Inactivated sludge-based anaerobic ammonium oxidation rapid enhancement starting method

A technology of anaerobic ammonium oxidation and activated sludge, applied in the field of wastewater biological treatment, can solve the problems of restricting the application of anammox process engineering, reducing the start-up speed of anammox process, and the long start-up period of anammox process , to achieve the effect of shortening the start-up time, stabilizing the removal efficiency and maintaining the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

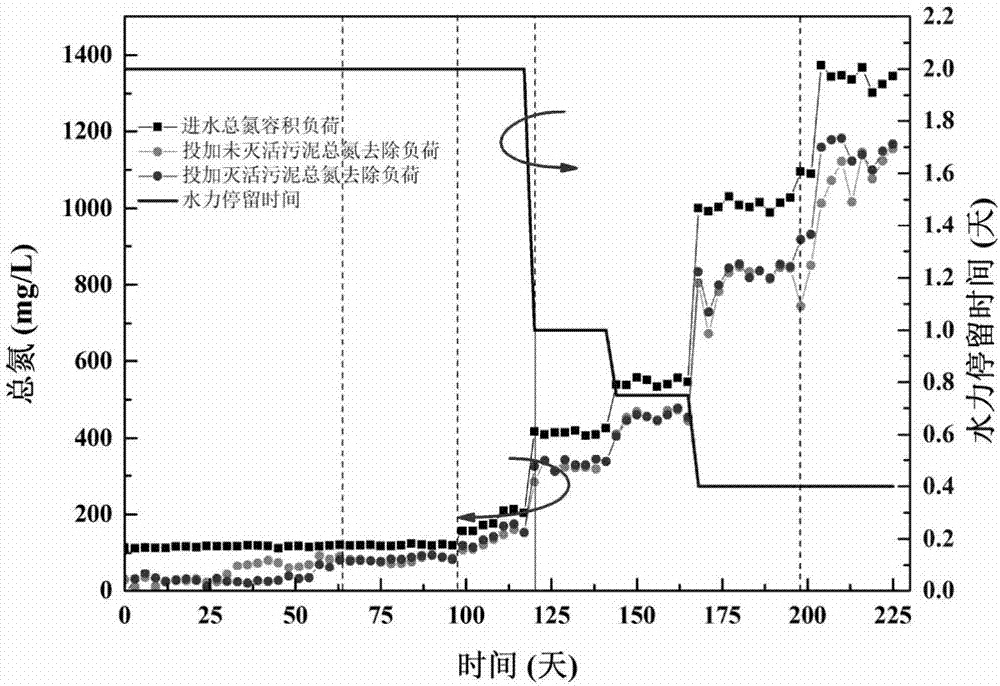

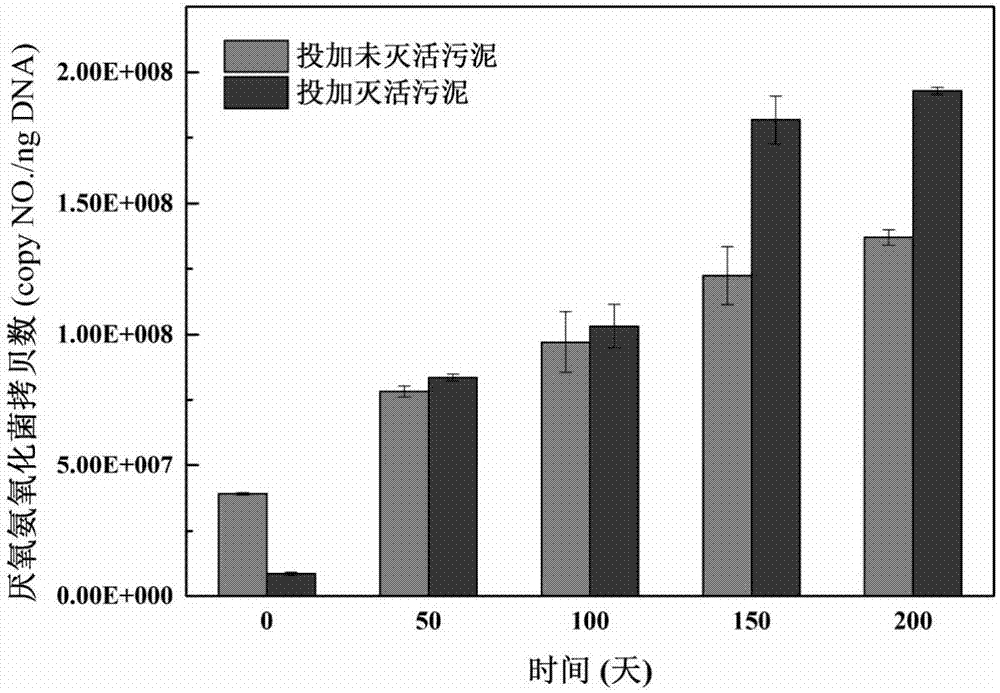

[0035] A kind of anaerobic ammonium oxidation quick strengthening start-up method based on inactivated sludge, comprises steps as follows:

[0036] (1) Put the activated anaerobic granular sludge under the conditions of pressure 0.13MPa and temperature 120°C for 30 minutes to inactivate with high-pressure steam to obtain inactivated sludge, and then add it to the reaction zone of the upflow anaerobic reactor, At the same time, add active anaerobic ammonium oxidation sludge into the reactor and mix with inactivated sludge evenly. The mass ratio of active anaerobic ammonium oxidation sludge to inactivated sludge is 0.5:1, unit: g / kg. The moisture content of the mixed sludge is greater than or equal to 99wt%. The height range of the upflow anaerobic reactor is 75cm, the inner diameter range is 9cm, the effective volume is 6L, the top is provided with a three-phase separator, and the side wall is provided with sampling at different heights mouth, the bottom is paved with a gravel ...

Embodiment 2

[0051] A kind of anaerobic ammonium oxidation quick strengthening start-up method based on inactivated sludge, same as embodiment 1, the difference is:

[0052] In step (1), the activated aerobic granular sludge was inactivated by high-pressure steam for 30 minutes at a pressure of 0.3 MPa and a temperature of 122° C. to obtain inactivated sludge. Other treatment steps were carried out as in Example 1.

[0053] The upflow anaerobic reactor successfully started the sludge anammox reaction after 60 days of operation.

Embodiment 3

[0055] A kind of anaerobic ammonium oxidation quick strengthening start-up method based on inactivated sludge, same as embodiment 1, the difference is:

[0056] The mass ratio of activated anammox sludge to inactivated sludge in step (1) is: 0.8:1, unit: g / kg, and other treatment steps are carried out as in Example 1. The upflow anaerobic reactor successfully started the sludge anammox reaction after 54 days of operation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com