Nickel polymetallic ore separation technology

A polymetallic ore and process technology, applied in flotation, solid separation, etc., can solve the problems of high MgO content in concentrate, poor flotation effect, and poor suppression effect, achieving high recovery rate, less operation, The effect of less potion consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

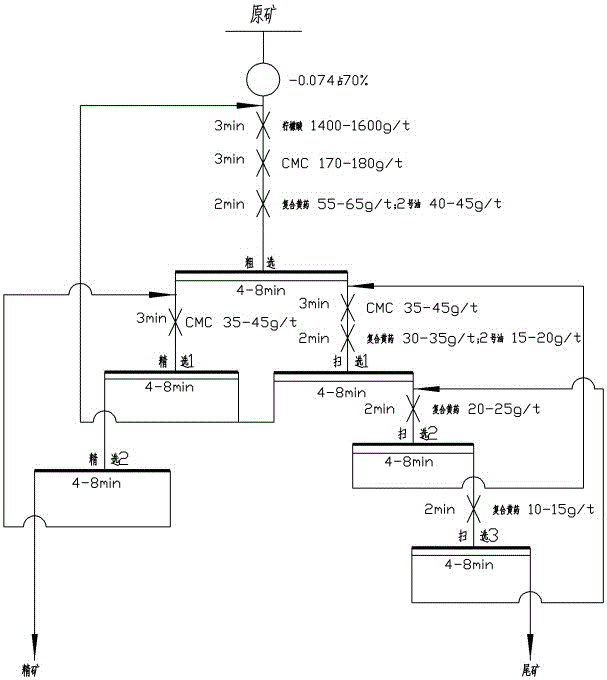

[0023] see figure 1 , a process flow chart of a nickel-polymetallic ore dressing process. The raw ore with a particle size of 400mm is crushed and screened. The grade of nickel in the raw ore is 0.75%, the grade of copper is 0.18%, and the grade of cobalt is 0.029%. Obtain fine ore with a particle size of 12mm; classify the fine ore with a particle size of 12mm through grinding to obtain a pulp with a particle size of -200 mesh accounting for 70%; add lemon to the pulp with a particle size of -200 mesh and account for 70% Acid, the dosage of citric acid is to add 1500g per ton of dry ore, the action time of citric acid is 3min, then add CMC, the consumption of CMC is to add 175g per ton of dry ore, and the action time of CMC is 3min; then add compound xanthate and For No. 2 oil, the dosage of compound xanthate is 60g per ton of dry ore, and the dosage of No. 2 oil is 43g per ton of dry mineral. The action time of compound xanthate and No. 2 oil is 2min. After stirring evenly, ...

Embodiment 2

[0025] see figure 1, a process flow chart of a nickel-polymetallic ore dressing process. The raw ore with a particle size of 300mm is crushed and screened. The grade of nickel in the raw ore is 0.73%, the grade of copper is 0.16%, and the grade of cobalt is 0.029%. Obtain fine ore with a particle size of 10mm; classify the fine ore with a particle size of 10mm through grinding to obtain a pulp with a particle size of -200 mesh accounting for 70%; add lemon to the pulp with a particle size of -200 mesh and account for 70% Acid, the dosage of citric acid is to add 1400g per ton of dry ore, the action time of citric acid is 3min, then add CMC, the consumption of CMC is to add 170g per ton of dry ore, and the action time of CMC is 3min; then add compound xanthate and For No. 2 oil, the dosage of compound xanthate is 55g per ton of dry ore, and the dosage of No. 2 oil is 40g per ton of dry mineral. The action time of compound xanthate and No. 2 oil is 2min. After stirring evenly, e...

Embodiment 3

[0027] see figure 1 , a process flow chart of a nickel-polymetallic ore dressing process. The raw ore with a particle size of 500mm is crushed and screened. The grade of nickel in the raw ore is 0.8%, the grade of copper is 0.2%, and the grade of cobalt is 0.03%. Obtain fine ore with a particle size of 15mm; classify the fine ore with a particle size of 15mm through grinding to obtain a pulp with a particle size of -200 mesh accounting for 70%; add lemon to the pulp with a particle size of -200 mesh and account for 70% Acid, the dosage of citric acid is to add 1600g per ton of dry ore, the action time of citric acid is 3min, then add CMC, the consumption of CMC is to add 180g per ton of dry ore, and the action time of CMC is 3min; then add compound xanthate and For No. 2 oil, the dosage of compound xanthate is 65g per ton of dry ore, and the dosage of No. 2 oil is 45g per ton of dry mineral. The action time of compound xanthate and No. 2 oil is 2min. After stirring evenly, ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com