Long-acting hydrophilic material

A hydrophilic material, long-term technology, applied in the composition and preparation field of long-term hydrophilic polymer materials, can solve the problems of lack of adhesion, non-smooth, uneven surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

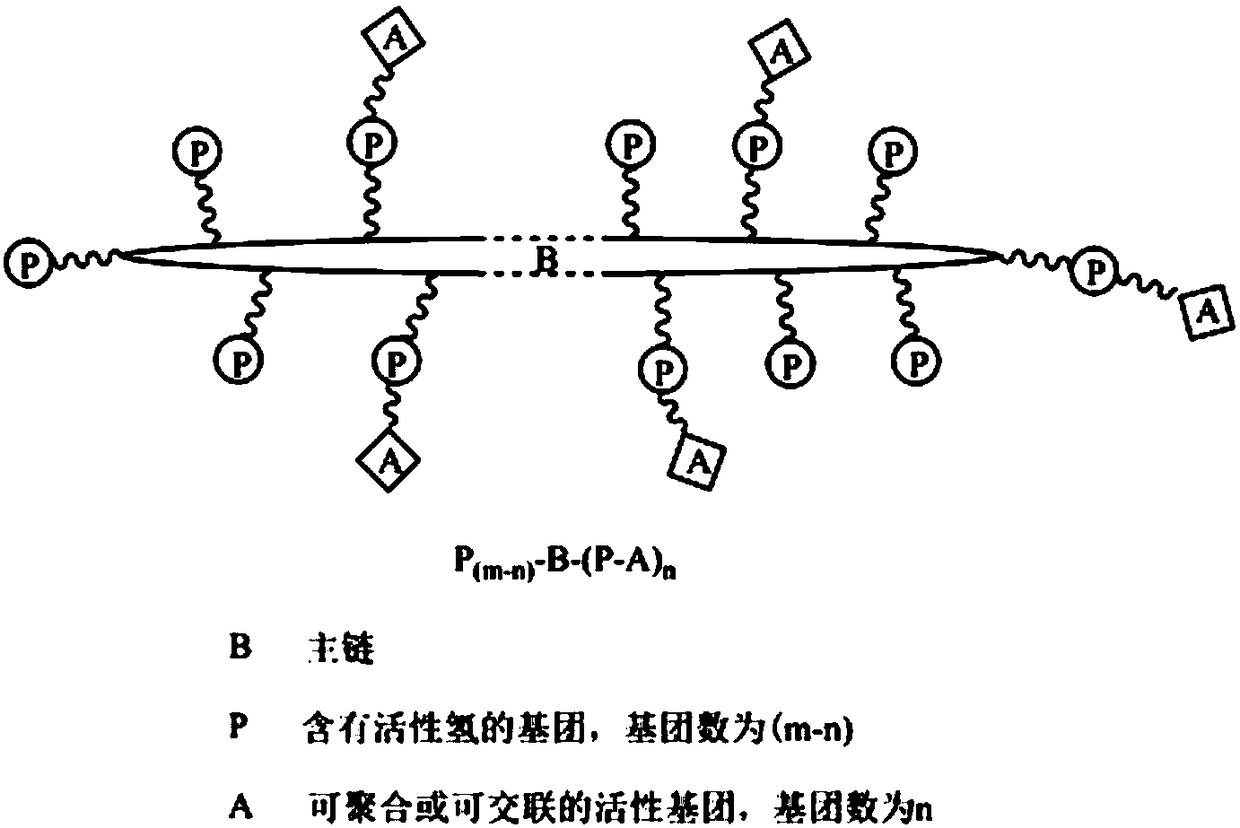

Image

Examples

Embodiment 1

[0070] Example 1 Synthesis and Preparation of Two Functional Groups, Polymerizable and / or Crosslinkable Polyurethane with Hydrophilic Properties

[0071] The first step: the monoadduct (TDI-HEA) of toluene diisocyanate and 2-hydroxyethyl acrylate (TDI-HEA), the intermediate, its synthesis process is as follows:

[0072] 1) In a clean 100mL three-necked flask, weigh 40.00g (0.2297mol) toluene diisocyanate (TDI) and 0.0669g (0.100wt%) dibutyltin dilaurate (DBTDL) successively, and then rapidly add A thermometer, a mechanical stirrer and a 50mL constant-pressure dropping funnel connected to a drying tube are respectively installed on each bottle mouth; in addition, 0.1004g (0.150wt%) p-methoxyphenol (MEHQ) is weighed successively, 0.06694g (0.100wt%) wt%) of 2,6-di-tert-butyl-p-cresol (BHT) and 26.67g (0.2297mol) of hydroxyethyl acrylate (HEA), mixed in a beaker, fully stirred with a glass rod until MEHQ and BHT are completely Dissolve to obtain a colorless or light yellow react...

Embodiment 2

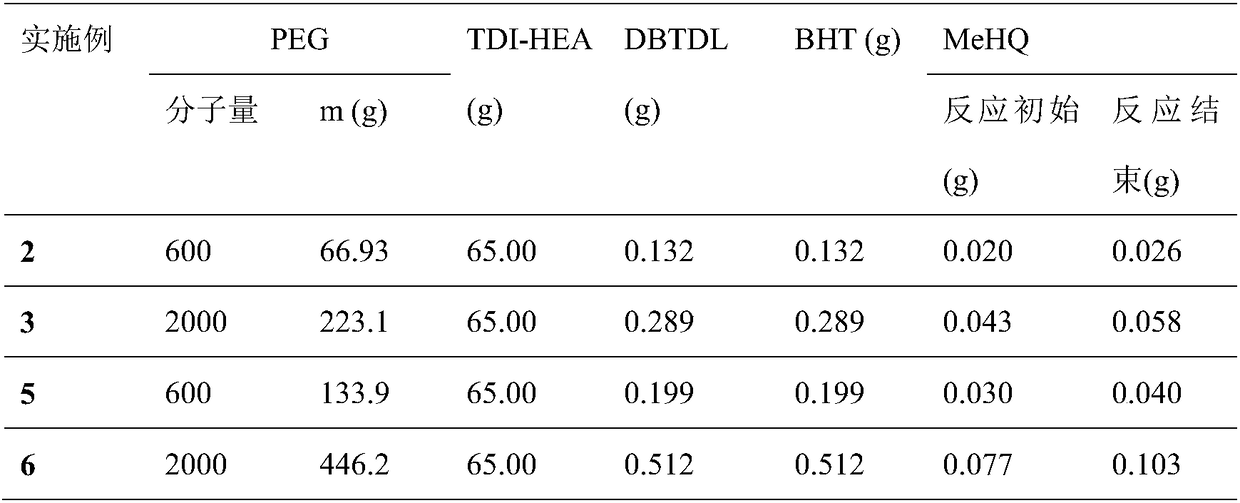

[0079] Example 2 Synthesis and preparation of two functional groups, polymerizable and / or crosslinkable polyurethane with hydrophilic properties-transforming the molecular weight of the main chain

[0080] The same steps as in Example 1 were adopted, but in the second step, PEG1000 was replaced with polyethylene glycol 600 (PEG600), and fed according to Table 1, to obtain polyethylene glycol 600 diurethane acrylate, marked as PEG600DUA.

Embodiment 3

[0081] Example 3 Synthesis and Preparation of Two Functional Groups, Polymerizable and / or Crosslinkable Polyurethane with Hydrophilic Properties-Transformation of Main Chain Molecular Weight

[0082] The exact same steps as in Example 1 were adopted, but in the second step, PEG1000 was replaced with polyethylene glycol 2000 (PEG2000), and fed according to Table 1, to obtain polyethylene glycol 2000 diurethane acrylate, marked as PEG2000DUA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com