Device and method for rapid short-cut denitrification treatment of sewage

A short-range denitrification and sewage technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

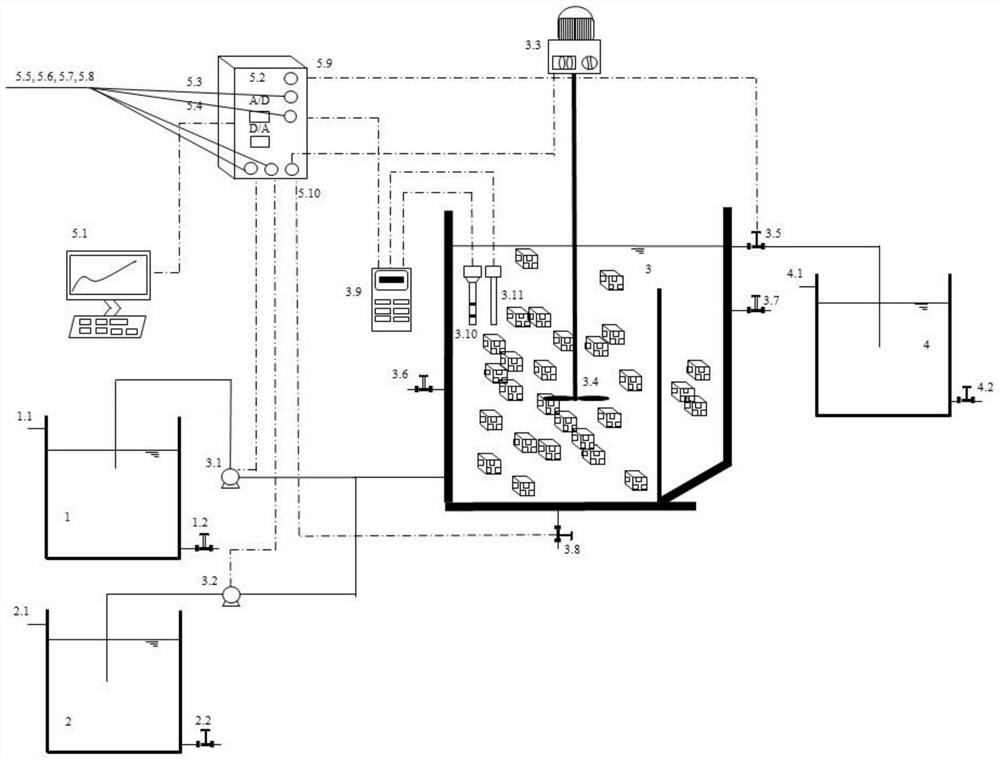

[0023] The device for rapid short-range denitrification treatment of sewage described in this embodiment is as follows: figure 1 As shown, it includes urban sewage raw water tank 1, nitrate water distribution tank 2, continuous flow short-path denitrification SBBR reactor 3, effluent water tank 4, online monitoring feedback control system 5; the left upper end of urban sewage raw water tank 1 is provided with a first The overflow pipe 1.1 is provided with a first vent pipe 1.2 at the lower end on the right side, and the urban sewage raw water tank 1 is connected with the continuous flow short-path denitrification SBBR reactor 3 through the first water inlet pump 3.1; the upper left end of the nitrate distribution tank 2 A second overflow pipe 2.1 is provided, and a second vent pipe 2.2 is provided at the lower end on the right side. The nitrate water distribution tank 2 is connected to the continuous flow short-path denitrification SBBR reactor 3 through the second water inlet ...

Embodiment 2

[0032] In this embodiment, the PDA-SBBR reactor 3 is used to replace the continuous flow short-path denitrification SBBR reactor 3, and other structures are the same as in Embodiment 1. The urban domestic sewage is taken from a sewage treatment plant domestic sewage, and the specific water quality is as follows: the COD concentration is 75 ~ 300mg / L, NH 4 + -N concentration is 55~90mg / L, NO 2 - -N concentration 3 - - N concentration figure 1 As shown, the nitrate water is the water containing only sodium nitrate, NO 3 - -N concentration is 70-120mg / L. PDA-SBBR reactor 3 is made of plexiglass, with an effective volume of 6L. The specific sewage treatment process is as follows:

[0033] (1) System startup:

[0034] The short-range denitrification sludge with good nitrite accumulation performance was added to PDA-SBBR reactor 3, and the sludge with good anaerobic ammonium oxidation performance was added to PDA-SBBR reactor 3, so that the PDA-SBBR after inoculation The con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com