Adhesive resin for multilayer coextrusion barrier package and barrier structure prepared from same

A bonding resin and multi-layer co-extrusion technology, applied in the direction of synthetic resin layered products, adhesives, layered products, etc., can solve the problems of poor adhesion, low transparency, large haze, etc., and achieve less crystal points, High transparency and excellent adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0030] An adhesive resin for multilayer co-extruded barrier packaging, which comprises the following components in parts by weight:

[0031] Component A: 85-55 parts of propylene-ethylene-α-olefin copolymer;

[0032] Component B: 5-15 parts of vinyl elastomer;

[0033] Component C: 10-30 parts of functionalized modified propylene-alpha olefin copolymer.

[0034] The bonding resin of the present invention is prepared by the following method: after compounding the three components of A, B and C, extruding, granulating and drying through a twin-screw extruder to obtain the bonding resin.

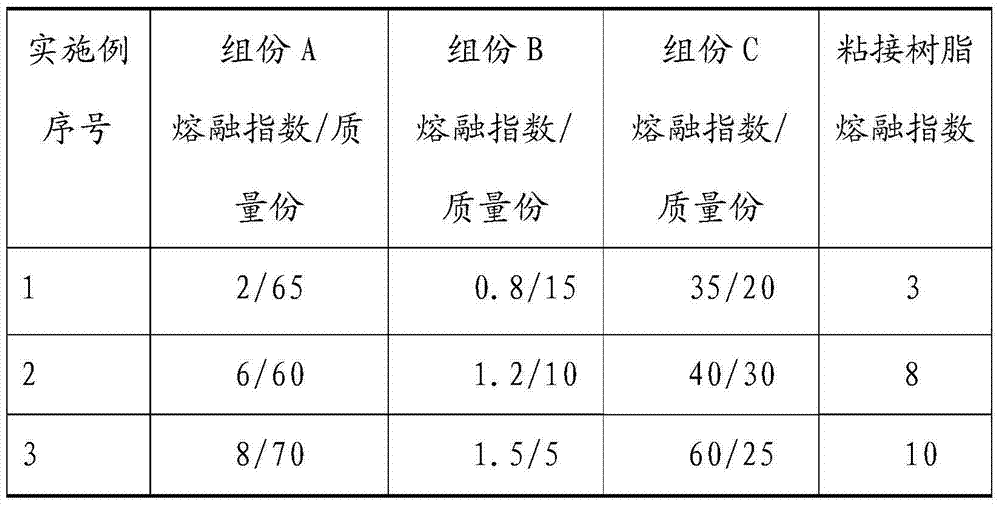

[0035] See Table 1, the three preferred combination formulations of the adhesive resins described in Examples 1-3 of the present invention.

[0036] The proportioning table of table 1 embodiment 1-3

[0037]

[0038] Note: Component B is a vinyl elastomer with a crystallinity of 10-30%. The unit of melt index is (g / 10min).

Embodiment 1

[0039] In Example 1, the component A is a propylene-ethylene-butene copolymer; the component B is an ethylene-butene copolymer with a degree of crystallinity of 10%; and the component C uses maleic anhydride as a modified unit It is obtained by modifying the propylene-butene copolymer.

Embodiment 2

[0040] In Example 2, the component A is a propylene-ethylene-hexene copolymer; the component B is an ethylene-hexene copolymer with a degree of crystallinity of 20%; and the component C uses maleic anhydride as a modified unit It is obtained by modifying the propylene-hexene copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com