Ultrasonic beneficiation method

A beneficiation method and ultrasonic technology, applied in the field of mineral separation method, to achieve the effect of less operation, large processing capacity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

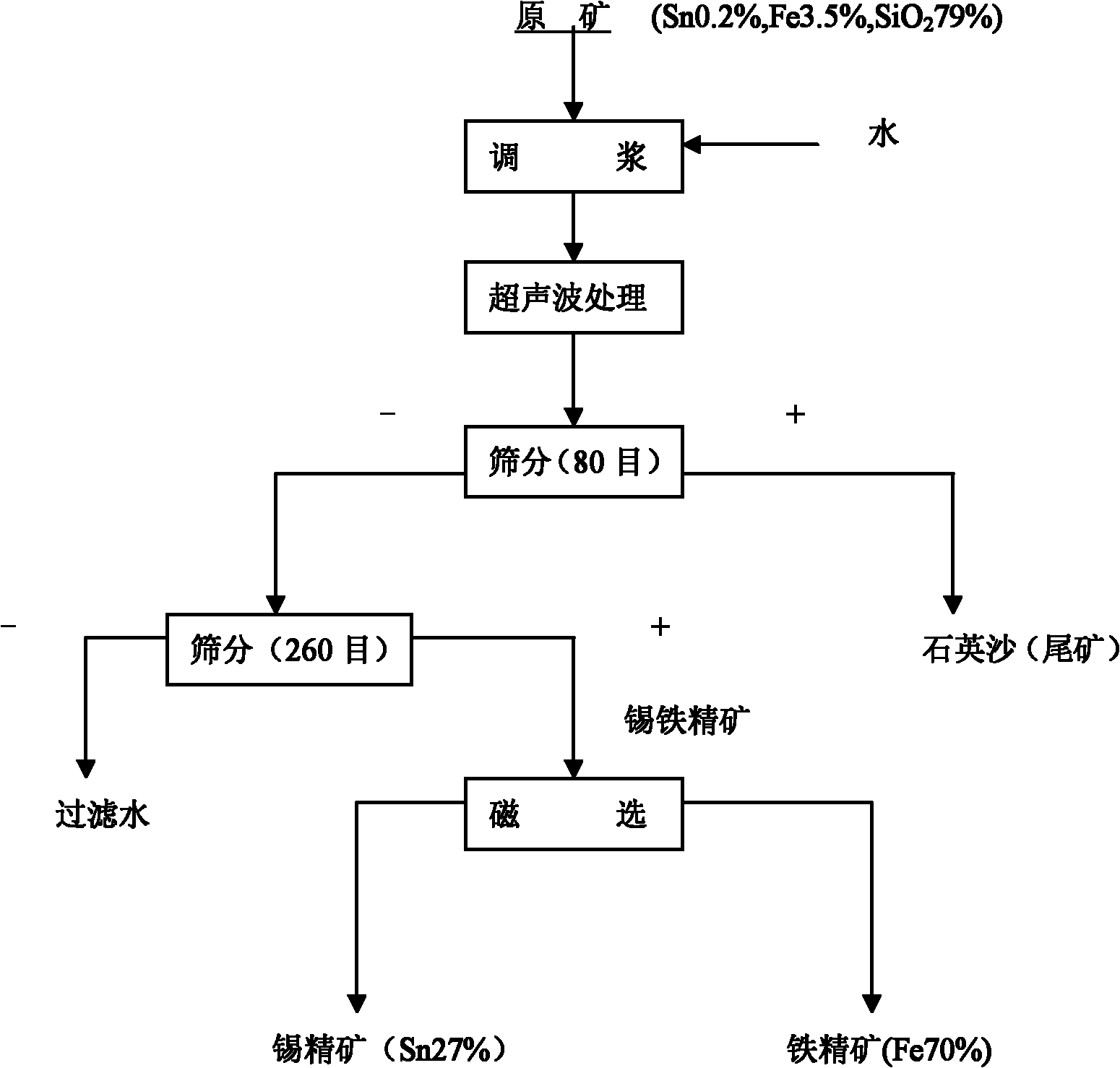

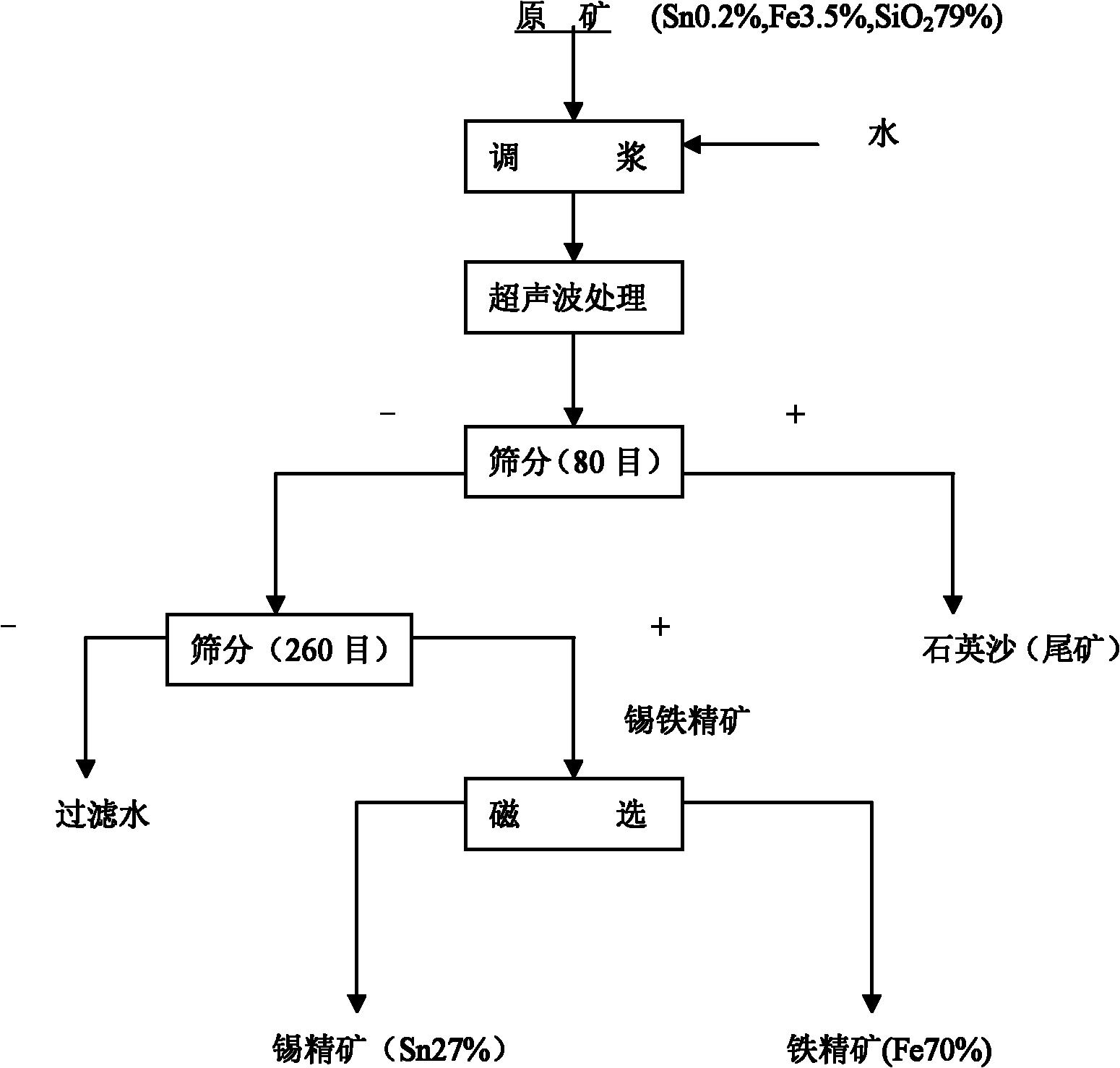

[0020] Example 1, such as figure 1 As shown, a batch of quartz-type weathered sand tin deposits were taken from a certain place in Shenshaba, Gejiu City, Yunnan Province. After passing through a 40-mesh sieve to remove too large particles, a 50Kg ore sample was obtained. The samples were sampled and analyzed by conventional sampling methods. The results were Yes: Sn0.2%, Fe3.5%, SiO 2 79%, and the remaining ingredients are 17.3%.

[0021] Inject clear water into a stainless steel container, put 10Kg of the above-mentioned ore sample into the water, allow the water to soak through the ore, and keep the cone shape of the natural accumulation of the ore. Then insert the ultrasonic vibrating plate into the water, start the ultrasonic equipment, carry out ultrasonic treatment on the mineral material for 3 minutes and 50 seconds and then stop. At this time, the cone-shaped mineral material has flattened in the water, and the water has also become turbid. The particle size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com