Method for quickly starting shortcut nitrification reactor

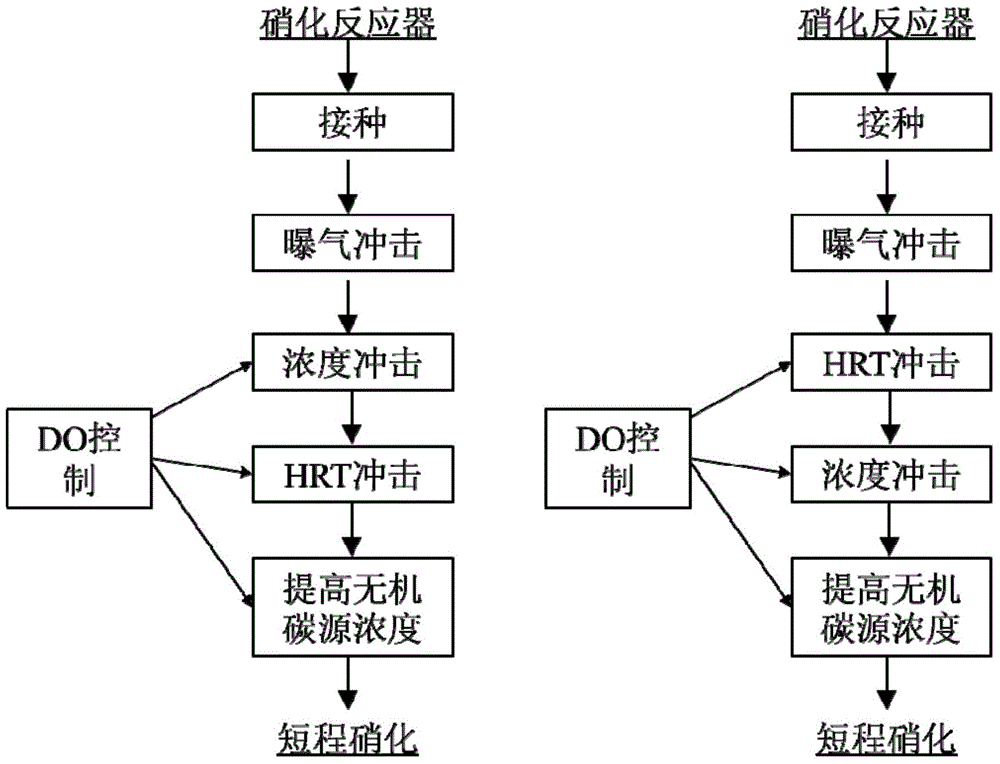

A nitrification reactor and short-path nitrification technology are applied in the field of quick-start short-path nitrification reactors, and can solve problems such as unfavorable short-path nitrification reactors to quickly start nitrite and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

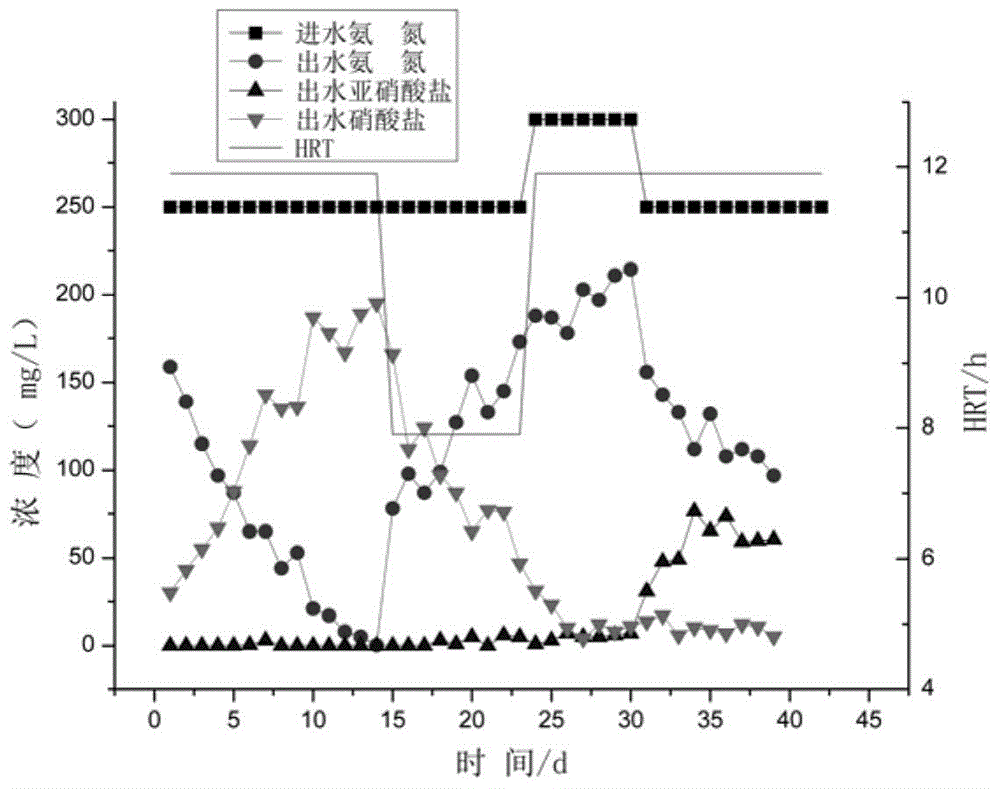

Embodiment 1

[0027] A 10L upflow air-lift nitrification reactor was used to inoculate 2L of nitrification sludge (sludge concentration 1.1gVSS / L) from a pilot nitrification reactor. The salt concentration is 1.0g / L, the HRT is 11.9h, and the average influent pH is 8.25. First, the reactor is aerated and impacted, and the gas flow rate is kept at 160L / h. The average dissolved oxygen concentration in the reactor is measured to be 2.0mg / h L, keeping for 14 days, the removal rate of ammonia nitrogen is close to 100%, almost all of ammonia nitrogen is converted into nitrate, and the accumulation rate of nitrite is basically 0, indicating that the whole process of nitrification has been realized in the reactor. Then reduce the gas flow rate to 10-30L / h, and reduce the HRT to 7.9h at the same time, keep it for 9 days, the measured dissolved oxygen concentration is 0.3-0.8mg / L, the removal rate of ammonia nitrogen is reduced to 31.2%, and the accumulation rate of nitrite less than 15%. Afterwards...

Embodiment 2

[0029] A 10L upflow air-lift nitrification reactor was used to inoculate denitrification sludge from a sewage treatment plant. After the inoculation, the measured sludge concentration was 2.3gVSS / L, and the initial average influent ammonia nitrogen concentration was controlled at 185mg / L. The salt concentration is 1.0g / L, the HRT is 21.5h, and the average influent pH is 8.4. First, the reactor is aerated and impacted, and the gas flow rate is kept at 200L / h. The average dissolved oxygen concentration in the reactor is measured to be 2.8mg / h L, kept for 16 days, the removal rate of ammonia nitrogen was close to 100%, and the accumulation rate of nitrite was 0. Subsequently, the concentration of ammonia nitrogen in the influent was increased to 300 mg / L, the gas flow rate was reduced to 5-20 L / h, and the measured dissolved oxygen concentration was 0.2-0.8 mg / L. After maintaining for 9 days, the removal rate of ammonia nitrogen was reduced to 47.3%. The rate of salt accumulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com