Cord thread spinning oil

A technology for spinning oil and cord, applied in textile and papermaking, chemical post-treatment of synthetic polymer rayon, fiber type, etc., can solve the problem of low fiber breaking strength, poor oil penetration, and smoke Large and other problems, to achieve the effects of fast wetting and spreading speed, excellent high temperature resistance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

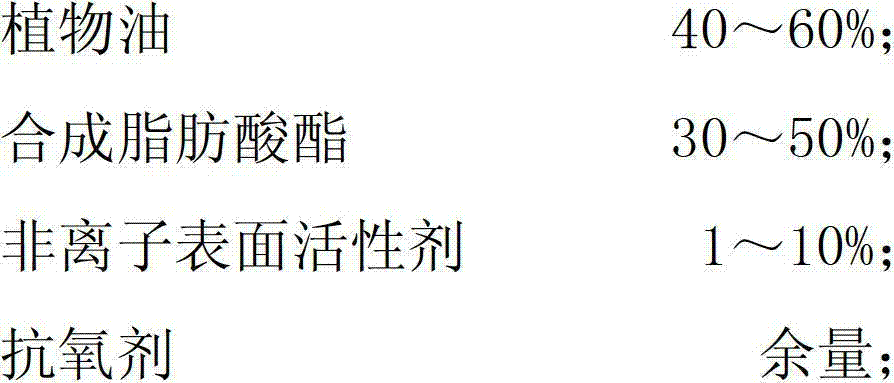

[0030] The weight percent of oil agent consists of:

[0031]

[0032] The preparation method of the oil agent is as follows: at a temperature of 45°C, add the following composition materials in the weight percent formula into a reaction kettle with a stirrer, and stir for 90 minutes to obtain the oil agent of the present invention. The viscosity of the oil is 87mm 2 / s, the solid content is 99.4%.

Embodiment 2

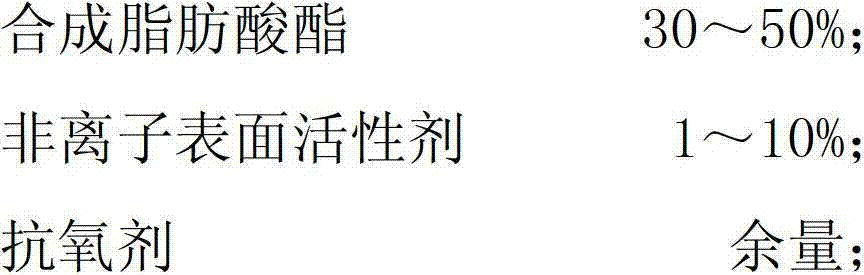

[0034] The oil agent of the present invention can be prepared by adding the following composition materials in the weight percent formula into a reaction kettle with a stirrer at a temperature of 40°C and stirring for 60 minutes. The viscosity of the oil is 93mm 2 / s, the solid content is 99.6%. The formula consists of:

[0035]

Embodiment 3

[0037] The oil agent of the present invention can be prepared by adding the following composition materials in the following weight percentage formula into a reaction kettle with a stirrer at a temperature of 35°C and stirring for 60 minutes. The viscosity of the oil is 76mm 2 / s, solid content 99.7%. The formula consists of:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com