Patents

Literature

190results about How to "Quick wet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

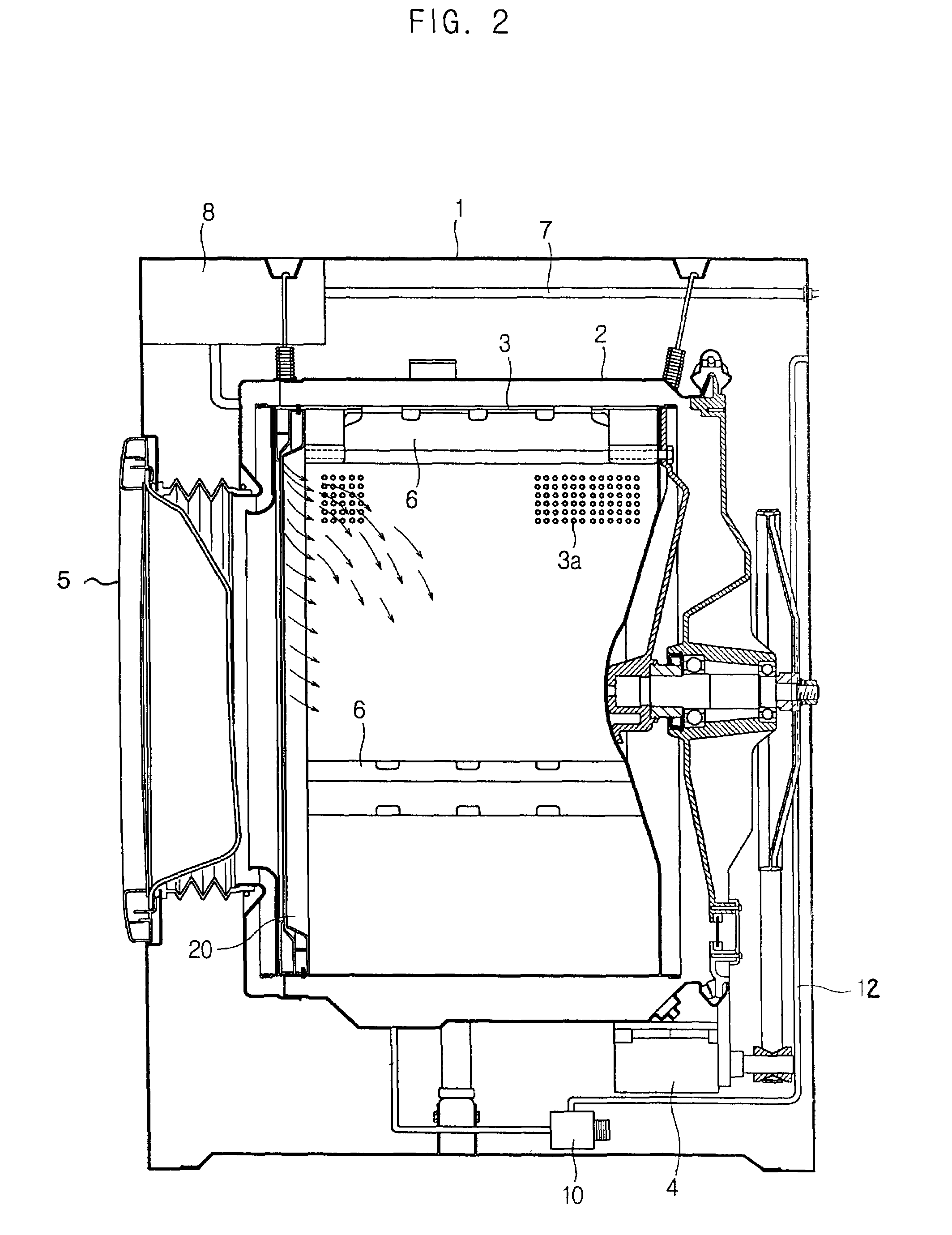

Spray type drum washing machine

InactiveUS20070107472A1Effectively come into contactEnhancement in washing and rinsing performanceOther washing machinesControl devices for washing apparatusWater circulationWash water

A spray type drum washing machine including a tub mounted in a cabinet, and adapted to contain wash water therein, a circulation line connected between a portion of the tub and another portion of the tub to circulate wash water through the tub, a pump installed at the circulation line, and adapted to forcibly feed wash water through the circulation line for the circulation of the wash water through the tub, and an atomizing device provided at the circulation line, and adapted to atomize the wash water fed through the circulation line, whereby the wash water to circulate through the tub is supplied in an atomized state into the tub. The wash water can rapidly permeate clothes contained in the drum, so that it can more effectively come into contact with contaminants attached to the clothes. As a result, it is possible to achieve an enhancement in washing and rinsing performances while reducing the consumption of wash water.

Owner:KIM JIN WOONG +3

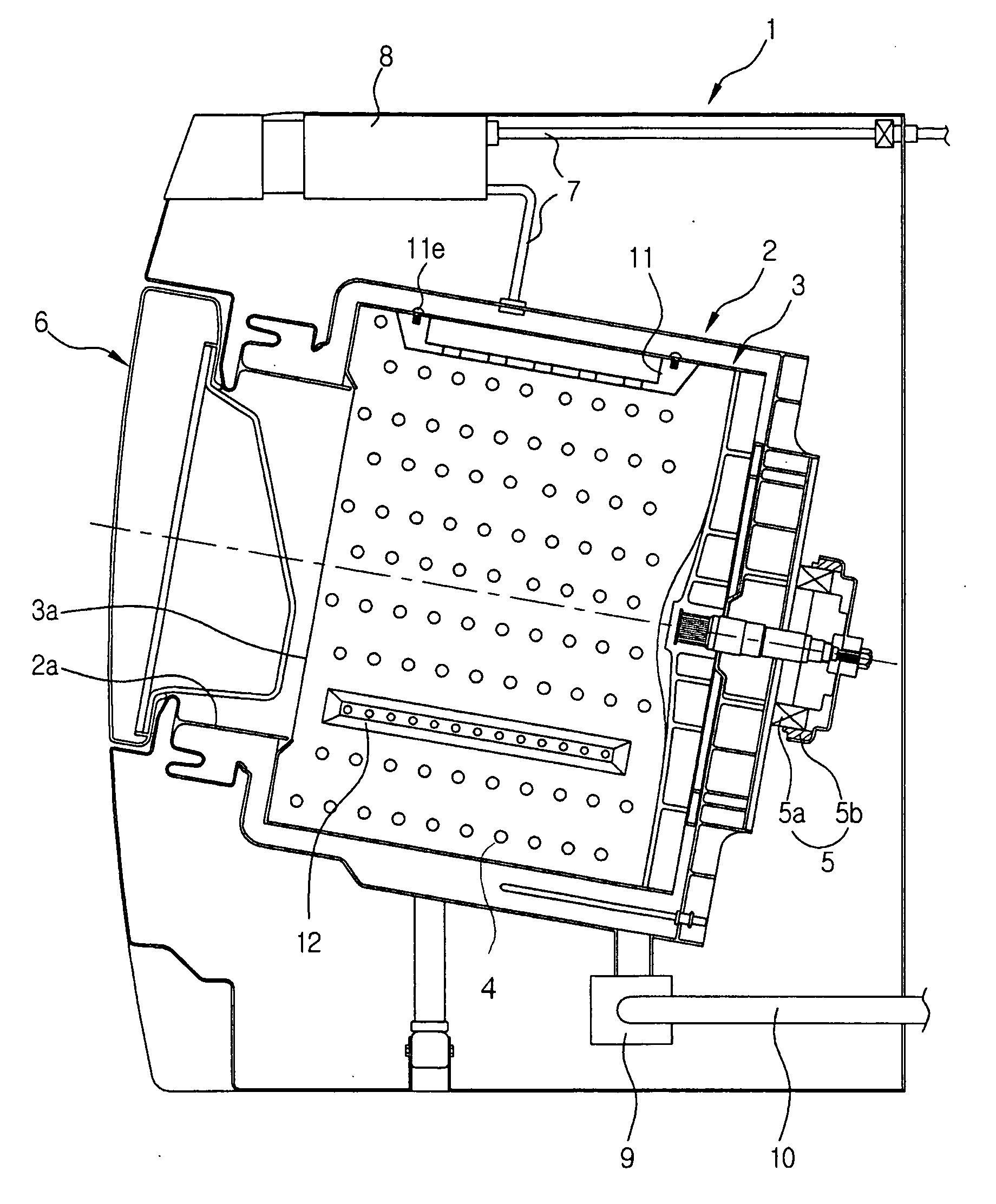

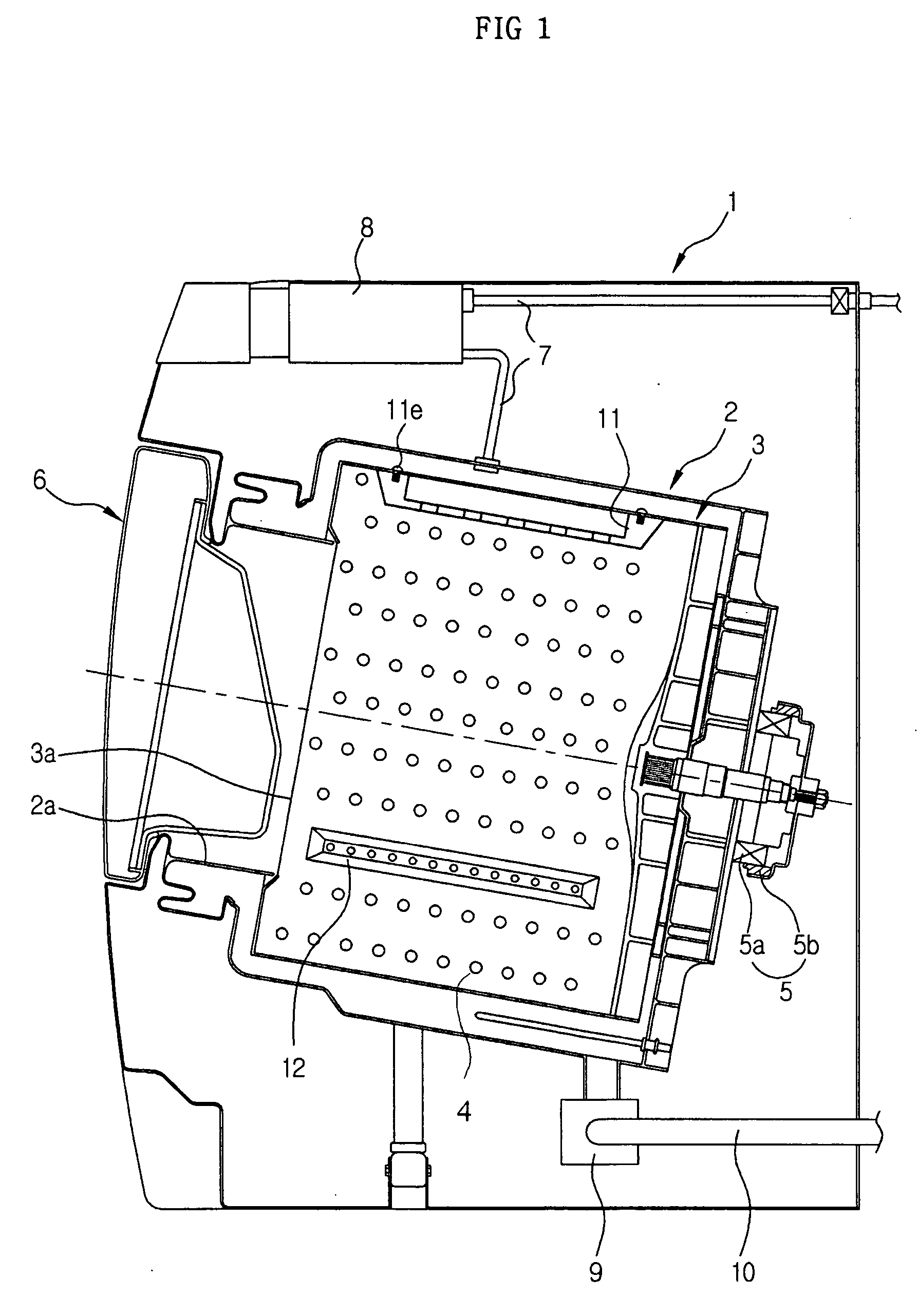

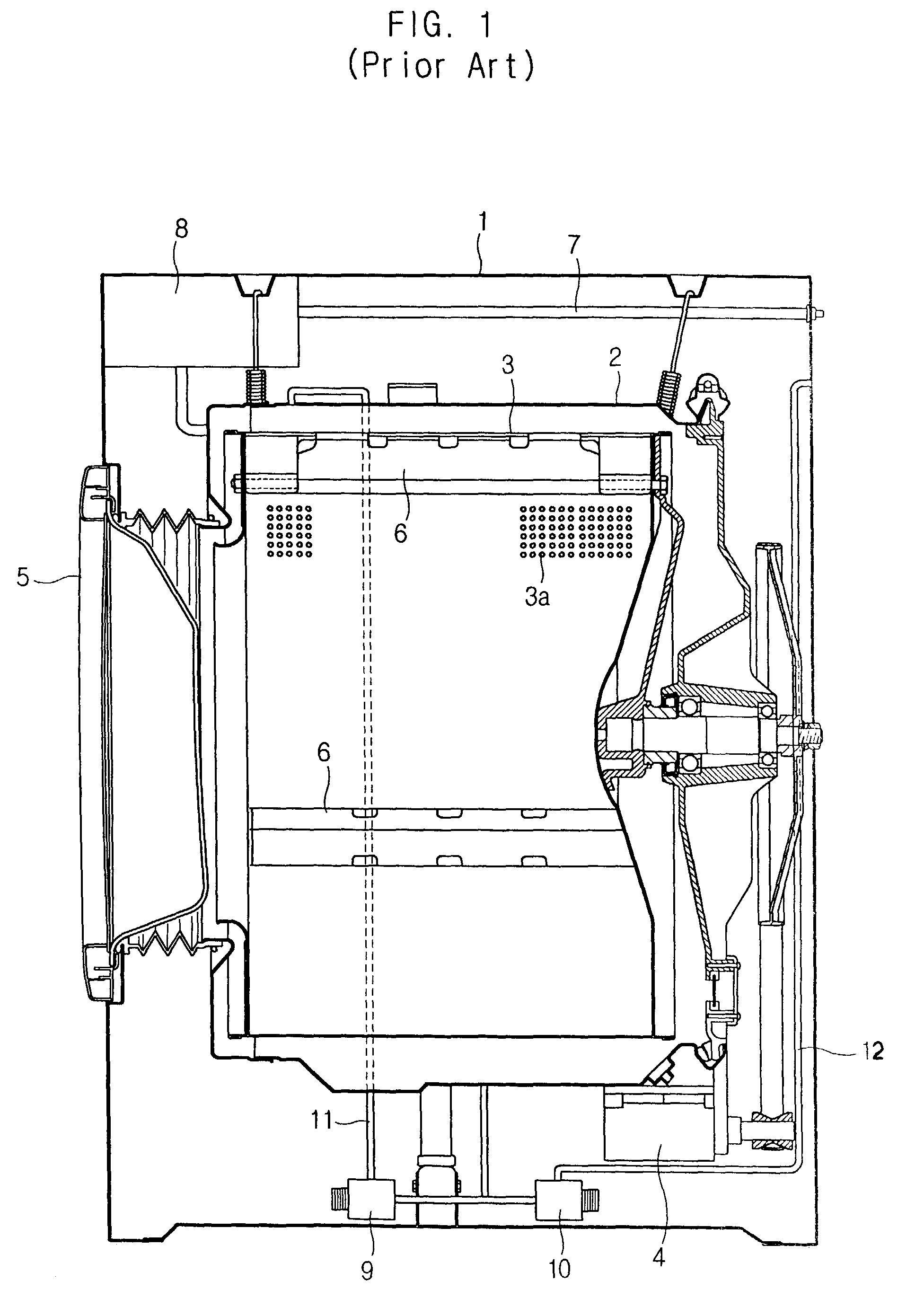

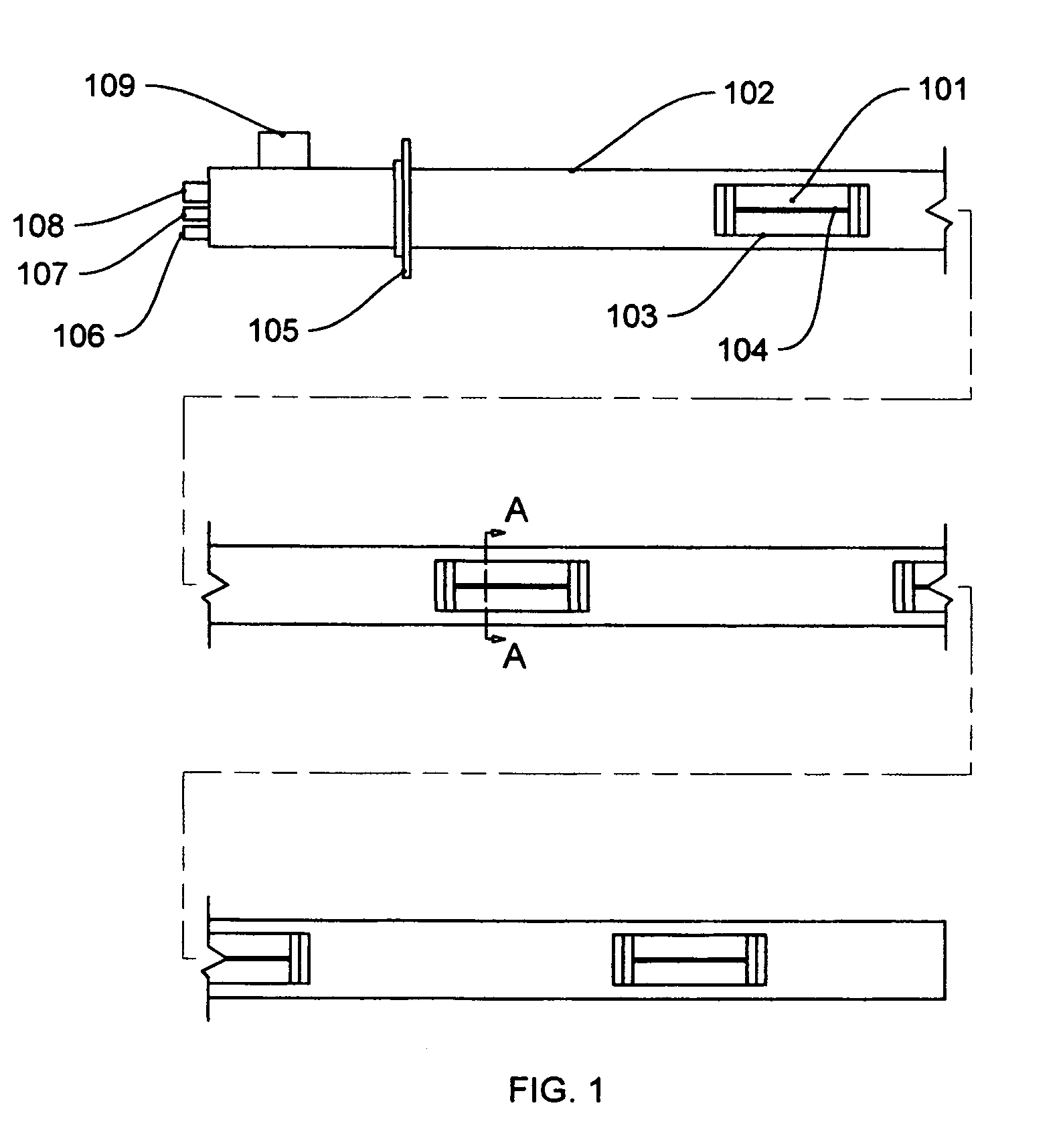

Drum-type washing machine

InactiveUS20050268669A1Improved water supply structureQuick wetOther washing machinesControl devices for washing apparatusWash waterAngle of rotation

A drum-type washing machine including at least one lifter for supplying wash water from the outside of a drum to the inside of the drum, and a controller for controlling water supply operations and washing operations based on the angle of rotation of the drum sensed by an angle sensing device. The controller positions the lifter under a water supply pipe so that the wash water is directly supplied from the outside of the drum to the inside of the drum through the lifter. Thus, laundry loaded in the drum is uniformly and rapidly wetted with the wash water. The controller also causes the laundry carried by the lifter to fall from the top position of the drum to maximize dropping power in a wash mode.

Owner:SAMSUNG ELECTRONICS CO LTD

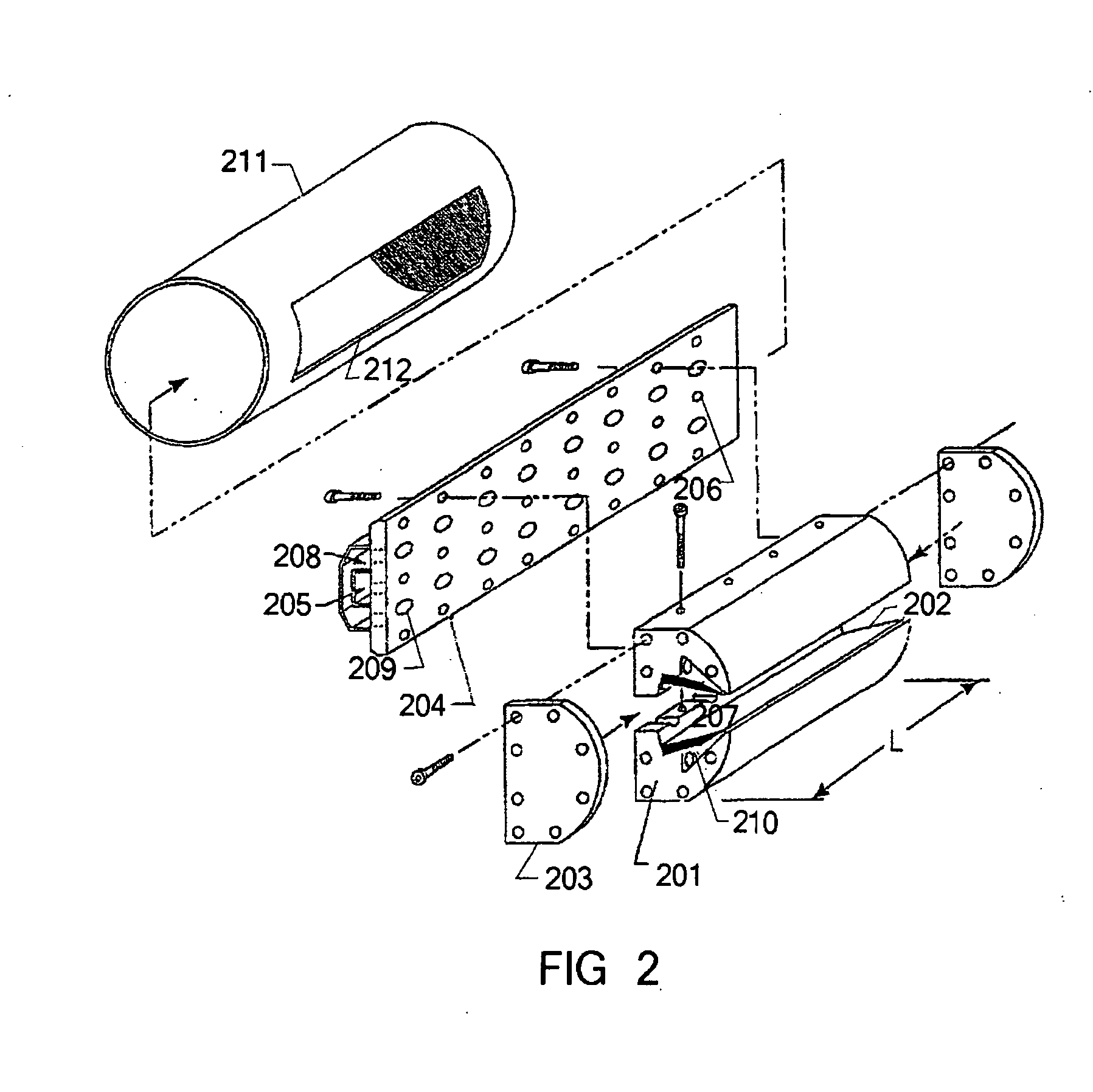

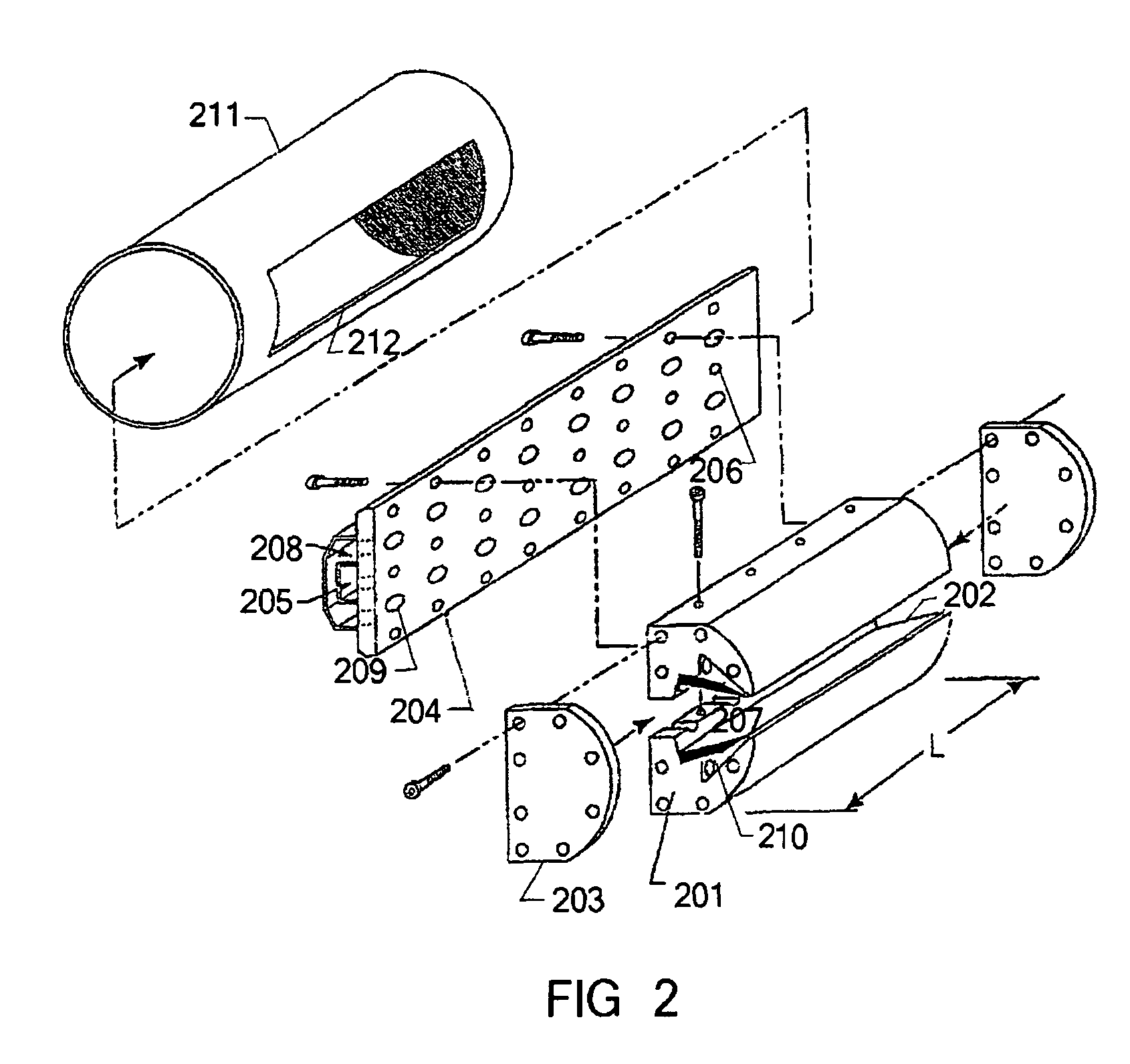

Joining the mixing and variable gas atomizing of reactive chemicals in flue gas cleaning systems for removal of sulfur oxides, nitrogen oxides and mercury

InactiveUS20100068111A1Short reaction timeIncreased time requirementCombination devicesGas treatmentAmount of substanceFossil fuel

Diverse methods of utilization and the corresponding, related modifications, of linear type, Variable Gas Atomization (VGA) nozzles and lances are described. Therein is joined the mixing and gas atomization of chemicals that react to form active products that further react with harmful flue gas constituents of combustion so as to enable their effective collection. One version combines, in a lance assembly of nozzles, the injection of reactants, in the form of finely divided dry solids conveyed in a carrier air stream, and the fine atomization of water, aqueous solutions or slurries. Atomization of such streams is employed to effectively wet the surfaces of the dry particles and, thereby, promote the rapid sorption of gaseous constituents of flue gas being treated. Another version simultaneously mixes and atomizes reacting chemicals to produce, and release into the flue gas stream, strongly oxidizing, transient, species of their reaction products. The simultaneous atomization and chemical reaction enables the effective capture of targeted flue gas constituents. An accompanying flue gas duct modification is described providing means for cost effective, high-performance system operation of linear VGA nozzle-lance arrays, as components of the various subject flue gas cleaning processes. The combination of linear VGA nozzle-lances and, as needed, flue gas duct enhancement, is intended to provide an economical and technically practicable means of retrofitting existing fossil fueled boilers of a wide range of capacities to meet future emission limits for SO2, SO3, NOx and mercury.

Owner:WALSH JR WILLIAM ARTHUR

Multipurpose, non-corrosive cleaning compositions and methods of use

ActiveUS20070203049A1Absent surface corrosionHighly effectiveOrganic detergent compounding agentsNon-surface-active detergent compositionsNitrogenous baseAlkanesulfonic Acids

Compositions comprising an alkanesulfonic acid and an organic nitrogenous base, and related methods of use.

Owner:WIN CHEM

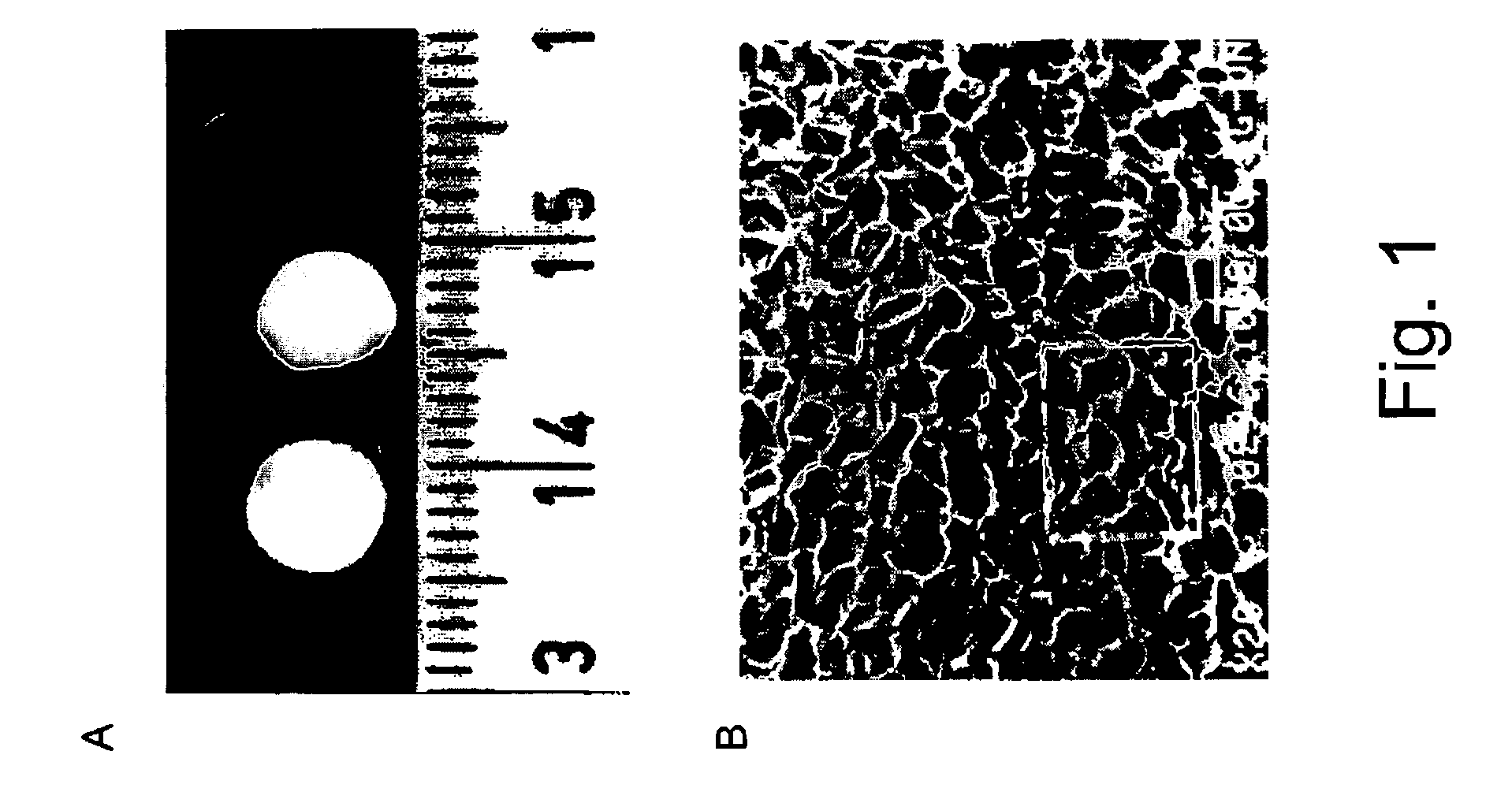

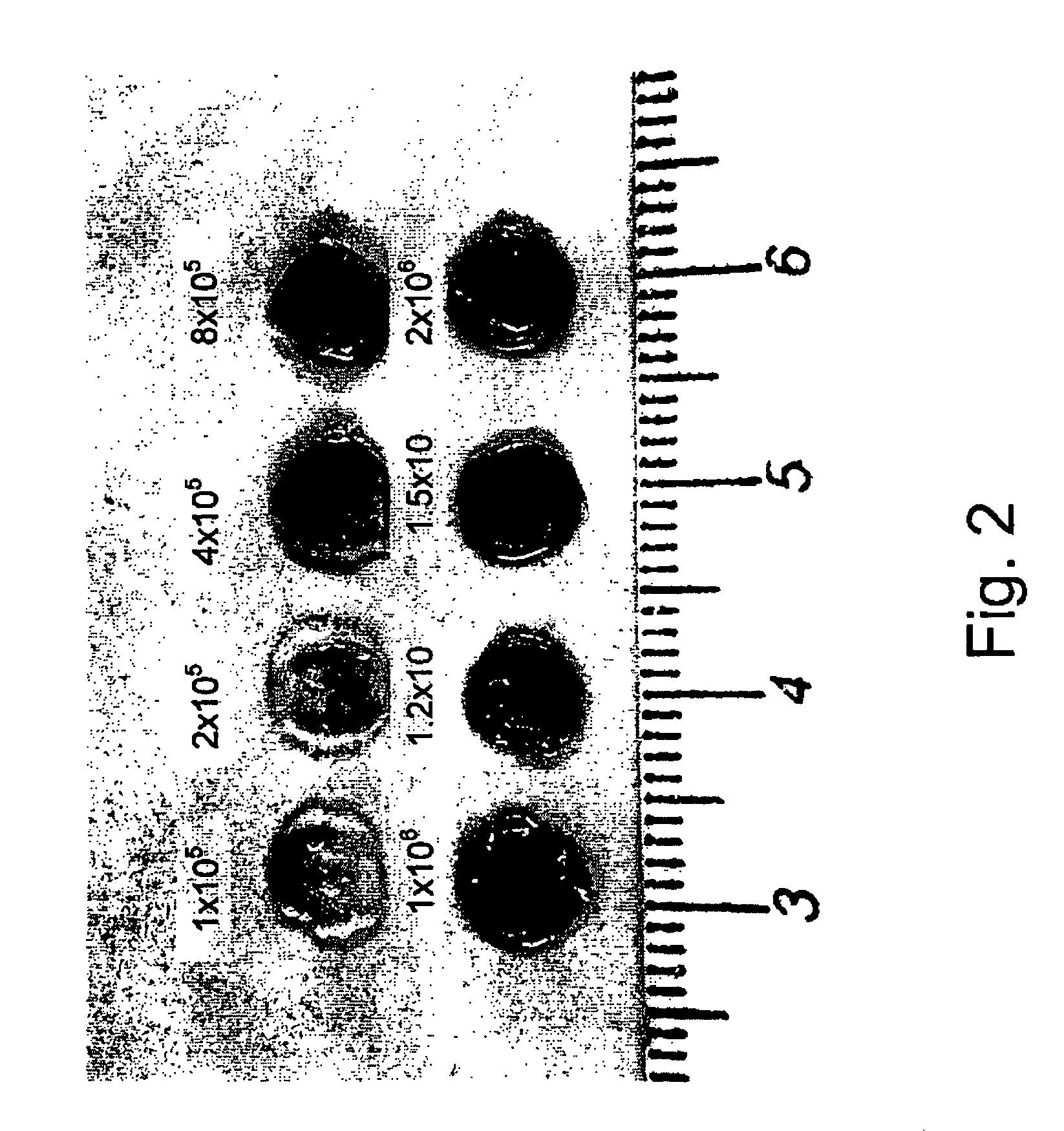

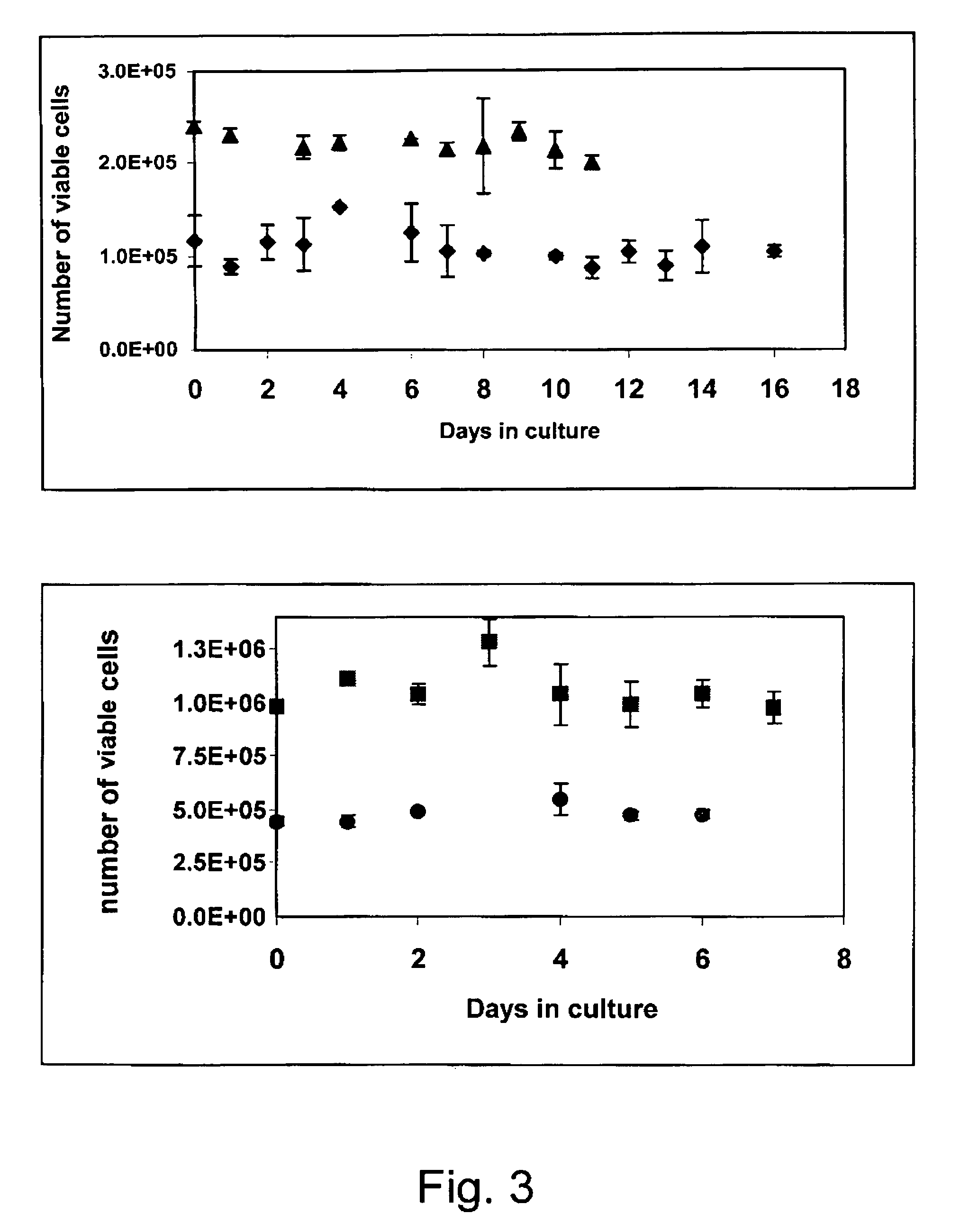

Tissue engineered biografts for repair of damaged myocardium

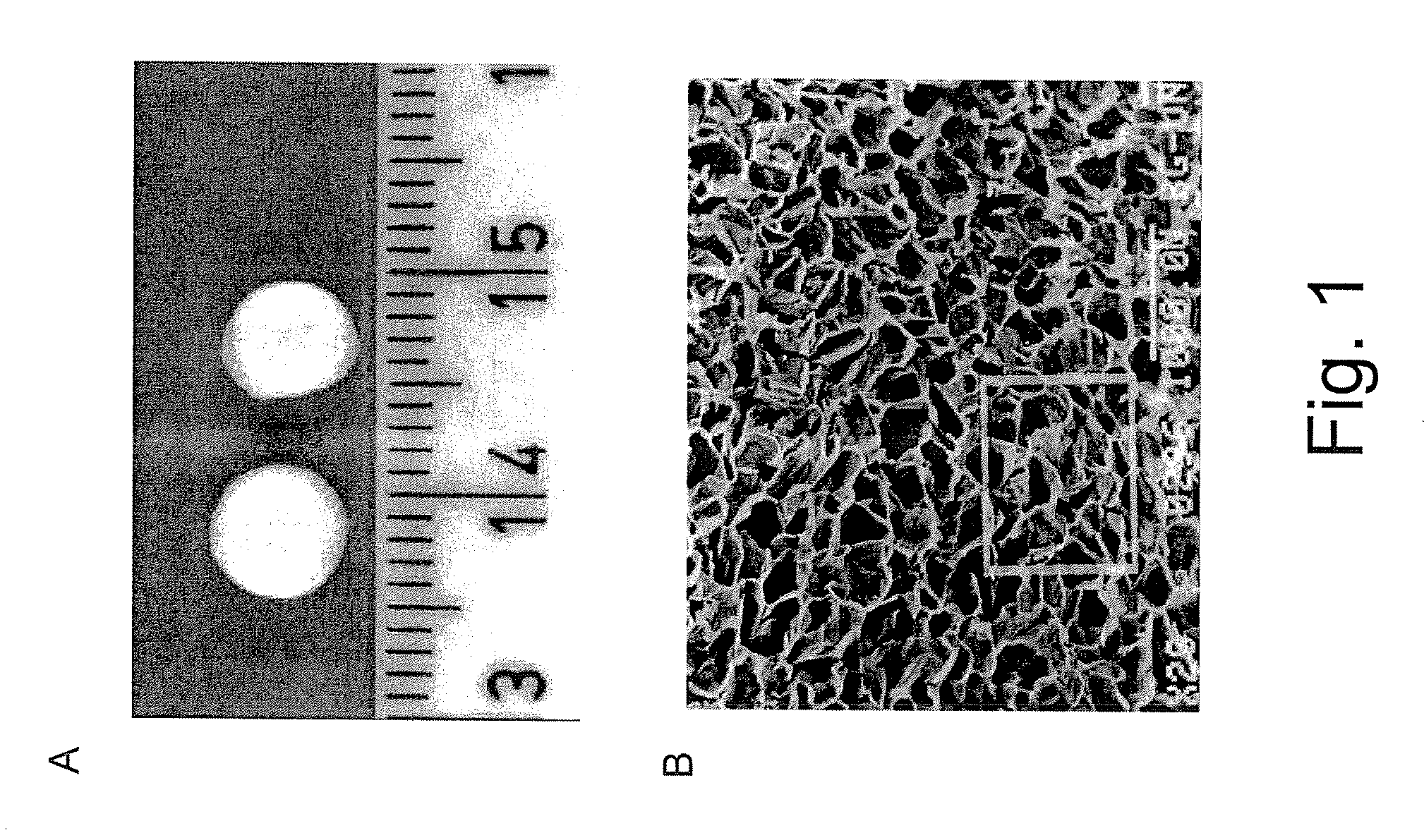

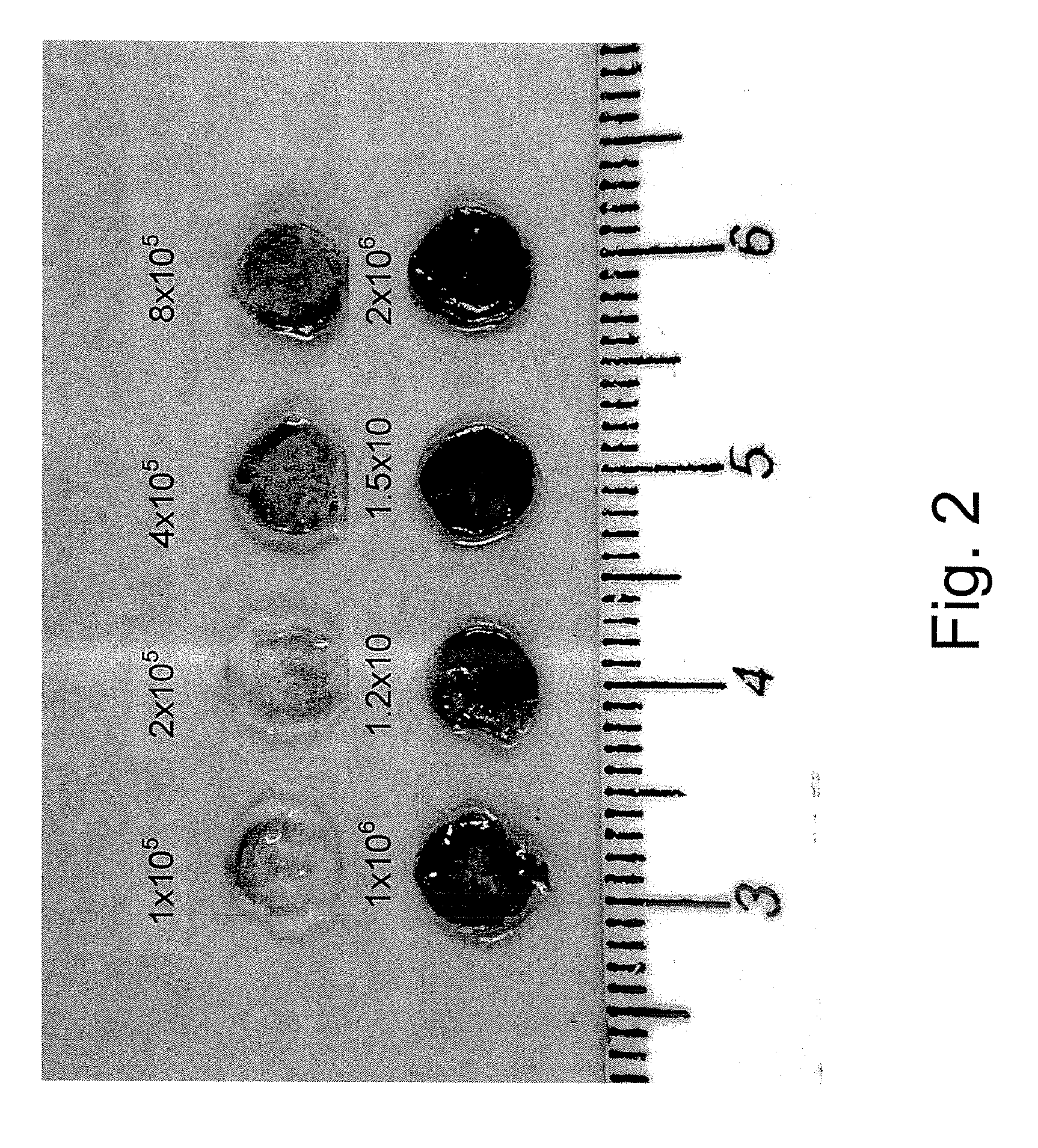

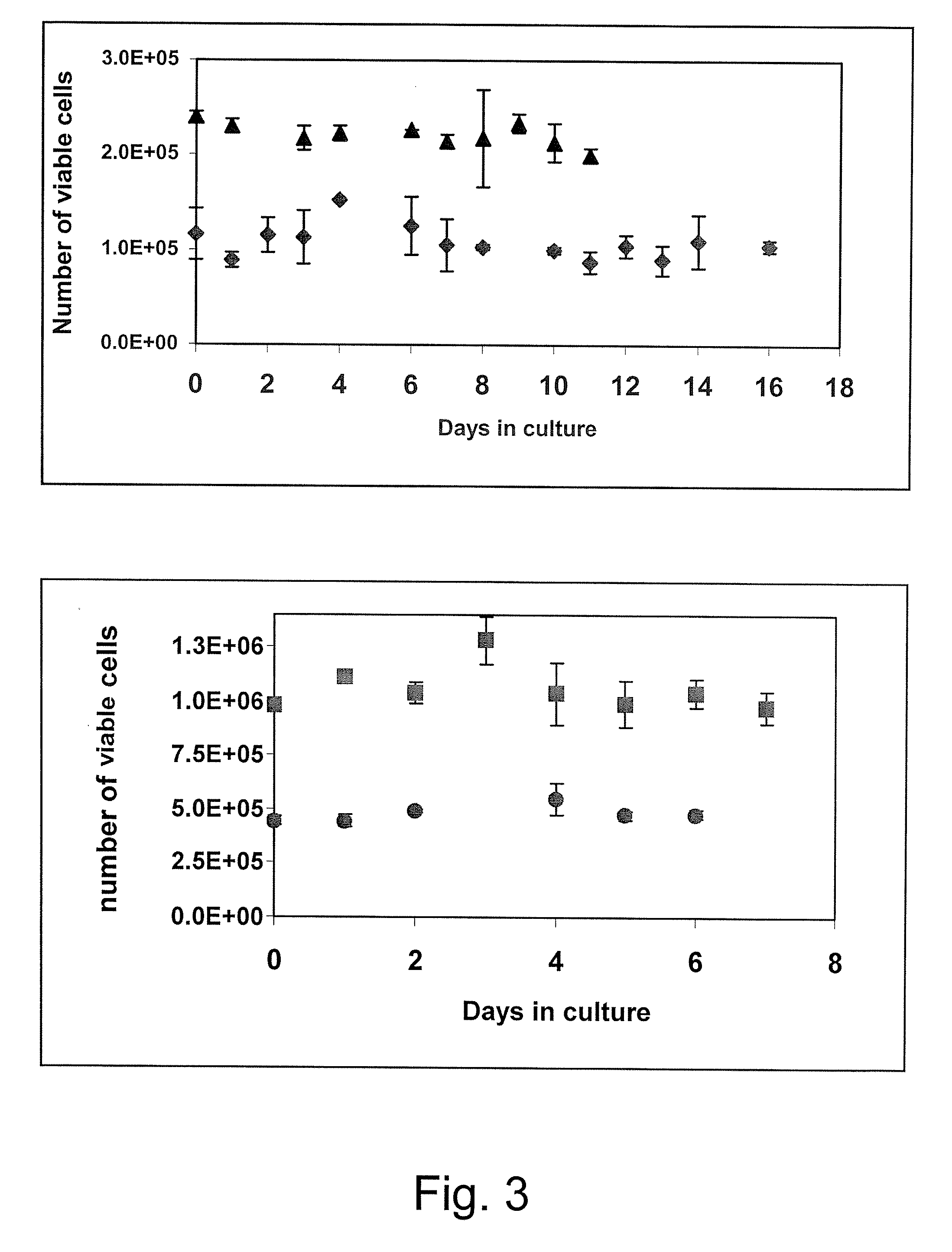

The invention is directed to tissue-engineered biografts, methods for preparing the biografts of the invention, and methods for repairing a damaged myocardium in a mammal. The methods of the invention can include providing a three-dimensional porous polysaccharide matrix; introducing mammalian cells into said matrix; growing said cells in said matrix in vitro, until a tissue-engineered biograft is formed; and transplanting the tissue-engineered biograft onto myocardial tissue or myocardial scar tissue of said mammal. The tissue-engineered biograft of the invention can form a contracting tissue. The methods of the invention can optionally include removing scar tissue or dead tissue from the site of implantation prior to transplanting the biograft.

Owner:UNIV OF THE NEGEV BEN GURION +1

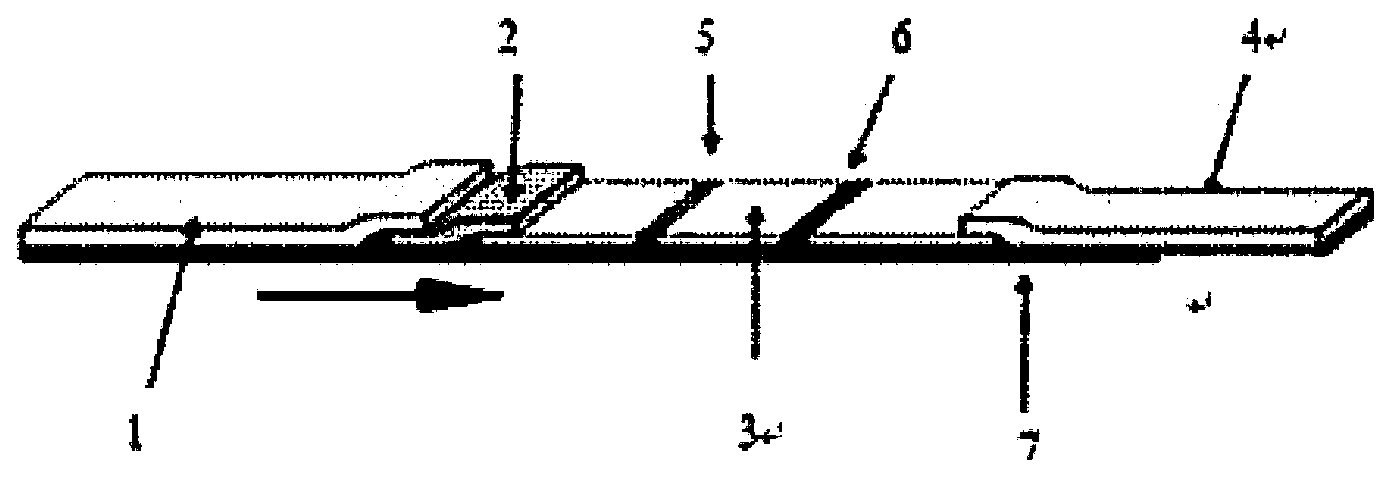

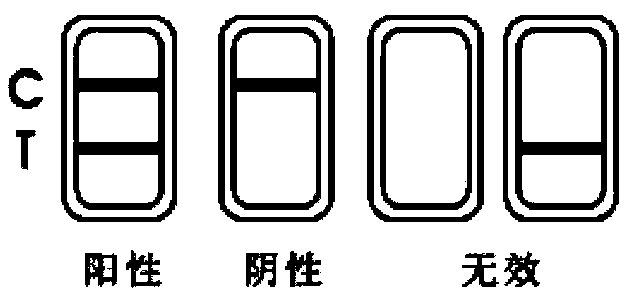

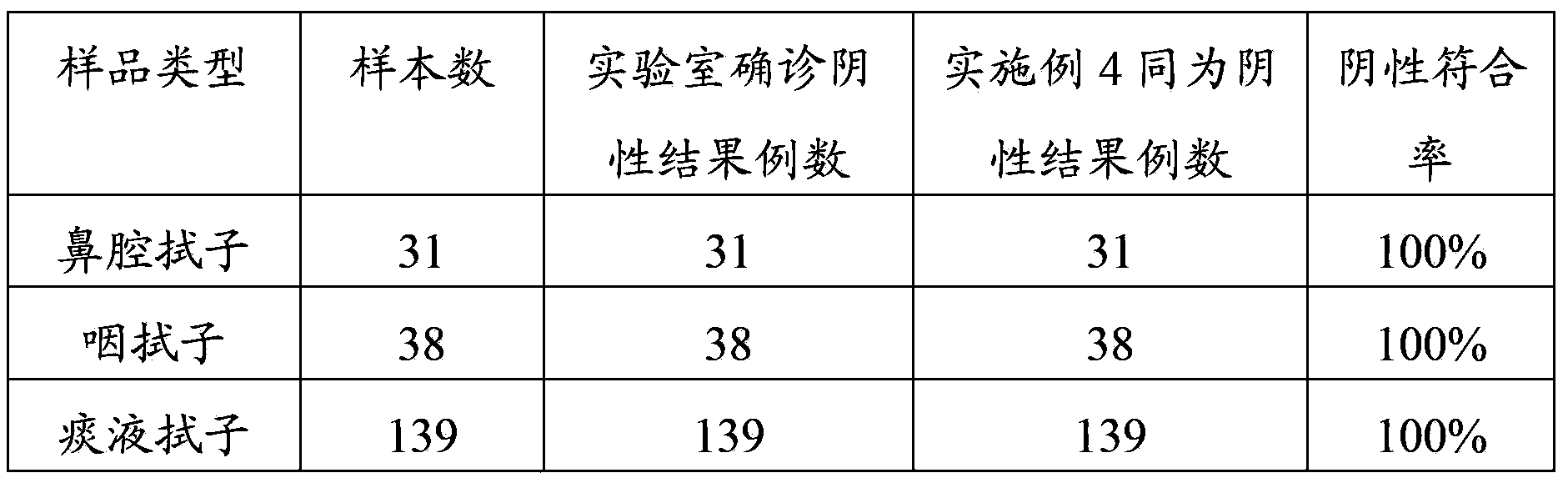

Sample pad processing liquid, H7 subtype avian influenza virus colloidal gold test strip and preparation method thereof

The invention discloses a sample pad processing liquid, a H7 subtype avian influenza virus colloidal gold test strip and a preparation method thereof, the processing liquid is prepared as follows: taking 8-20g of PEG(polyethylene glycol)-200, 11-25g of PVP (polyvinyl pyrrolidone), 10-45g of BSA (bovine serum albumin), 0.5-30ml of Triton X - 100, and 0.8-15ml of Twain-20, then using 5mM-10mM phosphate buffer solution to fix the volume to 1L, and adjusting the pH value to 9.5; and the colloidal gold test strip is formed by overlapping and pasting in turn a sample pad, a glass fiber membrane, a cellulose nitrate membrane and absorbent paper on a bottom plate, and the sample pad is processed by the processing liquid. The processing liquid can increase the sample pad hydrophilicity, contributes to the sample pad fast wetting, and promotes the chromatographic effect, aqueous solution formed by dissolving large molecules in water has suspension and dispersion effect, and can protect virus antigen in a sample. The test strip has the advantages of safe and simple operation, strong specificity, high sensitivity, and low rate of cross infection.

Owner:GUANGZHOU WONDFO BIOTECH

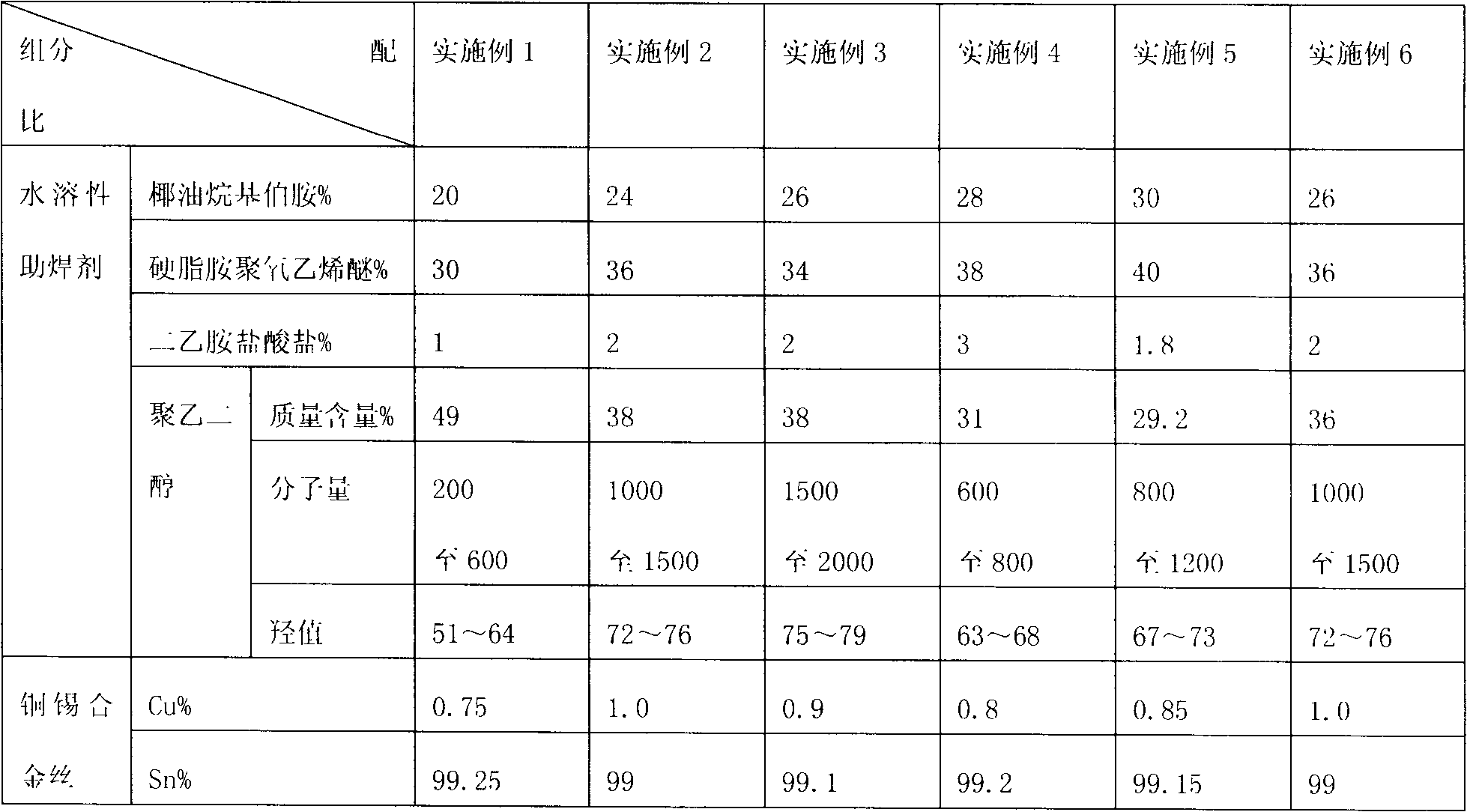

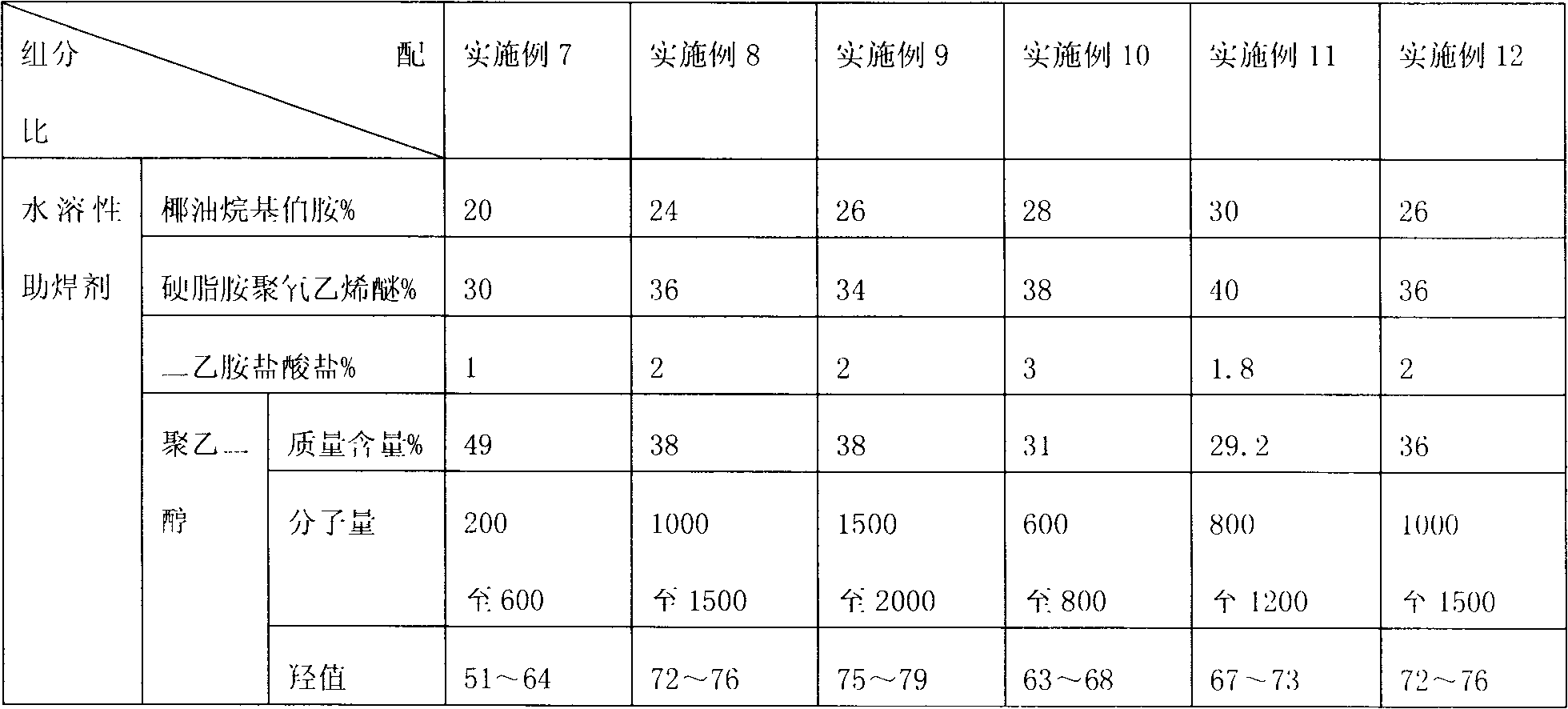

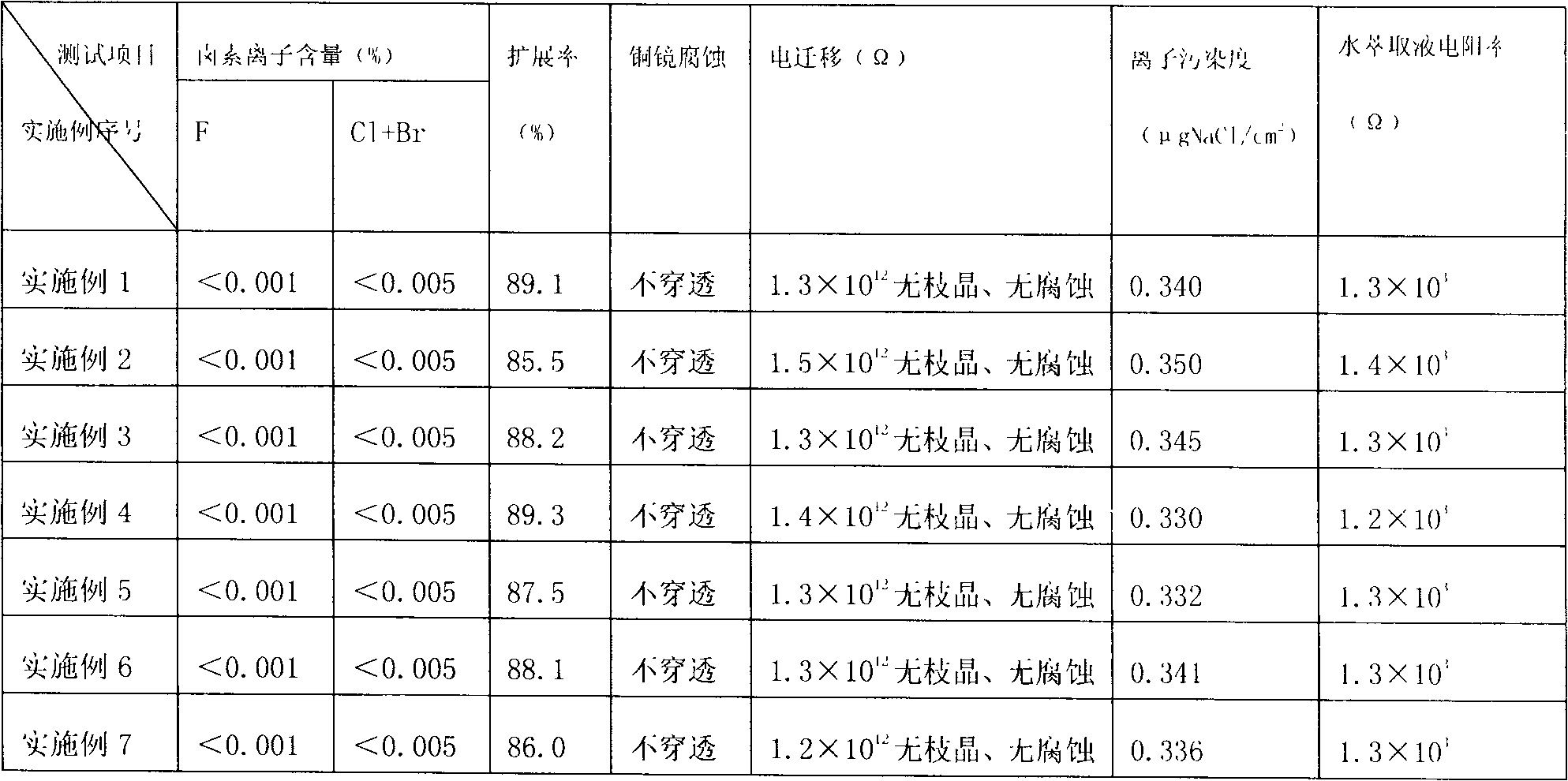

Lead-free welding tin wire and water-soluble welding flux used by same

ActiveCN102161135AReduce pollutionReduce interfacial tensionWelding/cutting media/materialsSoldering mediaPolyethylene glycolAlloy

The invention discloses a lead-free welding tin wire and a water-soluble welding flux used by the same. The lead-free welding tin wire comprises a copper-tin alloy wire provided with a hole cavity and the water-soluble welding flux arranged in the hole cavity; the proportion of the copper-tin alloy wire and the water-soluble welding flux is as follows: 2.0-2.2wt% of the water-soluble welding fluxand the balance of the copper-tin alloy wire, wherein the copper-tin alloy wire comprises the following components: 0.75-1.0wt% of Cu and the balance of Sn; the water-soluble welding flux comprises the following components: 20-30wt% of coconut oil alkyl carbinamine, 30-40wt% of octadecyl amine polyoxyethylene ether, 1-3wt% of diethylammonium chloride and the balance of water-soluble macromoleclarpolymer; the ammonium salt halogenide is diethylammonium chloride; and the water-soluble macromoleclar polymer is polyethylene glycol with the molecular weight of 200-2000. The lead-free welding tin wire provided by the invention has better welding performance and the water-soluble welding flux provided by the invention has better wettability.

Owner:浙江强力控股有限公司

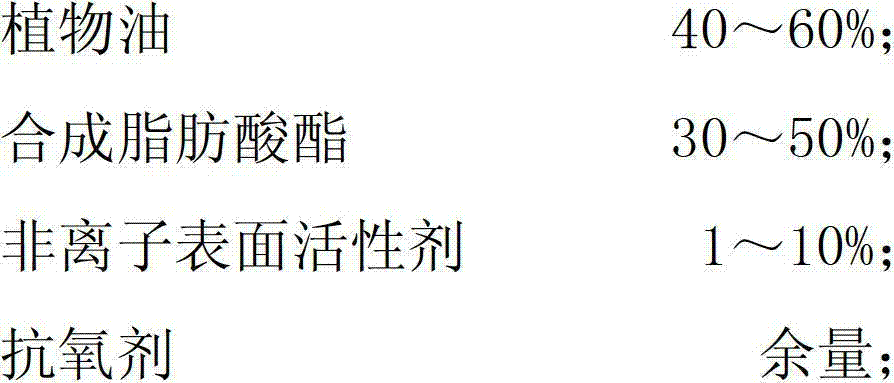

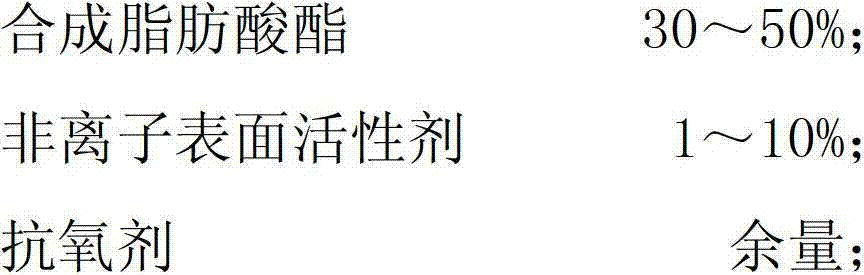

Cord thread spinning oil

InactiveCN103161068AImprove spinnabilityHigh spinnability, uniform fiber draft, high breaking strengthFibre typesSynthetic polymer filament chemical after-treatmentRapeseedEngineering

The invention discloses cord thread spinning oil. The cord thread spinning oil comprises, by mass, 40-60% of plant oil, 30-50% of compound fatty acid ester, 1-10% of non-ion surfactant, and the balance antioxidant. The plant oil is selected from at least one of peanut oil, soya-bean oil, linseed oil, castor oil, health oil, and rapeseed oil, refined processing is carried out on the plant oil, iodine value is higher than 70, the compound fatty acid ester is pentaerythritol ester or trimethylolpropane ester, and the non-ion surfactant is fatty alcohol-polyoxyethylene ether, fatty alcohol polyurethane propylene ether or fatty alcohol polyoxyethylene polyoxypropylene.

Owner:TIANJIN POLYTECHNIC UNIV

Engineered biografts for repair of damaged myocardium

InactiveUS20070014772A1High degreeEnhance cell viabilityBiocideArtificial cell constructsMammalGraft transplant

A method for repairing a damaged myocardium in a mammal, comprising: a) providing a three-dimensional porous polysaccharide matrix; b) introducing mammalian cells into said matrix; c) growing said cells in said matrix in vitro, until a tissue-engineered biograft is formed, comprising a contracting tissue; and d) transplanting the tissue-engineered biograft onto the myocardial tissue or myocardial scar tissue of said mammal, optionally previously removing scar or dead tissue from the site of implantation.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

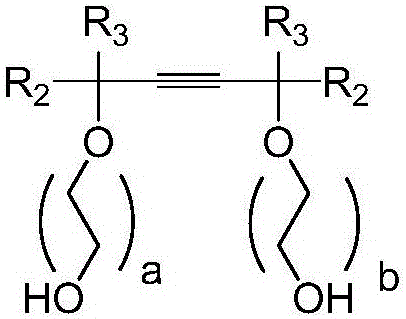

Compound wetting agent and coating formed by same

InactiveCN106084975AGood foam stabilization effectSolve the problem of poor wettingPolyurea/polyurethane coatingsChemistryOrganosilicon

The invention provides a compound wetting agent and a coating formed by the same. The compound wetting agent mainly comprises, by weight, 5-40% of polyether modified organosilicon surfactant, 50-90% of alkynediol surfactant and 1-10% of isomerized low-foam special polyether solubilizer. The compound wetting agent has low static surface tension and dynamic surface tension and good system compatibility, foam stability of polyether modified organosilicon is remarkably improved, and the compound wetting agent can be suitable for water-based wood paint of different resin systems such as an acrylic resin system and a polyurethane system.

Owner:岳阳凯门水性助剂有限公司

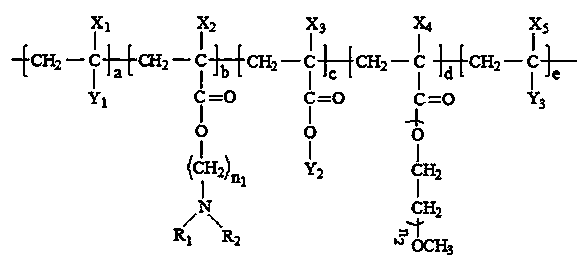

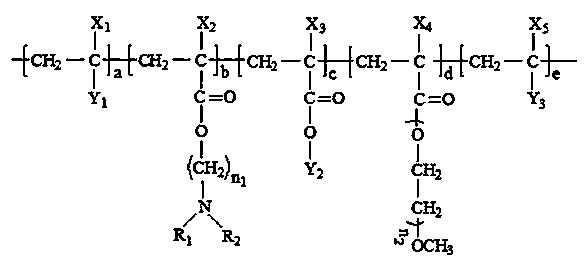

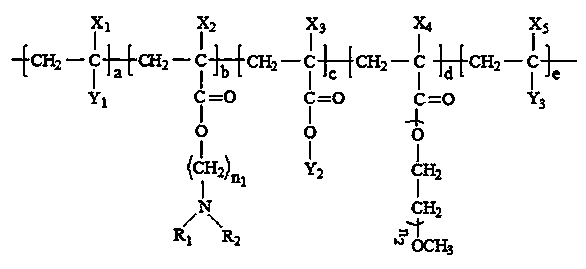

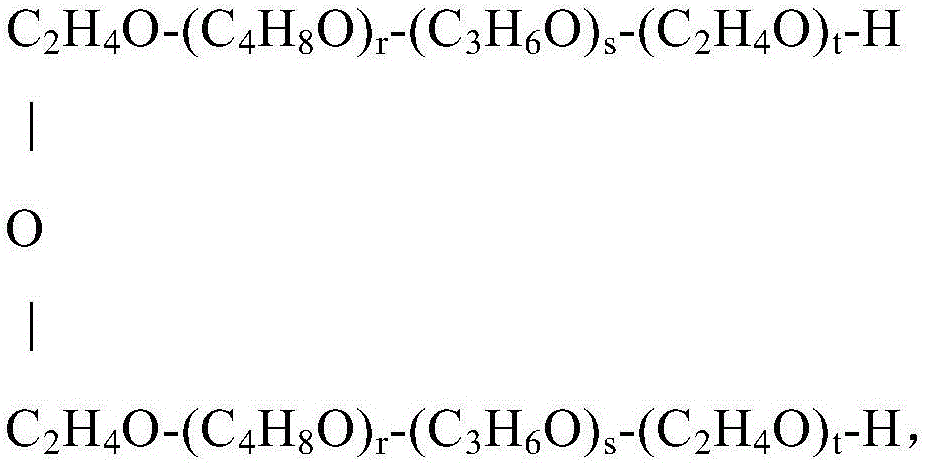

Solventtype block polymer dispersant

ActiveCN103897441AHigh purityHigh hiding powerOrganic dyesPigment treatment with macromolecular organic compoundsAcrylonitrileEthylene Homopolymers

The invention relates to a solvent type block polymer dispersant and a preparation method thereof, the molecular chain of the dispersant comprises an anchoring chain segment and a solvation chain segment, and has a structural formula shown in the specification. The solvent type block polymer dispersant fundamentally solves the defects of traditional dispersants, the molecular chain of the dispersant comprises the anchoring chain segment and the solvation chain segment, a homopolymer or copolymer of vinyl pyridine, vinyl imidazole, amino acrylate and other nitrogen-containing vinyl monomers is used as the pigment anchoring chain segment, a homopolymer or copolymer of nitrogen-free vinyl monomer such as acrylate, acrylonitrile and styrene is used as the solvation chain segment, and pigment flocculation and sedimentation during storage can be prevented.

Owner:NANTONG HANTAI CHEM

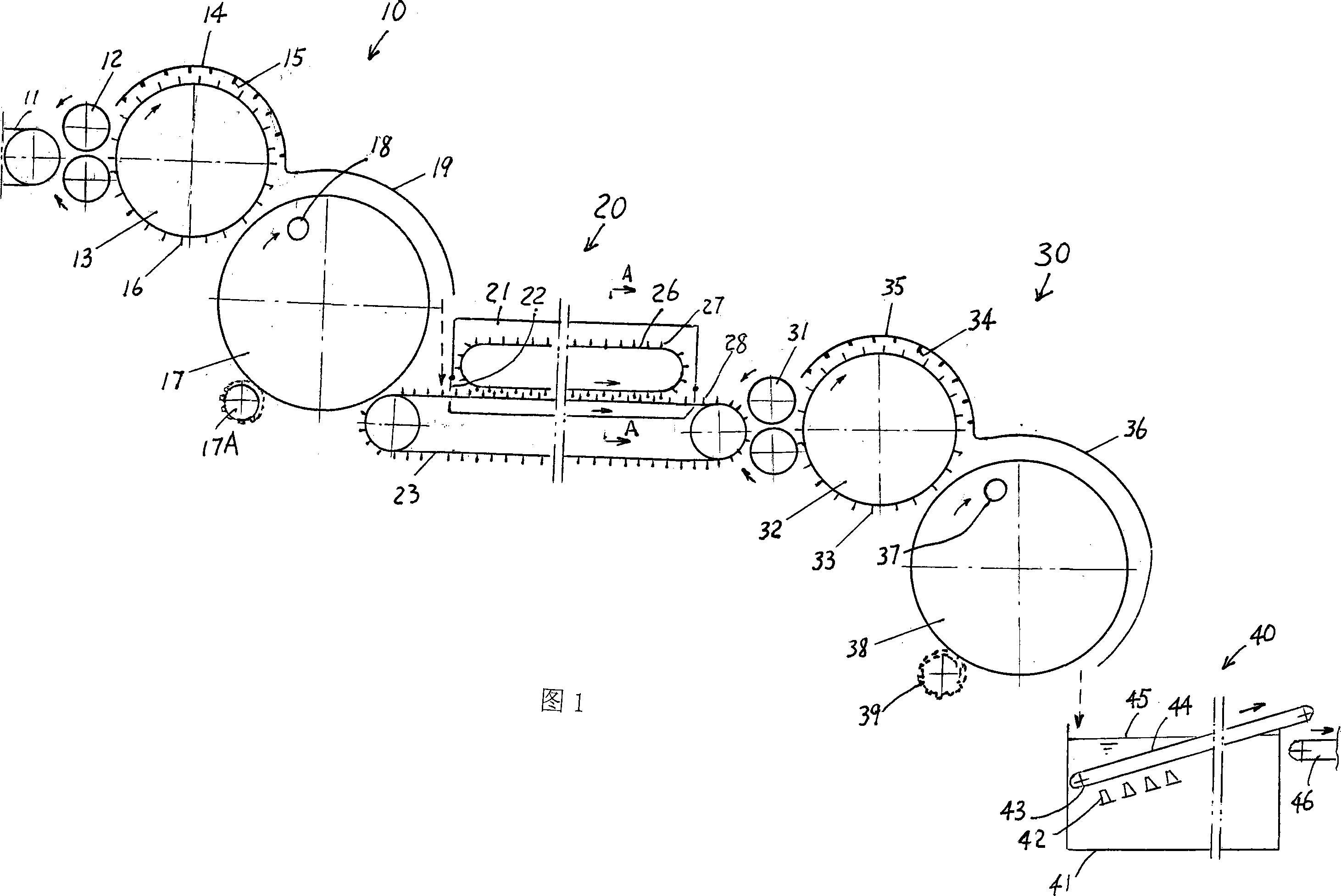

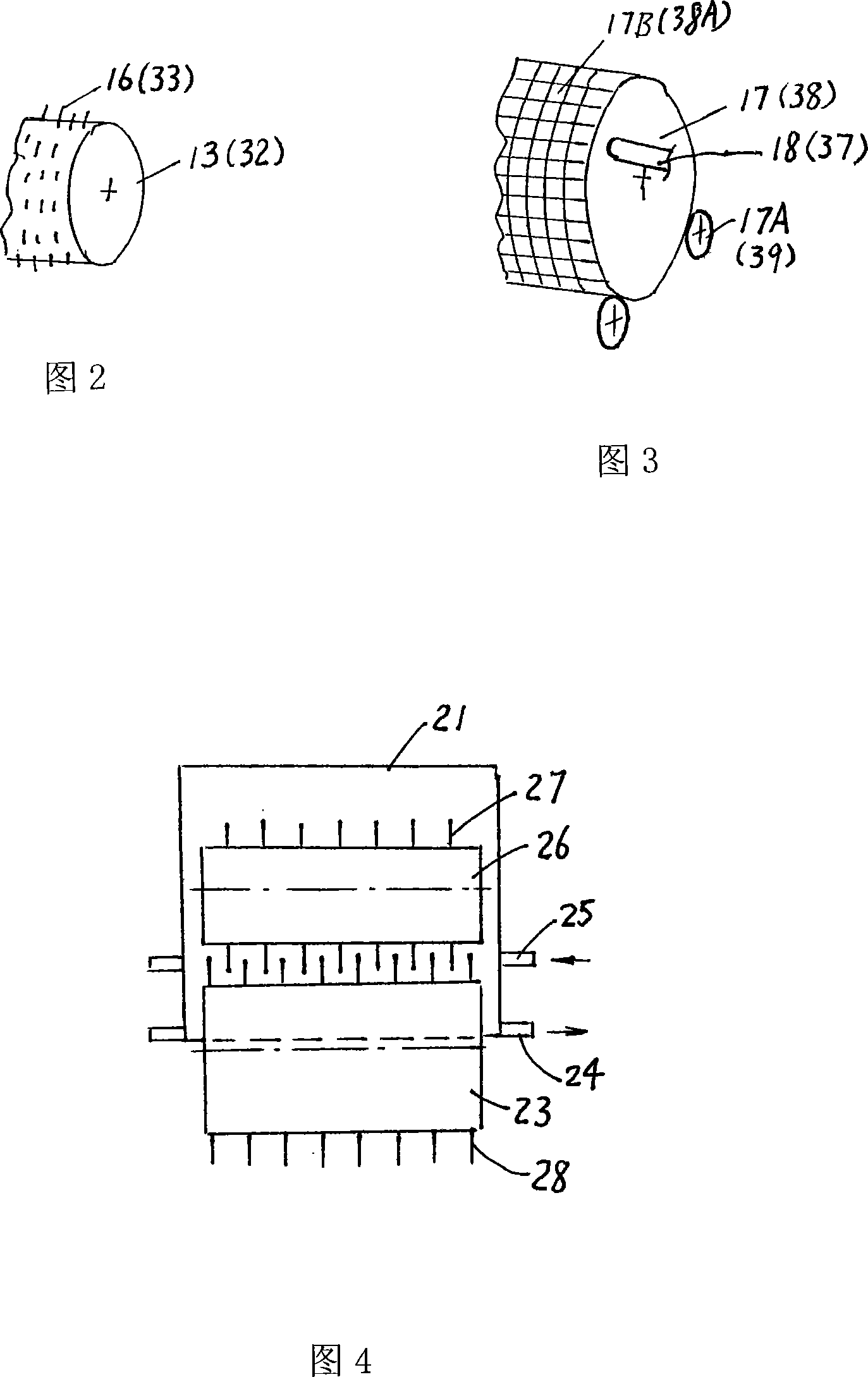

Method and device for extracting straw fibre

The invention relates to the method and device used to extract straw stalk fiber. It includes the following steps: breaking the straw stalk, peeling off to do rough extraction; heating, moistening by steam, peeling off, carding; further peeling off, carding to remove adhesion tissue to obtain straw stalk fiber; cleaning. Compared with existing technology, the invention can increase efficiency, save water, protect environment, save transport cost, suits for extracting various crops, can be used in town and country.

Owner:徐丕义

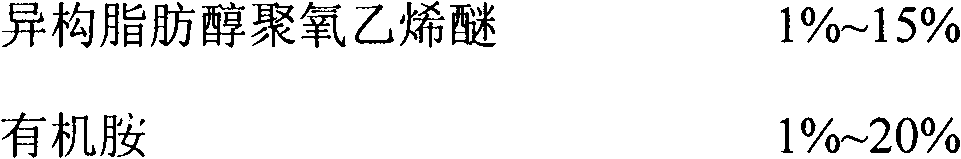

Cleaning solution for light-emitting diode (LED) chip

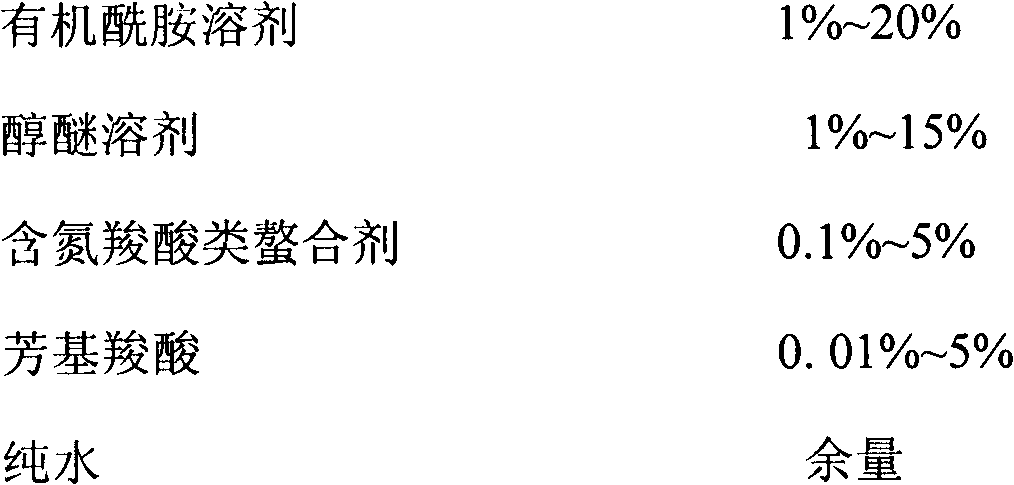

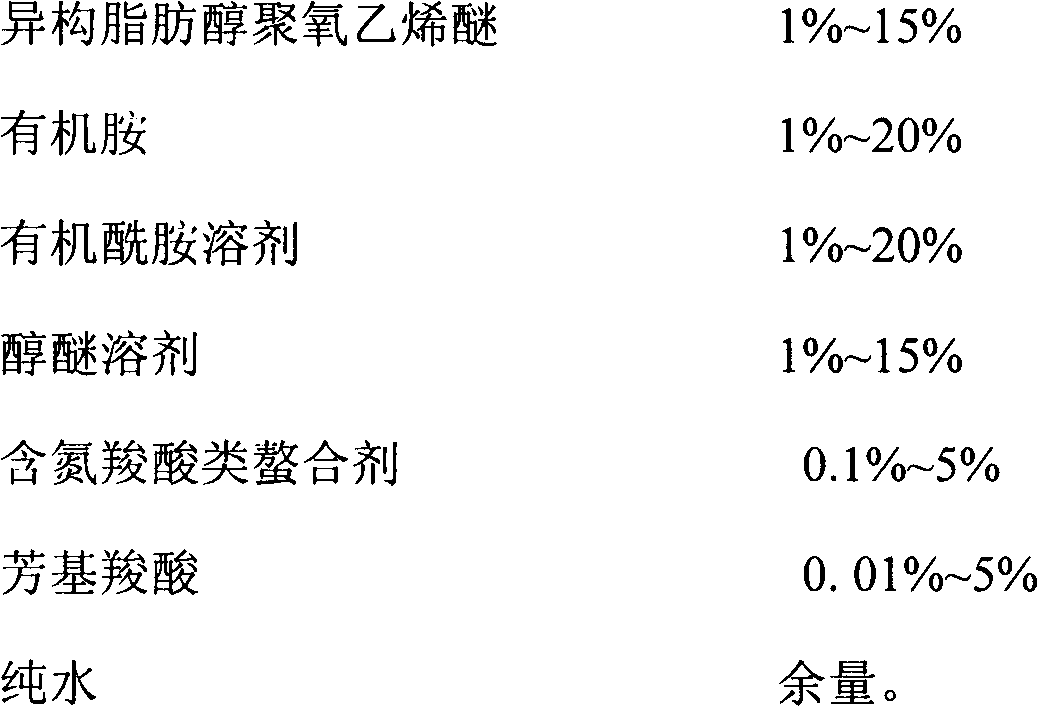

ActiveCN102660393AReduce surface tensionQuick wetSurface-active detergent compositionsDetergent compounding agentsAlcoholNitrogen

The invention discloses a cleaning solution for a light-emitting diode (LED) chip. A preparation method for the cleaning solution is simple, and the cleaning solution is low in cost and high in cleaning efficiency, and has low corrosion rate to substrate materials and wire harnesses. The cleaning solution consists of the following components in percentage by weight: 1 to 15 percent of isomerized fatty alcohol-polyoxyethylene ether, 1 to 20 percent of organic amine, 1 to 20 percent of organic amide solvent, 1 to 15 percent of alcohol ether solvent, 0.1 to 5 percent of nitronic acid-containing chelating agents, 0.01 to 5 percent of arylcarboxylic acid, and the balance of pure water.

Owner:ZHEJIANG AUFIRST MATERIAL TECH CO LTD

Cutting and rapid propagation method for flowers and plants

InactiveCN107318415APromote rootingImprove drought resistancePlant growth regulatorsBiocideVitamin B12Salicylic acid

The invention relates to the technical field of agriculture and biology, in particular to a cutting and rapid propagation method for flowers and plants. The method comprises the steps of disinfection, soaking with an inductive agent solution, cutting, leaf fertilizer spraying, seedling exercising, transplanting and the like, wherein branches serve as cutting slips; the inductive agent solution is mainly prepared from a seaweed extracting solution, a willow extracting solution, an alfalfa extracting solution, salicylic acid, fulvic acid, vitamin B12, white sugar, paclobutrazol, brassinolide, a compound fertilizer, bone glue, waste molasses, sodium alkylnaphthalenesulfonate, polyoxyethylene alkyl ether and the like; the leaf fertilizer is mainly prepared from diethylaminoethyl hexanoate, compound sodium nitrophenolate, tulip, cumin, lavender, thyme, urea, starch paste, tea-seed oil and the like. The cutting and rapid propagation method for the flowers and plants is simple in propagation operation, quick in rooting speed and strong and developed in root system, plant diseases and insect pests are reduced, the pesticide utilization rate is reduced, the environmental pollution is reduced, and the rooting rate and the survival rate of the flowers and plants are obviously improved.

Owner:GUANGXI MODERN GARDEN GREENING ENGINEERING SEEDLING CO LTD

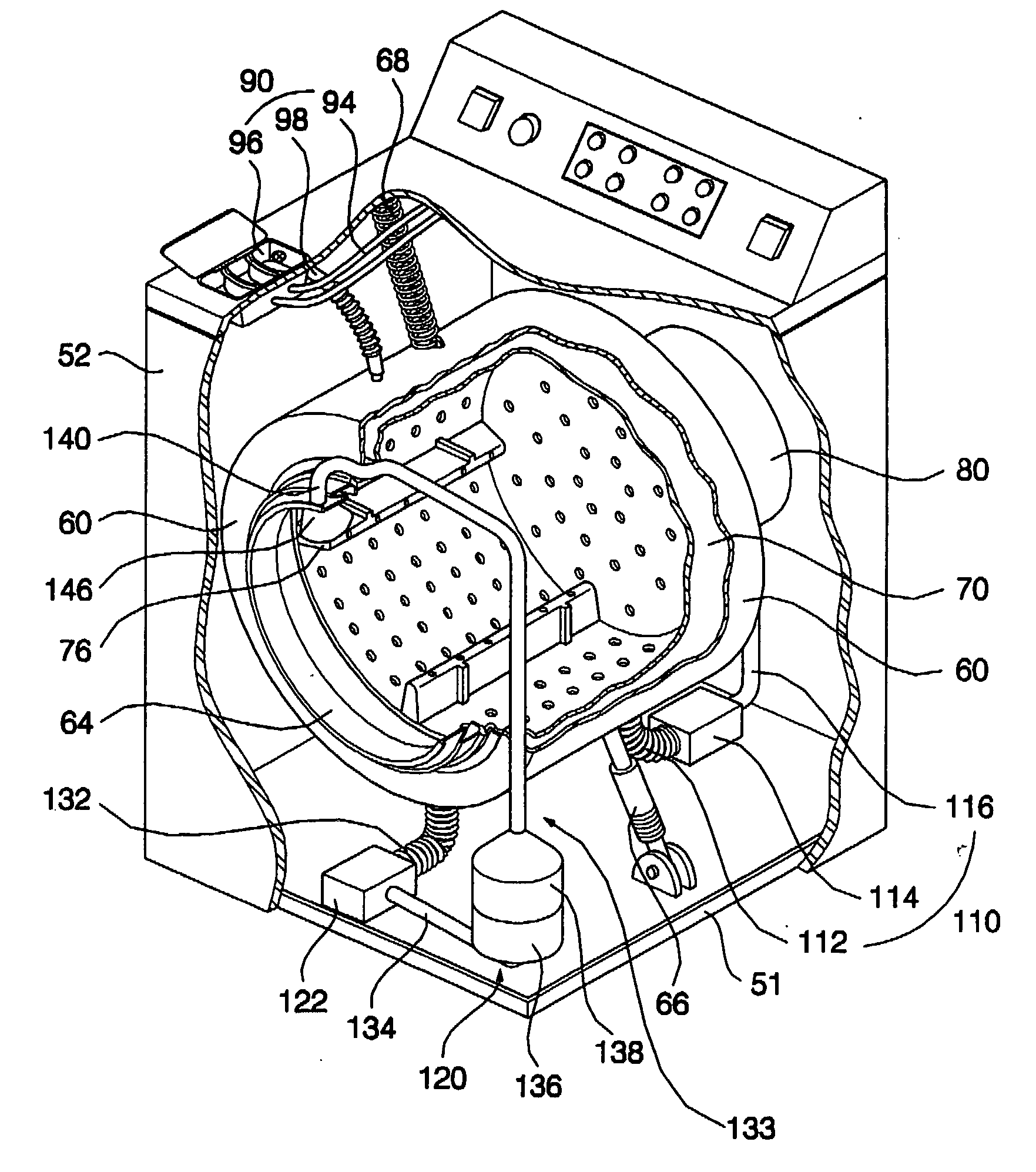

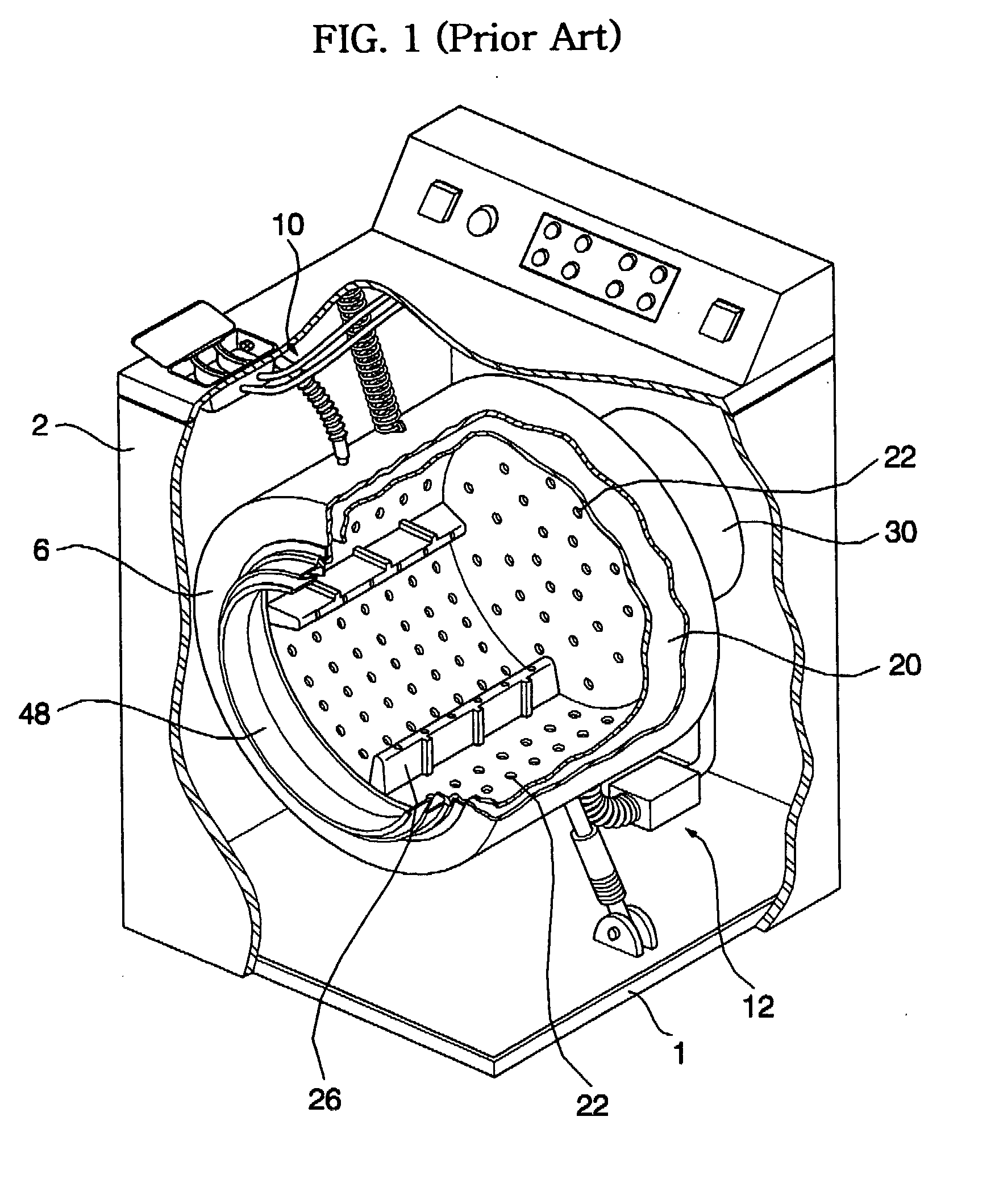

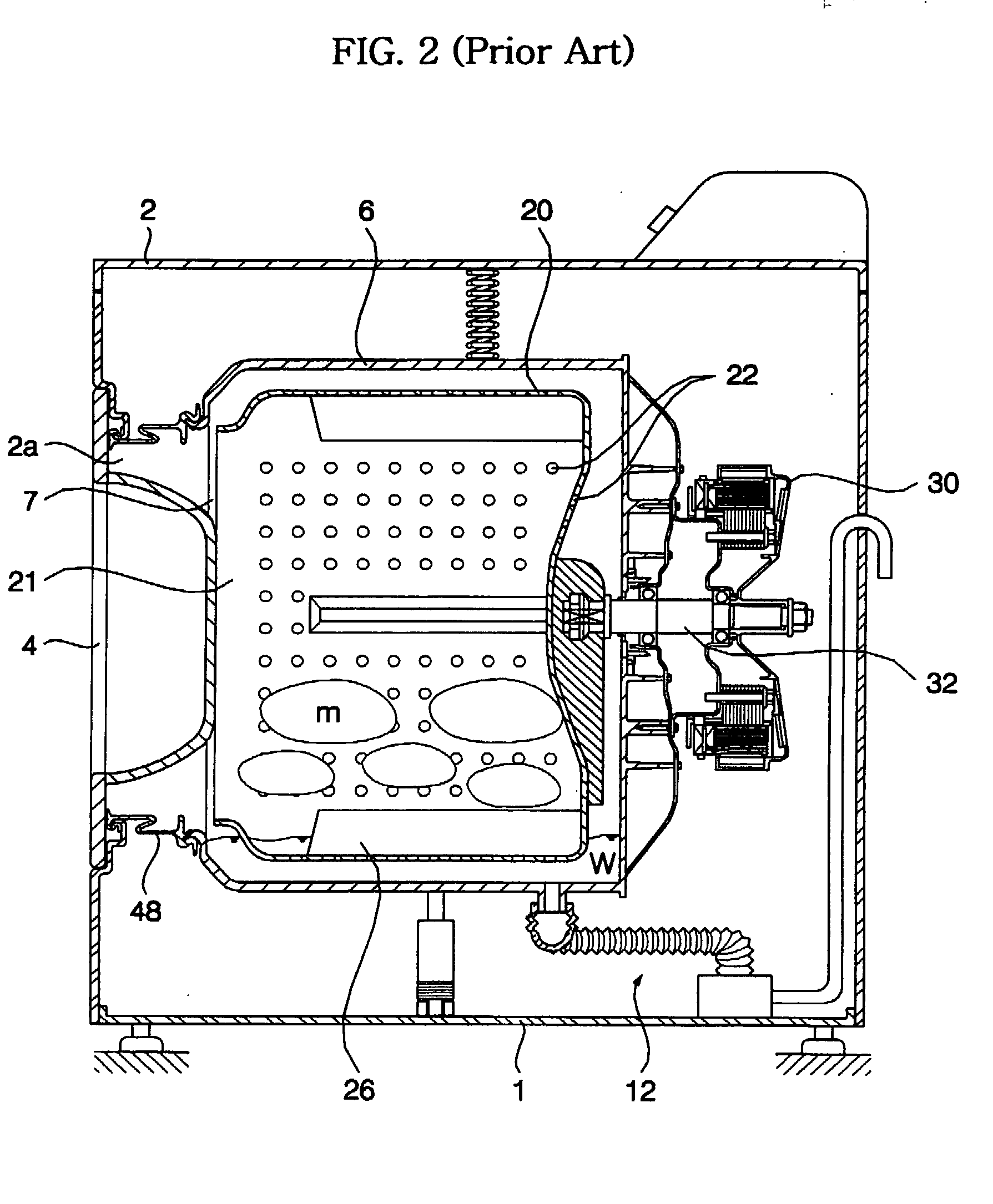

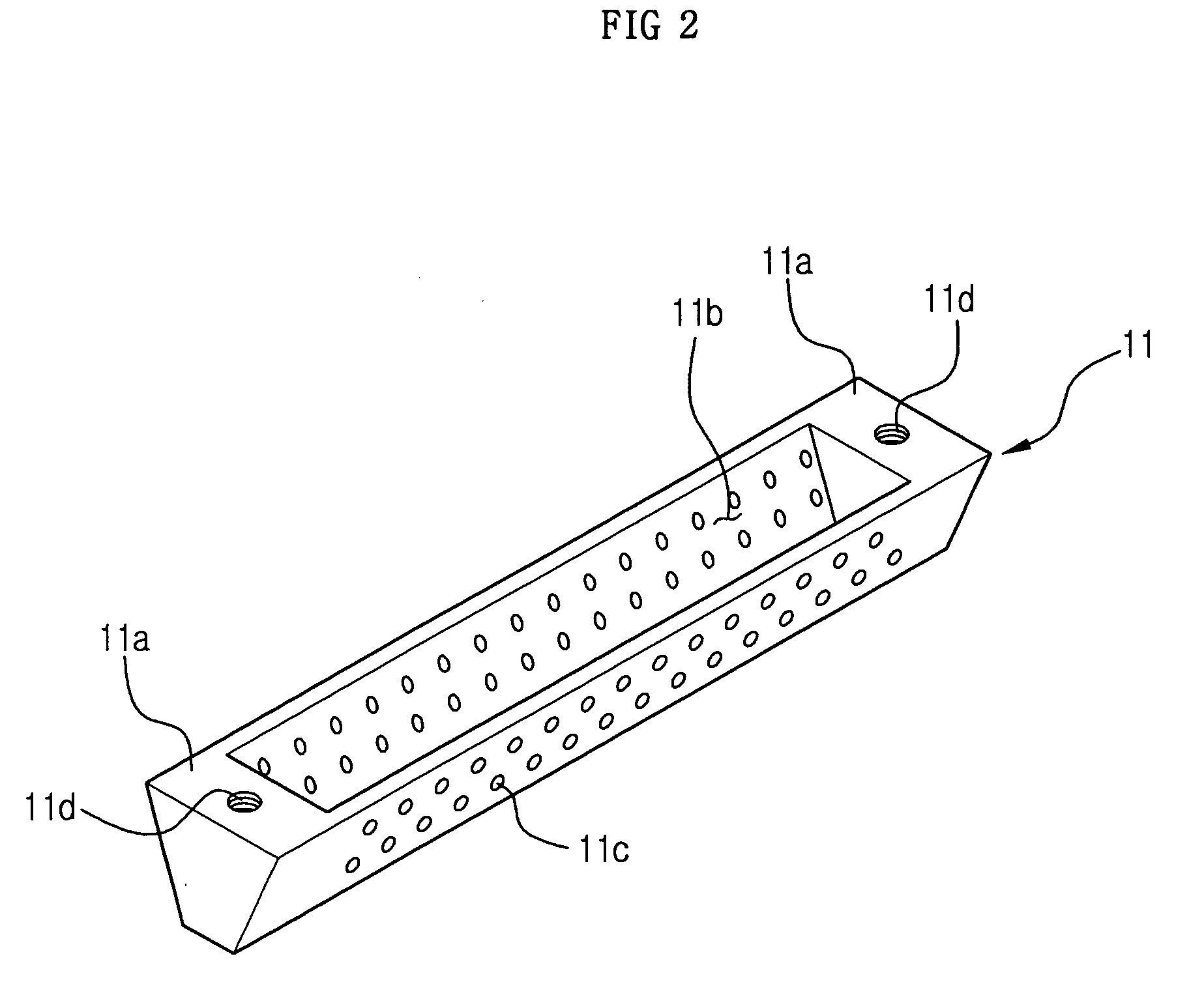

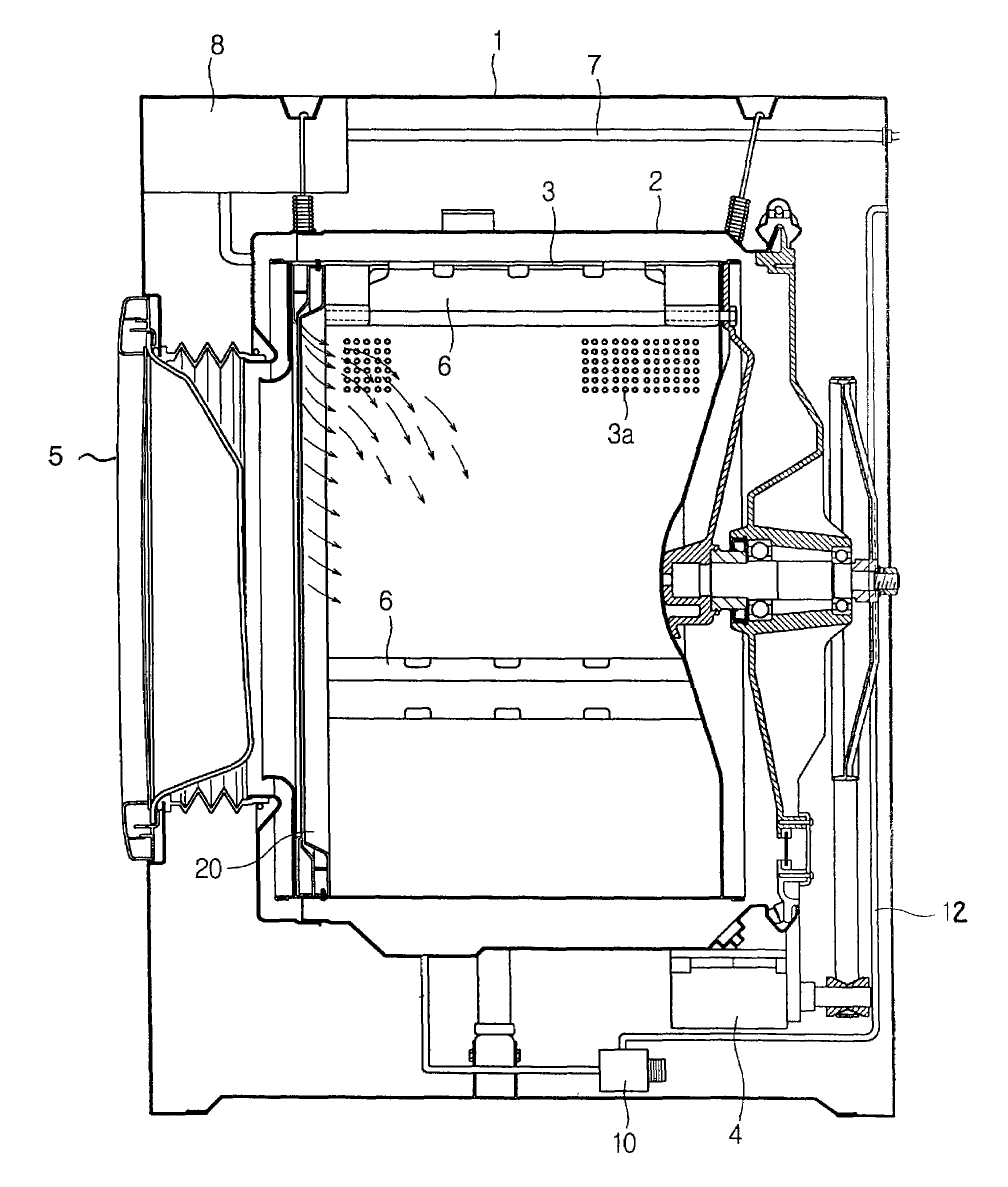

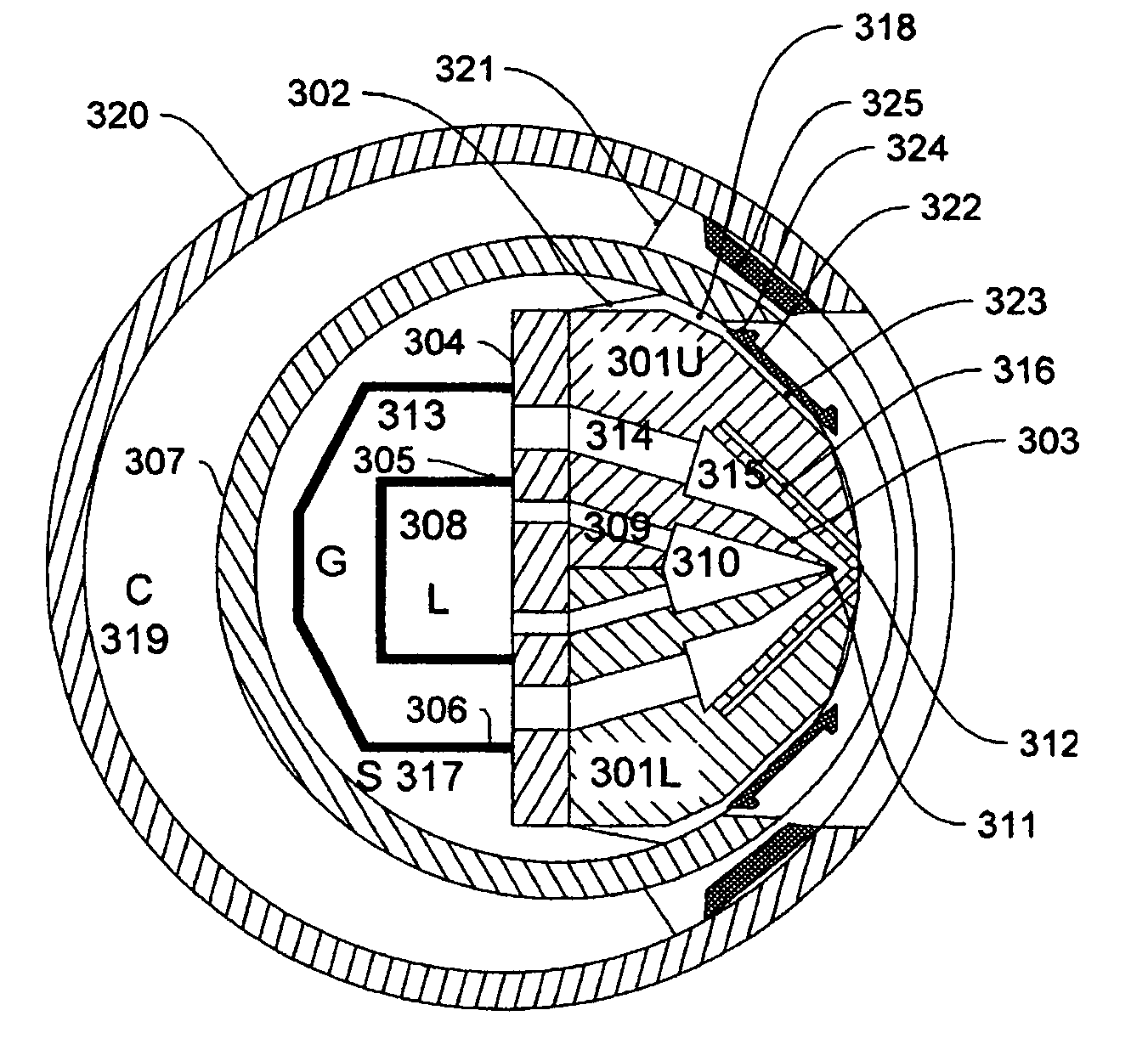

Drum type washing machine

InactiveUS7010942B2Quick wetImprove washing effectOther washing machinesDrying machines with non-progressive movementsWash waterWater turbine

A drum type washing machine includes a cabinet which defines an outer appearance of the washing machine, a water tub set inside the cabinet to contain wash water therein, a rotary tub having spin drying perforations and rotatably set in the water tub, and a water turbine which is mounted at an open front of the rotary tub and rotates along with the rotary tub to spray the wash water contained in the water tub into the rotary tub. The water turbine includes an external member having an annular shape, and an internal member having an annular shape corresponding to the external member. The internal member is arranged apart from the external member by a predetermined interval. A vane unit is set between the external and the internal members, and raises the wash water contained in the water tub and sprays the wash water into the rotary tub.

Owner:SAMSUNG ELECTRONICS CO LTD

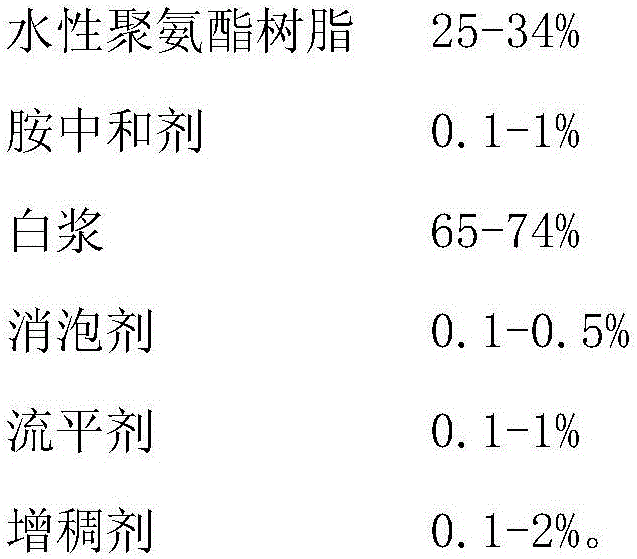

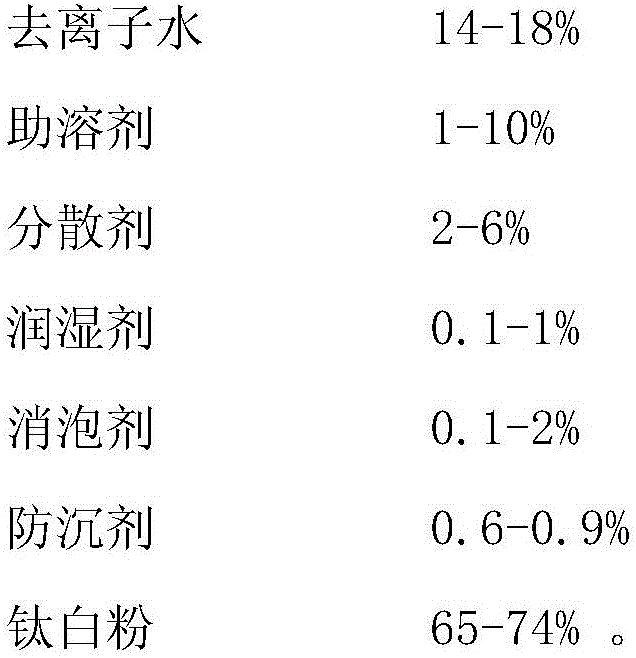

Automotive water-borne one-component white paint with excellent comprehensive property and preparation method thereof

ActiveCN105860806AGood storage stabilityGood lookingPolyurea/polyurethane coatingsWeather resistanceFreezing thawing

The invention discloses automotive water-borne one-component white paint with an excellent comprehensive property and a preparation method thereof. The water-borne one-component white paint is composed of resin, an amine neutralizer, white pulp and auxiliaries, wherein the white pulp is composed of deionized water, cosolvent, auxiliaries and titanium dioxide. After material feeding is completed according to a formula of the white pulp, high speed dispersion is conducted on the materials for 10 min to 15 min, then the dispersed materials enter a sand mill to be milled till the fineness is smaller than 5 micrometers, and the white pulp is obtained; material feeding is conducted according to a formula of the white paint in sequence, stirring is conducted to be uniform, and the water-borne white paint is obtained. The water-borne one-component white paint has the advantages of being excellent in storage stability, freeze-thaw stability, covering capacity, water resistance, chemical resistance, weather resistance, application property, anti-sagging property and drying speed.

Owner:GUANGDONG YATU CHEM

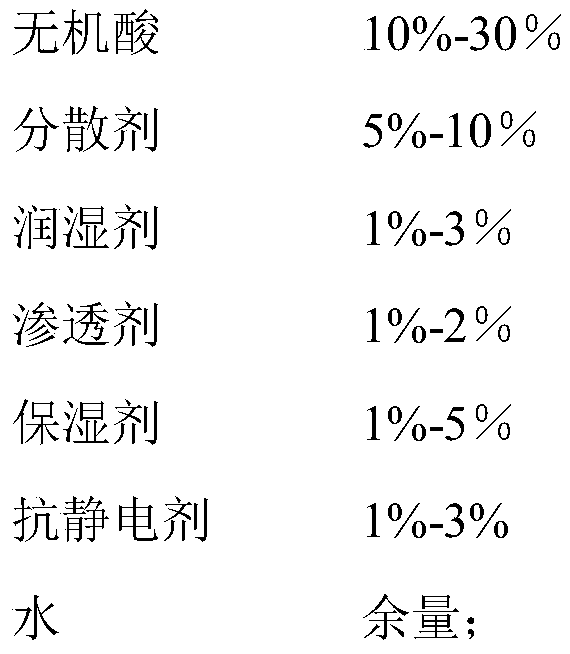

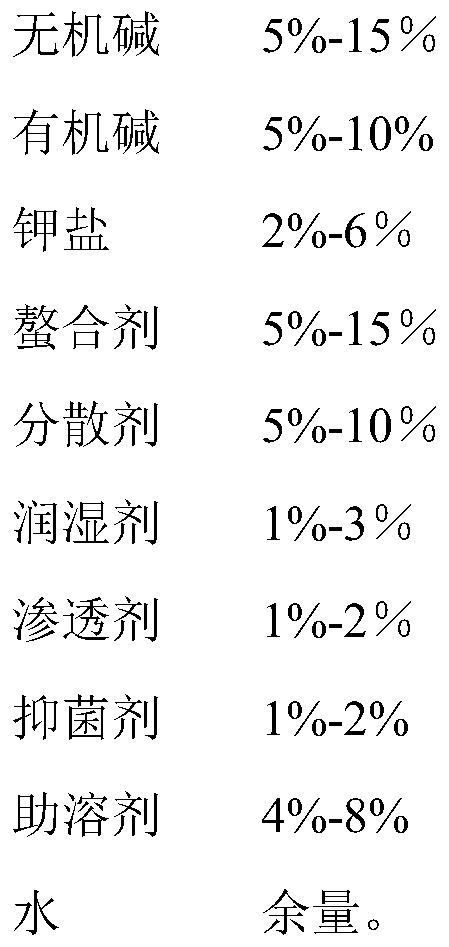

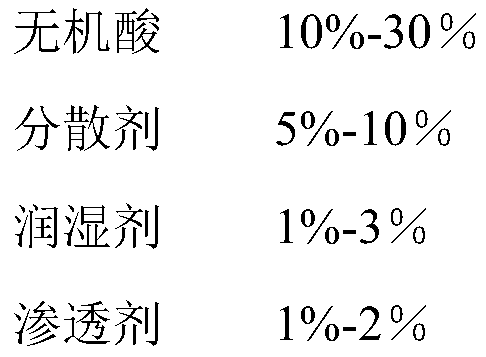

Glass cover plate cleaning agent and cleaning method thereof

InactiveCN111073767AGood cleaning effectTransparent surfaceInorganic/elemental detergent compounding agentsCationic surface-active compoundsMegasonic cleaningOrganic inorganic

The invention relates to the technical field of glass cover plate cleaning, in particular to a glass cover plate cleaning agent and a cleaning method thereof, and the glass cover plate cleaning agentcomprises an acidic cleaning agent and an alkaline cleaning agent; the method comprises the following steps: putting the glass cover plate into an ultrasonic cleaning machine, firstly cleaning the glass cover plate for 2-6 minutes at the temperature of 40-80 DEG C by adopting the acidic cleaning agent, then cleaning the glass cover plate for 5-15 minutes at the temperature of 40-80 DEG C by adopting the alkaline cleaning agent, then washing the glass cover plate with water, and then drying the glass cover plate. According to the cleaning agent, by adopting the dispersing agent, small-particleimpurities adhered to the surface of the glass cover plate can be separated, fingerprints, dust, glass powder, grease and other organic and inorganic solid particles on the surface of the glass coverplate are effectively removed, and the cleaning effect is good. The cleaning method disclosed by the invention is particularly suitable for cleaning polished 2.5 D and 3D glass, can avoid a manual brushing process and use of a strong alkaline cleaning agent, and can improve the cleaning efficiency and the cleaning yield.

Owner:DONGGUAN JINGBO PHOTOELECTRIC BIT CO

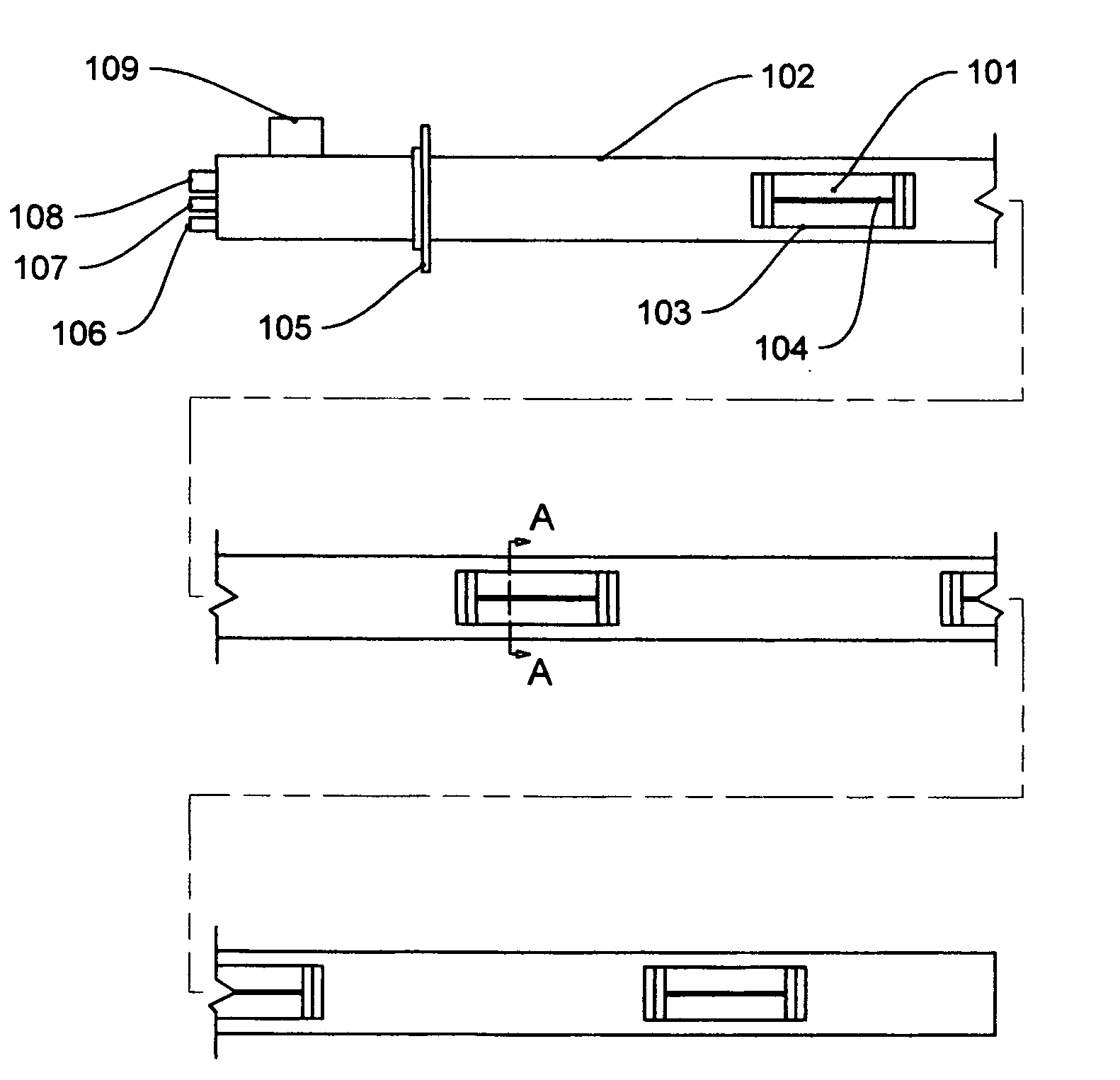

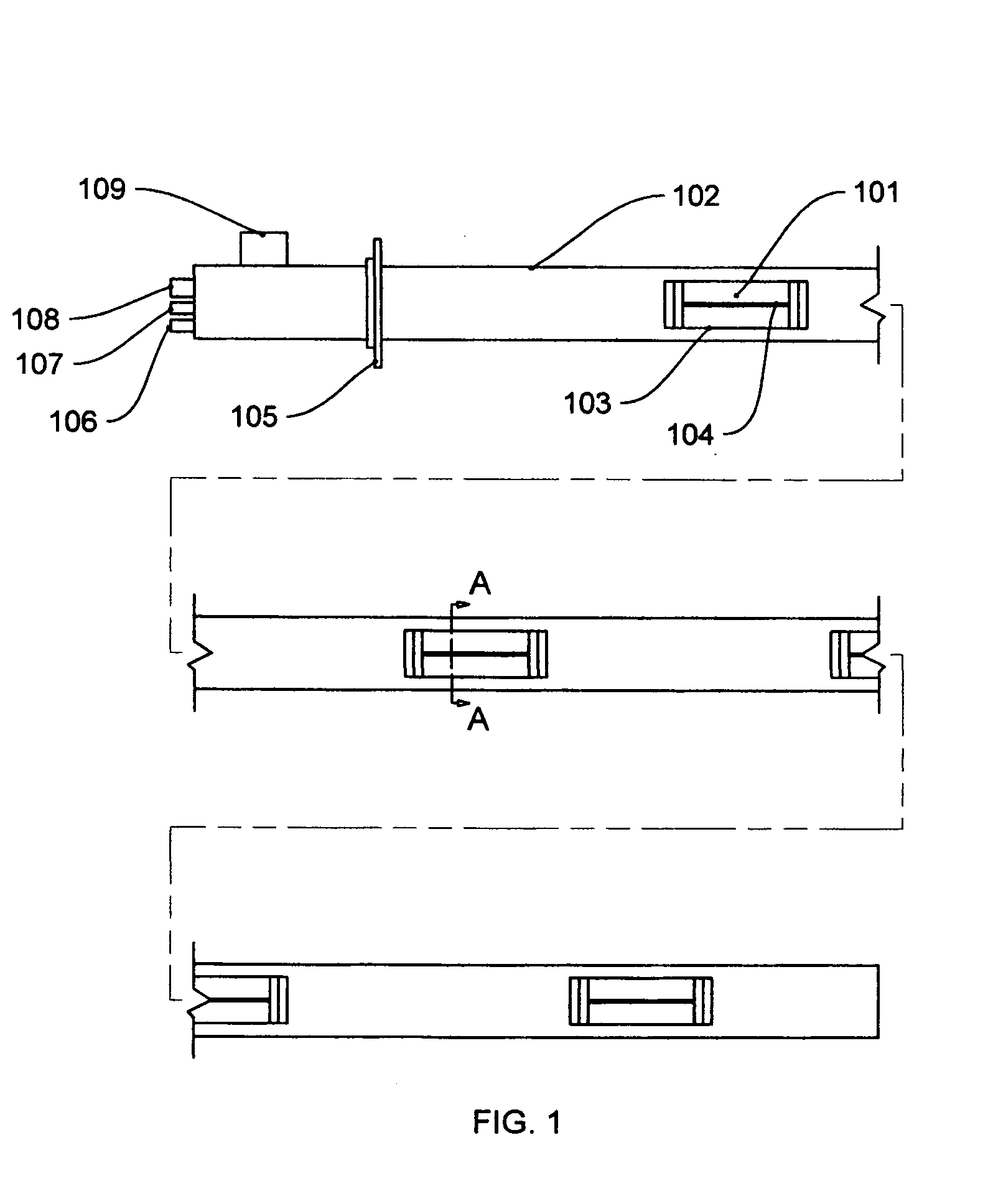

Joining the mixing and variable gas atomizing of reactive chemicals in flue gas cleaning systems for removal of sulfur oxides, nitrogen oxides and mercury

InactiveUS7731100B2Affordable retrofit and new installation costQuick wetCombination devicesGas treatmentChemical reactionSlurry

Diverse methods of utilization and the corresponding, related modifications, of linear type, Variable Gas Atomization (VGA) nozzles and lances are described. Therein is joined the mixing and gas atomization of chemicals that react to form active products that further react with harmful flue gas constituents of combustion so as to enable their effective collection. One version combines, in a lance assembly of nozzles, the injection of reactants, in the form of finely divided dry solids conveyed in a carrier air stream, and the fine atomization of water, aqueous solutions or slurries. Atomization of such streams is employed to effectively wet the surfaces of the dry particles and, thereby, promote the rapid sorption of gaseous constituents of flue gas being treated. Another version simultaneously mixes and atomizes reacting chemicals to produce, and release into the flue gas stream, strongly oxidizing, transient, species of their reaction products. The simultaneous atomization and chemical reaction enables the effective capture of targeted flue gas constituents.

Owner:WALSH JR WILLIAM ARTHUR

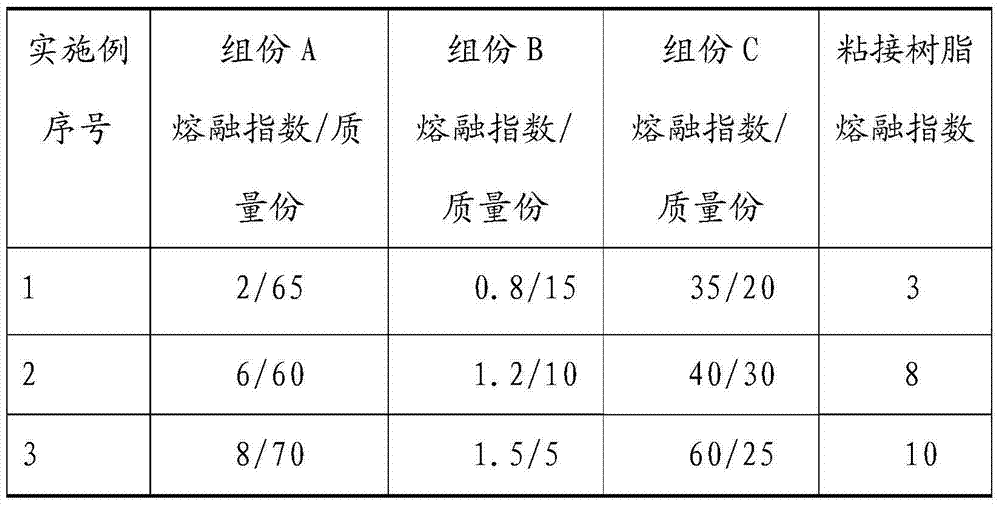

Adhesive resin for multilayer coextrusion barrier package and barrier structure prepared from same

ActiveCN103756595AGood adhesionEasy to processSynthetic resin layered productsAdhesivesElastomerAlpha-olefin

The invention discloses an adhesive resin for multilayer coextrusion barrier package and a barrier structure prepared from the same. The adhesive resin comprises the following components in parts by weight: 85-55 parts of propylene-ethylene-alpha olefin copolymer, 5-15 parts of vinyl elastomer and 10-30 parts of functionalization modified propylene-alpha olefin copolymer. The barrier structure comprisesa barrier layer, wherein at least one surface of the barrier layer is bonded with a polypropylene layer through an adhesive layer; the adhesive layer is the adhesive resin in the first target; the barrier layer is an ethylene-vinyl alcohol copolymer or nylon; and the adhesive resin accounts for 10-15 wt% of the barrier structure. The adhesive resin has the advantages of favorable bonding property, favorable working properties, fewer crystal points, high transparency and the like.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

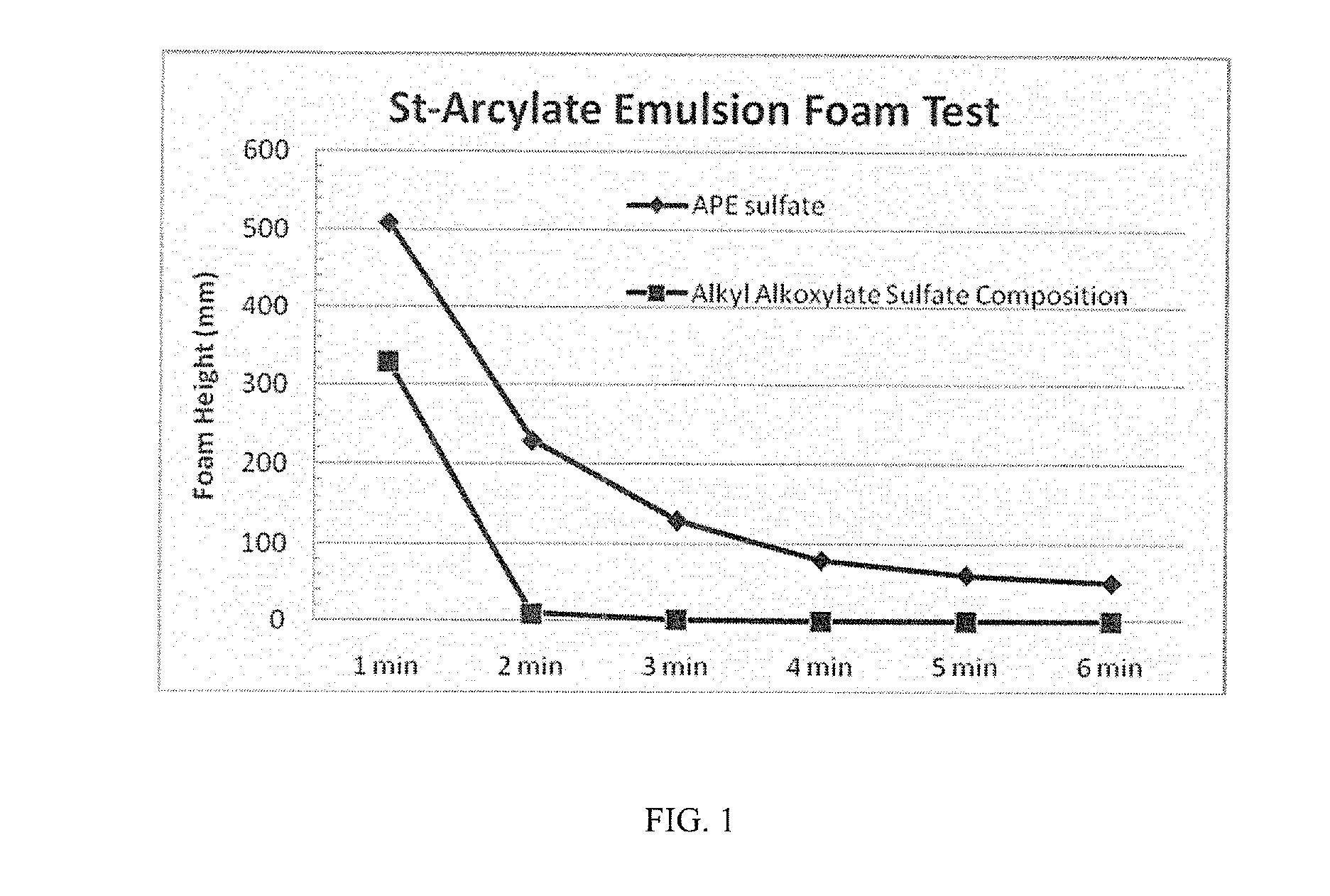

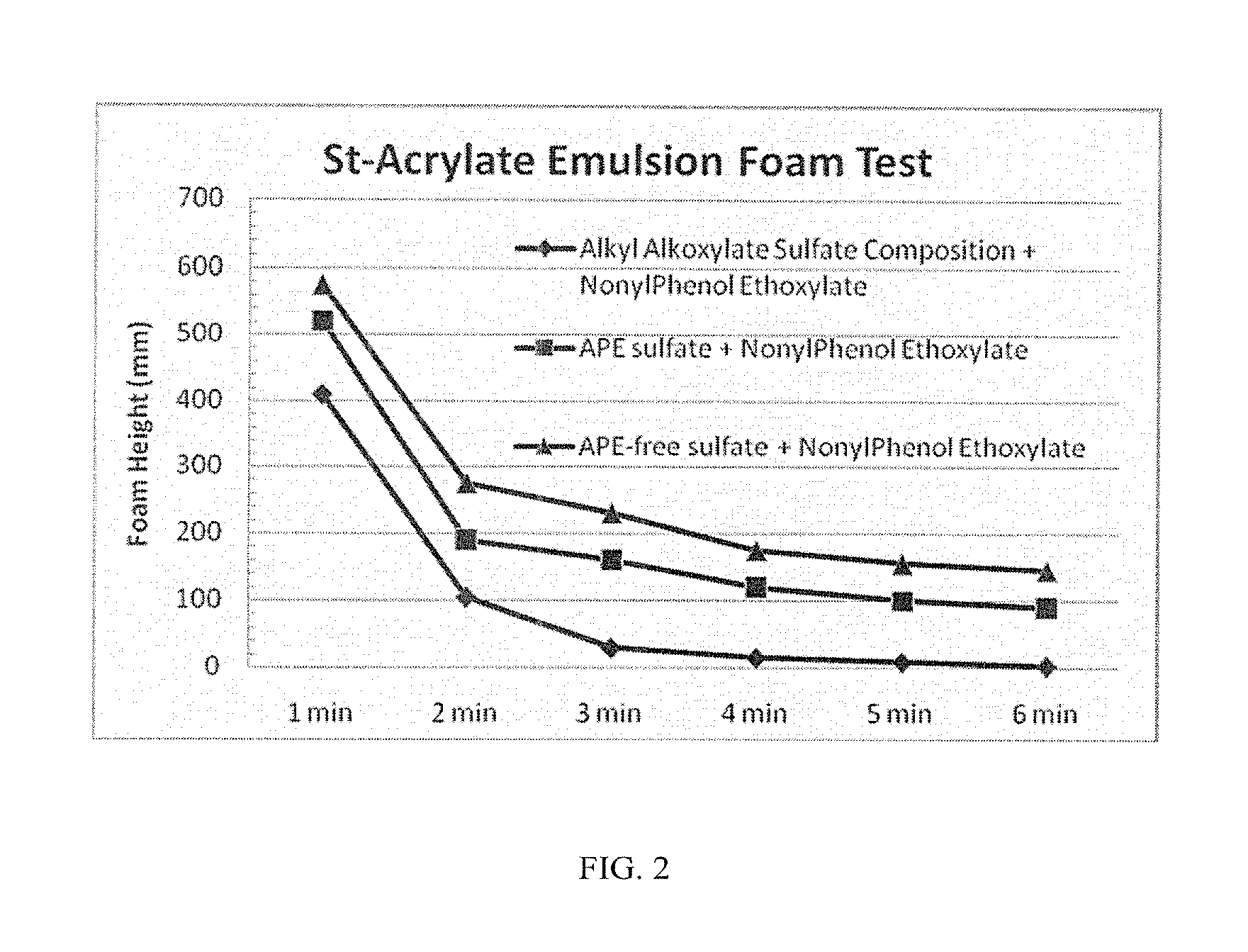

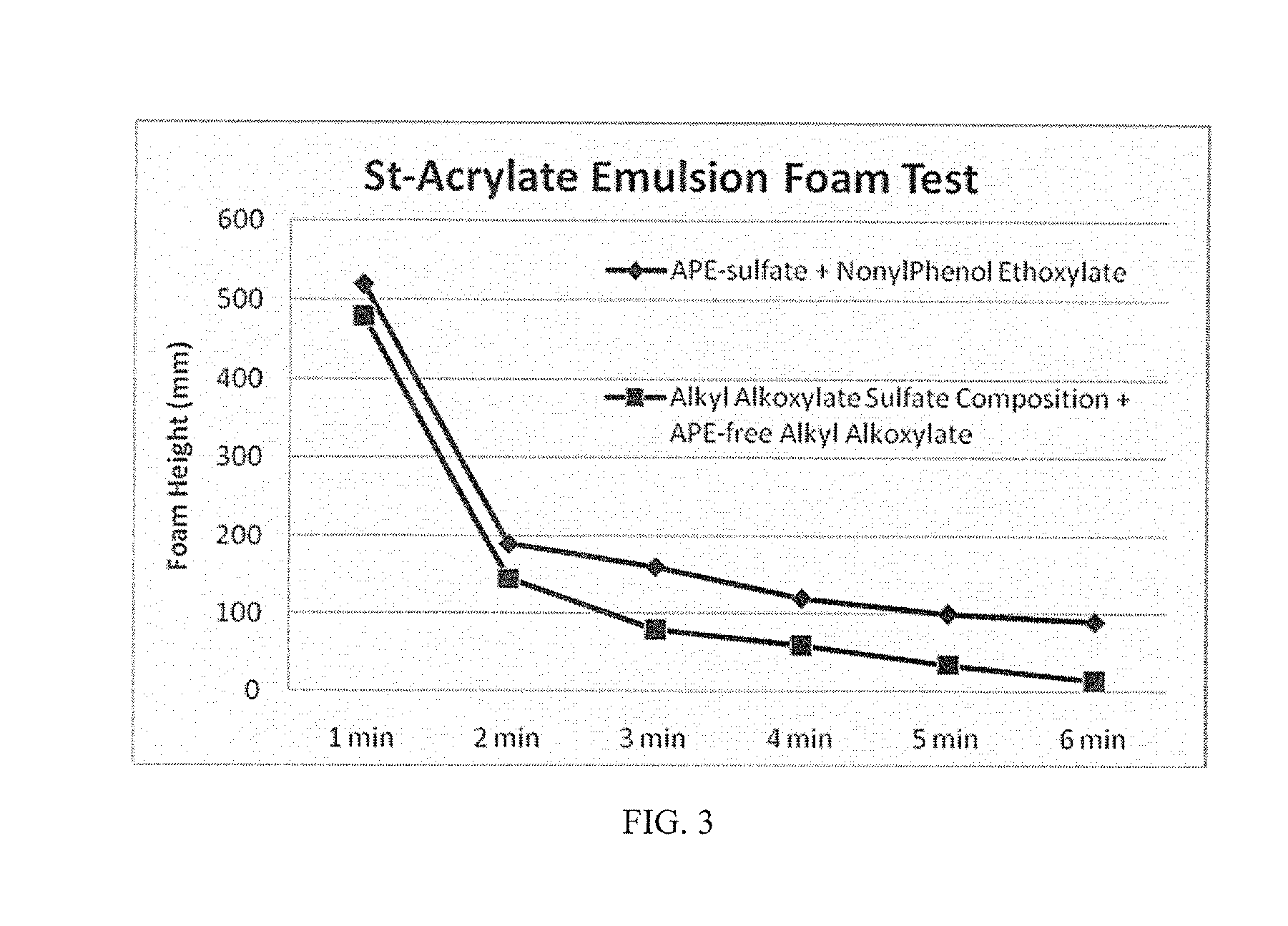

Anionic surfactant compositions and use thereof

ActiveUS20150224462A1Increase surface tensionLow foamingOrganic chemistryOther chemical processesEmulsion polymerizationSulfate

Provided are surfactant compositions that are useful as alternatives to alkylphenol ethoxylates (APEs) type surfactants in emulsion polymerization. The surfactant compositions comprise: an alkyl alkoxylate sulfate of formula (I): R1O—(CH2CH(R2)—O)x—(CH2CH2O)y—SO3M wherein R1, R2, x, y, and M are as defined herein.

Owner:DOW GLOBAL TECH LLC

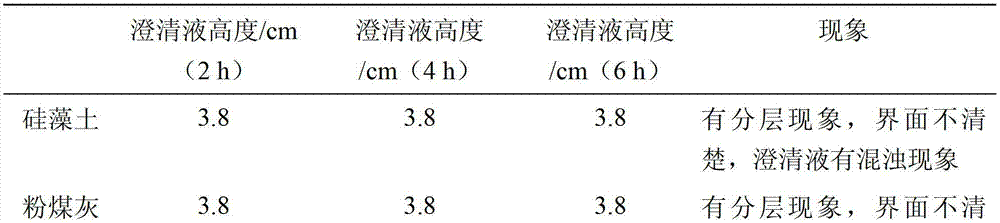

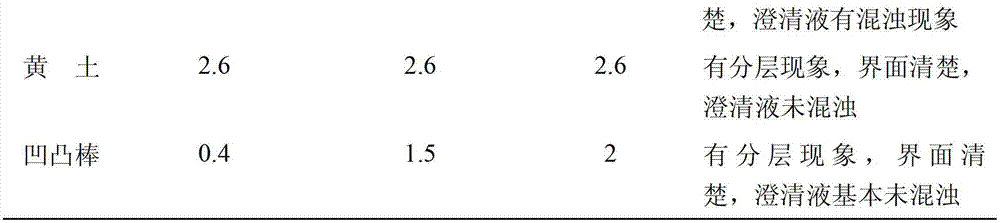

Extinguishing material for coal mine, and production method thereof

The invention relates to extinguishing material for coal mine and a production method thereof and belongs to the field of coal mine materials for fire preventing and extinguishing. The extinguishing material is made by mixing well 5-15wt% of attapulgite, 1-5wt% of salt-resistant super-absorbent polymer and water. Preparation of the salt-resistant super-absorbent polymer includes: adding 3 parts of acrylic acid into an ice bath, neutralizing with sodium hydroxide, adding 4 parts of acrylamide to from a monomer, and sequentially adding potassium peroxodisulfate accounting for 0.25% of the total weight of the monomer and N, N-methylene bisacrylamide accounting for 0.25% of the total weight of the monomer; heating a water bath to 70 DEG C, allowing for reaction for 7h, and filtering and drying the cooled reaction product. Aggregate using the attapulgite as colloid is fine in suspendability and large in specific area, the obtained colloid is remarkably uniform and long in shelf life.

Owner:BEIJING UNIV OF TECH

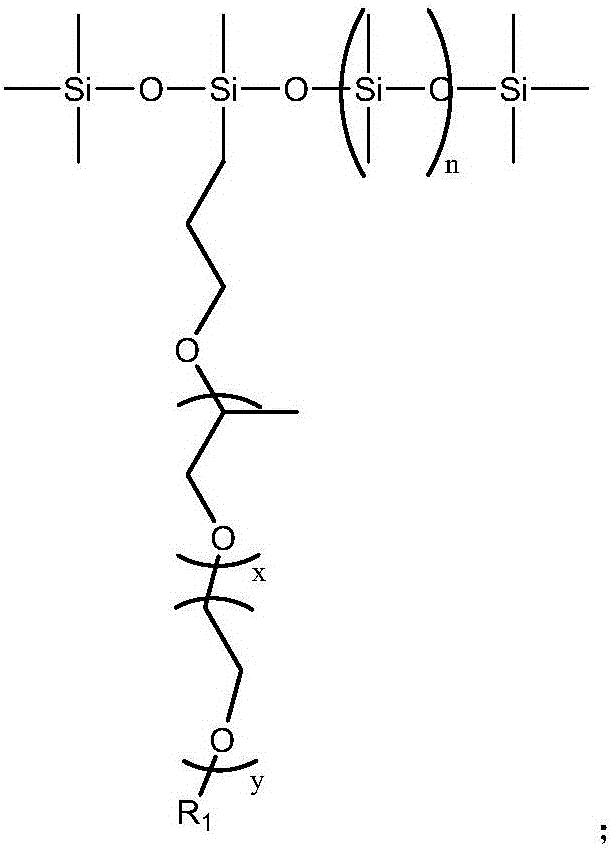

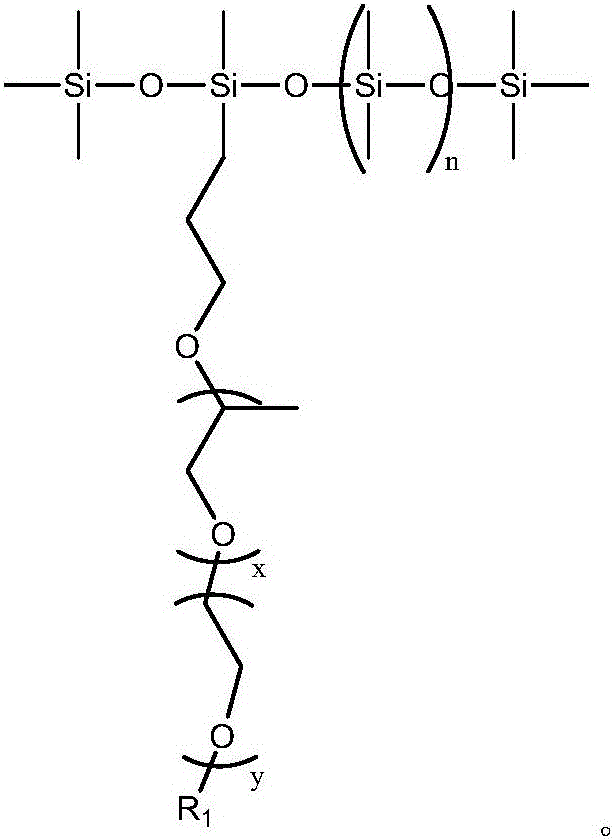

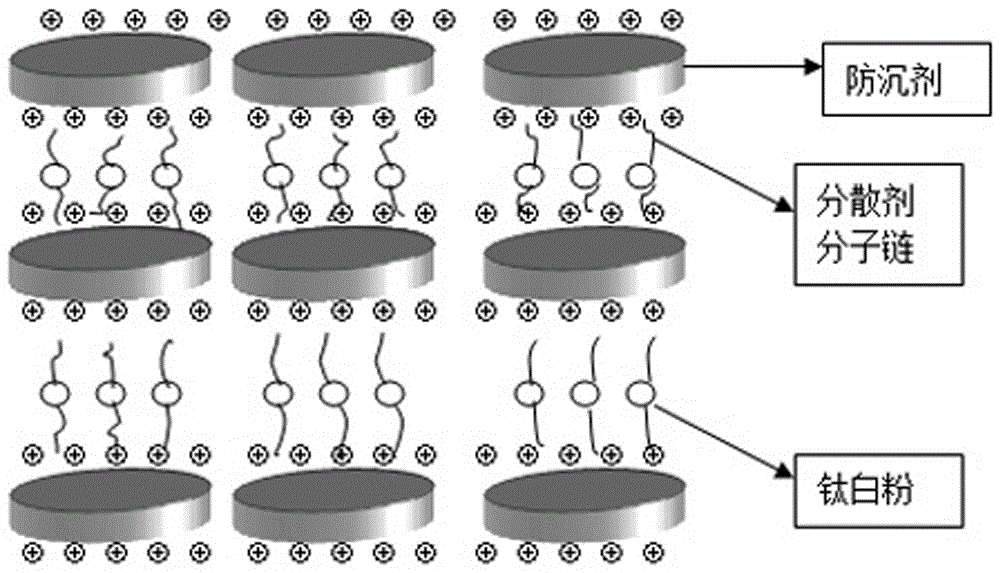

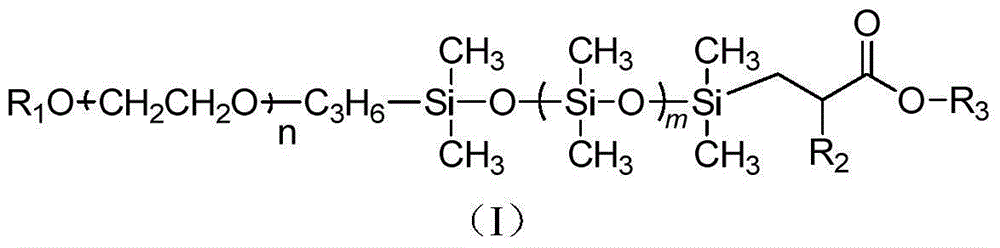

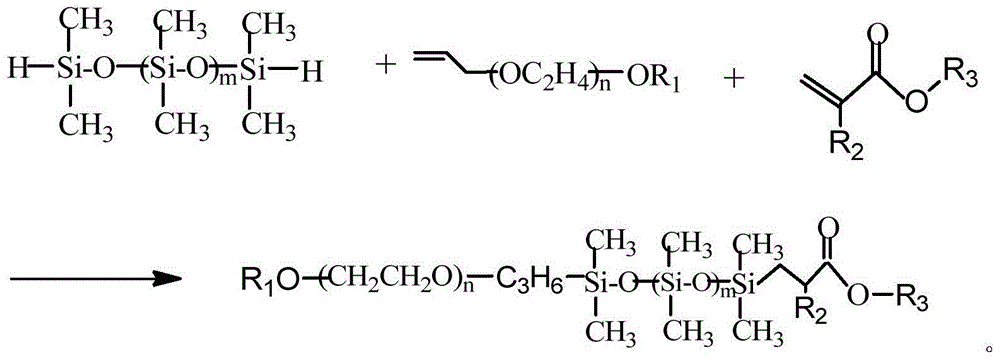

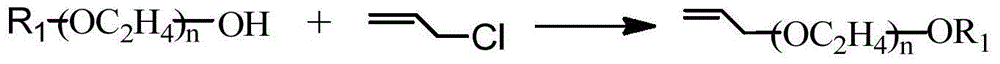

Block polysiloxane polymer and pigment dispersant containing same

The invention discloses a block polysiloxane polymer with a structure shown by a formula (I) shown in the specification, wherein n is 5-100, m is 10-200, R1 is H, -CH3, -CH2CH3 or -CH2CH2CH3, R2 is H, -CH3, -CH2CH3 or -CH2CH2CH3, and R3 is H or C1-C20 alkane or C1-C20 alkyl containing hydroxy. An acrylic acid or methacrylate block in the block polysiloxane polymer is an anchoring chain segment which can be adsorbed on the surface of organic pigment particles under the action of hydrogen bonds, acid-base action and covalent bonds; in a waterborne system, a polyether block is used as a solvation chain and can be well dissolved in a dispersion medium, the steric hindrance of the polyether block can prevent the pigment particles from flocculation, and the polyether block can quickly wet the organic pigment particles and shorten the grinding time; a polysiloxane chain can effectively improve the fluidity and coloring power of the pigment; and the polyether block is used as a dispersant of the solvation chain, and has a good dispersion effect on the pigment in the waterborne system.

Owner:杭州百合辉柏赫颜料有限公司 +1

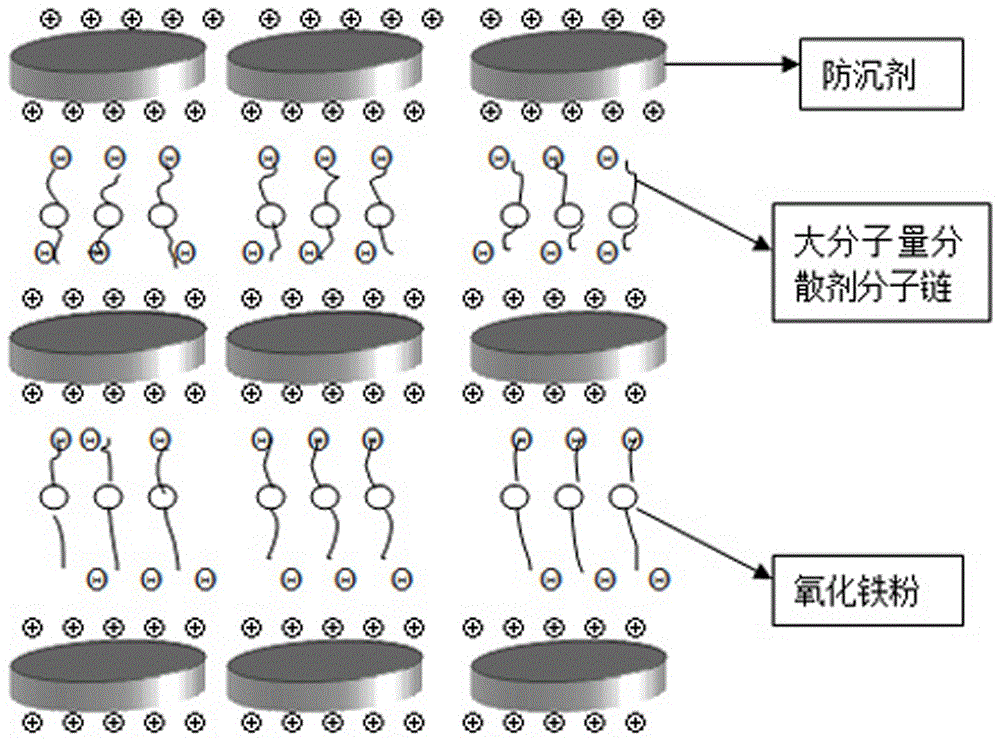

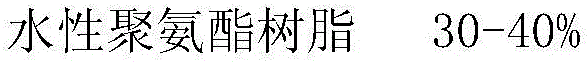

Water-based one-component automobile paint containing iron oxide pigment and preparation method of water-based one-component automobile paint

ActiveCN105885658AGood storage stabilityGood lookingPolyurea/polyurethane coatingsPigment pastesWater basedFreeze thawing

The invention discloses water-based one-component automobile paint containing iron oxide pigment and a preparation method of the water-based one-component automobile paint. The water-based one-component automobile paint containing the iron oxide pigment is prepared from resin, an amine neutralizer, iron oxide color paste and an assistant, wherein the iron oxide color paste is prepared from deionized water, a cosolvent, an assistant and iron oxide powder. The preparation method comprises the following steps of firstly, feeding materials according to a formula of the iron oxide color paste, and then dispersing at high speed for 10 to 15 minutes; secondly, entering a sand mill and grinding until the fineness is smaller than 5 microns, thus obtaining the iron oxide color paste; thirdly, sequentially feeding the materials according to the formula of the iron oxide colored paint, and uniformly stirring to obtain water-based iron oxide colored paint. The water-based one-component iron oxide colored paint provided by the invention has the advantages of excellent storage stability, excellent freeze-thaw stability, excellent covering power, excellent water resistance, chalking resistance and weather resistance, excellent constructability and sagging resistance, and great drying speed.

Owner:GUANGDONG YATU CHEM

Ultraviolet light chain type initiated self-reaction low-viscosity high-thickness full-curing glue

ActiveCN113088239ALow viscosityImprove wettabilityPolyureas/polyurethane adhesivesMethacrylatePolymer science

The invention discloses an ultraviolet light chain type initiated self-reaction low-viscosity high-thickness full-curing glue. The ultraviolet curing glue is prepared from the following substances in parts by mass: 10 to 30 parts of polyurethane (methyl) acrylate, 0 to 10 parts of trifunctional / multifunctional (methyl) acrylate, 5 to 30 parts of bifunctional (methyl) acrylate, 50 to 80 parts of monofunctional (methyl) acrylate and 0.1 to 3.0 parts of photoinitiator. The ultraviolet curing glue is low in viscosity, easy to defoam, good in wettability, convenient to use, high in curing speed, moderate in heat release, high in test block transparency and good in surface state, is suitable for packaging of electronic products, and is particularly suitable for packaging detection of metallographic cold-embedded printed circuit boards needing rapid testing.

Owner:YANTAI UNIV

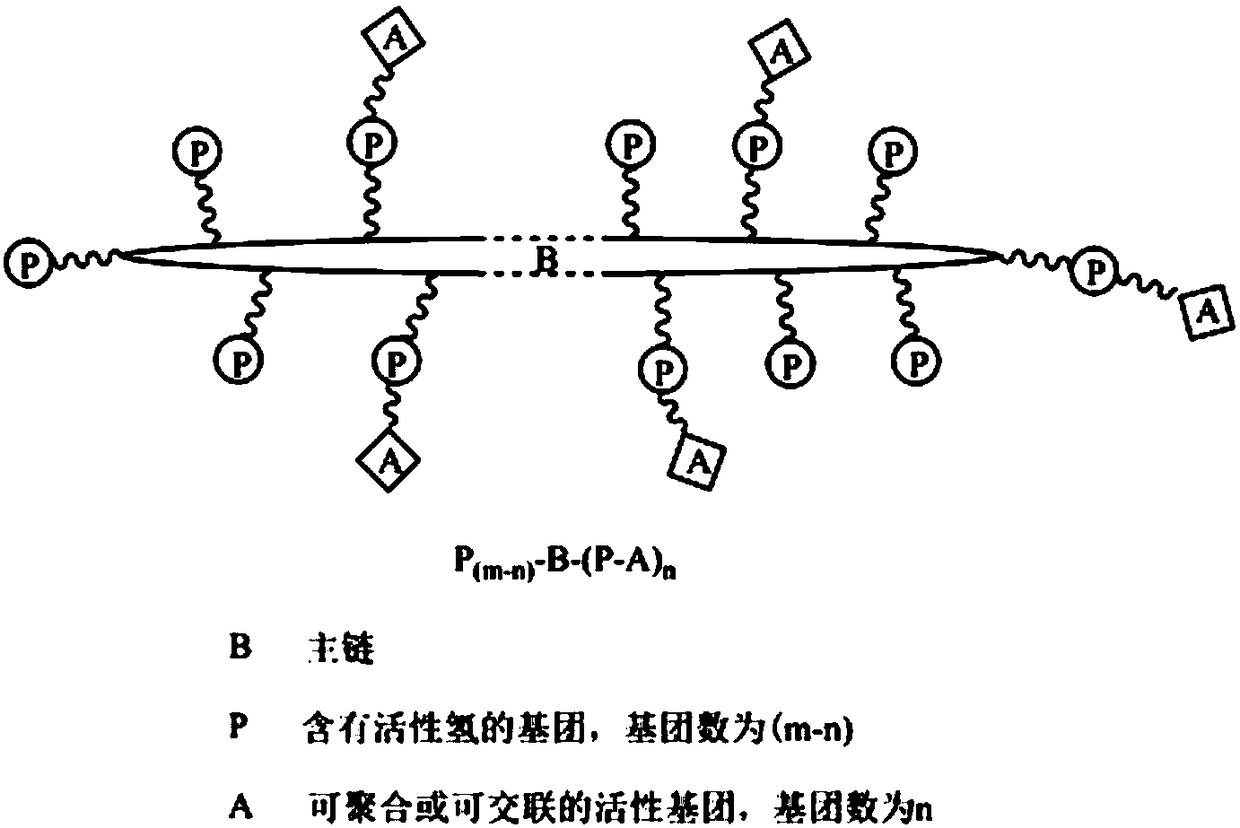

Long-acting hydrophilic material

ActiveCN108503791AImprove hydrophilicityHas the ability to absorb waterHydrophilic monomerChemical Linkage

The invention discloses a long-acting hydrophilic material. The long-acting hydrophilic material is characterized by being mainly prepared from the following components of hydrophilic resin with polymerizing and / or crosslinking active groups, a hydrophilic monomer with polymerizing and / or crosslinking active groups, hydrophobic resin with polymerizing and / or crosslinking active groups, a hydrophobic monomer with polymerizing and / or crosslinking active groups, an ionic surfactant, a curing additive and / or an additive, wherein the type of the hydrophobic resin is the same with the type of the hydrophilic resin; the components are uniformly mixed, and are subjected to thermal chemical reaction or optical chemical reaction, and the hydrophilic components and the hydrophobic components are polymerized and / or crosslinked by chemical bonds, and are entrapped with the ionic surfactant to be compounded together, so as to obtain the long-acting hydrophilic material. The long-acting hydrophilic material has the advantages that the hydrophilic property is high, the effectivity is maintained for a long time, the anti-fog property is high, the wiping-resistant property is excellent, the good adhesion force to a substrate is realized, the optical transparency is high, and the heat stability is high.

Owner:武汉铌欧能源材料有限公司

High shearing production method for film coating agent

ActiveCN101559231AOvercoming electrostatic attractionAvoid destructionPharmaceutical delivery mechanismPharmaceutical non-active ingredientsLow speedPlasticizer

The invention relates to a high shearing production method for a film coating agent. The innovation of the invention is that the production method comprises the following steps of: refining of a colorant, coating of the colorant, compounding of the coated colorant, and plasticization of a mixture. The invention provides the innovative high shearing production method for the film coating agent, adopts a high-speed shearing mode to perform dry dispersion on an insoluble colorant, coats a surfactant to prevent the colorant from agglomerating at the same time, finishescomplete mixing of a film former and even distribution of a plasticizer under low-speed shearing conditions, and has the advantages of high production efficiency, low energy consumption, good application performance of obtained finished products of the coating agents and the like.

Owner:TIANJIN BOKELIN MEDICINE PACKAGING TECH

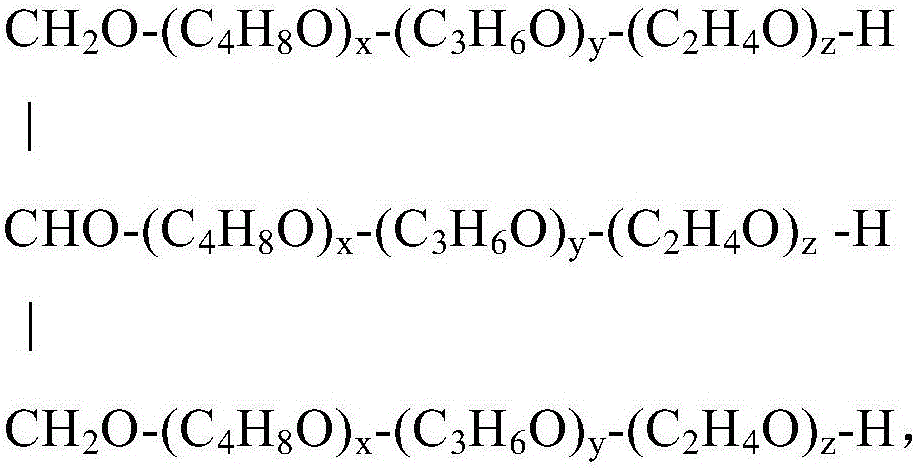

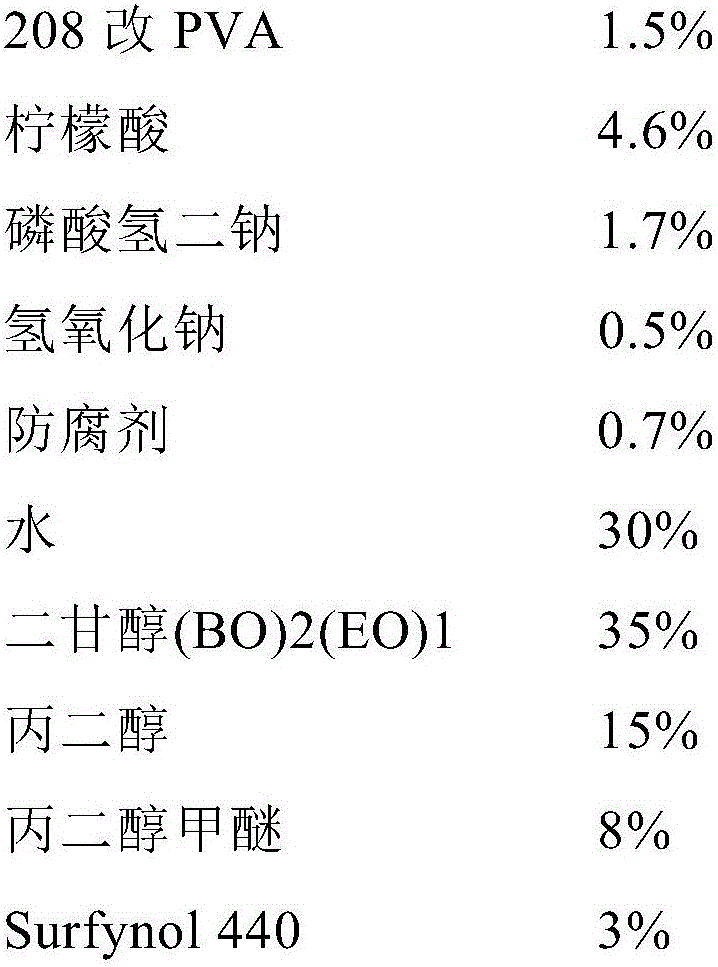

Environment-friendly ethyl-alcohol-free fountain solution

The invention relates to an environment-friendly ethyl-alcohol-free fountain solution. The environment-friendly ethyl-alcohol-free fountain solution is prepared from the following components and raw materials including, by mass, 0.03-3.33 parts of water-soluble polymer film-forming components, 3.7-5.5 parts of citric acid, 1.4-2 parts of disodium hydrogen phosphate, 0.4-0.6 part of sodium hydroxide, 0.5-0.9 part of preservative, 24-36 parts of water, 30-38 parts of a wetting solvent, 12-18 parts of lubricating components, 6.4-9.6 parts of a dissolving solvent and 2.4-3.6 parts of Surfynol 440. Compared with the prior art, the modified polyvinylalcohol water-soluble polymer film-forming components and diethylene glycol or glycerin tetrahydrofuran / propylene oxidation / ethoxyquin wetting solvent have the beneficial effects that the viscosity and the diffusion film forming speed are both achieved, rapid wetting is achieved, the ability of rapidly, clearly and evenly spreading the corners is achieved, and the dynamic surface tension is rapidly reduced. The environment-friendly propylene glycol series lubrication components and the environment-friendly propylene alcohol ether series dissolving solvent enable the ethyl-alcohol-free fountain solution to be more environmentally friendly.

Owner:上海数印智能科技股份有限公司

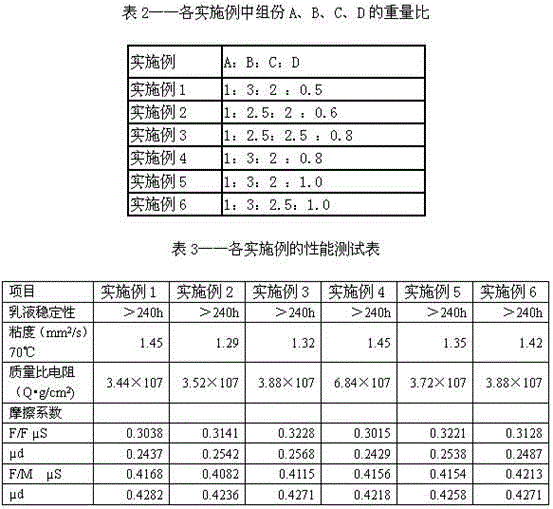

Environment-friendly acrylic spinning oil

The invention discloses environment-friendly acrylic spinning oil comprising a component A, a component B, a component C and a component D in the weight ratio of 1:(2-4):(1-3):(0.5-1), wherein the component A is gemini quaternary ammonium salt with the general formula of [RN(R1)2(R2)3]<2+>X<2->; the component B is polyol fatty acid ester with the general formula of RCOO(CH2CH2O)nH or RCOO(CH2CH2O)nCOOR; the component C is heterogeneous fatty alcohol polyoxyethylene ether with the chemical formula of R1R2O(CH2CH2O)mH; the component D is amino silicon oil with the chemical formula of R1(CH3)2SiO[(CH3)2SiO]m[(R2)(CH3)SiO]nSi(CH3)2R1; R1 is methyl or hydroxyl; and R2 is amino hydrocarbyl with primary amine and secondary amine. The environment-friendly acrylic spinning oil is good in antistatic property, flexibility, gliding property and bundling property, good in biodegradability and environment-friendly.

Owner:安庆五宁精细化工有限责任公司

Silicone pressure sensitive adhesive compositions and protective films containing the same

ActiveUS20160355714A1Improve cleanlinessReduce adhesionPressure sensitive film/foil adhesivesTectorial membraneHydrosilylation

There is provided herein a silicone pressure sensitive adhesive composition comprising (A) a linear olefinically-functional polyorganosiloxane copolymer gum possessing a degree of polymerization in excess of 3,000; (B) a silicone resin including at least one MH unit and at least one Q unit; and, (C) a hydrosilylation catalyst, wherein the composition is in the substantial absence of low molecular weight siloxane having a degree of polymerization of less than 3,000 and wherein the composition has low peel adhesion to and clean removal from a substrate. There is also provided a protective film including the same as well as a method of making the protective film.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

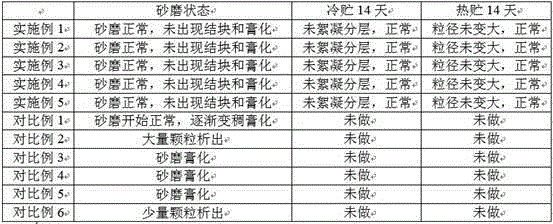

Suspending agent containing pyraclostrobin and difenoconazole and preparation method of suspending agent

InactiveCN105191959ASpecial structureImprove adsorption capacityBiocideFungicidesSuspending AgentsDefoaming Agents

The invention belongs to the field of pesticides, and particularly relates to a suspending agent containing pyraclostrobin and difenoconazole and a preparation method of the suspending agent. The suspending agent comprises, in percentage by mass, 0-40% of a pyraclostrobin original, 0-40% of a difenoconazole orignal, 5%-8% of a polycarboxylate dispersing agent DSC2006, 1%-4% of a modified polyether wetting agent W2006, 1%-6% of a thickening agent, 0.1%-2% of a defoaming agent, 1%-6% of an anti-freezing agent and the balance of water.

Owner:北京中农益田化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com