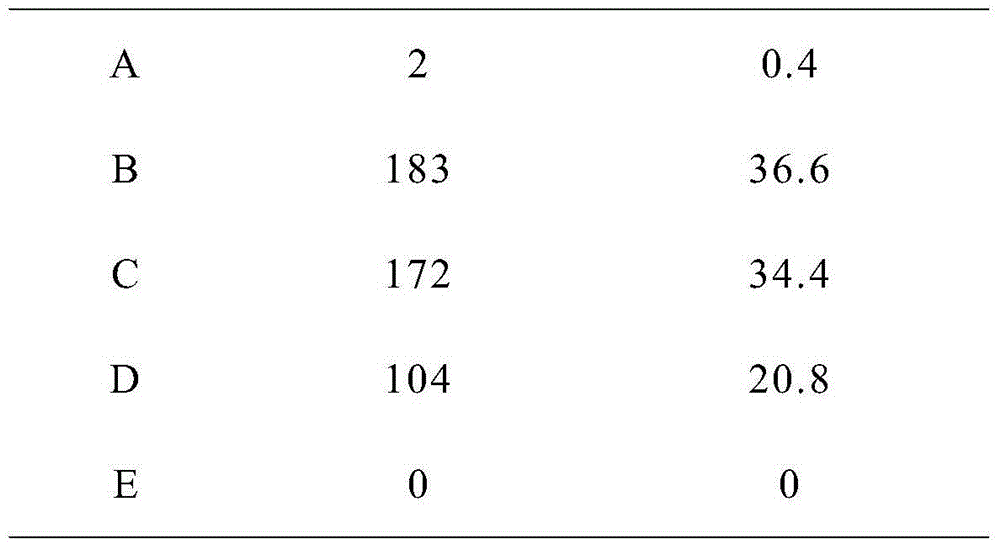

Method for double-crop no-tillage planting of winter rape after planting of corn with fully covered film on double ridges and furrows

InactiveCN106941907AIncrease productionImprove qualityFertilising methodsSeed immunisationAridDisease

The invention discloses a method for double-crop no-tillage planting of winter rape after planting of corn with a fully covered film on double ridges and furrows. The method comprises the following steps: 1) soil preparation and moisture conservation; 2) base fertilizer application: a step of applying farmyard manure and a mixed fertilizer of urea and calcium superphosphate, and cooperatively applying a nutrient equilibrium agent; 3) planting the corn by adopting a form of ridging and film-mulching; 4) corn harvesting and topdressing: after harvesting of the corn, mixing pure N, P2O5 and K20 with the ratio of N to P to K to be 1: 1.14: 1.05, then applying the mixture by spray irrigation, and cooperatively applying the nutrient equilibrium agent; 5) seed selection and seed treatment: a step of carrying out seed dressing by mixing with toxic fine soil; 6) winter rape dibbling: a step of dibbling the winter rape on an original corn film; 7) reinforcement of field management; and 8) disease and pest control and harvesting. The planting method provided by the invention has the advantages of simple operating process, less labor and capital investment and conservation of time, labor and cost, guarantees high yield of the corn, improves the yield and the quality of the winter rape, realizes double cropping every year, achieves complementation in summer and autumn, and expands the planting area of the winter rape to northern arid areas and edge-forest mountainous areas.

Owner:吴明明 +1

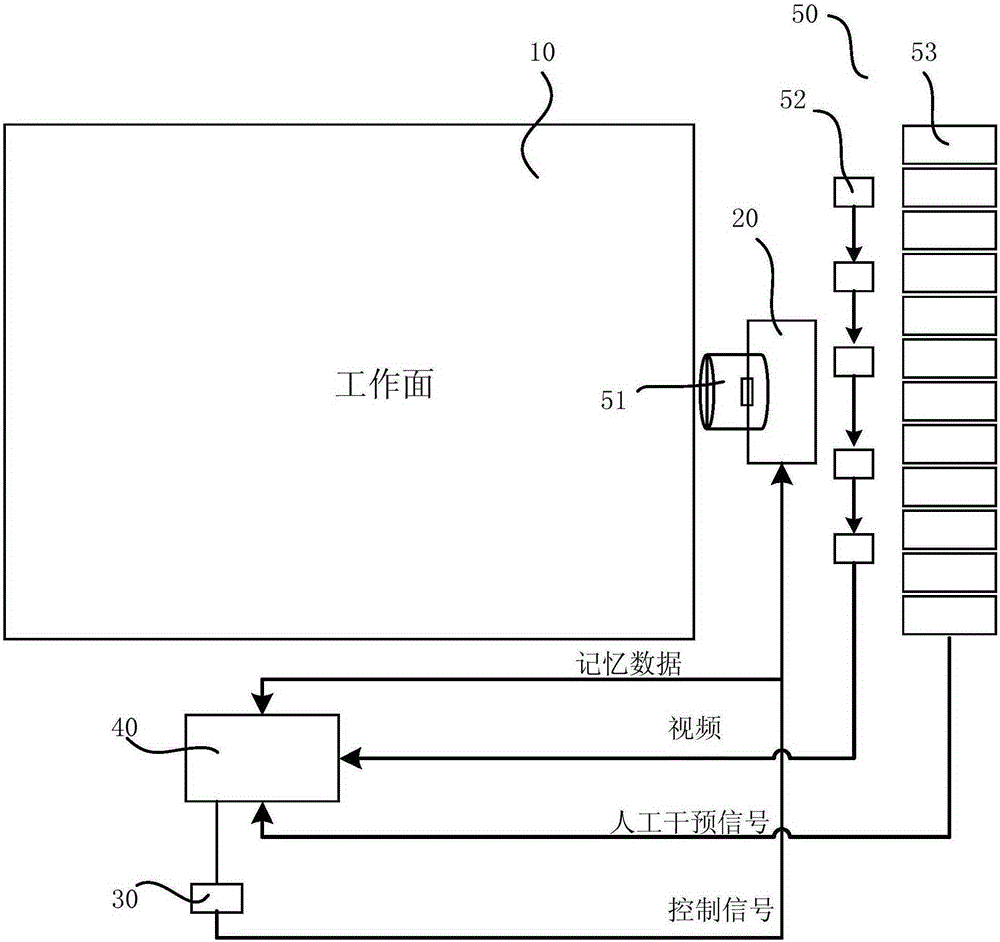

Mining system and mining method for high-dipping super-high seam shortwall working face

InactiveCN105201507ARealize automated miningNo reduction in productionUnderground miningSlitting machinesData acquisitionRocker arm

The invention discloses a mining system and a mining method for a high-dipping super-high seam shortwall working face. The mining system comprises a coal cutter, an operating floor for controlling the coal cutter, a coal seam data acquisition subsystem for acquiring coal seam roof change data according to the geological condition of the working face, and a main control computer. The mining method comprises the steps of acquiring reference trajectory data of a rocker arm in a primary circulation coal mining working process of the coal cutter by the operating floor; acquiring the coal seam roof change data according to the geological condition of the working face by the coal seam data acquisition subsystem; receiving the reference trajectory data and the coal seam roof change data by the main control computer, and calculating planned trajectory data of the rocker arm according to the reference trajectory data and the coal seam roof change data; receiving the planned trajectory data by the operating floor, and controlling the coal cutter to perform mining operation according to the planned trajectory data. The mining system and the mining method can automatically adapt to geological condition change, and are also suitable for the high-dipping super-high seam shortwall working face.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

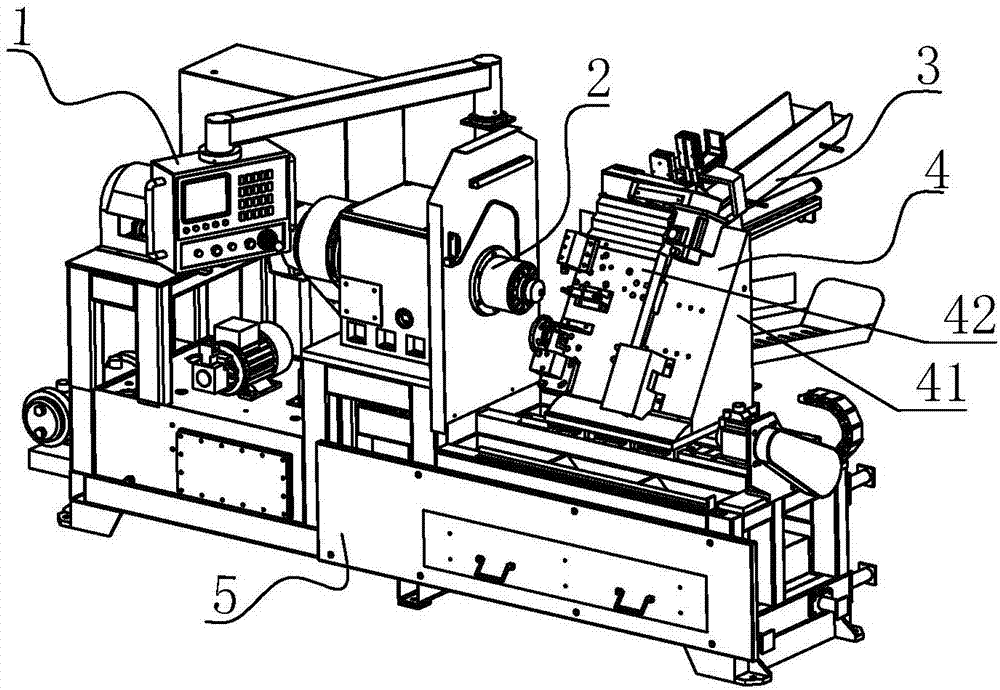

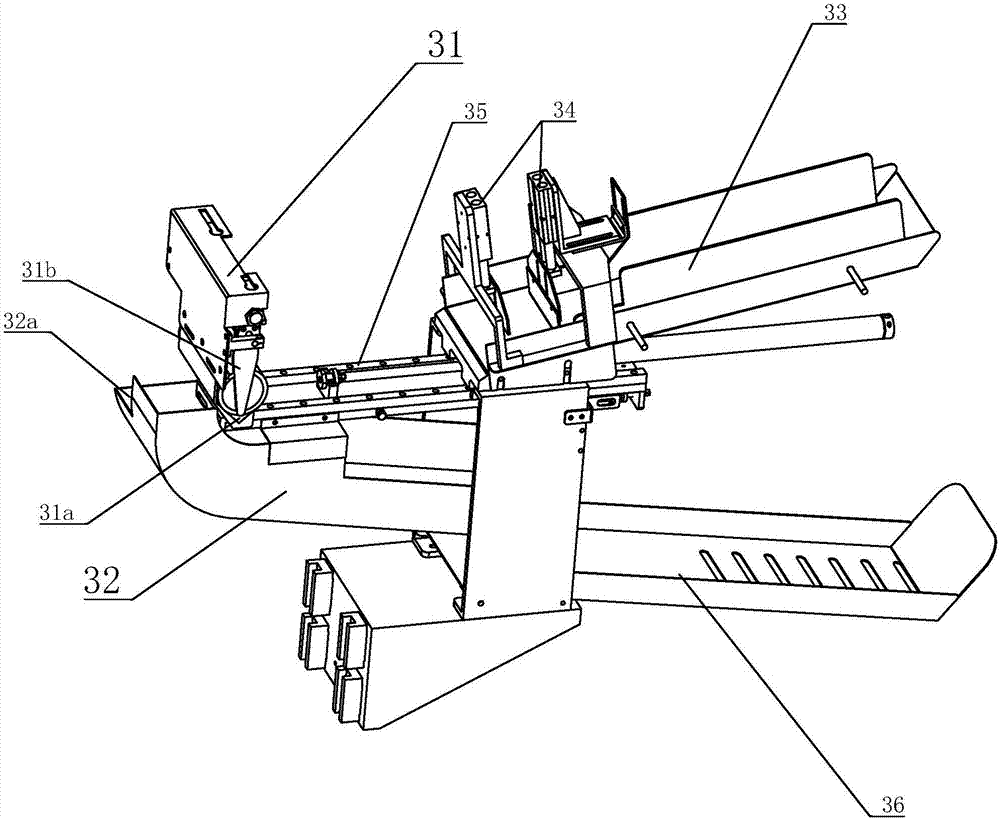

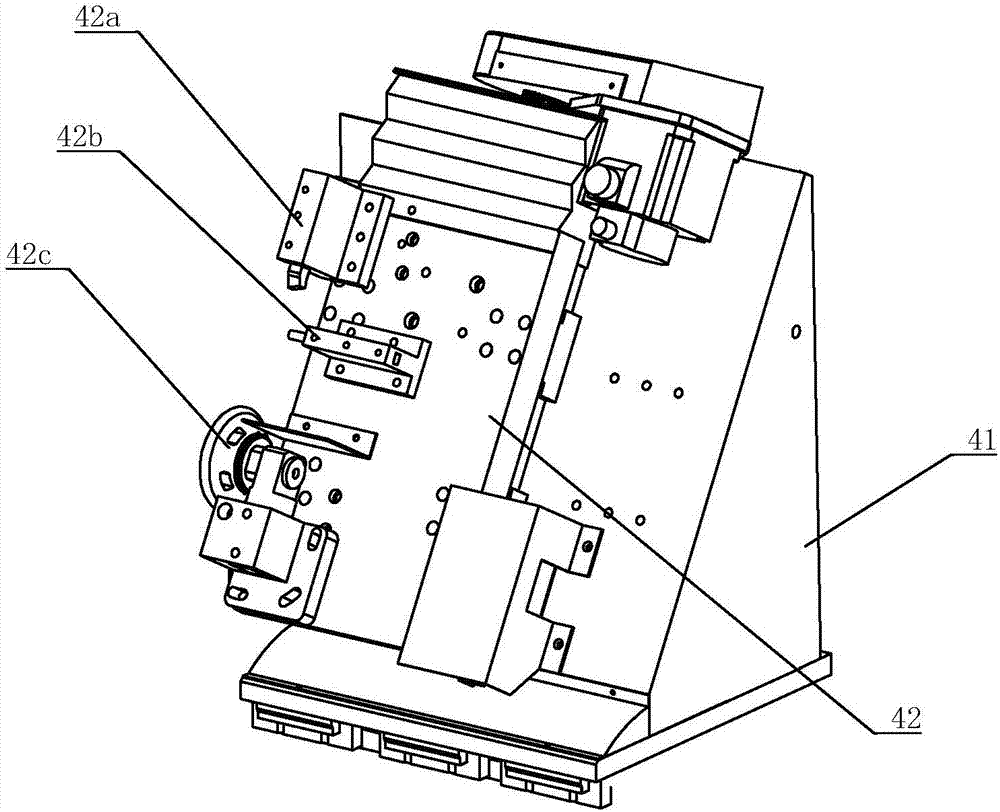

Heavy spinning machine

InactiveCN107952857AEasy to cleanReduce homeworkMetal-working feeding devicesOther manufacturing equipments/toolsMachiningPush out

The invention discloses a heavy spinning machine which comprises a control device, a spinning spindle, a feeding and discharging device, a tool machining table and a rack. The tool machining table andthe spinning spindle are arranged on the upper portion of the rack, and the feeding and discharging device is arranged on the side of the rack. The spinning spindle is used for carrying out clampingmachining on a workpiece and pushing out the machined workpiece. The spinning spindle is connected with a first drive mechanism driving the spinning spindle to rotate. The tool machining table comprises a tool frame and a base table. The base table and the rack are in sliding connection. The upper surface of the base table is an inclined face. The tool frame is in sliding connection to the inclined face of the base table. Multiple tools are arranged on the tool frame. The tool frame is connected with a second drive mechanism driving the tool frame to slide on the inclined face of the base table. The base table is connected with a third drive mechanism driving the base table to slide on the rack. Through the machine, machining scraps can be automatically gathered, clearing is easy, manual work is reduced, the production cost is reduced, automatic operation is achieved in the whole process, and the production efficiency is improved.

Owner:ZHONGSHAN CLG AUTOMATION EQUIP

Locking assembly applied to gauge-changeable bogie

The invention belongs to the technical field of bogie systems, and particularly relates to a locking assembly applied to a gauge-changeable bogie. The locking assembly comprises a sliding piece and alocking piece; at least two rows of locking grooves are formed in the outer side wall of the sliding piece, the locking piece comprises a locking rod and a locking block, the locking block is connected to the upper portion of the locking rod and is matched with a locking groove. According to the locking assembly applied to the gauge-changeable bogie, the problem that the transporting efficiency islow when a train passes railways with different gauges is solved, the locking assembly is applied to the bogie, wheels can be locked after being adjusted in the axial direction relative to axles, thedistance of wheel-to-wheel of bogie is changed to adapt to railways with different gauges. To carry out railway transportation of 'silk road economic belt', the problem that the railway gauges are not uniform must be faced, and therefore, carrying out of design of the gauge-changeable bogie system has very important and profound significance.

Owner:SOUTHWEST JIAOTONG UNIV +1

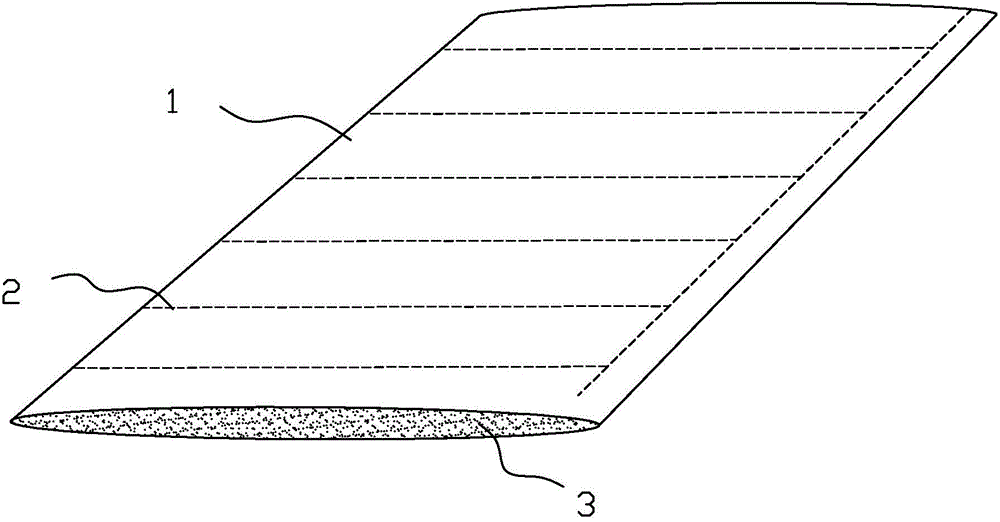

Method for manufacturing seaweed seed bottom laying layer

InactiveCN104521729AWill not pollutePrevent stack slippageClimate change adaptationCultivating equipmentsUnderwaterEngineering

The invention relates to a method for manufacturing a seaweed seed bottom laying layer. The method comprises the steps that seaweed seeds are collected and pretreated; the pretreated seaweed seeds and a matrix are uniformly mixed to form a mixture; net cloth is selected as a bottom laying layer net frame and folded to form the double-layer bottom laying layer net frame, and the double-layer bottom laying layer net frame is sewn with twine in an equally spaced mode so that multiple interlayers of the double-layer bottom laying layer net frame can be formed; the interlayers of the net frame are filled with the mixture from the open end of the net frame, the open end is sewn with twine, and then the seaweed seed bottom laying layer is formed; the manufactured seaweed seed bottom laying layer is placed in a water tank, transported to a bottom laying site and directly put into the sea. Materials adopted in the method are all natural materials and can gradually degrade after being planted underwater without causing secondary pollution to the environment. The method facilitates planting, laying, management and maintenance of seaweed.

Owner:河北省海洋与水产科学研究院

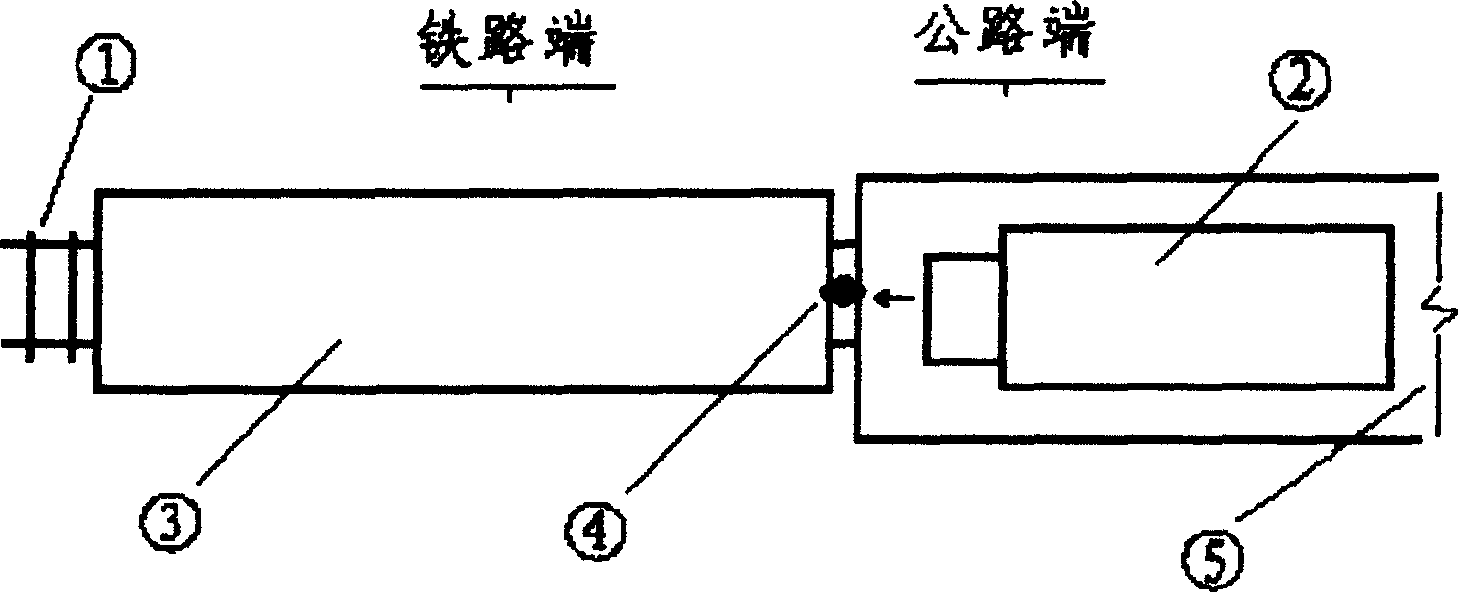

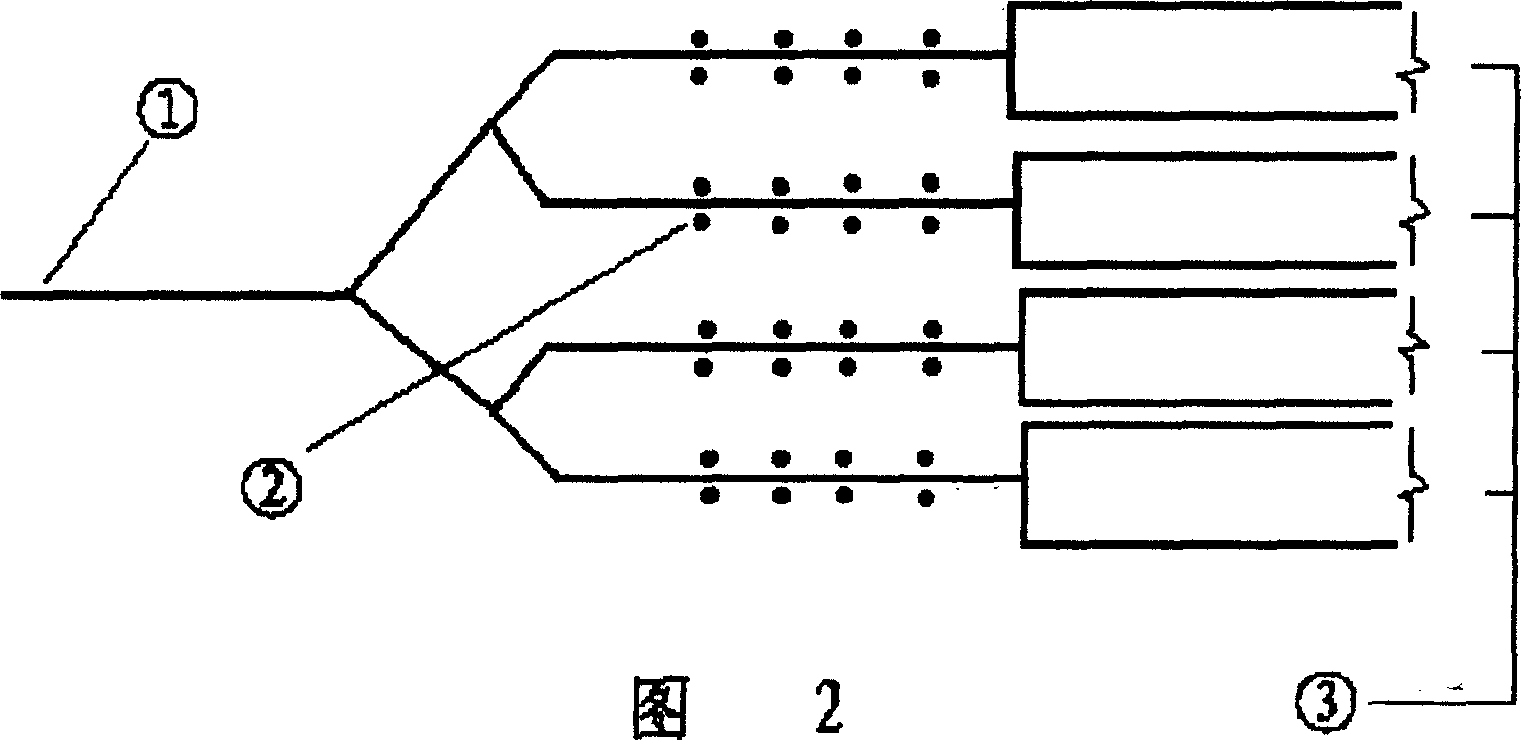

Systematic metyhod of transporating goods by train

InactiveCN1537765AIncrease passenger capacityReduce loading and unloadingWagons/vansRailway stationRail freight transportTruck

A systematic method for transporting goods by train features that after the goods is loaded on the trucks designed specially, these trucks can run onto the railway flatcars by thermoselves, and after the railway flatcars reach their destination, said trucks can run down to ground by themselves and then to respective destinations.

Owner:周仰星

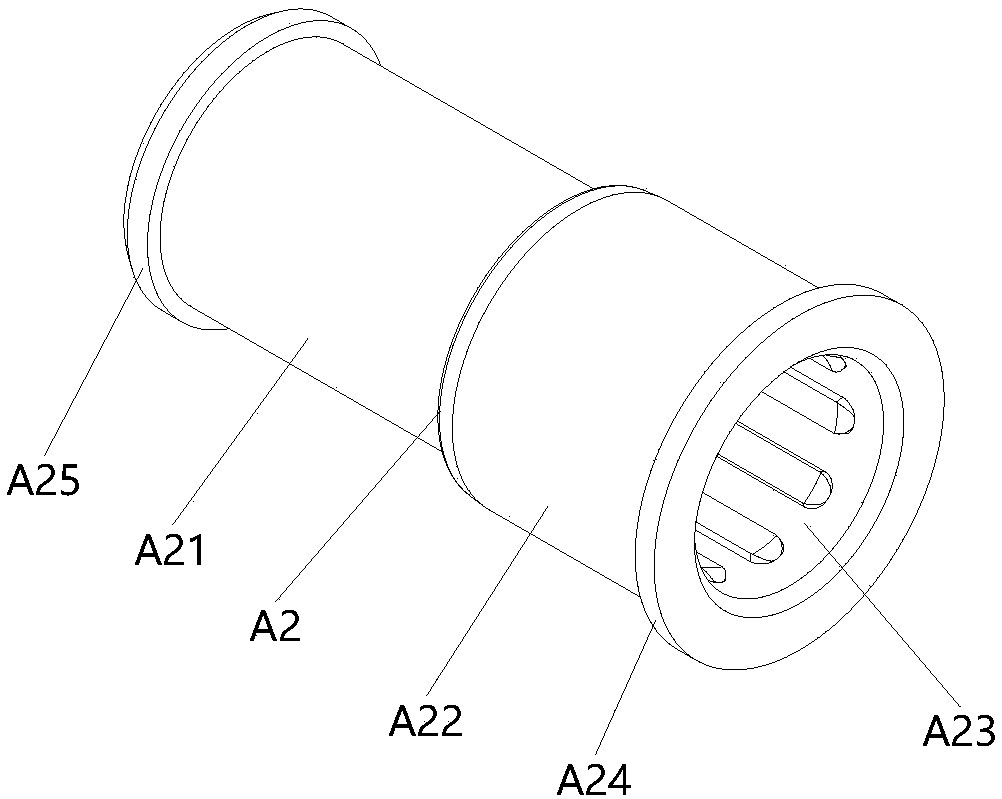

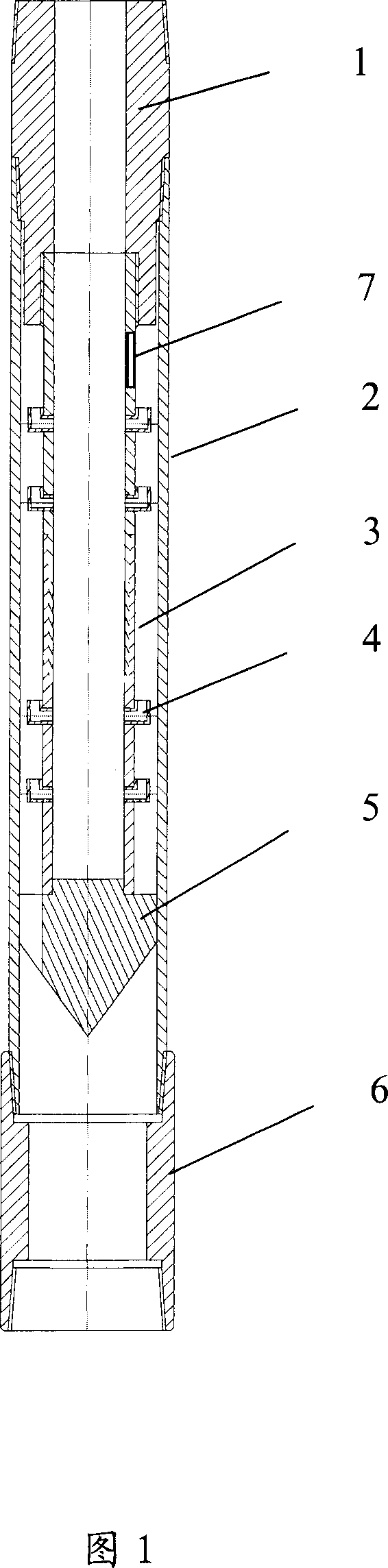

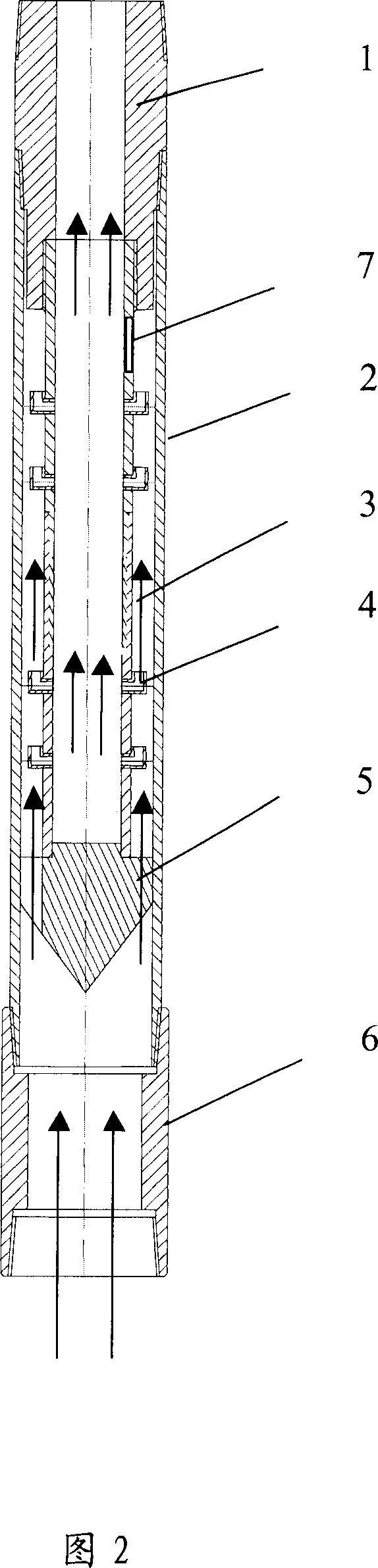

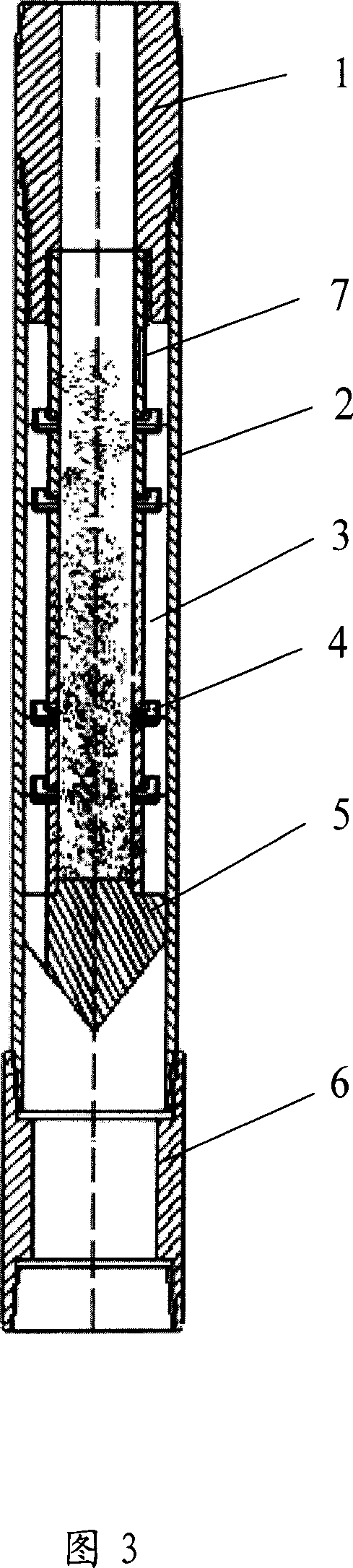

Sand production oil well electric pump protector

InactiveCN1955438ASimple structureExtended service lifeDrilling rodsPositive displacement pump componentsPetroleumElectricity

An electric pump protector for the sand production oil well is composed of an external pipe and an internal pipe, which are connected by an upper jointer and a lower jointer, a short centralizing jointer connected to lower end of internal pipe and in contact with external pipe for blocking the lower end of internal pipe and centralizing it, at least one nozzle on internal pipe, and at least one gas-oil flowing slot on the upper part of internal pipe.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

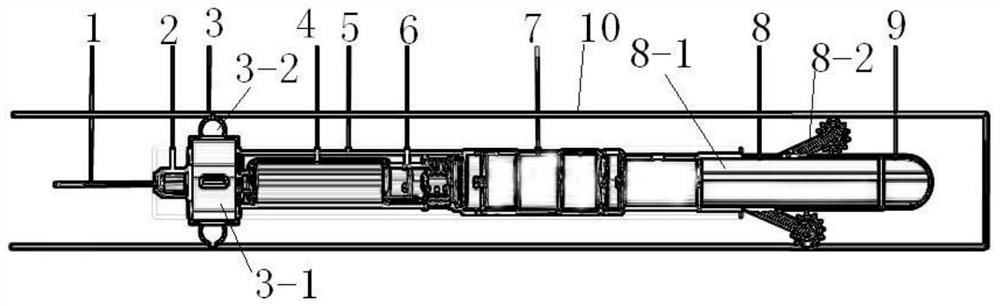

Electric control self-walking packer for horizontal well

InactiveCN112211586AImprove securityAchieve precise positioningDrilling rodsSealing/packingHorizontal wellsControl engineering

The invention belongs to the technical field of oil extraction, and particularly provides an electric control self-walking packer for a horizontal well. The electric control self-walking packer comprises a cable, a centralizer, an oil bag, a setting mechanism, a rubber sleeve, a crawling mechanism and a guide head which are sequentially connected from left to right. The problems that repeated setting times of a conventional packer are limited, setting force and unsetting force are difficult to control accurately, safety faults of an underground pipe column are prone to being caused, a well repair power device needs to be matched when an existing packer is adjusted, the operation process is complex, the cost is high, and operation safety risks exist are solved; and remote electric control position adjustment and repeated setting and unsetting of the packer at any position of a horizontal wellbore are achieved, power devices such as a workover treatment vehicle must be matched when the whole process pipe column is dragged are omitted, the operation process is simplified, meanwhile, the operation and matching cost can be greatly reduced, and the safety performance of downhole operation is improved.

Owner:PETROCHINA CO LTD

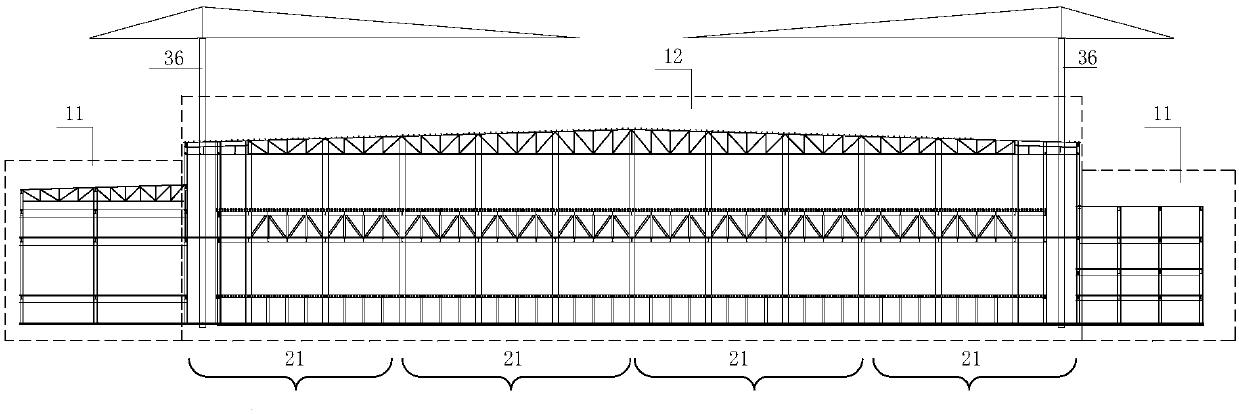

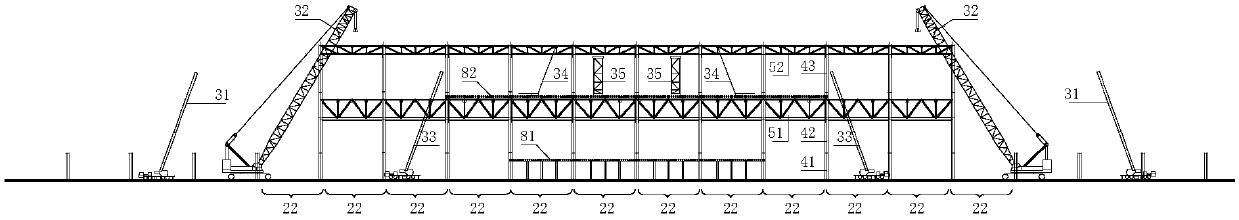

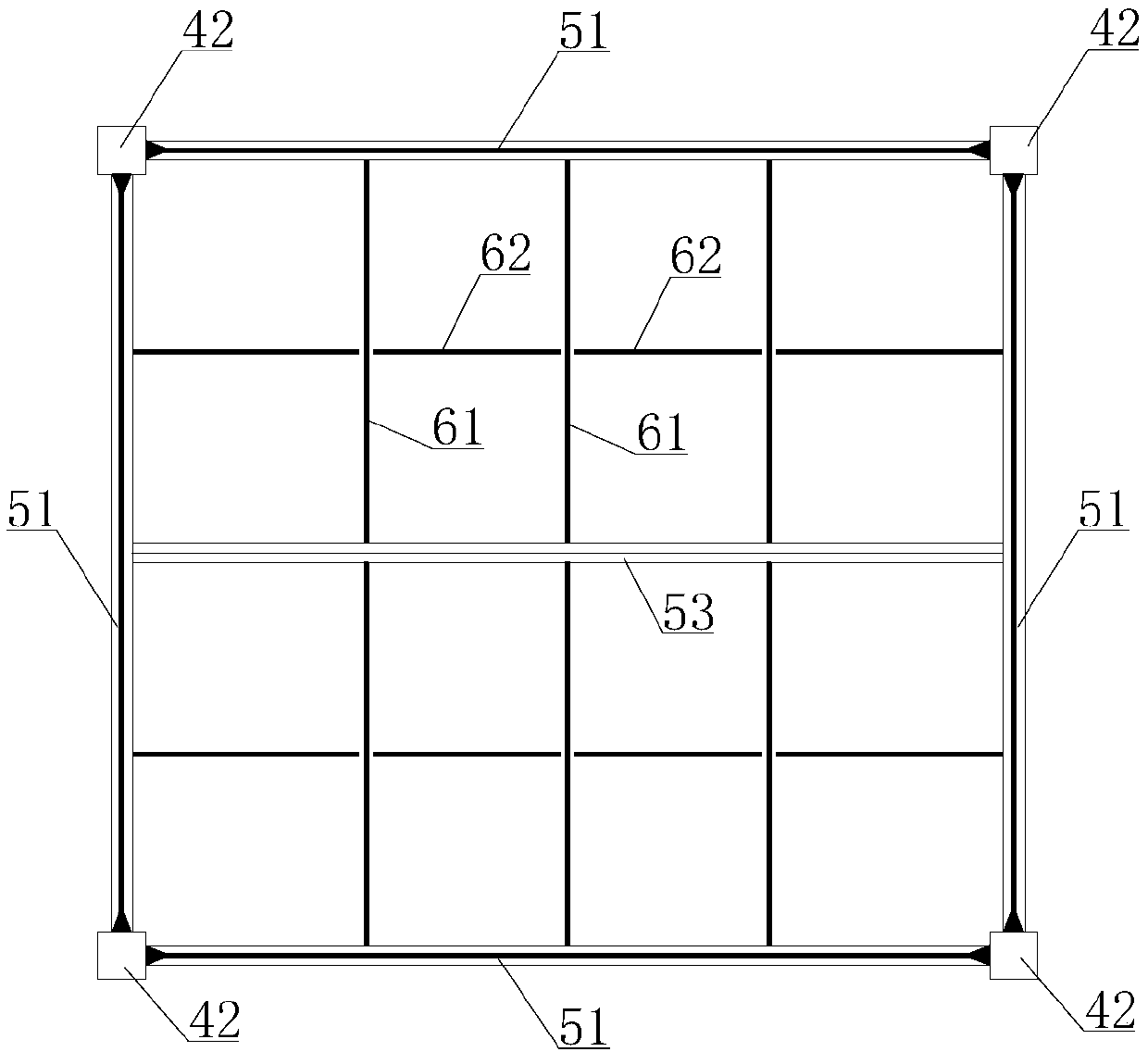

Echelon mounting method of oversized plane multi-layer steel truss electronic workshop steel structure

ActiveCN108049666AIncrease risk resistanceImprove hoisting efficiencyBuilding constructionsIndustrial buildingsKeelEngineering

The invention discloses an echelon mounting method of an oversized plane multi-layer steel truss electronic workshop steel structure. The echelon mounting method comprises the following steps that (1), division of a plane hoisting area and a hoisting unit is conducted, specifically, hoisting equipment is selected according to the maximum weight of a hoisting component, construction areas are divided according to the rotating radius of the hoisting equipment, construction is conducted simultaneously in the longitudinal direction from the middles of the construction areas; (2), a first section of frame column is mounted in each construction unit in each construction area; (3), second section of frame columns and third to fourth layers of main steel trusses and third to fourth layers of secondary steel trusses corresponding to the second section of frame columns are mounted; (4) a third layer of main beams, a third layer of secondary beams, a fourth layer of main beams and a fourth layerof secondary beams are mounted; (5), third section of frame columns and fifth to sixth layers of main steel trusses and fifth to sixth layers of secondary steel trusses are mounted; (6), a fifth layerof secondary beams and a sixth layer of secondary beams are mounted; and (7), a fifth layer of hoisting keels and a sixth layer of purlines are mounted, and accordingly mounting of the oversized plane multi-layer steel truss electronic workshop steel structure is completed.

Owner:SCEGC MECHANIZED CONSTR GRP COMPANY

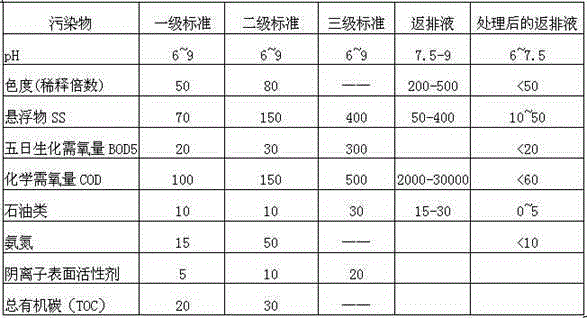

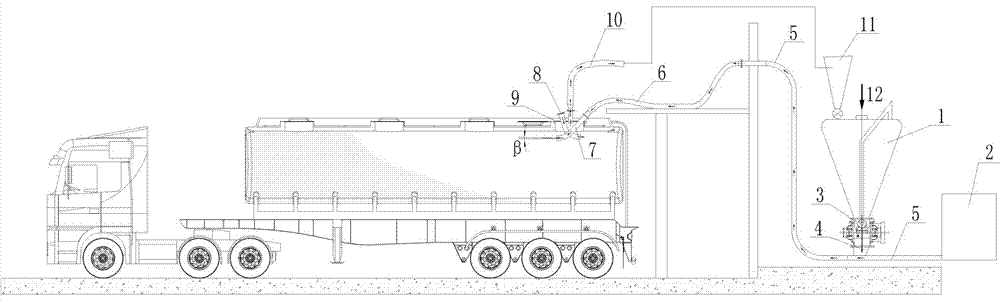

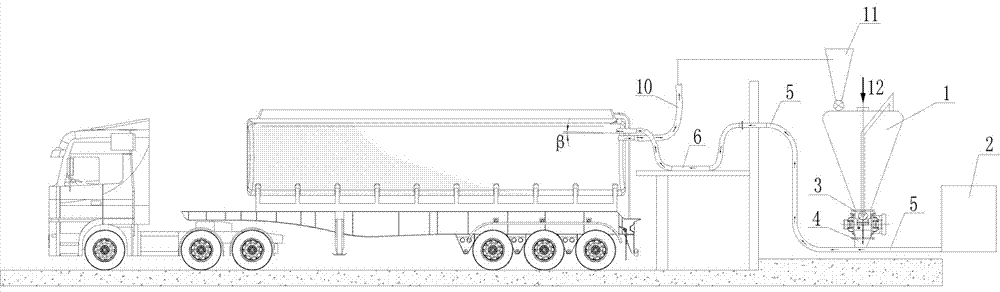

High-concentration pressure feeding continuous in-bulk system

ActiveCN107572270AGuaranteed full rateGuaranteed loading speedBulk conveyorsLoading/unloadingHigh concentrationFilling rate

The invention relates to a high-concentration pressure feeding continuous in-bulk system which comprises a feeding device and a dust-extraction unit. The feeding device comprises a high pressure sending tank (1), an air compressor (2), a pressure feeding pipe and a tank car inlet cover (9) at the top of a carriage of a flour in-bulk tank car; and one end of the pressure feeding pipe is connected with the high pressure sending tank (1) and the air compressor (2), the other end of the pressure feeding pipe is provided with a double-way crossed inclined type feeding pipe assembly, the double-waycrossed inclined type feeding pipe assembly extends into the carriage of the flour in-bulk tank car through the tank car inlet cover (9) and is close to the top position in the carriage of the flour in-bulk tank car. Compared with the prior art, the high-concentration pressure feeding continuous in-bulk system has the beneficial effects that high-concentration powder pressure feeding manner is adopted, loading is efficient, the filling rate is high, gas consumption is small, material and has separation is easy, the flour in-bulk tank car does not need to be moved secondarily, the number of middle links of loading is greatly reduced, the loading time is greatly saved, and operation safety is greatly improved.

Owner:WUXI DADONG GRAIN ENG TECH CO LTD

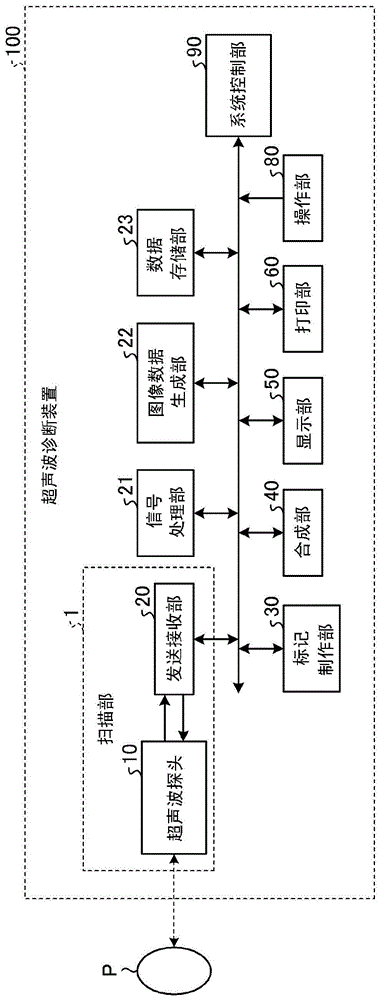

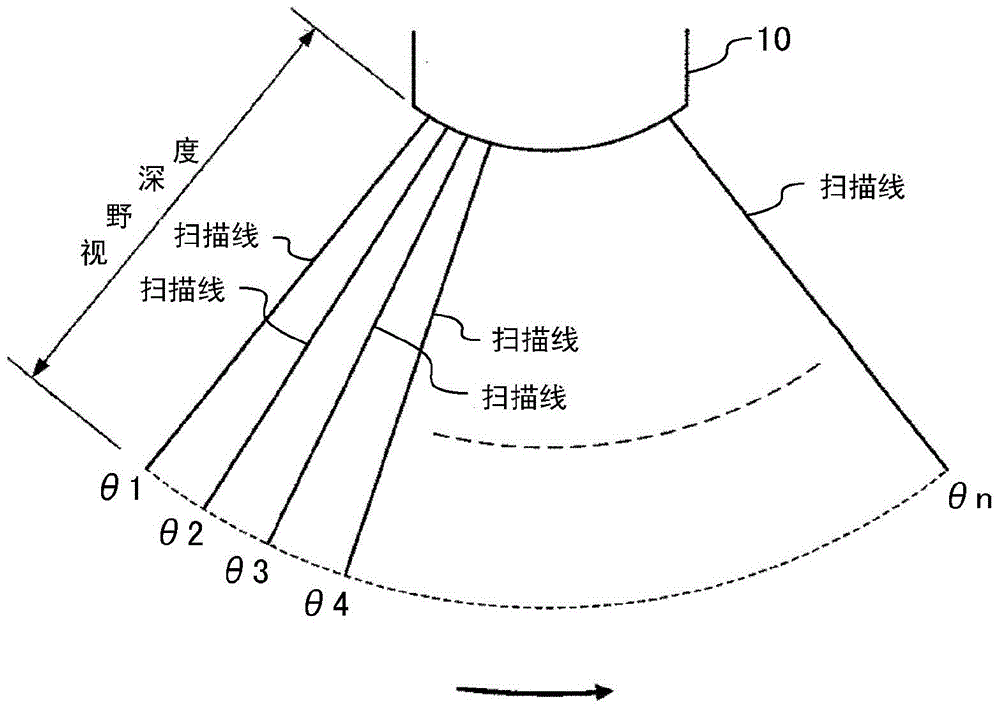

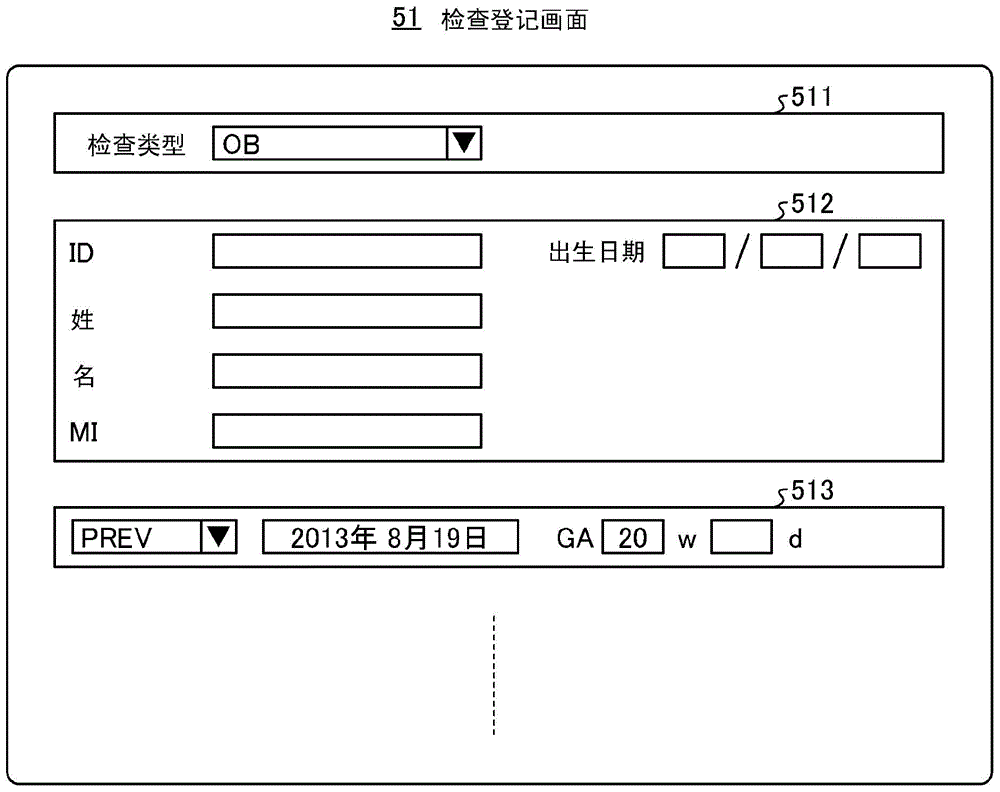

Medical image diagnostic apparatus and medical image processing apparatus

ActiveCN105266846AReduce homeworkUltrasonic/sonic/infrasonic diagnosticsImage analysisImaging processingImaging diagnostic

The embodiment method relates to a medical image diagnostic apparatus and a medical image processing apparatus. A medical image diagnostic apparatus and a medical image processing apparatus which can reduce working in checking through simple operation. A medical image diagnostic apparatus according to the embodiment includes a scanner, image generating circuitry, marker generating circuitry, and control circuitry. The scanner performs scanning to generate an image of the inside of a subject. The image generating circuitry generates an image based on the result of scanning performed by the scanner. The marker generating circuitry generates a marker provided with information at a position serving as a reference for comparison with a certain structure. The control circuitry displays the image and the marker on the same screen of a display.

Owner:TOSHIBA MEDICAL SYST CORP

Construction method for shield launching by short sleeve

ActiveCN108843337AReduce homeworkSimple structureUnderground chambersTunnel liningEngineeringWater tightness

The invention belongs to the technical field of subway tunnel shield construction, particularly relates to a construction method for shield launching by a short sleeve, and solves the problems that during the shield launching of existing tunnel construction, tunnel doors are sealed by traditional tunnel door rubber curtain cloth plates and tunnel door pressing plates and water tightness of the tunnel doors and establishment of effective soil pressure in soil bins during shield launching cannot be ensured. The short sleeve comprises a short sleeve guide ring and a sealing steel ring. Accordingto the construction method, the short sleeve guide ring, the sealing steel ring and a guide ring concrete ring frame beam are combined and connected for shield launching. Compared with traditional endjet grouting reinforcement, the method has high construction speed, and can realize effective sealing of shield construction without pipeline relocation and traffic relief, and the situation that development of shield construction is restricted by the shield launching for a long time is redefined.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

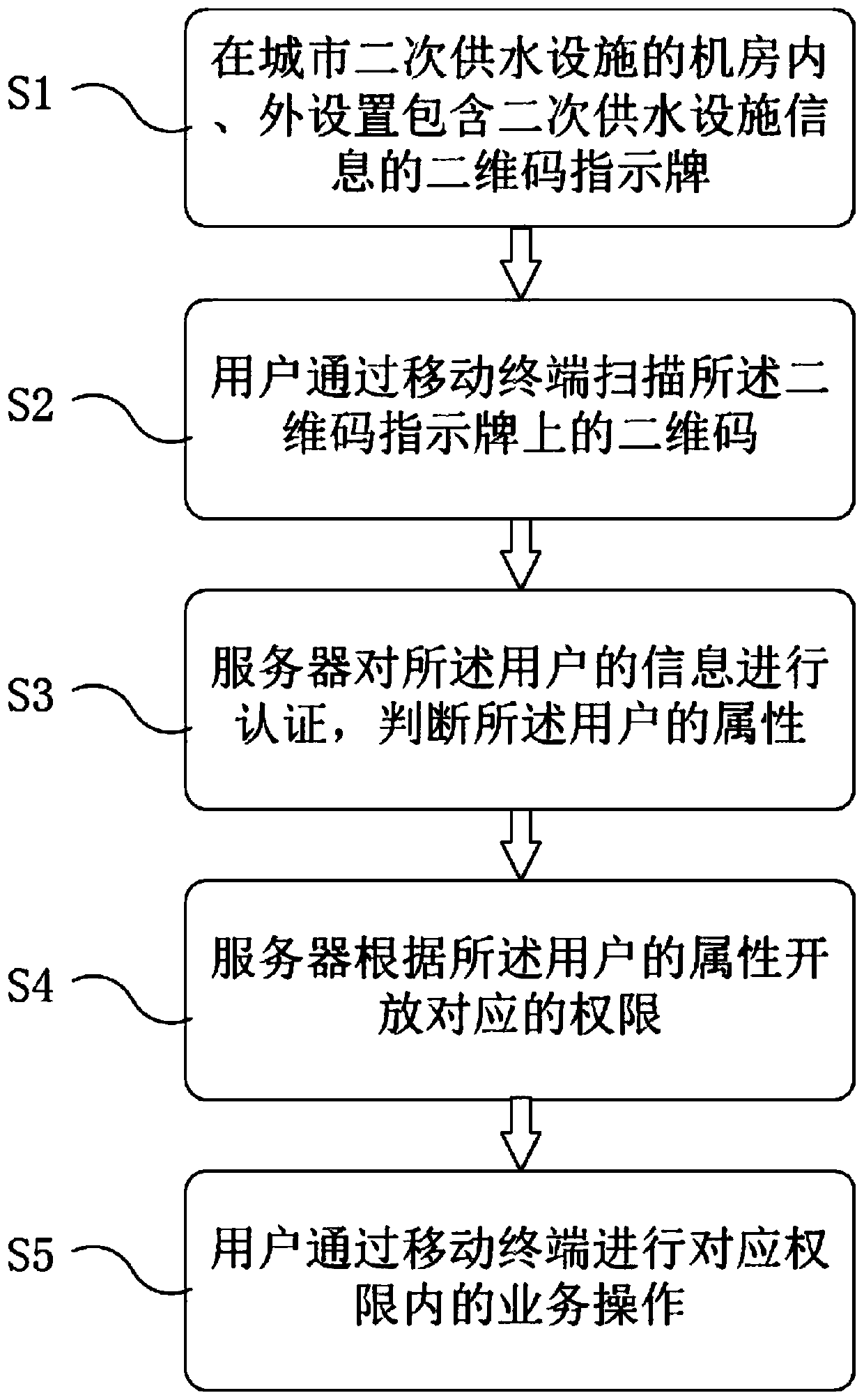

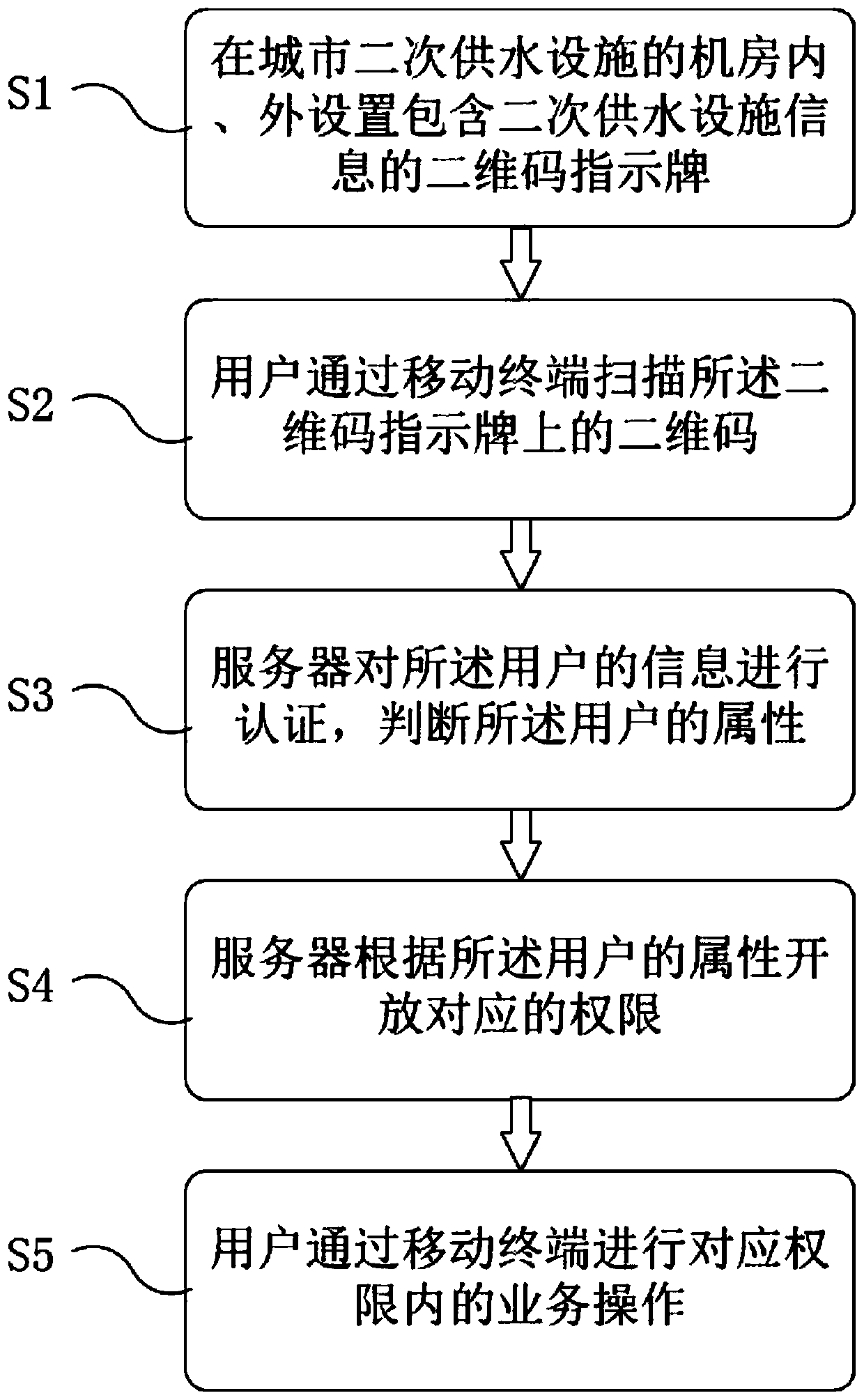

Urban secondary water supply facility management method and system based on a two-dimensional code

The embodiment of the invention discloses an urban secondary water supply facility management method and system based on a two-dimensional code, and relates to the field of water supply facility management. The method comprises the following steps: arranging a two-dimensional code indication board containing secondary water supply facility information inside and outside a machine room of an urbansecondary water supply facility; enabling a user to scan the two-dimensional code on the two-dimensional code indication board through a mobile terminal; enabling the server to authenticate the information of the user and judges the attribute of the user; enabling the server to open the corresponding authority according to the attribute of the user; ; enabling the user to carry out service operation in the corresponding authority through the mobile terminal.The system comprises a server, a mobile terminal and a two-dimensional code indication board. According to the embodiment of the invention, the problem that the data of the secondary water supply facility are inconvenient to look up, record and manage in the prior art can be solved.

Owner:重庆市万盛自来水有限公司

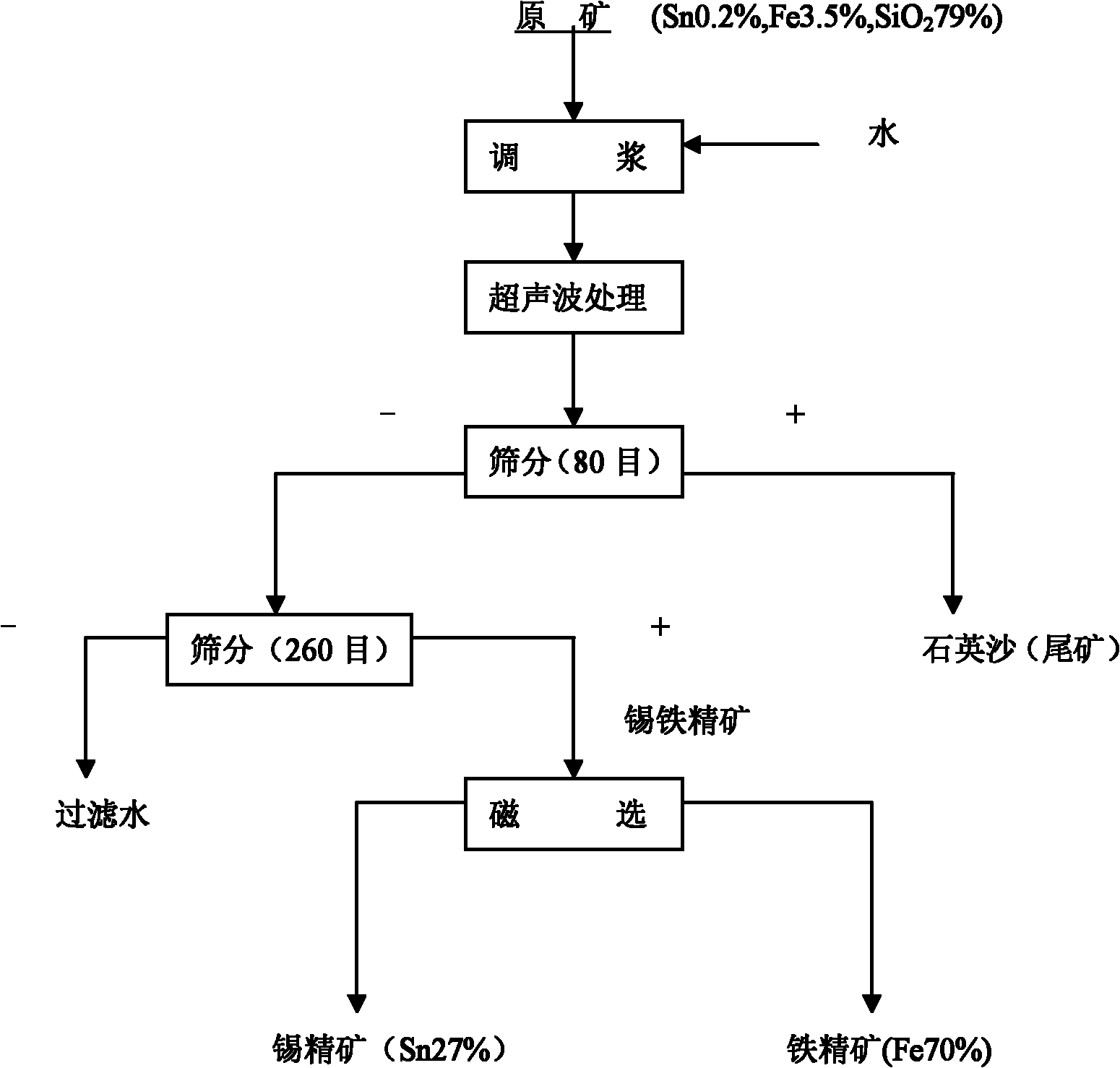

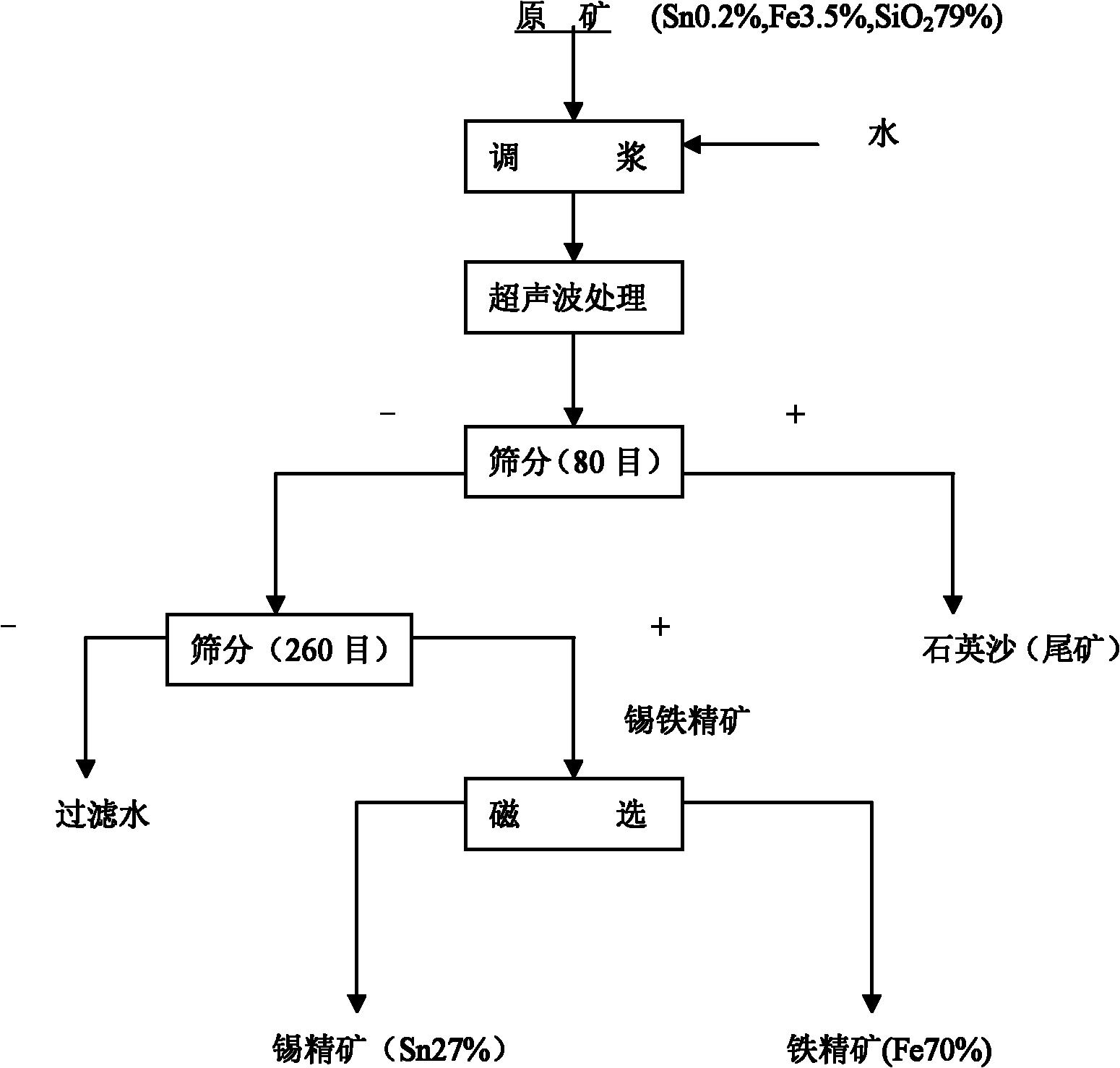

Ultrasonic beneficiation method

The invention relates to an ultrasonic beneficiation method which comprises the following steps of: (1) adding water into a container containing crushed raw ore material until the water level is higher than the surface of the material; (2) inserting an ultrasonic vibration plate into the material water, and starting ultrasonic equipment to carry out ultrasonic treatment on the mineral aggregate; and (3) screening the mineral aggregate after the ultrasonic treatment so as to obtain tailings above the screen and concentrate below the screen, wherein if the obtained concentrate contains ferric magnetic minerals, a magnetic separator is used for separating the ferric magnetic minerals so as to further improve the target mineral concentrate grade and simultaneously obtain iron concentrate. The ultrasonic beneficiation method provided by the invention has an optimal effect on treating quartz type weathered sand tin ore. In the invention, the ultrasonic treatment is adopted as main operation aided with few routine works of screening, filtering and magnetic separation, process flows are short, works are few, the operation is relatively simple, target minerals can be quickly enriched, a large number of tailings can be eliminated simultaneously, and the obtained concentrate has the advantages of high enrichment ratio, large treatment capacity, low production cost, no adoption of beneficiation reagents and no pollution on the ambient environment, thus the beneficiation method provided by the invention is a new environment-friendly high-efficiency beneficiation method.

Owner:龙念

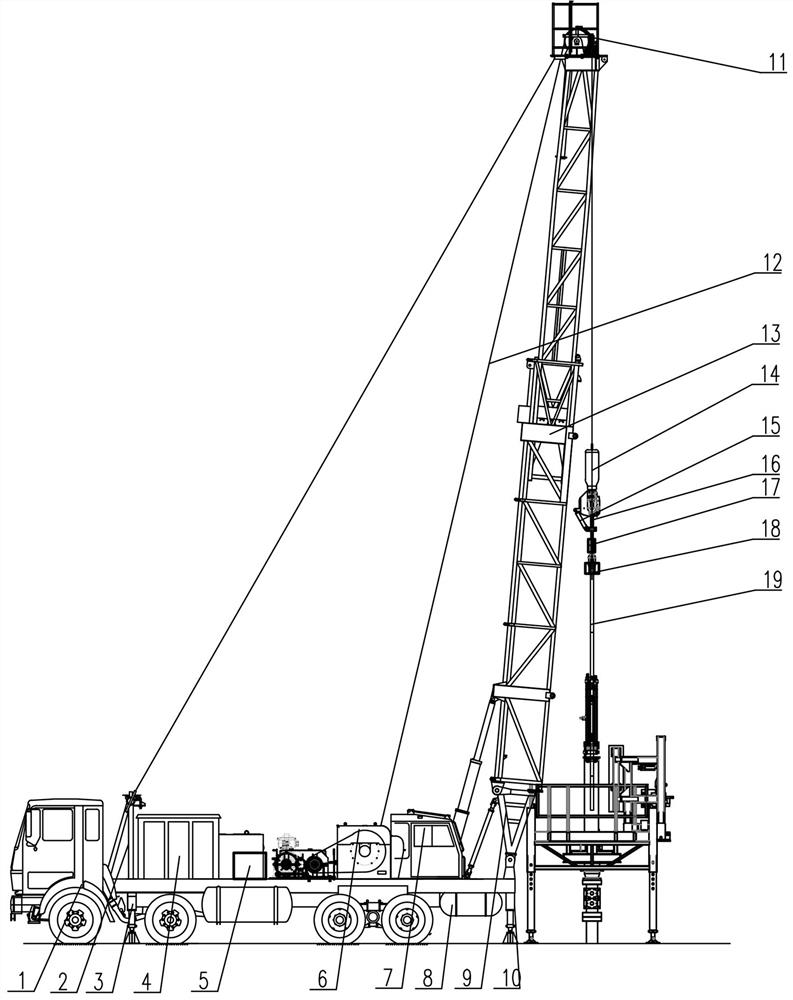

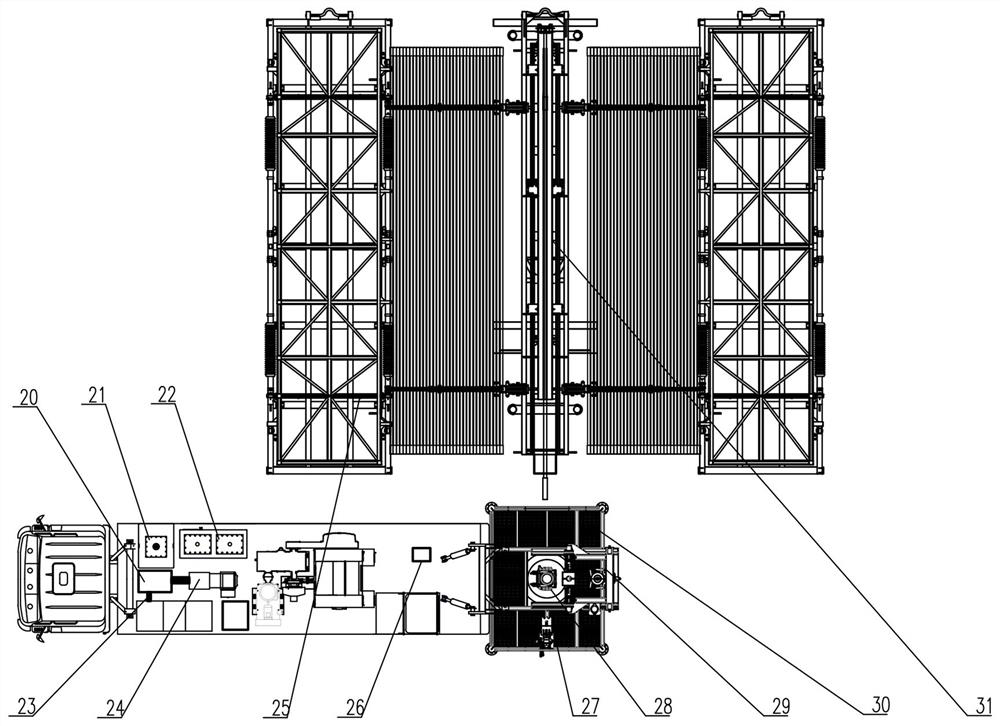

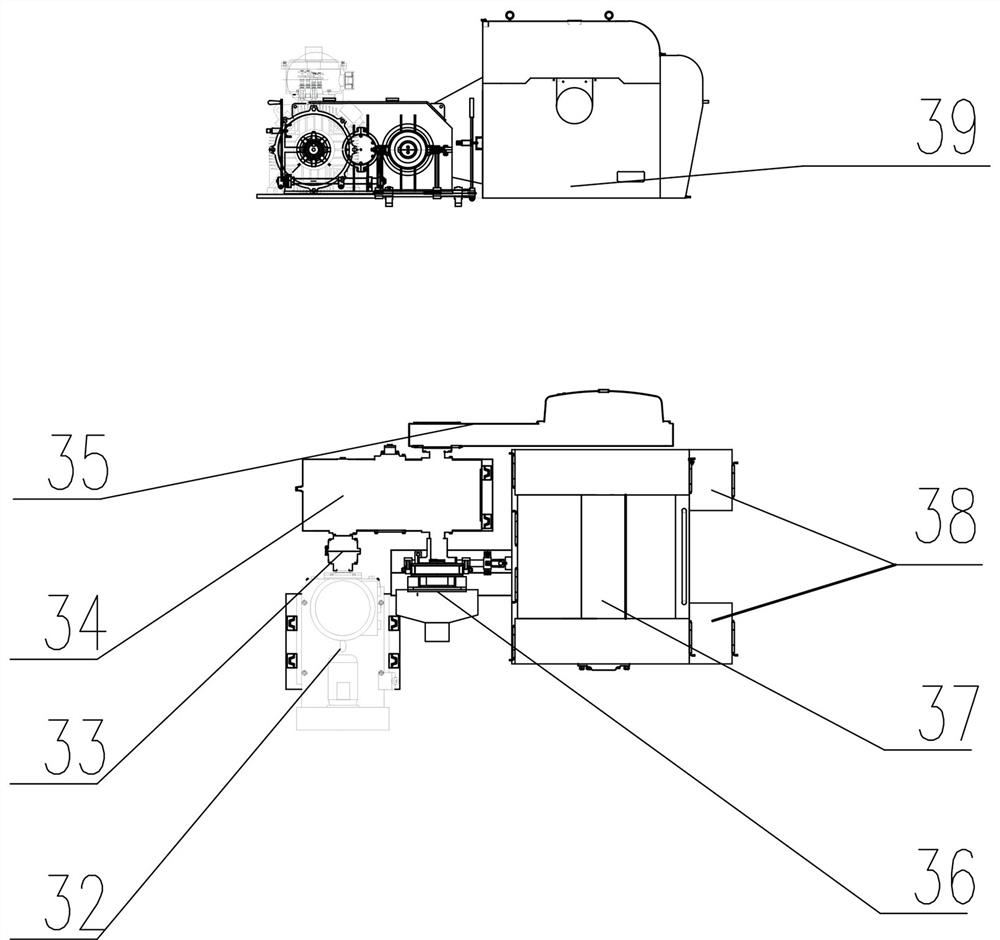

Automatic workover rig driven by power grid

ActiveCN113073948AReduce homeworkGood energy saving and environmental protection effectDrilling rodsDrilling casingsGear wheelBlock and tackle

The invention discloses an automatic workover rig driven by power grid. A derrick front support, an electric control room and a hydraulic system are arranged at the front end of a self-propelled chassis of equipment, an electric air compressor, a multi-gear variable-speed winch and a deadline anchor are arranged in the middle of the self-propelled chassis, an operation room, an air storage tank and a derrick rear support are arranged at the tail of the self-propelled chassis, a working platform is arranged on a wellhead at the tail part of the self-propelled chassis, a tubular column storage device is connected with a tubular column conveying device and is vertically arranged on one side of the upper end surface of the working platform, one end of a steel wire rope is connected with the multi-gear variable-speed winch and the deadline anchor, the other end of the steel wire rope is connected with a grabbing system after bypassing a crown block pulley block, and the grabbing system is used for grabbing a tubular column. According to the automatic workover rig driven by the power grid, various matched devices and systems are connected with respective control systems, workers only need to conduct whole-process monitoring in a driller control room in the whole workover operation, and full-automatic operation of wellhead tubular column connection, buckling, screwing-on and screwing-off and tubular column feeding and discharging operation platforms is achieved.

Owner:中石化四机石油机械有限公司 +1

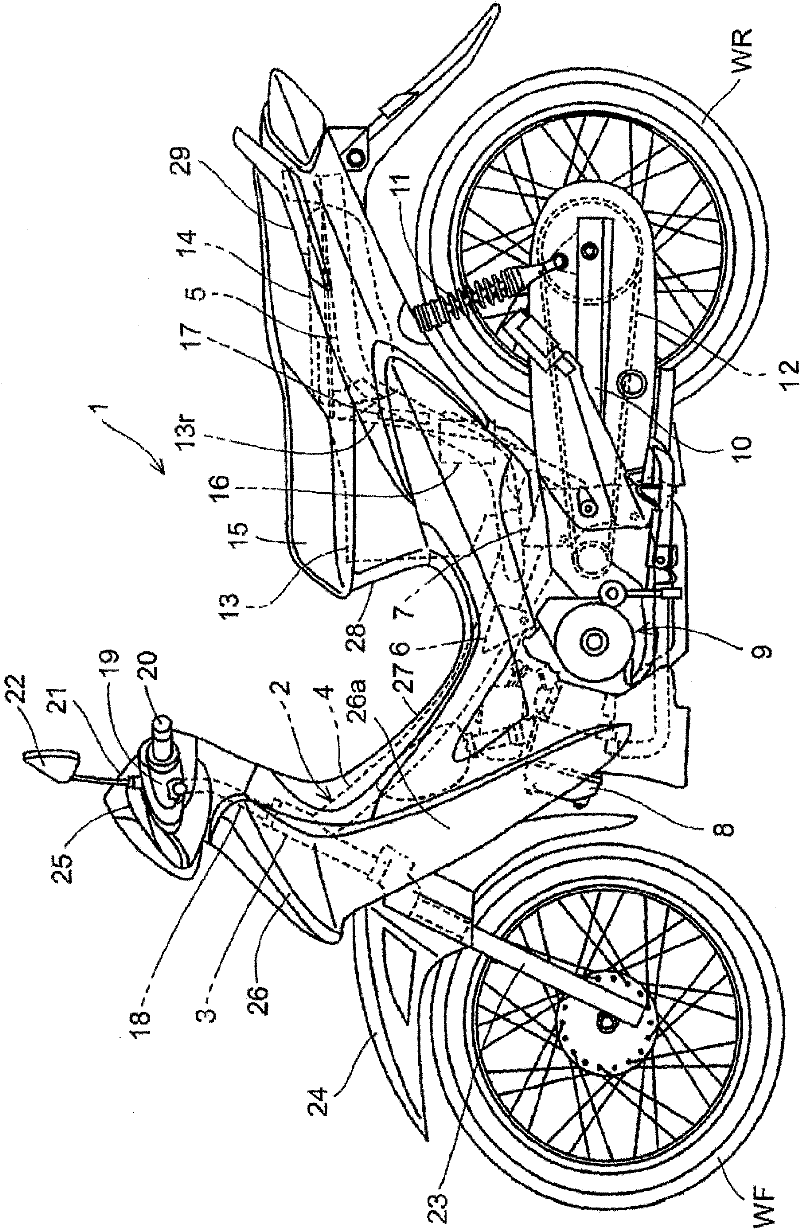

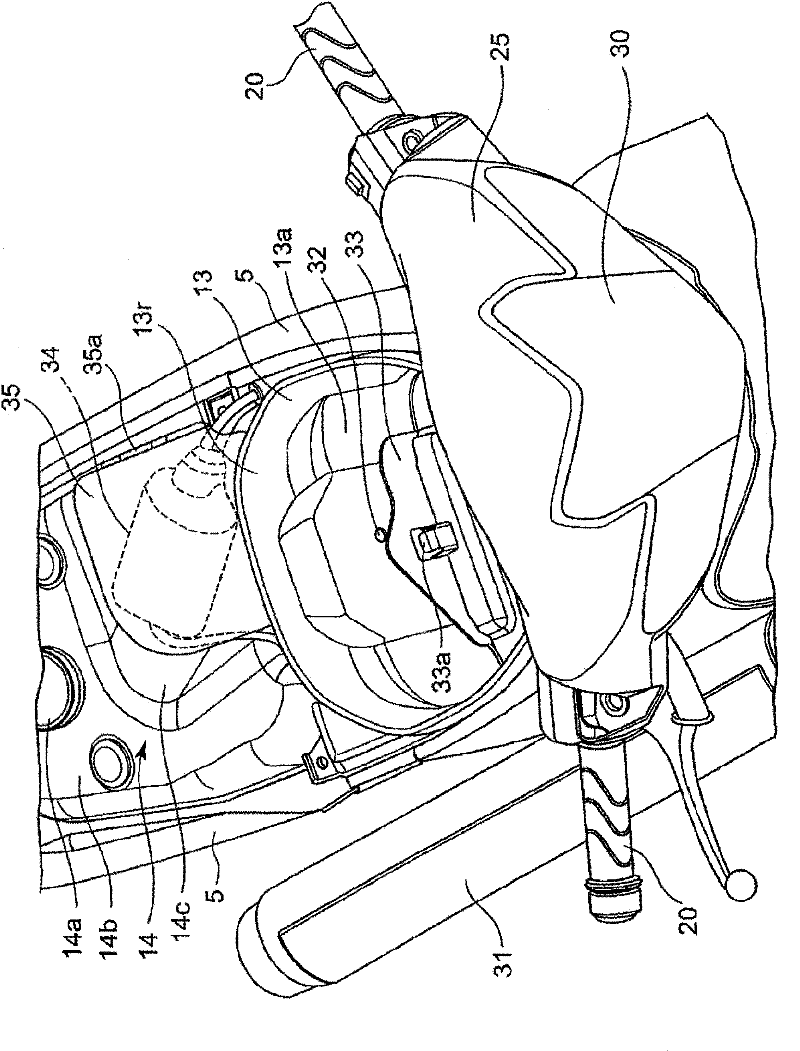

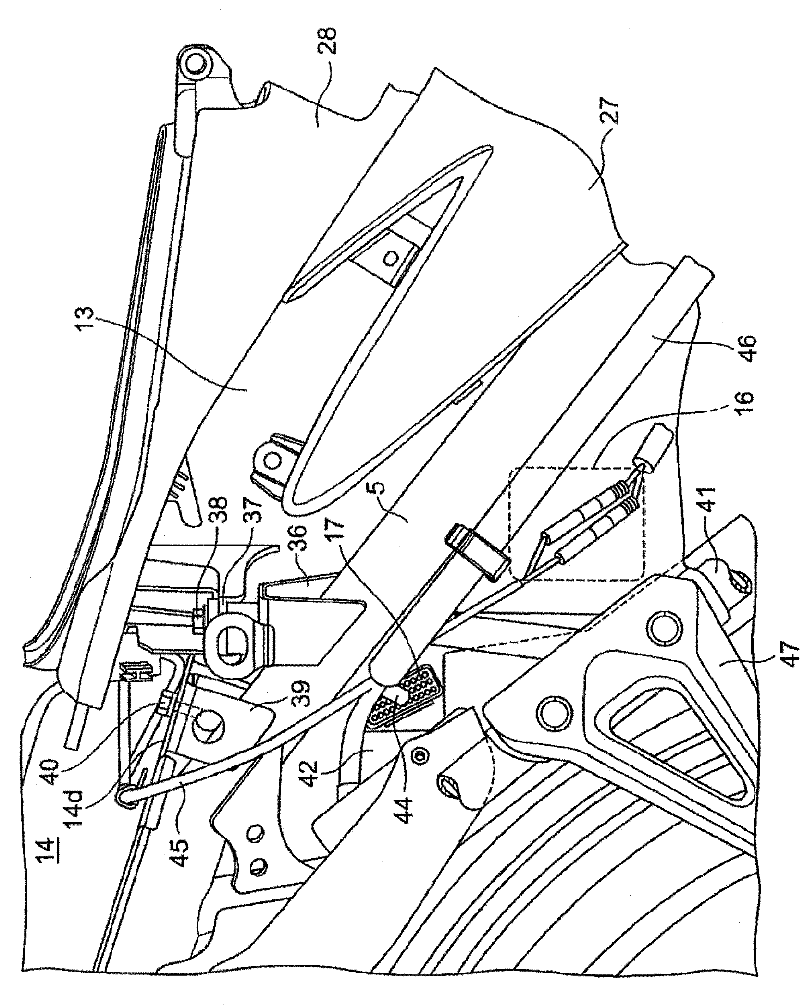

State display device of vehicle

InactiveCN102198849AImprove layout freedomSave material costCycle equipmentsInstrument arrangementsDisplay deviceEngineering

The invention provides a state display device of vehicle, from which an indicator of an integrated controlling means covered by a cover component can be seen. An indicator (48) with LED fault display is integratedly disposed at a FI-ECU (17). The FI-ECU (17) is adjacently disposed at the rear part of a vehicle body with respect to a luggage case (13), and is provided with a face (48a) configured with the indicator (48) and facing the front upper part of the vehicle body. A through hole (32) is disposed on a wall (13a) of the luggage case (13) along an extending line of a line (L) lead from the indicator (48) in a direction vertical to the face (48a), and forms a confirmation hole of the indicator (48). The confirmation hole can confirm the indicator (48), and can expand the size of a maintenance cover (33) and the maintenance cover (33) of a battery (16) disposed at the lower part of the luggage case (13) can be used to block the through hole (32).

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com