Patents

Literature

37results about How to "Fast enrichment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

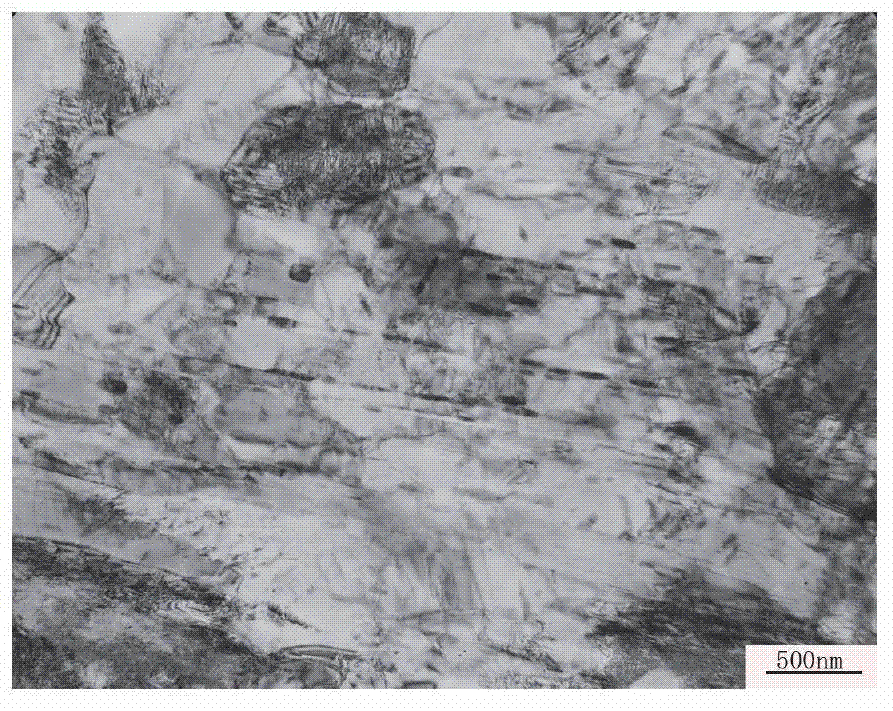

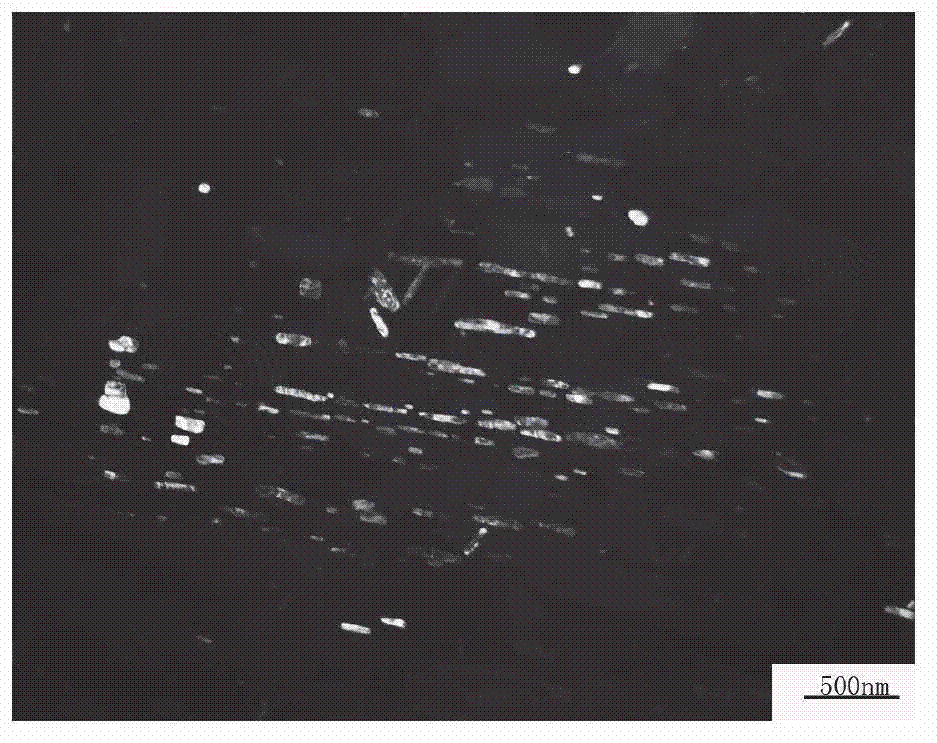

Method for producing high-strength and elongation product automobile steel plate by continuous annealing technology

The invention provides a method for producing a high-strength and elongation product automobile steel plate by a continuous annealing technology, belonging to the technical field of an automobile steel plate. The method comprises the following steps: based on the reasonable chemical component design and the alloy element partition, firstly, obtaining transition carbide with fine dispersion distribution by a cold rolled plate coil importantly, and promoting austenite inverse phase transformation through the solid solution of the fine carbide through two-phase region annealing, to obtain more and stable austenite phases to be remained. According to the method, the strict technological conditions for forming the finely-dispersed carbide and the strict interval for carrying out the technological parameters of the two-phase region annealing are given, so that the method has the advantages that the continuous annealing plate coil which is even in performance and good in surface quality can be obtained due to the short-time annealing of the existing continuous annealing production line of a steel factory, wherein the strength of the steel plate is 0.6-1.2GPa, the percentage elongation of the steel plate is 45-20%, and the product of strength and elongation is 25-40GPa%.

Owner:CENT IRON & STEEL RES INST

Technique for separating boron isotope with boron specific resin ion-exchange chromatography

ActiveCN101274217AEasy to separateHigh separation factorCation exchanger materialsOrganic anion exchangersIon exchangeIsotope

The invention provides a process for separating boron isotope with a boron special-effect resin ion exchange chromatography. The process adopts chelate-typed ion exchanging resin-boron special-effect resin, separates <10>B from boric acid solution, and uses hydrochloric acid or nitric acid as eluent to separate the boron isotope in the boric acid solution by the adsorption of the boric acid on resin columns and the washing of the eluent on the boric acid adsorbed on the resin. According to the process of the invention, the enrichment ratio of the <10>B can be enriched from natural 20 percent or so to 91 percent or so, with fast enrichment speed. The process of the invention is a simple and high-efficiency process which separates the boron isotope from the boric acid solution.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

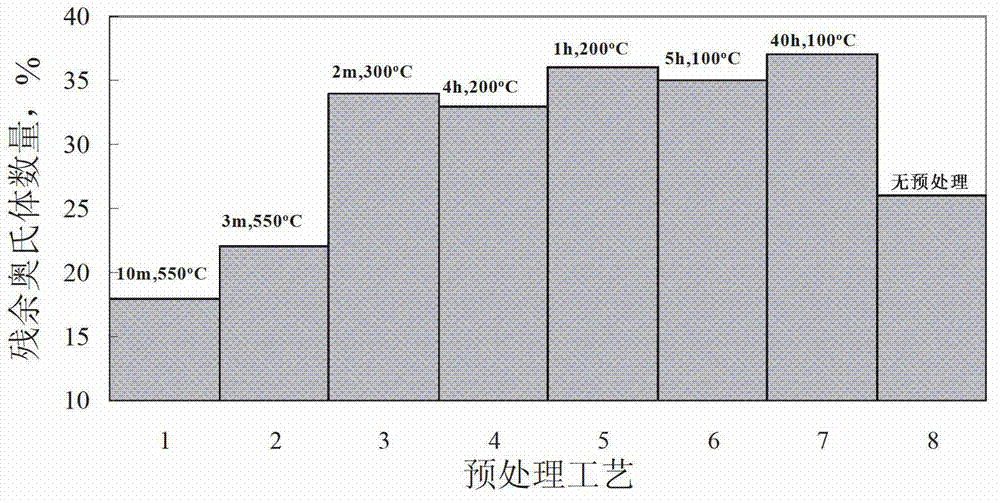

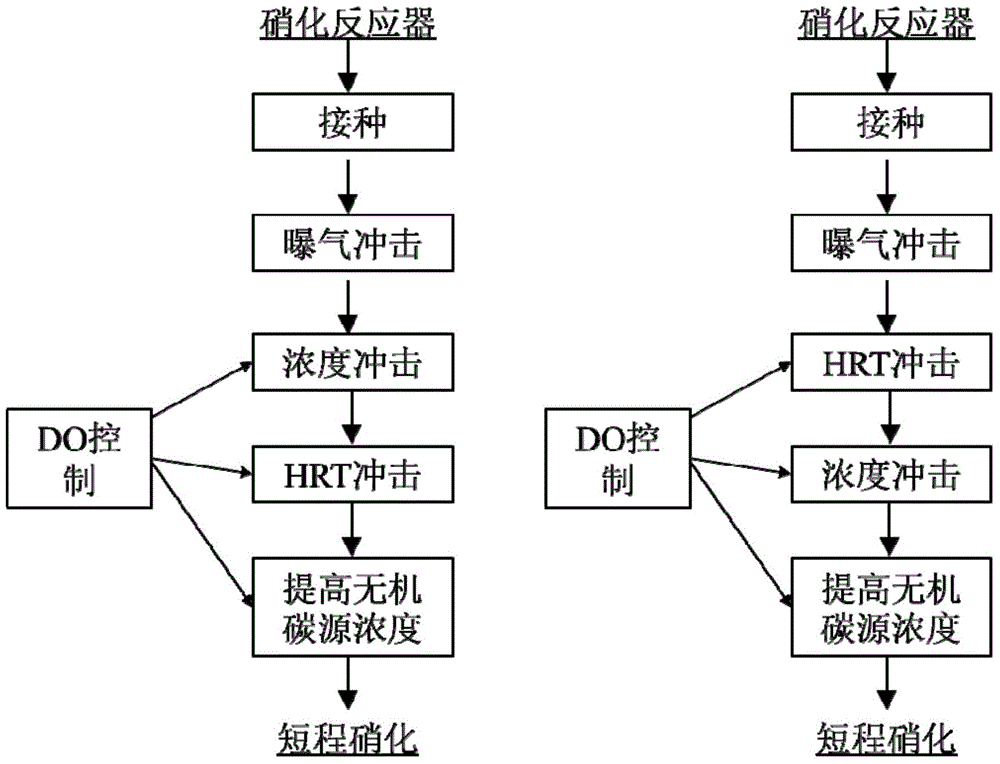

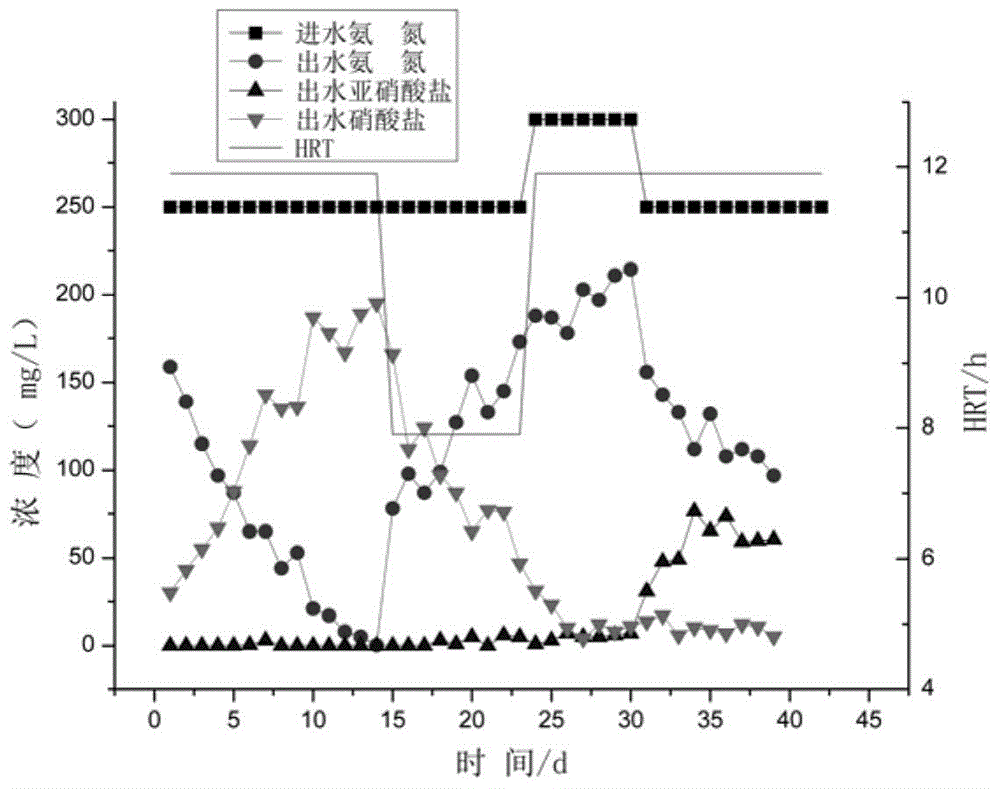

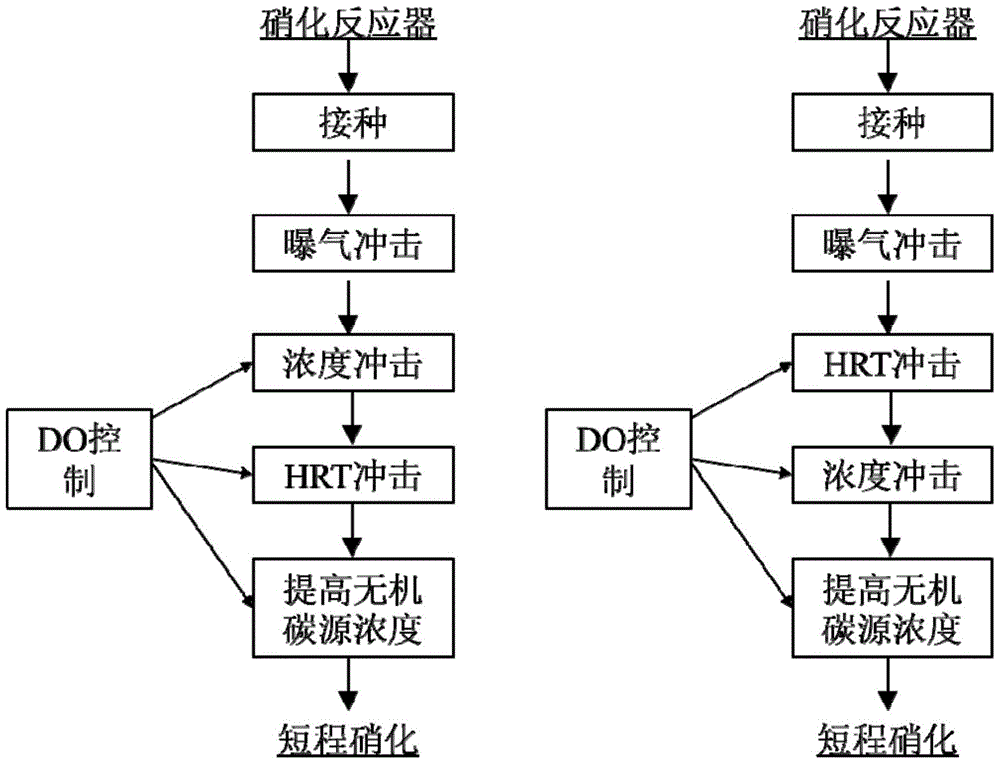

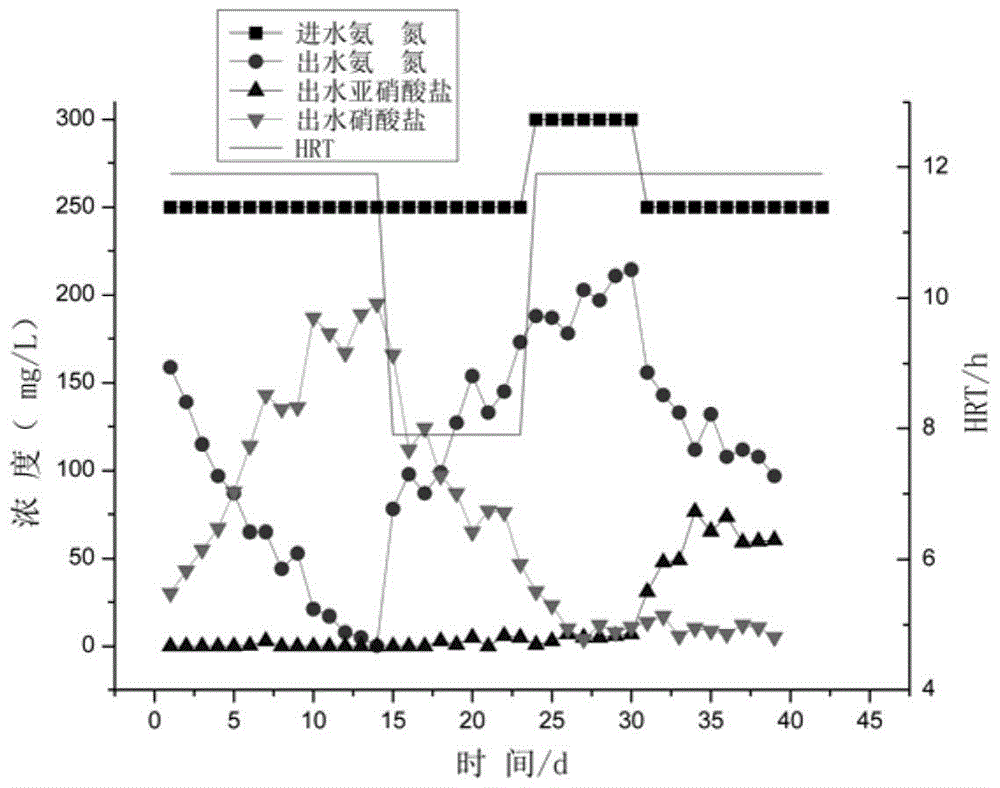

Method for quickly starting shortcut nitrification reactor

ActiveCN104556356AIncrease dissolved oxygen concentrationSpeed up hydrolysisWater treatment parameter controlTreatment using aerobic processesAmmonia-oxidizing bacteriaNitrifying bacteria

The invention discloses a method for quickly starting a shortcut nitrification reactor. The method comprises the following steps: after performing inoculation on the reactor, firstly performing overaeration, and applying an aeration impact so as to accelerate the elimination of anaerobic bacteria in sludge; quickly enriching nitrifying bacteria, and then applying a combined load impact comprising a substrate concentration impact and a hydraulic retention time impact so as to quickly restrain and eliminate nitrite oxidizing bacteria; finally, under the condition that an appropriate substrate concentration and an appropriate hydraulic retention time are maintained, increasing the concentration of an inorganic carbon source so as to enrich ammonia oxidizing bacteria and accelerate the accumulation of nitrite. According to the invention, the various continuous impacts are combined, the enrichment of the ammonia oxidizing bacteria in the sludge is accelerated within a shorter time, and the quick start of the shortcut nitrification reactor is realized.

Owner:CENT SOUTH UNIV

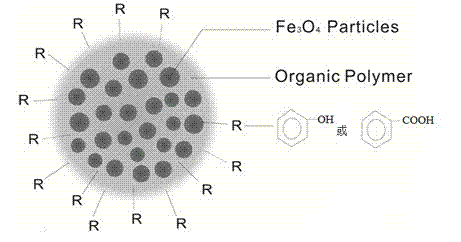

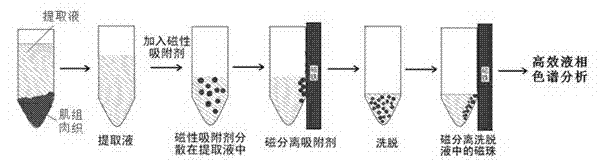

Method for enriching nature tetracycline antibiotics in aquatic products

InactiveCN103076415AEfficient enrichmentHigh extraction recoveryComponent separationOther chemical processesBiotechnologyBenzoic acid

The present invention discloses a method for enriching nature tetracycline antibiotics in aquatic products, and relates to a sample pretreatment in the field of food safety analysis. The method comprises the following steps: a 0.1 mol / L disodium ethylenediaminetetraacetate / Mcllvaine extraction buffer solution pretreatment, phenol or benzoic acid-modified polystyrene superparamagnetic bead adsorption, elution collection and the like, wherein an eluent can be directly added to liquid chromatography or LC-MS to carry out analysis. Compared with the traditional sample pretreatment method for tetracycline antibiotics in aquatic products, the method of the present invention has the following characteristics that: a sample pretreatment operation process is substantially simplified, a sample pretreatment time is shortened, the adsorbent use amount is reduced, and an extraction yield of the tetracycline antibiotics in the sample is increased.

Owner:NANCHANG UNIV

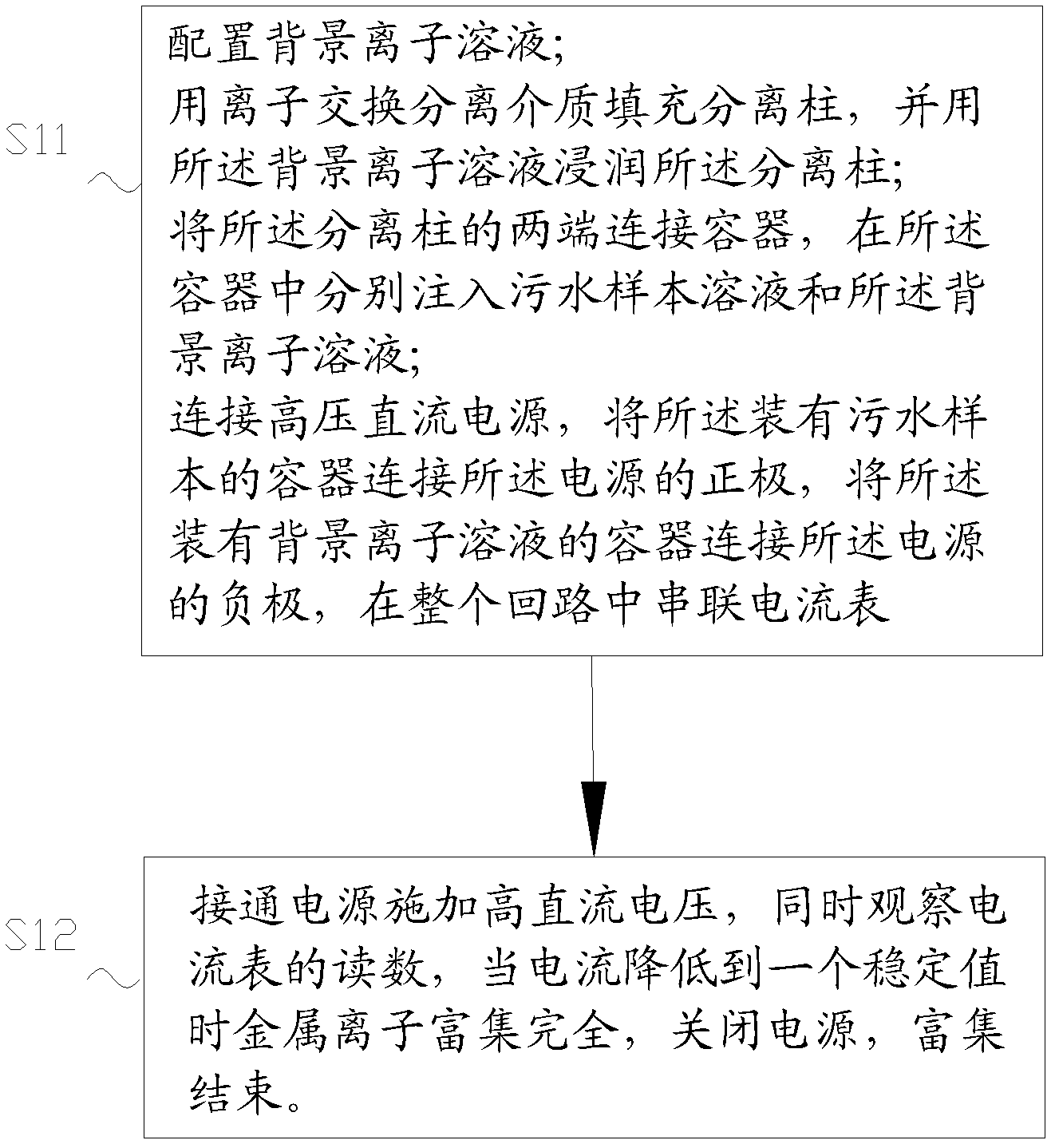

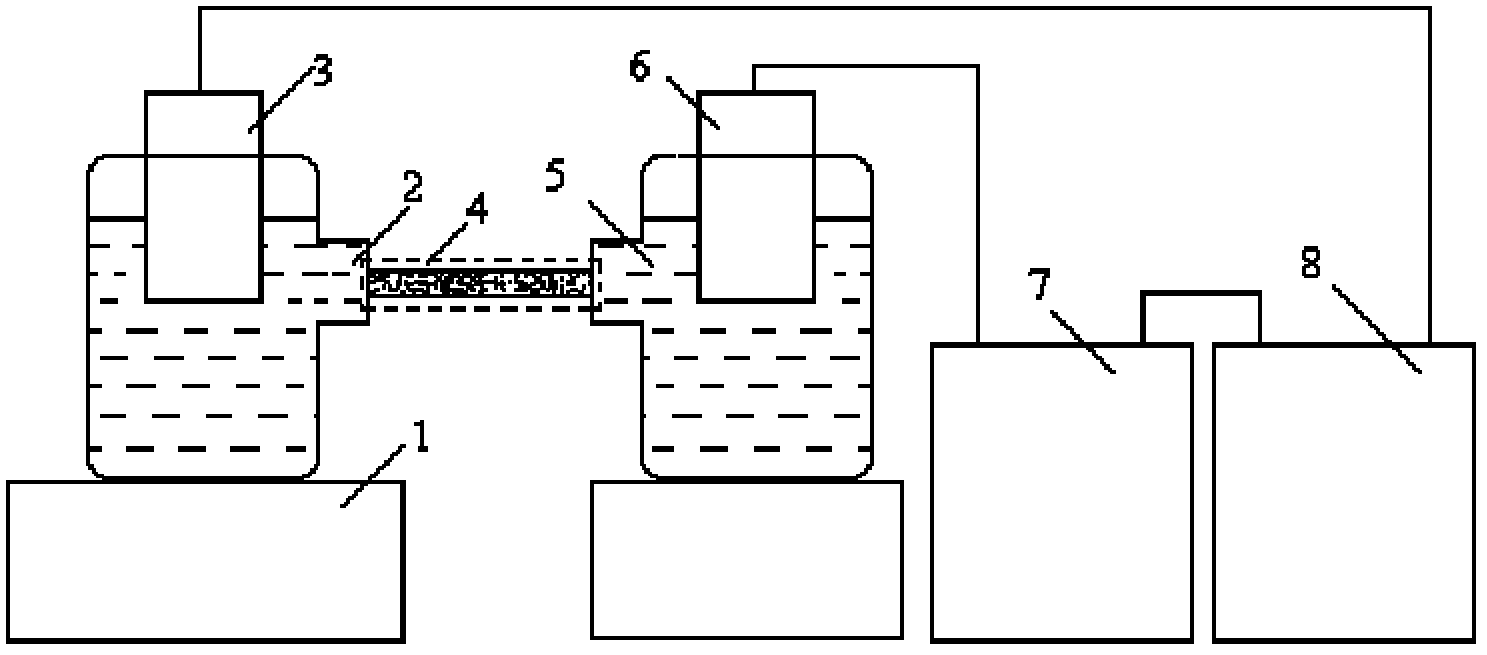

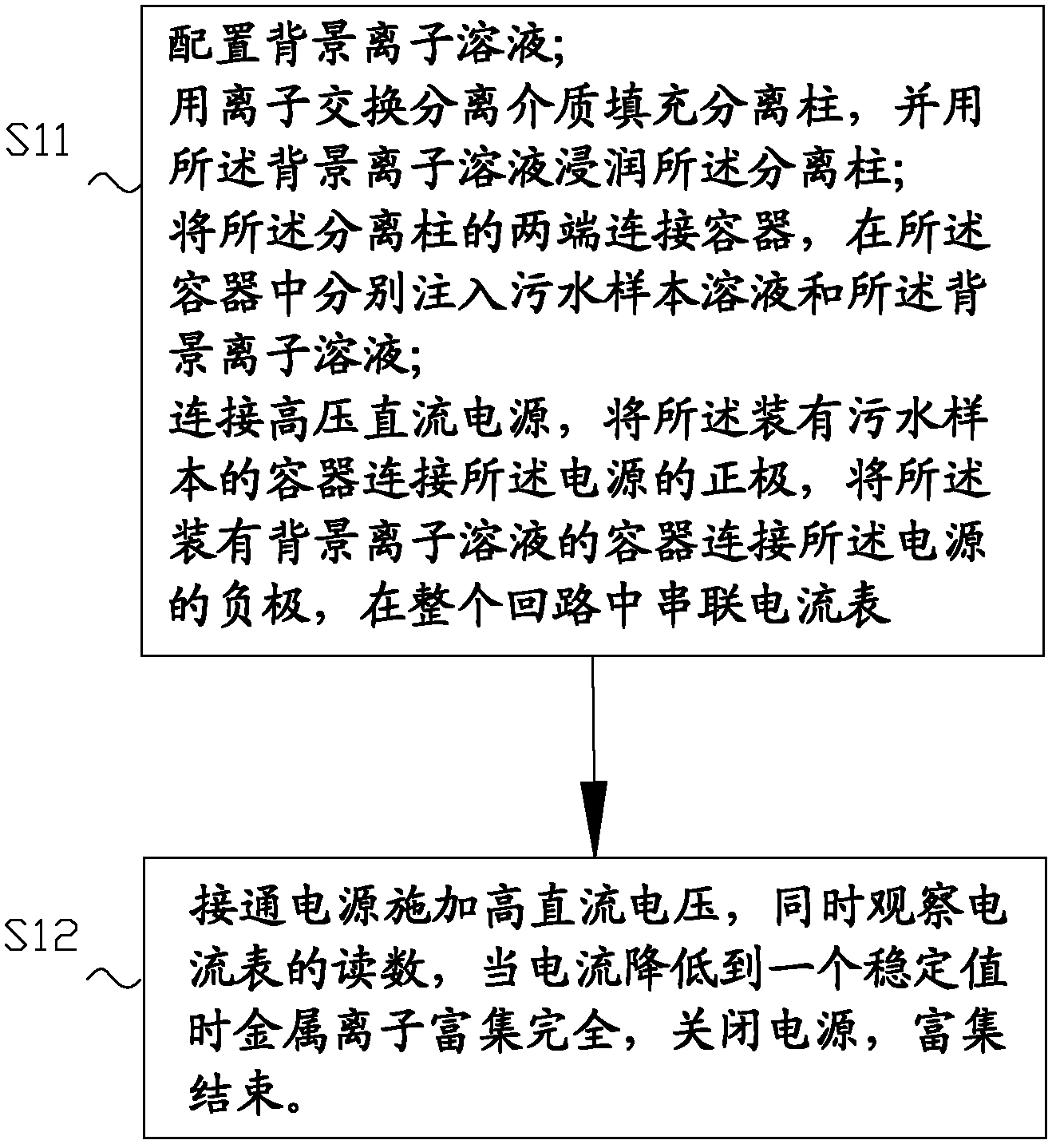

Novel method and apparatus for enriching and separating metal ions in sewage

ActiveCN102557205ARapid enrichmentEasy to separateWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by ion-exchangeHigh concentrationHigh rate

The invention discloses a novel method and a novel apparatus for enriching and separating metal ions in sewage. According to the invention, vessels are connected to two ends of a separating column filled with an ion exchange separation medium; a sewage sample and a high-concentration background ion solution are respectively added into the vessels; high direct-current voltage is applied on the two ends of the separating column; under the effect of electric fields, the metal ions in the sewage form electrophoresis currents, such that the metal ions are rapidly enriched to the ion exchange separation medium with a set orientation; based on a field reinforcing effect caused by a factor that the concentration of the background ion solution is higher than that of the sample solution, the metal ions are enriched into a narrow band at an inlet of a channel. The enriching apparatus is advantaged in convenient application, simple structure, compatibility with various detections, high enriching efficiency, high enriching speed, easy configuration, and easy operation. With the apparatus and the method, high-rate enrichment of trace-amount heavy metal ions which are hard to detect in water can be realized, and primary separation can be carried out upon different metal ions.

Owner:杭州精进科技有限公司

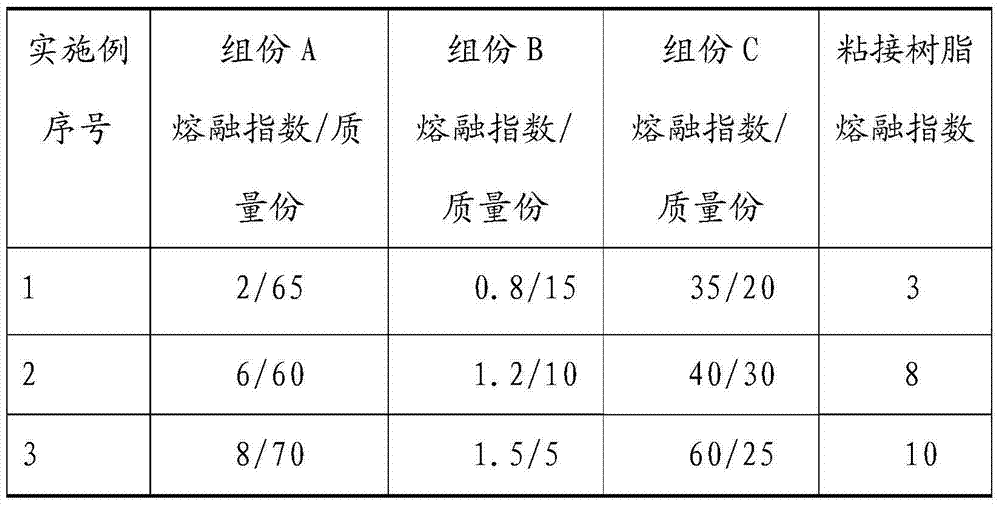

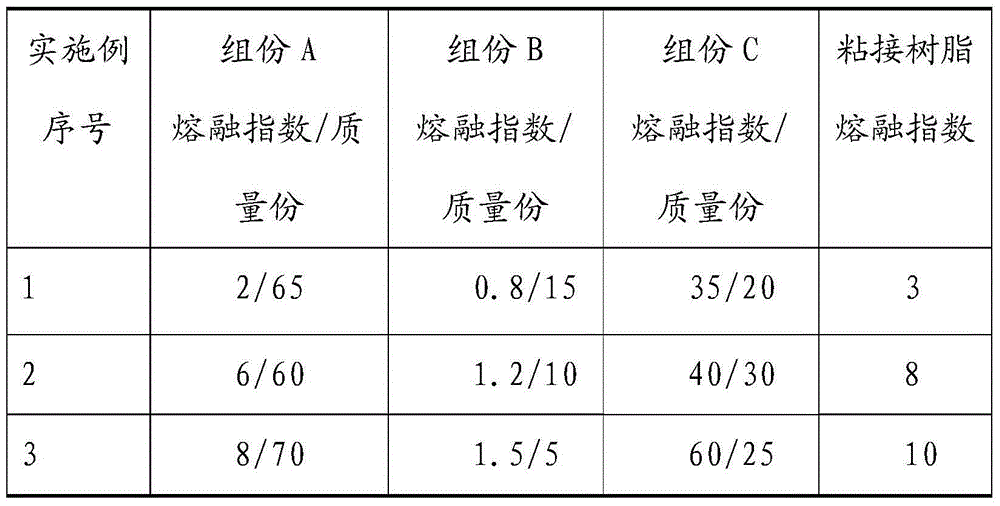

Adhesive resin for multilayer coextrusion barrier package and barrier structure prepared from same

ActiveCN103756595AGood adhesionEasy to processSynthetic resin layered productsAdhesivesElastomerAlpha-olefin

The invention discloses an adhesive resin for multilayer coextrusion barrier package and a barrier structure prepared from the same. The adhesive resin comprises the following components in parts by weight: 85-55 parts of propylene-ethylene-alpha olefin copolymer, 5-15 parts of vinyl elastomer and 10-30 parts of functionalization modified propylene-alpha olefin copolymer. The barrier structure comprisesa barrier layer, wherein at least one surface of the barrier layer is bonded with a polypropylene layer through an adhesive layer; the adhesive layer is the adhesive resin in the first target; the barrier layer is an ethylene-vinyl alcohol copolymer or nylon; and the adhesive resin accounts for 10-15 wt% of the barrier structure. The adhesive resin has the advantages of favorable bonding property, favorable working properties, fewer crystal points, high transparency and the like.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

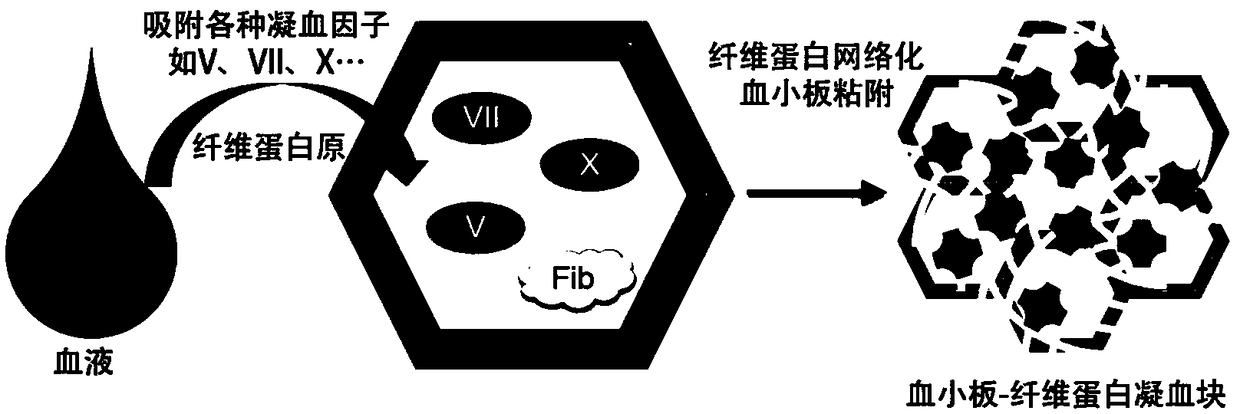

Composite hemostatic material for external trauma and preparation method thereof

PendingCN109172857AGood biocompatibilityImprove securityPharmaceutical delivery mechanismAbsorbent padsMacroporeBiocompatibility Testing

The invention discloses a composite hemostatic material for external trauma and a preparation method thereof. The hemostatic material comprises a porous material, a metal oxide and a high molecular polysaccharide, and the mass ratio is 1: 0.50-0.01: 5-0.05, and the pore size range of the porous material is 1 nm-100 mu m. The material has porous structure, can quickly adsorb various proteins in blood, so that coagulation factors are enriched in macropores. The chitosan hydrogel provides a positively charged surface, accelerates the enrichment rate of coagulation factors, and further acceleratesthe coagulation reaction. And the material has good biocompatibility, and can be used in animal models of rat femoral artery trauma for effective hemostasis. The hemostatic material can be made intopowder or added into fabric to make tourniquet, hemostatic sponge and other forms, and is suitable for complex wounds. The hemostatic process does not exothermic has higher safety, and the hemostaticmaterial can still retain efficacy after moisture absorption, and is convenient for long-term storage.

Owner:CHINA PHARM UNIV

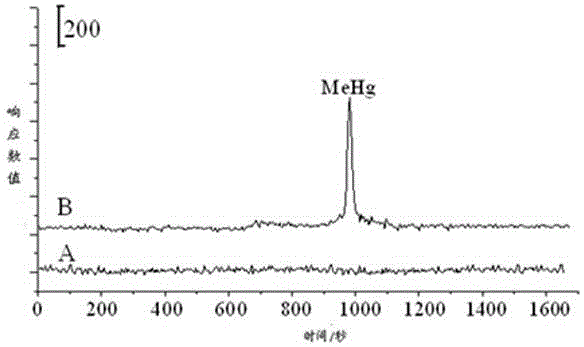

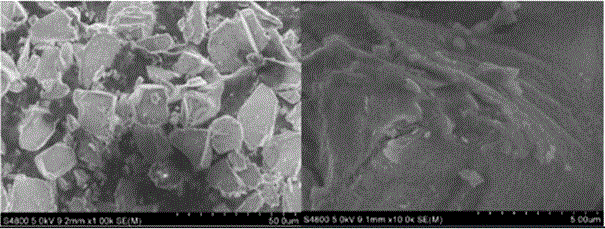

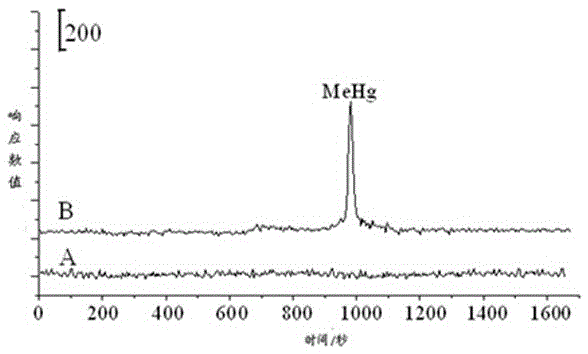

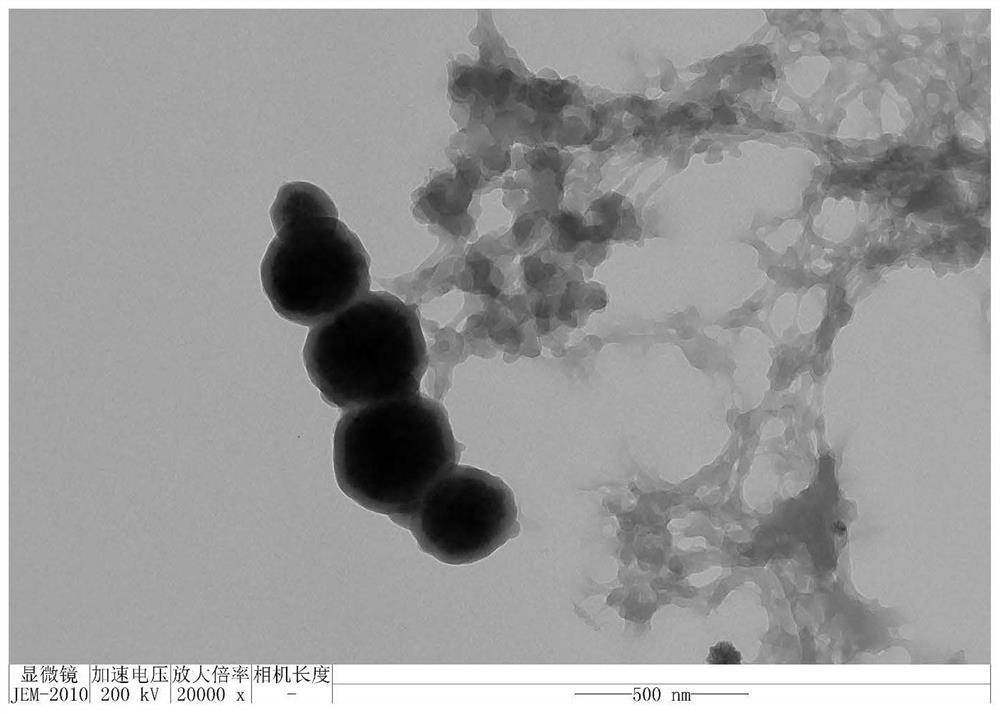

Ionic imprinting material for enriching ultratrace methyl mercury in water body

InactiveCN104353441ADoes not affect enrichment separationFast enrichmentOther chemical processesWater contaminantsFunctional monomerMethylmercury

The invention discloses an ionic imprinting material for enriching ultratrace methyl mercury in a water body and a preparation method and application of the ionic imprinting material. A silicon dioxide microsphere serving as a carrier, methyl mercury chloride and pyrrolidinecarbodith which serve as templates, methacrylic acid serving as a functional monomer, TMPTMA serving as a crosslinking agent and azodiisobutyronitrile serving as an initiator are synthesized to form a silicon dioxide microsphere, on the surface of which a three-dimensional cavity ionic imprinting polymer with a methyl mercury ion structure is arranged. The ionic imprinting material has the advantages of short enrichment time, simplicity in operation, high specificity, high enrichment capacity, low cost and the like and can be used for quickly pre-enriching and separating ultratrace methyl mercury ions in various water samples.

Owner:FUZHOU UNIV

Method for extracting huperzine A

The invention discloses a method for extracting huperzine A. The method comprises the following steps: soaking huperzia serrata with an acidic organic solvent to extract total huperzine, adjusting pHvalue after concentration, and then carrying out extraction, decoloration and mud flocculation, recrystallization, normal phase column chromatography and recrystallization to obtain huperzine A. The method is simple and easy in operation, little in pollution, short in production cycle, low in cost and high in yield, and is applicable to industrial application and market popularization.

Owner:YUNNAN HANDE BIO TECH

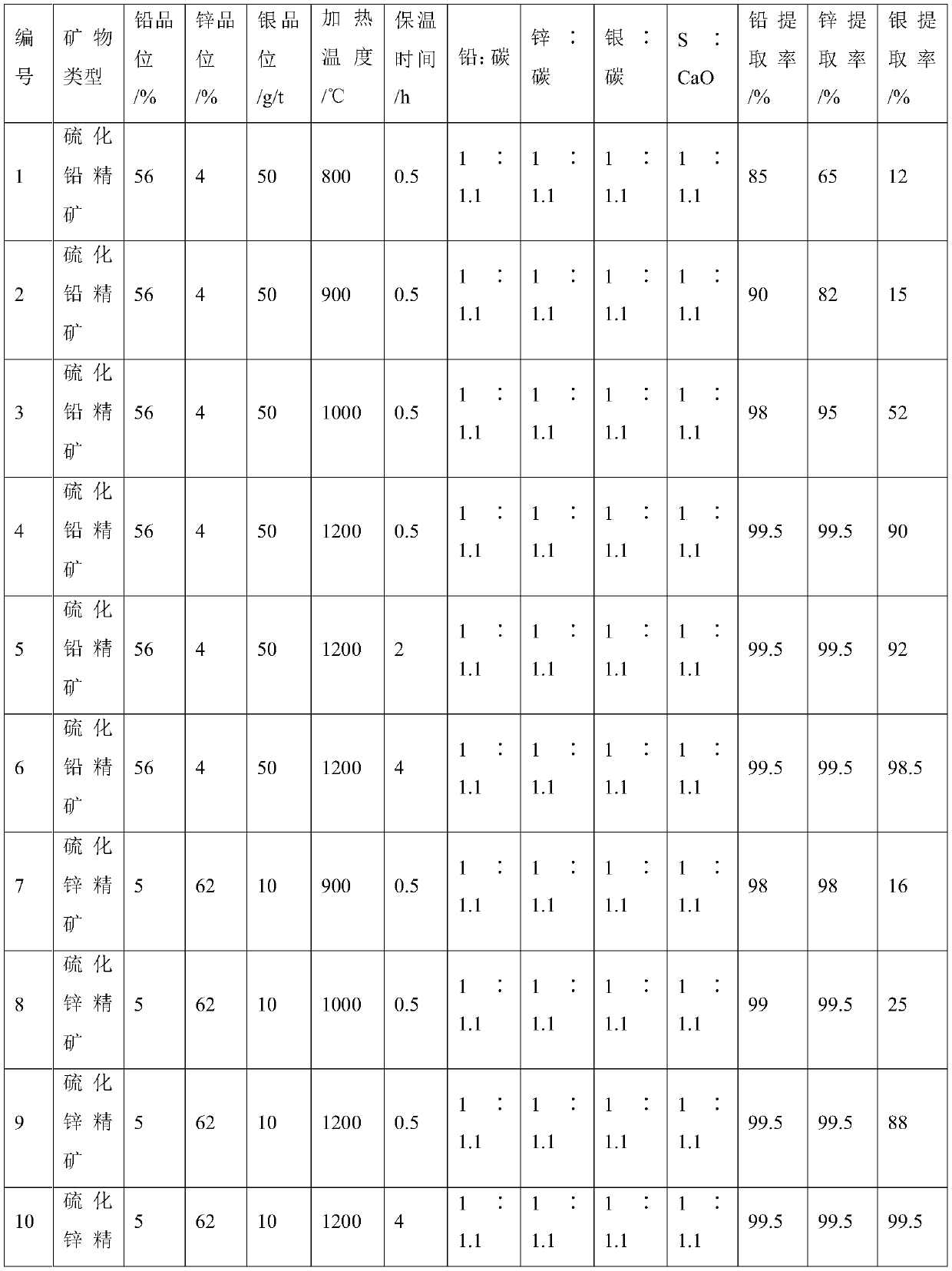

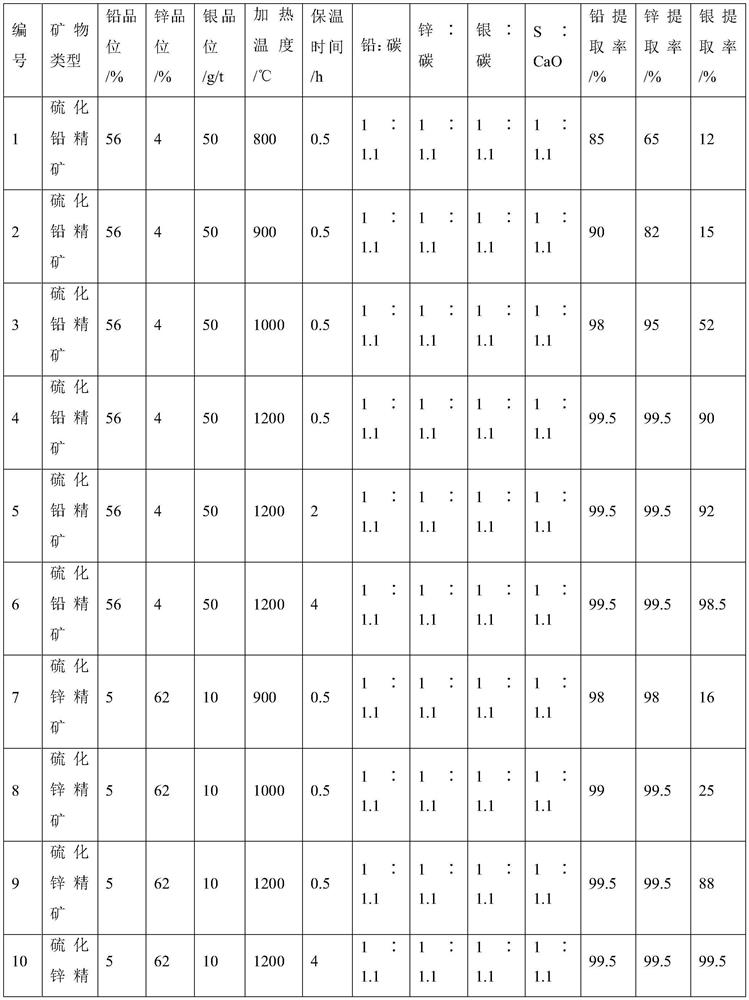

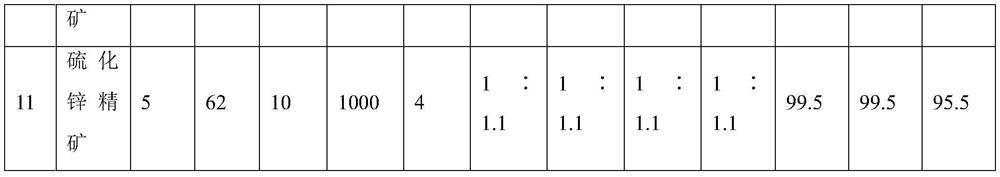

Method for extracting lead, zinc and silver in lead-zinc-silver composite sulfide minerals

The invention provides a method for extracting lead, zinc and silver in lead-zinc-silver composite sulfide minerals. The method comprises the steps of adding pulverized coal and quicklime powder intoa composite raw mineral material containing lead and / or zinc and / or sliver to be mixed evenly to form a mixture, conducting pelletization on the mixture; conducting vacuums heating reduction on the pelletized mixture, controlling the heating temperatures according to the components extracted from the minerals correspondingly, collecting the obtained lead and / or zinc and / or sliver metal steam in acondensing mode to obtain a collected condensation product which is the mixture of the lead and / or zinc and / or sliver. The method has the advantages of convenient operation, safety, sanitation and non-pollution. The method is used for enriching metallic-state lead and zinc has the advantages of high enrichment speed, high production efficiency and small pollution. The method is used for separatingmetals in the minerals and has the characteristics of short technological process, short cycle, high efficiency and high resource comprehensive utilization rate. The separation and extraction efficiency of the metals can be greatly improved. By means of the method, the direct yield rates of lead and zinc can reach up to 98% or more.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

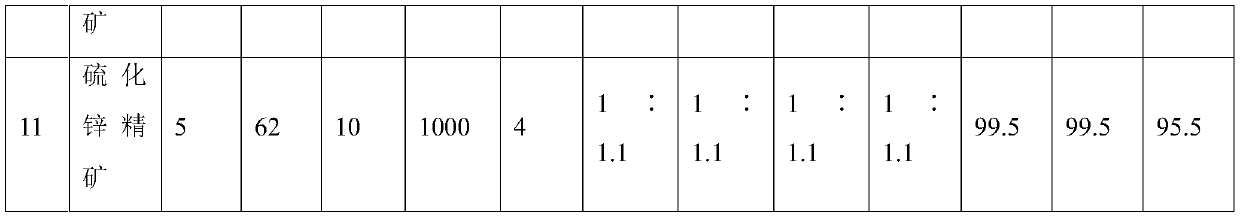

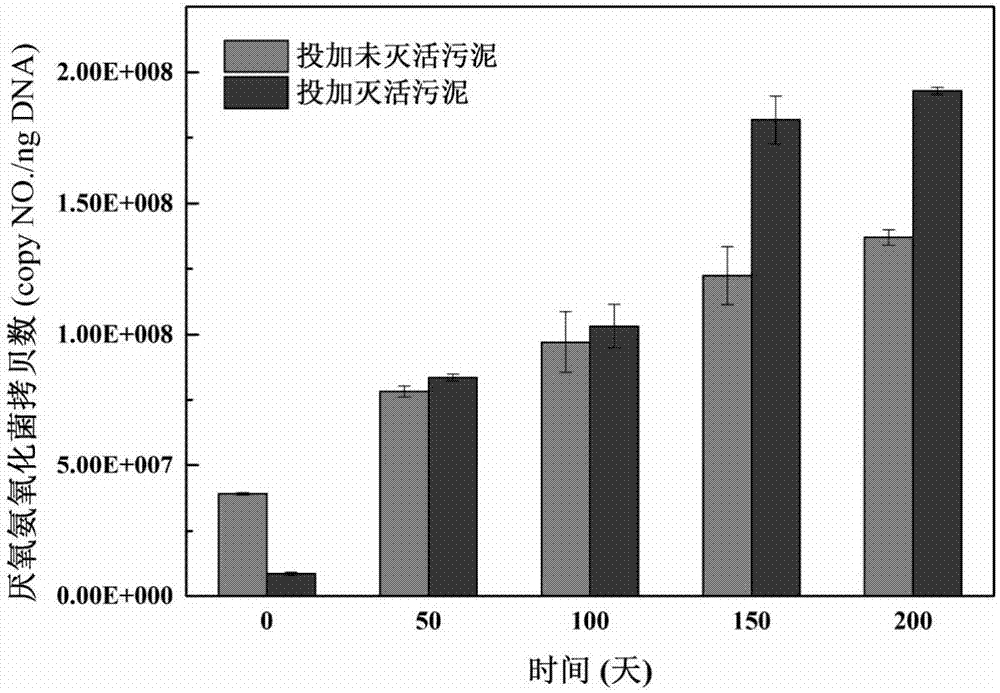

Inactivated sludge-based anaerobic ammonium oxidation rapid enhancement starting method

ActiveCN107253761AReduce startup timeFast enrichmentWater contaminantsTreatment with anaerobic digestion processesPeristaltic pumpStart time

The invention relates to an inactivated sludge-based anaerobic ammonium oxidation rapid enhancement starting method. The method comprises the following steps: feeding deactivated sludge and active anaerobic ammonium oxidation sludge into a reaction area of an upflow type anaerobic reactor and evenly mixing, wherein the mass ratio of the active anaerobic ammonium oxidation sludge to deactivated sludge (unit: g / kg) is (0.5-1.8):1; introducing to-be-treated waste water from the bottom of the upflow type anaerobic reactor by utilizing a peristaltic pump, so that the hydraulic retention time of the to-be-treated waste water in the upflow type anaerobic reactor lasts for 10 to 48 hours; and successfully starting anaerobic ammonium oxidation reaction of sludge after the upflow type anaerobic reactor runs for 40-70 days, thus realizing the high-efficiency removal of nitrogen in sewage. By utilizing the method, the starting time of the anaerobic ammonium oxidation technology can be effectively shortened, and the enrichment speed of anaerobic ammonium oxidation bacteria can be obviously accelerated; the starting time of the upflow type anaerobic reactor can be shortened by 9.3%; and after running for 200 days, the enrichment quantity of anaerobic ammonium oxidation bacteria in the upflow type anaerobic reactor inoculated with deactivated anaerobic granular sludge and active anaerobic ammonium oxidation sludge can be increased by 40.9%.

Owner:山东美泉环保科技有限公司

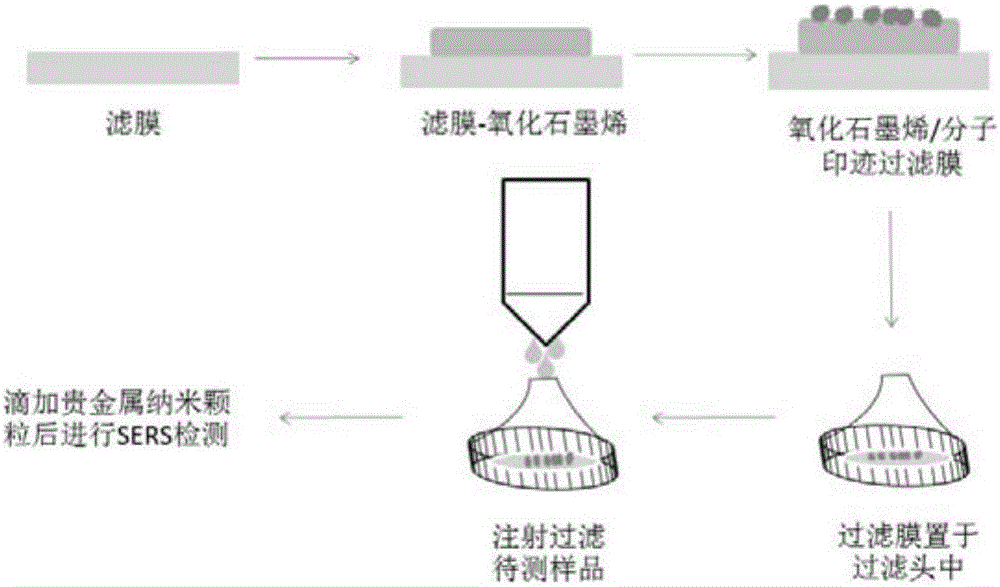

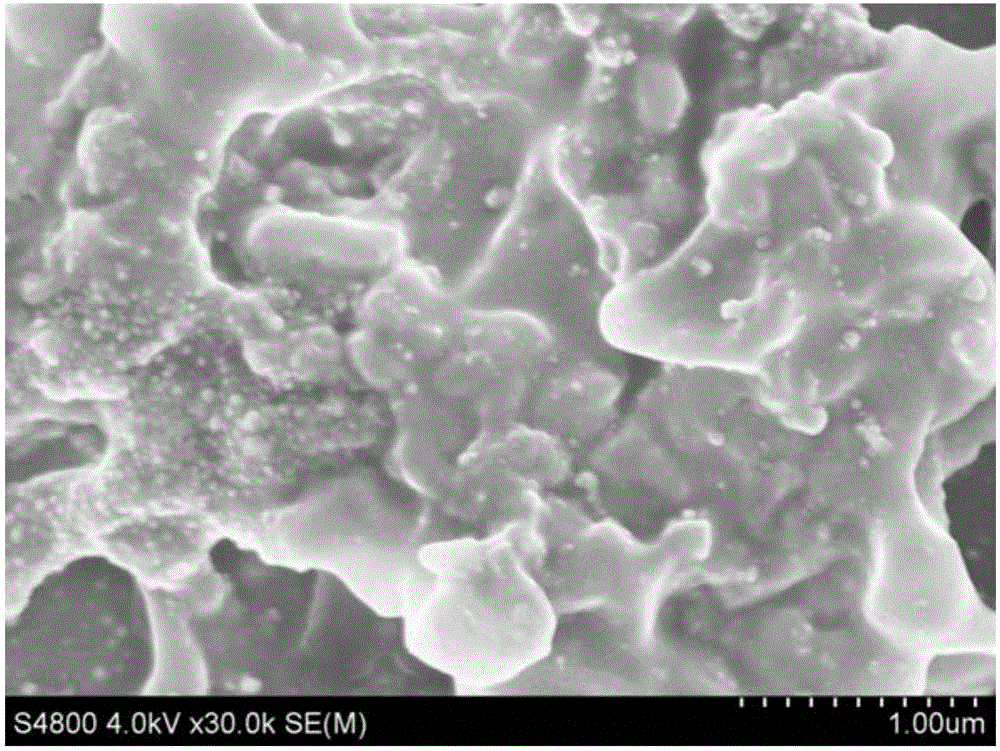

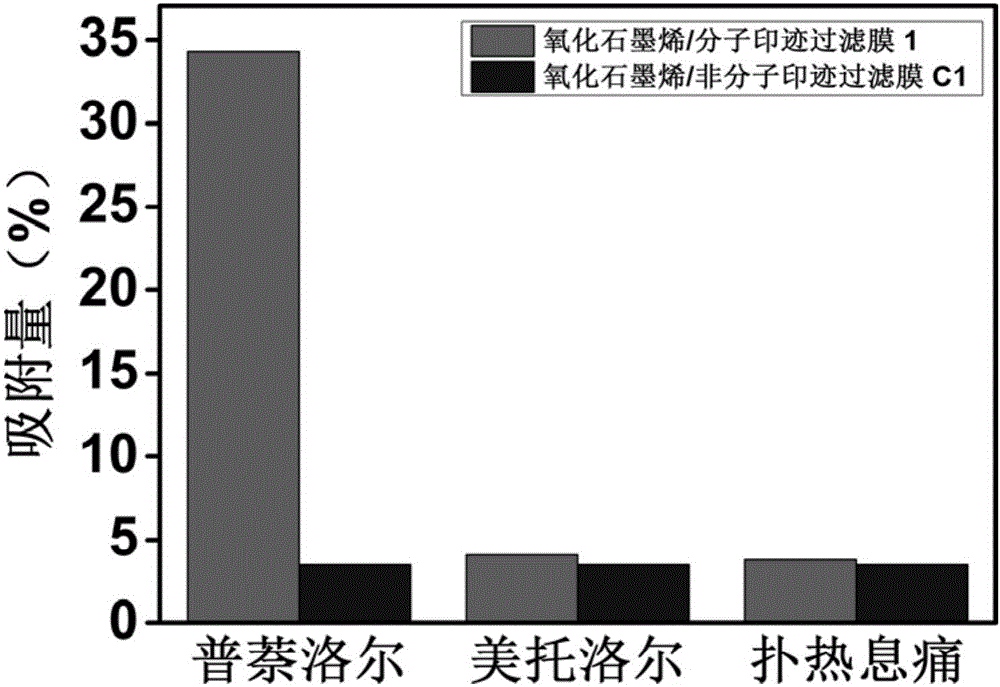

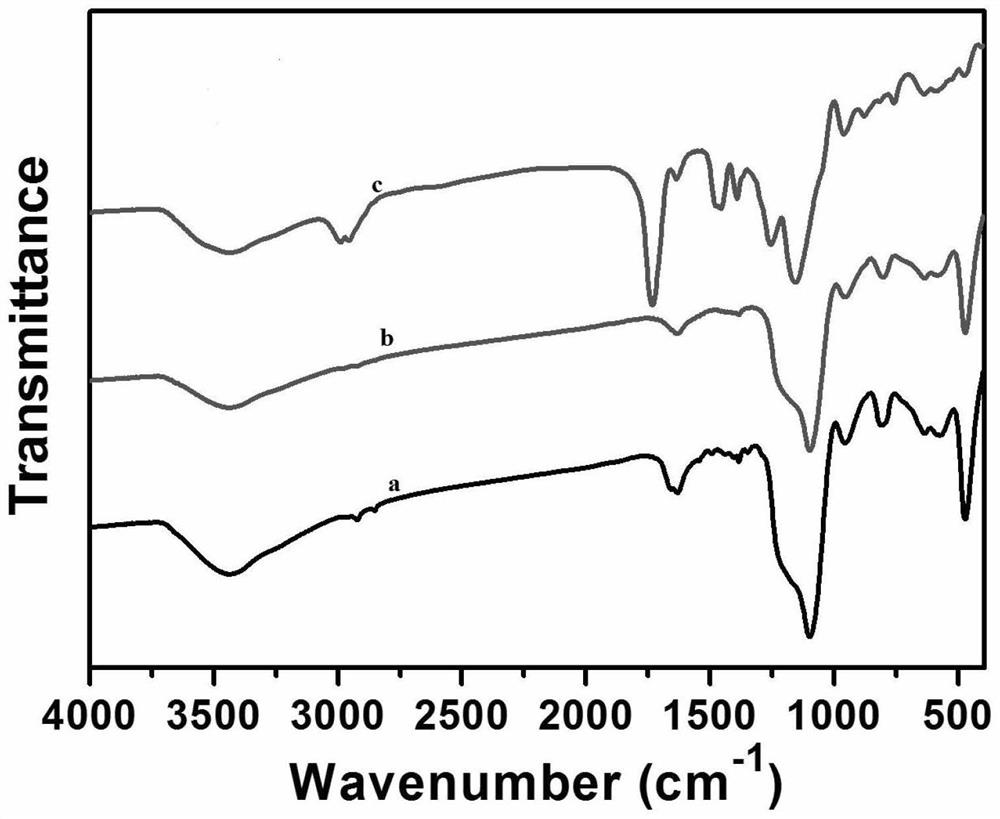

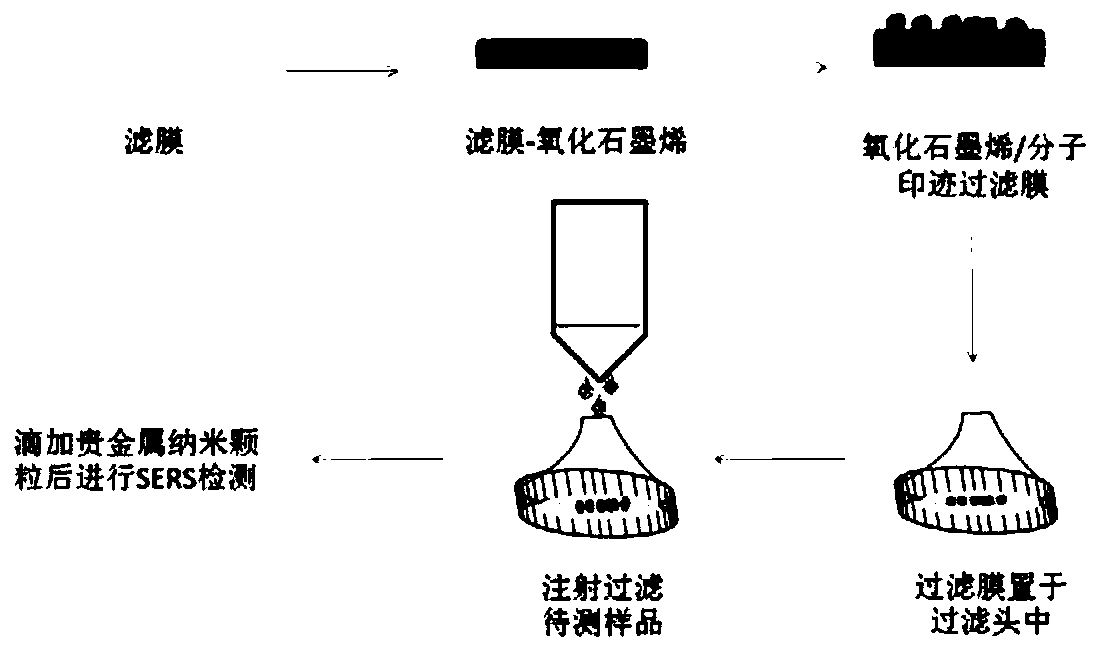

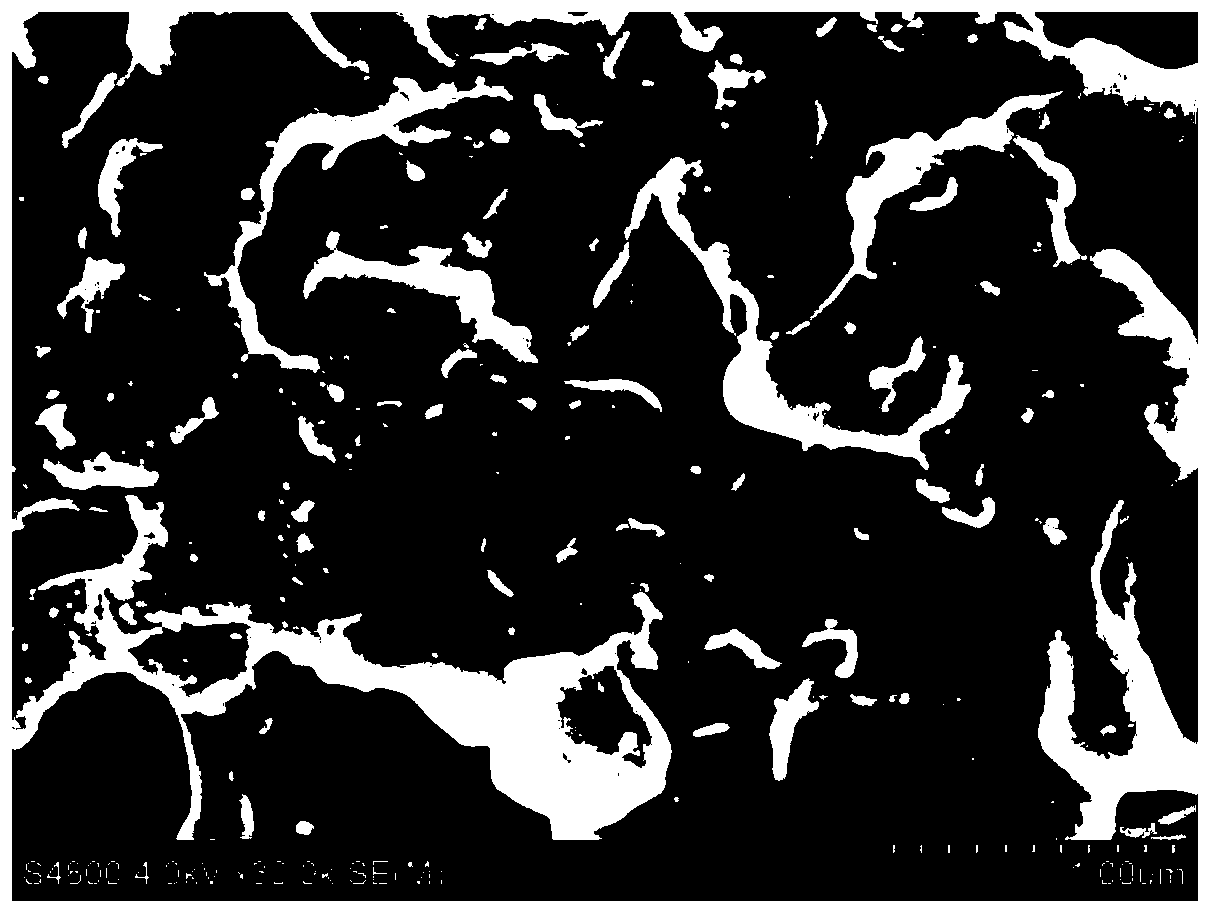

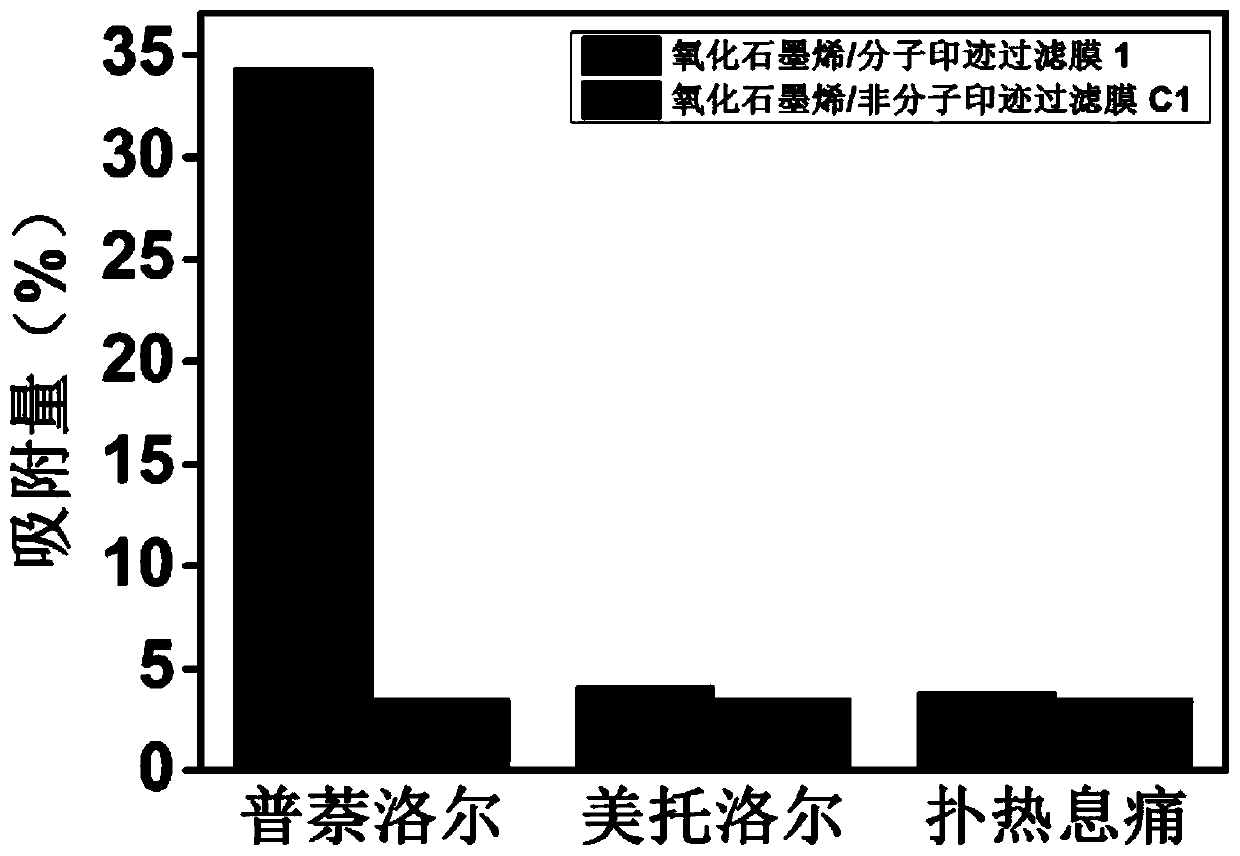

Graphene oxide/molecular imprinting filtering membrane for detecting propranolol, as well as preparation and application thereof

ActiveCN106770179AGood choiceImprove adsorption capacityRaman scatteringGrapheneMolecular imprinting

The invention relates to a graphene oxide / molecular imprinting filtering membrane for detecting propranolol, as well as a preparation and an application thereof. Specifically, the invention discloses a method for detecting propranolol in a detected sample by adopting the graphene oxide / molecular imprinting filtering membrane and a metallic nanometer grain combined raman technique. The detection method has the advantages of high sensitivity, simple and convenient operation, less time consumption, low cost, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

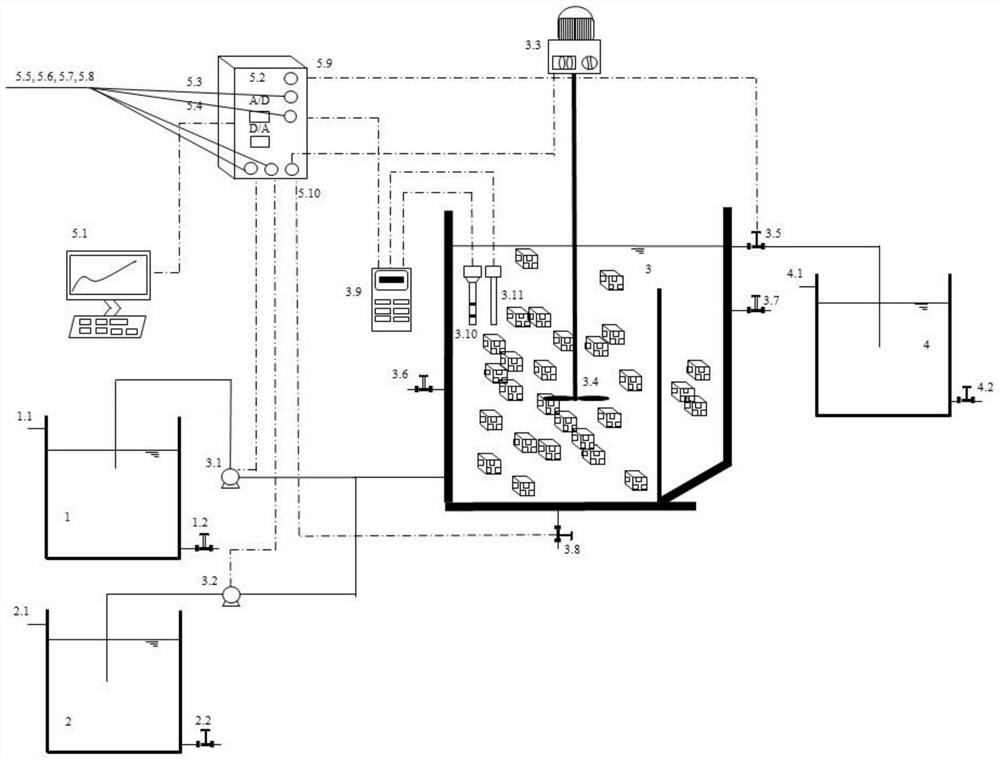

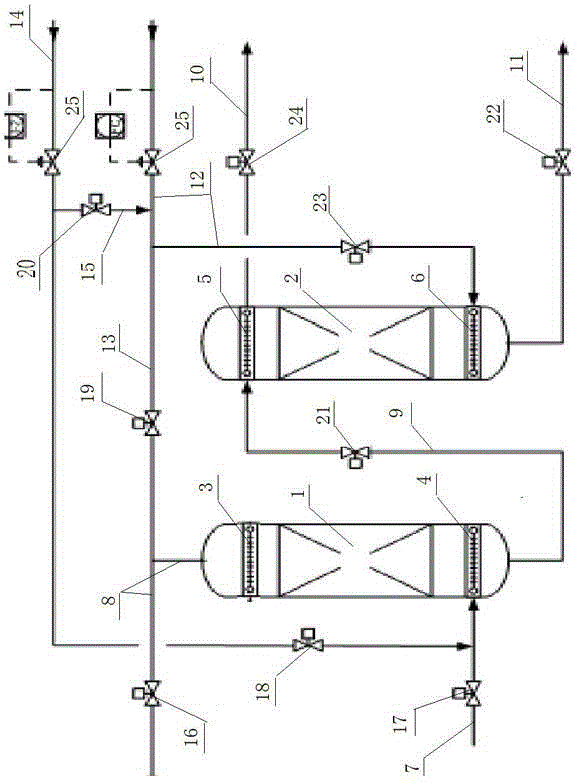

Device and method for rapid short-cut denitrification treatment of sewage

PendingCN113526658AAvoid churnFast enrichmentWater contaminantsTreatment with anaerobic digestion processesBiofilmNitrate salts

The invention belongs to the technical field of biological sewage treatment, and relates to a device and a method for rapid short-cut denitrification treatment of sewage. According to the invention, municipal sewage is continuously fed into a continuous flow short-cut denitrification SBBR (sequencing batch biofilm reactor) from a municipal sewage raw water tank, and nitrate distribution water is continuously fed into the continuous flow short-cut denitrification SBBR from a nitrate distribution water tank; C / N is adjusted by controlling a water inlet proportion, and hydraulic retention time is adjusted by controlling the total water inlet flow, so the nitrite accumulation rate of a biological membrane is increased, the short-cut denitrification capacity of the biological membrane is optimized, and the purpose of rapidly obtaining the biological membrane with the short-cut denitrification capacity is achieved; and after the reaction of the sewage in the continuous flow short-cut denitrification SBBR is finished, the sewage enters a right-side non-turbulent-flow settling zone to be drained, and effluent is drained into an effluent tank through an electric drain valve. The device and the method are simple in structure and process flow, easy to operate, low in energy consumption, free of greenhouse gas and friendly to environment, and can be used for quickly culturing a short-cut denitrification biological membrane for low-C / N urban sewage and treating the sewage.

Owner:QINGDAO UNIV

Adhesive resin for multi-layer co-extruded barrier packaging and barrier structure made of it

ActiveCN103756595BShort reaction timeImprove liquiditySynthetic resin layered productsAdhesivesElastomerCo extrusion

The invention discloses an adhesive resin for multilayer coextrusion barrier package and a barrier structure prepared from the same. The adhesive resin comprises the following components in parts by weight: 85-55 parts of propylene-ethylene-alpha olefin copolymer, 5-15 parts of vinyl elastomer and 10-30 parts of functionalization modified propylene-alpha olefin copolymer. The barrier structure comprisesa barrier layer, wherein at least one surface of the barrier layer is bonded with a polypropylene layer through an adhesive layer; the adhesive layer is the adhesive resin in the first target; the barrier layer is an ethylene-vinyl alcohol copolymer or nylon; and the adhesive resin accounts for 10-15 wt% of the barrier structure. The adhesive resin has the advantages of favorable bonding property, favorable working properties, fewer crystal points, high transparency and the like.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

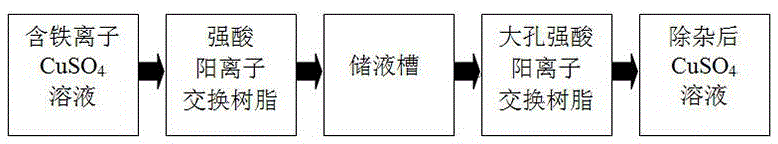

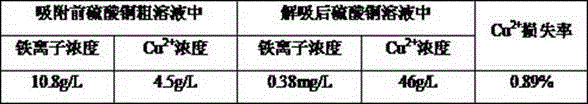

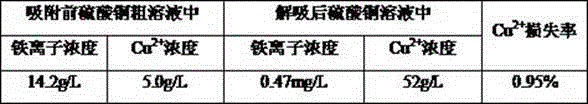

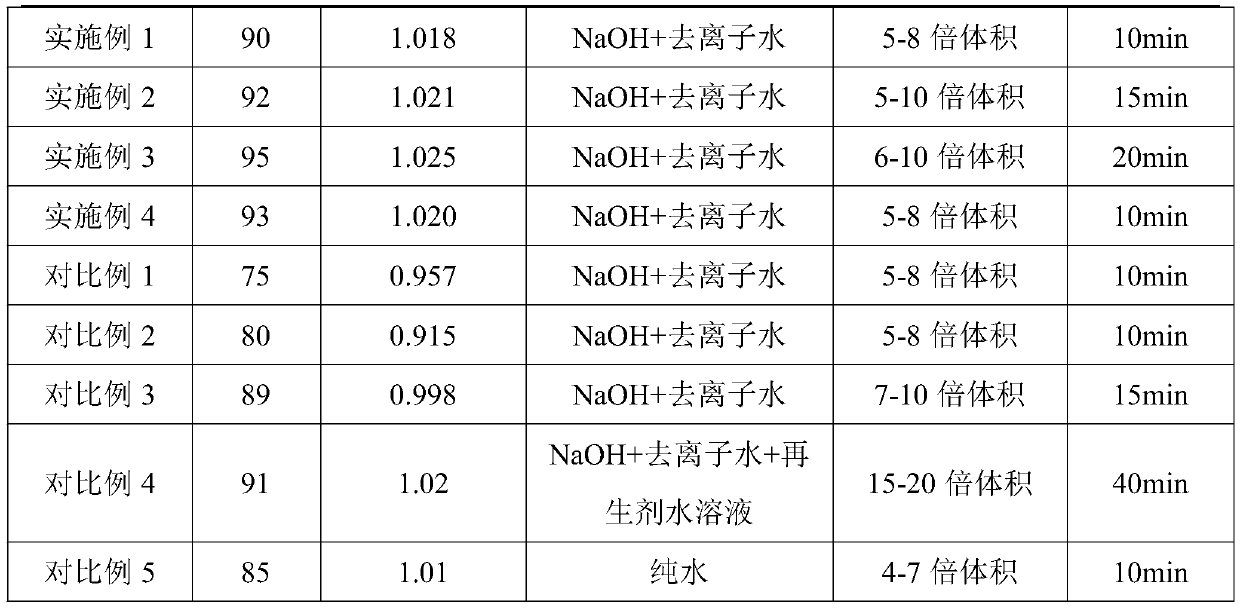

A method for removing iron impurities in copper sulfate solution and enriching copper ions

The invention relates to a method for removing iron impurities and gathering cupric ions in a copper sulfate solution. The method includes the steps of adding a strong acid cation exchange resin column to a copper sulfate crude solution for removing iron; adding a macroporous strong acid cation exchange resin column to the copper sulfate solution with low iron content for adsorbing and gathering all cupric ions; backwashing for desorption with sulfuric acid after cupric ions adsorbed by the macroporous strong acid cation exchange resin are saturated, wherein the desorbed macroporous strong acid cation exchange resin can be recycled. The method for removing the iron impurities and the gathering cupric ions in the copper sulfate solution is simple in technology, short in process, high in copper extraction rate, low in production costs and capable of achieving the purpose of copper gathering as well as iron removing, the obtained copper sulfate solution is high in purity, the strong acid cation exchange resin and the macroporous strong acid cation exchange resin can be recycled, and the entire process is environmentally friendly and pollution-free.

Owner:HENAN GONGXIN ENVIRONMENTAL PROTECTION & TECH CO LTD

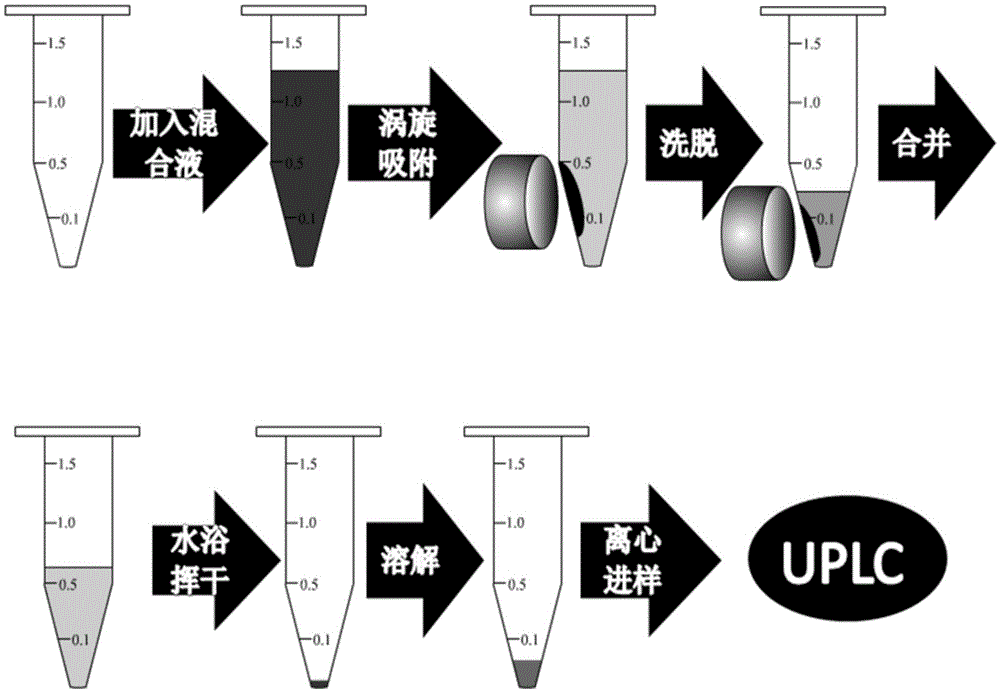

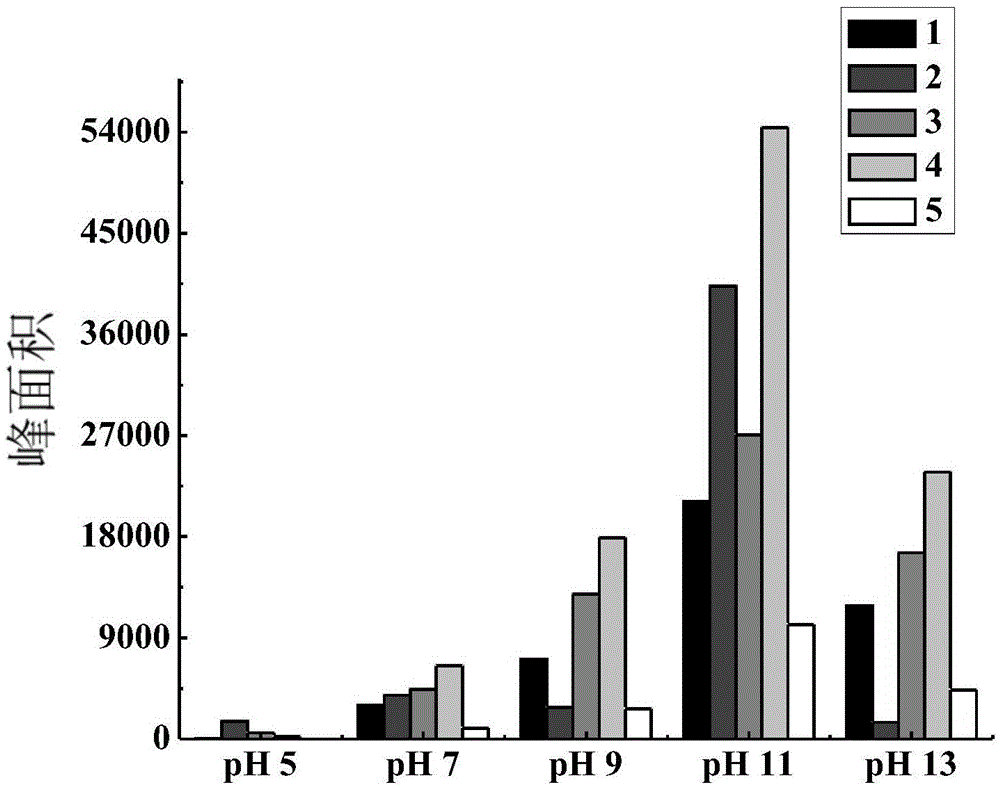

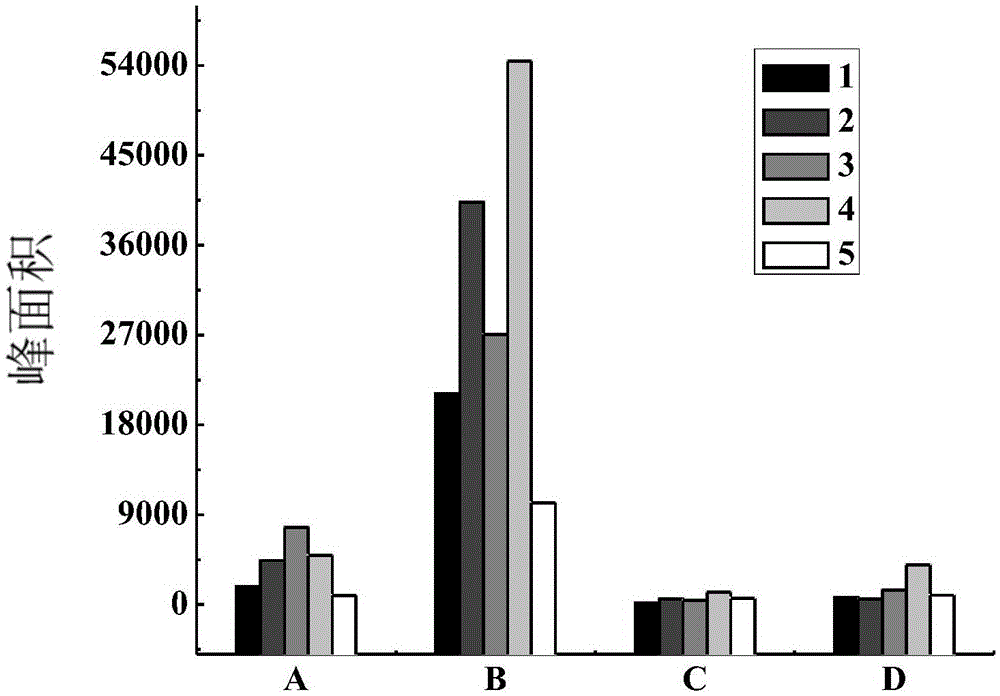

A magnetic extraction and enrichment method for effective components in rhubarb

ActiveCN103655749BGood separation and enrichment effectImprove enrichment capacityPlant ingredientsEnrichment methodsDistillation

The invention discloses a magnetic extraction and enrichment method of an effective component in rheum officinale. A rheum officinale extracting solution is prepared from rheum officinale medicinal materials or a rheum officinale solid preparation according to the pharmacopeia, wherein the rheum officinale extracting solution, mesoporous ferroferric oxide nano-particles and an ionic liquid are prepared into enriched mixed liquor in a manner of adding water; each 1230mu L of enriched mixed liquor comprises the following components: 20mu L of rheum officinale extracting solution, 8-20mg of nano mesoporous ferroferric oxide, 0.2-0.6mg of ionic liquid, and the balance of water; the pH value is 9-13. The method comprises the following steps: loading the enriched mixed liquor into a centrifuge tube, whirling for 10-30 seconds on a vortex finder, approaching the bottom of the centrifuge tube by a magnet after standing; gathering the mesoporous ferroferric oxide nano-particles at the bottom of the centrifuge tube, and removing an upper water solution, so as to obtain enriched mesoporous ferroferric oxide nano-particles; eluting by a methanol solution containing acetic acid of which the mass fraction is 1-4%; collecting eluent and drying by distillation, so as to prepare enriched rheum officinale extractum, wherein the ionic liquid is brominated 1-dodecyl-3-methylimidazole, chloridized 1-dodecyl-3-methylimidazole, 1-butyl-3-methyl imidazolium tetrafluoroborate or 1-butyl-3-methyl imidazole polystyrene sulfonate, preferably chloridized 1-dodecyl-3-methylimidazole. The method disclosed by the invention is fast in speed, good in enrichment effect, and high in repeatability and reproducibility.

Owner:HANGZHOU NORMAL UNIVERSITY

Method for starting anaerobic ammonium oxidation reactor to treat high-salt nitrogenous wastewater

InactiveCN102976489BSolve the problem of slow enrichmentFast enrichmentWater contaminantsTreatment with aerobic and anaerobic processesWater basedLow nitrogen

The invention discloses a method for starting an anaerobic ammonium oxidation reactor to treat high-salt nitrogenous wastewater. Anaerobic sludge and aerobic sludge are inoculated to a reactor, starting strategies are as follows: at first, anaerobic ammonium oxidation bacteria are enriched in the reactor through maintaining the conditions of anaerobism, organic carbon source-free feed water and no saltness, and a microflora system which takes the anaerobic ammonium oxidation bacteria as dominant bacteria is built; then, salt-tolerant anaerobic ammonium oxidation bacteria are preferentially selected under the conditions of low nitrogen concentration and low saltness, non-dominant bacteria are elutriated, and a microflora system which takes the salt-tolerant anaerobic ammonium oxidation bacteria as dominant bacteria is built; and finally, the nitrogen concentration and saltness are gradually increased, so that the ammonium oxidation bacteria can be suitable for high nitrogen concentration and high saltness environments. Through a mode of gradually changing a feed water base material, the problem of slow anaerobic ammonium oxidation bacteria enrichment under saltness inhibition is solved, the starting mode is simple and practicable, and the difficulty in starting a high-salt wastewater anaerobic ammonium oxidation treatment system is lowered.

Owner:CHONGQING UNIV

Antioxidant active peptide and preparation method by ultrasonic electrophoresis separation

InactiveCN102994599AHigh purityFast enrichmentPeptide preparation methodsFermentationPeptideChemistry

The invention discloses an antioxidant active peptide based on wheat germ protein zymolyte and a preparation method by ultrasonic electrophoresis separation. The preparation method comprises the following key stages of raw materials: 1, mixture of wheat germ and water; 2, compound raw materials; and 3, electrophoresis raw materials. By the method, the raw materials with low cost can be used, and antioxidant active peptide with consistent molecular weight is obtained; and secondary purification is performed by using a semipermeable membrane so as to obtain the antioxidant active peptide with high purity.

Owner:昆山冠强软件科技有限公司 +1

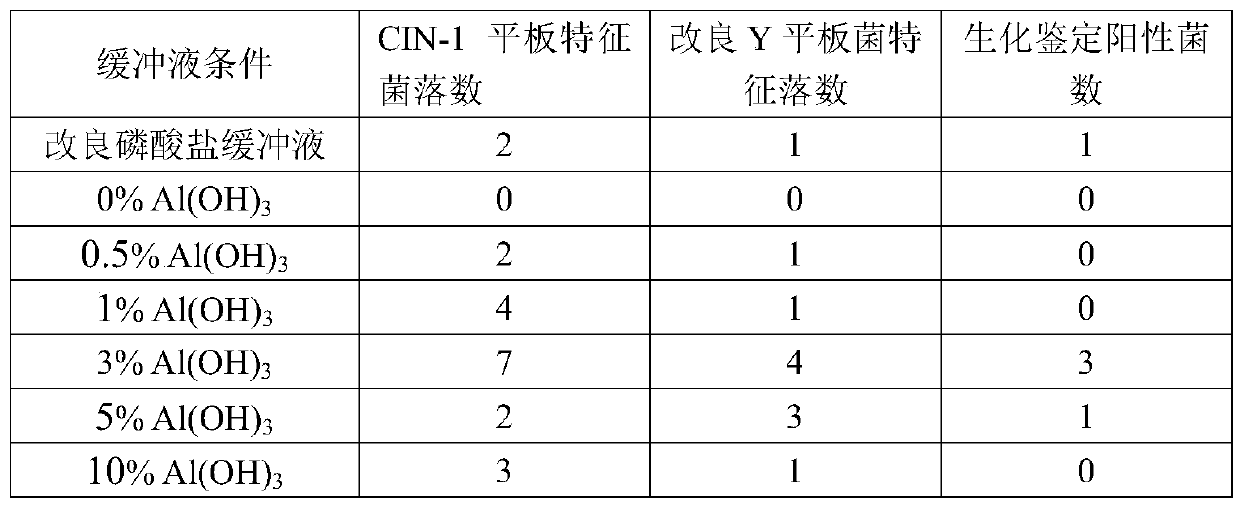

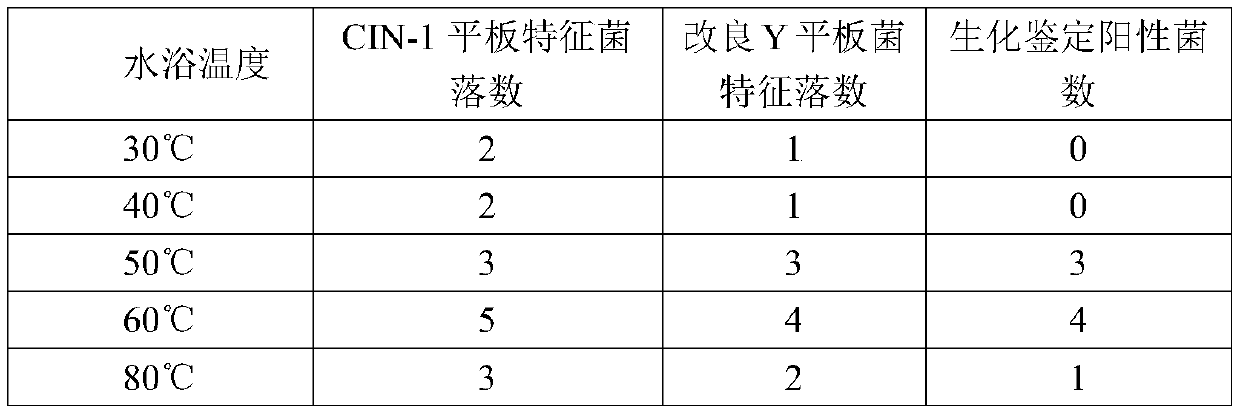

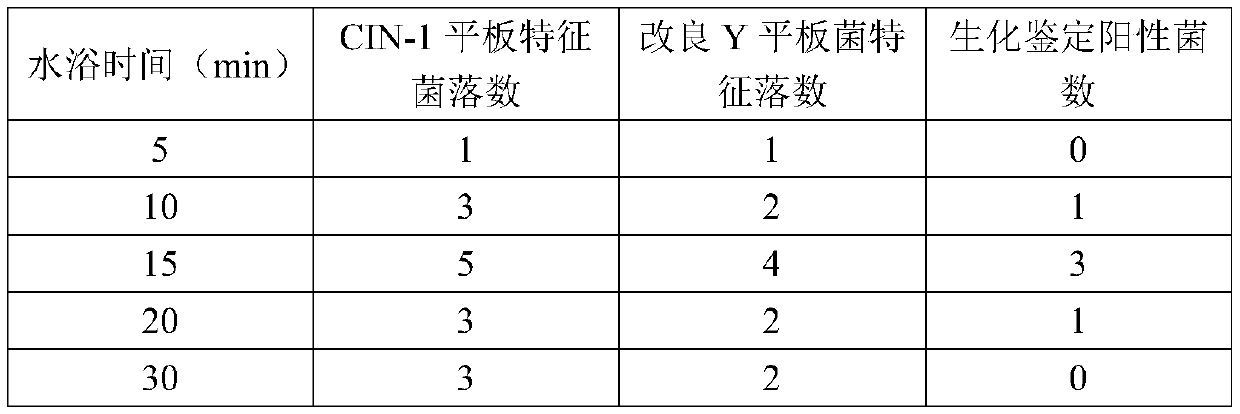

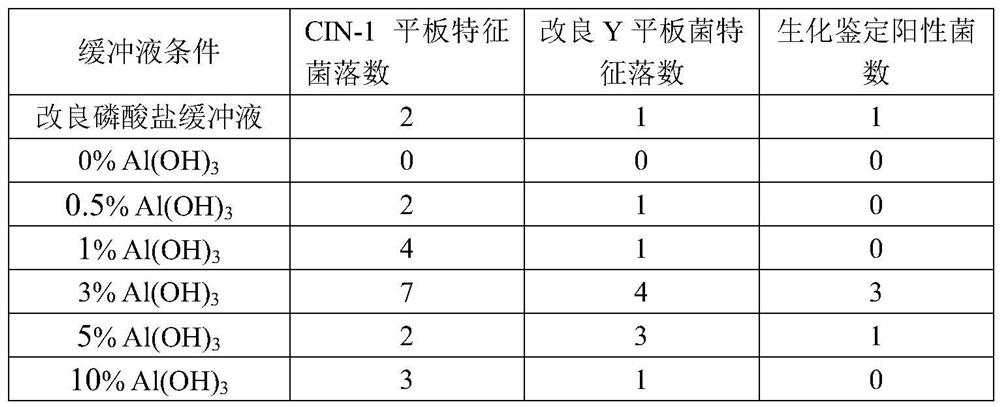

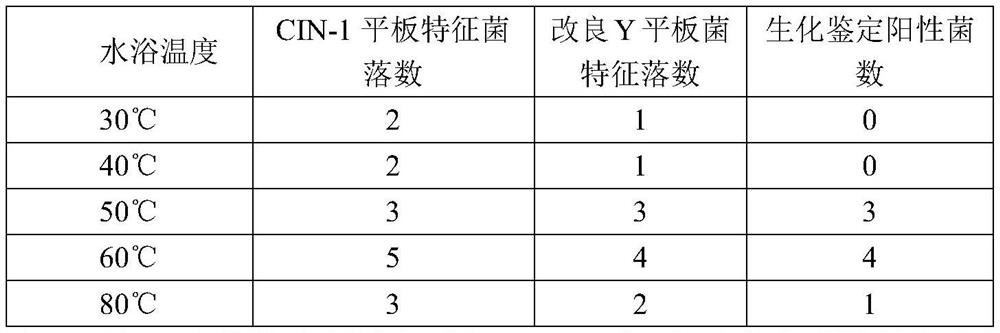

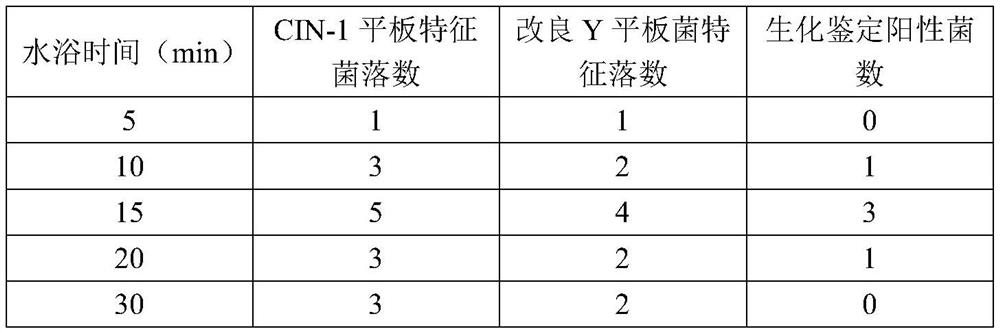

Method for detecting Y. enterocolitica

ActiveCN109696546AReduce distractionsImprove the detection rateMaterial analysisWater bathsMagnetic bead

The invention discloses a method for detecting Y. enterocolitica, which comprises the steps of (1) taking a sample to be detected under an aseptic condition, adding the sample into a PBS buffer solution containing Al(OH)3, and homogenizing to obtain a sample bacteria solution; (2) carrying out water-bath heat treatment on the sample bacteria solution, performing centrifugation, discarding the supernatant, and collecting thalluses; (3) adding Y. enterocolitica immune-magnetic beads into the thalluses, standing on a magnetic shelf for layering after oscillation, discarding the upper layer, obtaining Y. enterocolitica immune-magnetic beads attached with the thalluses, eluting the Y. enterocolitica immune-magnetic beads attached with the thalluses by an eluant, then adding the PBS buffer solution into the eluted Y. enterocolitica immune-magnetic beads, and uniformly mixing to obtain a sample solution to be detected; and (4) culturing, observing and detecting the sample solution to be detected. The detection method provided by the invention is high in specificity and sensitivity, and can effectively shorten the detection time and reduce the detection cost.

Owner:HENAN BUSINESS SCI RES INST

Method for separating and purifying boron-10 and boron-11

InactiveCN110143600AIncrease migration distanceShorten migration distanceIsotope separationBoron oxyacidsChromatographic separationIon exchange

The invention discloses a method for separating and purifying boron-10 and boron-11, belonging to the technical field of separation and preparation of isotopes. The method comprises the following three steps: the preparation of sample introduction liquid for a simulated moving bed; pretreatment of an ion exchange chromatographic column; and sample introduction and gradient elution. According to the method, the enrichment rate of <10>B can be increased to about 95% compared with a natural enrichment of 20%, and the speed of enrichment is fast; a simulated moving bed chromatographic separation system is used, so a long chromatographic column is not needed in the entire separation process, thereby reducing production cost; and gradient elution is utilized, so the purposes of reducing band migration distance and shortening separation period are achieved.

Owner:天津纯态化学工程技术有限公司

A kind of extraction method of lead-zinc-silver in lead-zinc-silver composite sulfide ore

A method for extracting lead-zinc-silver in lead-zinc-silver composite sulfide ore, adding coal powder and quicklime powder to composite mineral raw materials containing lead and / or zinc and / or silver, fully mixing to form a mixture, and pressing the mixture into balls, Then the mixture after briquetting is subjected to vacuum heating and reduction, the heating temperature is controlled separately according to the components extracted from the mineral, and the obtained metal vapor of lead and / or zinc and / or silver is collected by condensation, and the collected condensate A mixture of lead and / or zinc and / or silver. The invention is convenient to operate, safe, hygienic and pollution-free. The method for enriching metallic lead and zinc has the advantages of fast enrichment speed, high production efficiency and small amount of pollution. The method of the present invention for separating metals in minerals has the characteristics of short process, short period, high efficiency and high comprehensive utilization rate of resources, and can greatly improve the efficiency of metal separation and extraction. By adopting the method of the invention, the direct recovery rate of lead and zinc can be more than 98%.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A method for separating zinc-cadmium-lead alloy material from copper-cadmium slag and nickel-cobalt slag produced in zinc smelting process

ActiveCN108251651BEasy to separateImprove resource utilizationProcess efficiency improvementAlloyAlkaline earth oxides

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

An ion-imprinted material for the enrichment of ultra-trace methylmercury in water

InactiveCN104353441BDoes not affect enrichment separationFast enrichmentOther chemical processesWater contaminantsMethacrylateFunctional monomer

The invention discloses an ion-imprinted material for enriching ultra-trace methylmercury in water bodies and its preparation method and application. It uses silica microspheres as a carrier, methylmercury chloride and pyrrolidine dithioformic acid Ammonium is used as a template, methacrylic acid is used as a functional monomer, trimethylolpropane trimethacrylate is used as a crosslinking agent, azobisisobutyronitrile is mixed as an initiator, and the synthetic surface has three-dimensional holes with methylmercury ion structure Silica microspheres of ion-imprinted polymers have the advantages of short enrichment time, simple operation, good specificity, large enrichment capacity and low cost, and can be used for rapid pre-enrichment of ultra-trace methylmercury ions in various water samples set separated.

Owner:FUZHOU UNIV

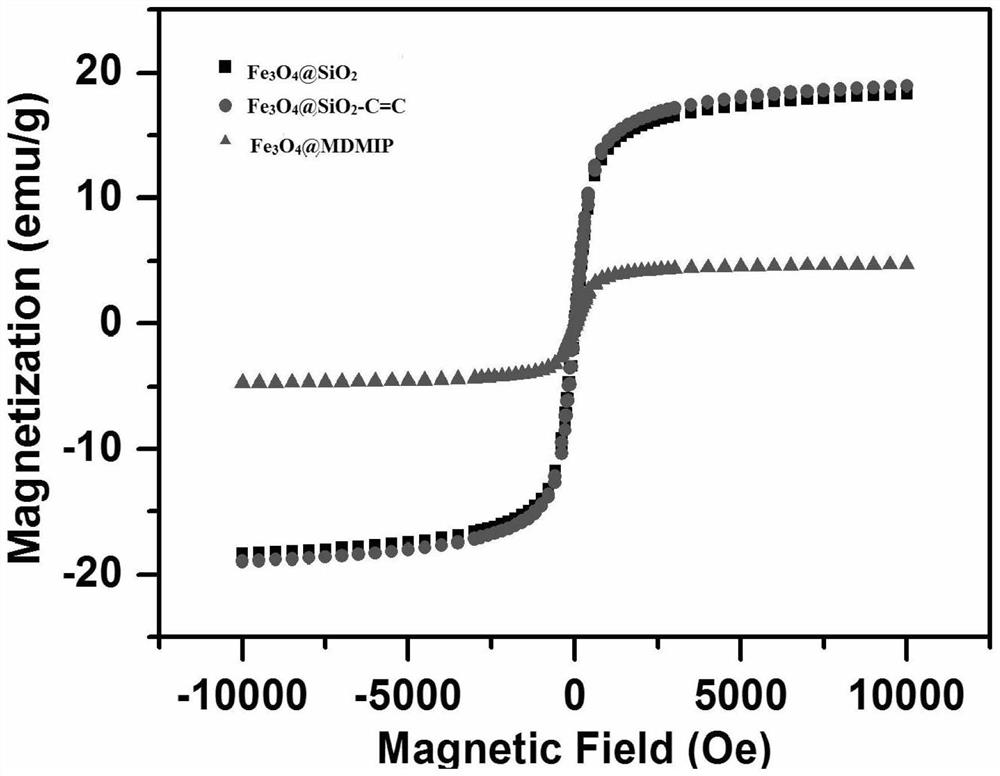

Tobacco-specific nitrosamine magnetic substitution template molecularly imprinted material and preparation method thereof

PendingCN114853961AUniform particle sizeImprove magnetic propertiesOther chemical processesComponent separationMagnetite NanoparticlesNitrosamine

The invention relates to the technical field of tobacco component detection, in particular to a tobacco-specific nitrosamine magnetic substitution template molecularly imprinted material and a preparation method thereof.The tobacco-specific nitrosamine magnetic substitution template molecularly imprinted material comprises magnetic molecularly imprinted polymer nanoparticles which are in a core-shell type, the magnetic molecularly imprinted polymer nanoparticle sequentially comprises a magnetic core, an inner shell layer and an outer shell layer from the inner layer to the outer layer, the magnetic core is a magnetic nanoparticle, the inner shell layer is silicon dioxide with the surface modified with alkenyl, and the outer shell layer is an alternative template molecularly imprinted polymer of tobacco-specific nitrosamine. According to the present invention, the cheap and low-toxicity substitution template material is adopted as the substitution template agent of the tobacco-specific nitrosamine, such that the problem of inaccurate result caused by template leakage when the molecularly imprinted polymer prepared by using the target compound as the template is used for the solid phase extraction material is overcome; the method has a wide application prospect in the field of analysis and detection of tobacco-specific nitrosamines in a complex system.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

A graphene oxide/molecularly imprinted filter membrane for detecting propranolol and its preparation and application

ActiveCN106770179BGood choiceImprove adsorption capacityRaman scatteringGrapheneMolecular imprinting

The invention relates to a graphene oxide / molecular imprinting filtering membrane for detecting propranolol, as well as a preparation and an application thereof. Specifically, the invention discloses a method for detecting propranolol in a detected sample by adopting the graphene oxide / molecular imprinting filtering membrane and a metallic nanometer grain combined raman technique. The detection method has the advantages of high sensitivity, simple and convenient operation, less time consumption, low cost, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Technique for separating boron isotope with boron specific resin ion-exchange chromatography

ActiveCN100551497CHigh separation factorEasy to separateCation exchanger materialsOrganic anion exchangersIon exchangeIsotope

The invention provides a process for separating boron isotope with a boron special-effect resin ion exchange chromatography. The process adopts chelate-typed ion exchanging resin-boron special-effect resin, separates <10>B from boric acid solution, and uses hydrochloric acid or nitric acid as eluent to separate the boron isotope in the boric acid solution by the adsorption of the boric acid on resin columns and the washing of the eluent on the boric acid adsorbed on the resin. According to the process of the invention, the enrichment ratio of the <10>B can be enriched from natural 20 percent or so to 91 percent or so, with fast enrichment speed. The process of the invention is a simple and high-efficiency process which separates the boron isotope from the boric acid solution.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

A method for detecting Yersinia enterocolitica

ActiveCN109696546BReduce distractionsImprove the detection rateMaterial analysisSmall intestineMicrobiology

The invention discloses a method for detecting Yersinia enterocolitica, comprising the following steps: (1) taking a sample to be tested under sterile conditions, adding Al(OH) 3 Homogenize in the PBS buffer solution to obtain the sample bacterial liquid; (2) heat-treat the sample bacterial liquid in a water bath, centrifuge, discard the supernatant, and collect the bacterial cells; (3) add Yersinia enterocolitica to the bacterial cells Bacteria immune magnetic beads, after shaking, put them on the magnetic stand for stratification, discard the upper layer, and obtain Yersinia enterocolitica immune magnetic beads with bacteria adsorbed; Yersinia immunomagnetic beads were eluted, and then PBS buffer was added to the eluted Yersinia enterocolitica immunomagnetic beads, and mixed evenly to obtain the sample solution to be tested; (4) The sample liquid is cultivated, observed and tested. The detection method provided by the invention has strong specificity and high sensitivity, and can effectively shorten the detection time and reduce the detection cost.

Owner:HENAN BUSINESS SCI RES INST

A kind of method for quick start of short-path nitrification reactor

ActiveCN104556356BIncrease dissolved oxygen concentrationSpeed up hydrolysisWater treatment parameter controlTreatment using aerobic processesAnaerobic bacteriaAmmonia-oxidizing bacteria

The invention discloses a method for quickly starting a shortcut nitrification reactor. The method comprises the following steps: after performing inoculation on the reactor, firstly performing overaeration, and applying an aeration impact so as to accelerate the elimination of anaerobic bacteria in sludge; quickly enriching nitrifying bacteria, and then applying a combined load impact comprising a substrate concentration impact and a hydraulic retention time impact so as to quickly restrain and eliminate nitrite oxidizing bacteria; finally, under the condition that an appropriate substrate concentration and an appropriate hydraulic retention time are maintained, increasing the concentration of an inorganic carbon source so as to enrich ammonia oxidizing bacteria and accelerate the accumulation of nitrite. According to the invention, the various continuous impacts are combined, the enrichment of the ammonia oxidizing bacteria in the sludge is accelerated within a shorter time, and the quick start of the shortcut nitrification reactor is realized.

Owner:CENT SOUTH UNIV

Method for realizing secondary purification by using semi-permeable membrane

InactiveCN103849669AHigh purityFast enrichmentPeptide preparation methodsFermentationElectrophoresesWheat germ

The invention discloses a method for realizing secondary purification by using a semi-permeable membrane. Key raw materials used in the invention comprise a wheat germ and water mixture 1, a composite raw material 2 and an electrophoresis raw material 3. Anti-oxidative bioactive peptides having a consistent molecular weight can be obtained by using low-cost raw materials through the method, and highly-pure anti-oxidative bioactive peptides can be obtained through the secondary purification by using the semi-permeable membrane.

Owner:上海市闵行区知识产权保护协会 +1

Metal ion separation device

ActiveCN103787454BCompact and reasonable structureEasy to useWater/sewage treatment by ion-exchangePhysical chemistryEngineering

The invention relates to the technical field of separation devices and provides a metal ion separation device. The metal ion separation device comprises an adsorption tower and a desorption tower, wherein an upper liquid distributor of the adsorption tower and a lower liquid distributor of the adsorption tower are fixedly installed in an upper inner cavity and a lower inner cavity of the adsorption tower respectively; an upper liquid distributor of the desorption tower and a lower liquid distributor of the desorption tower are fixedly installed in an upper inner cavity and a lower inner cavity of the desorption tower respectively; strongly acidic cationic resins are fixedly installed in an adsorption tower inner cavity between the upper liquid distributor of the adsorption tower and the lower liquid distributor of the adsorption tower; strongly acidic cationic resins are fixedly installed in a desorption tower inner cavity between the upper liquid distributor of the desorption tower and the lower liquid distributor of the desorption tower. The metal ion separation device has a reasonable and compact structure, is convenient to use, has the characteristics of strong selectivity, big concentration multiple, high enrichment efficiency, high enrichment speed, low investment, low operating cost, simplicity in procedure operation and control and the like and is especially suitable for separation and enrichment of the metal ions in low-concentration solutions.

Owner:新疆天利高新石化股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com