Cleaning solution for light-emitting diode (LED) chip

A technology for LED chips and cleaning solutions, which is applied in detergent compounding agents, detergent compositions, surface-active detergent compositions, etc., can solve problems such as corrosion and low removal efficiency of LED chip cleaning agents, and reduce corrosion and Surface tension, corrosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

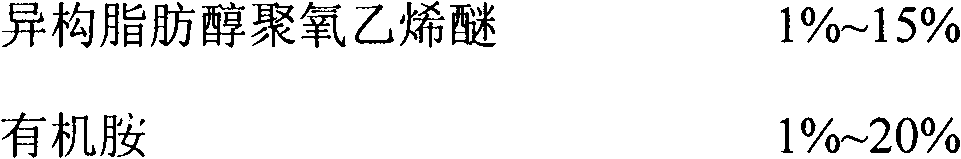

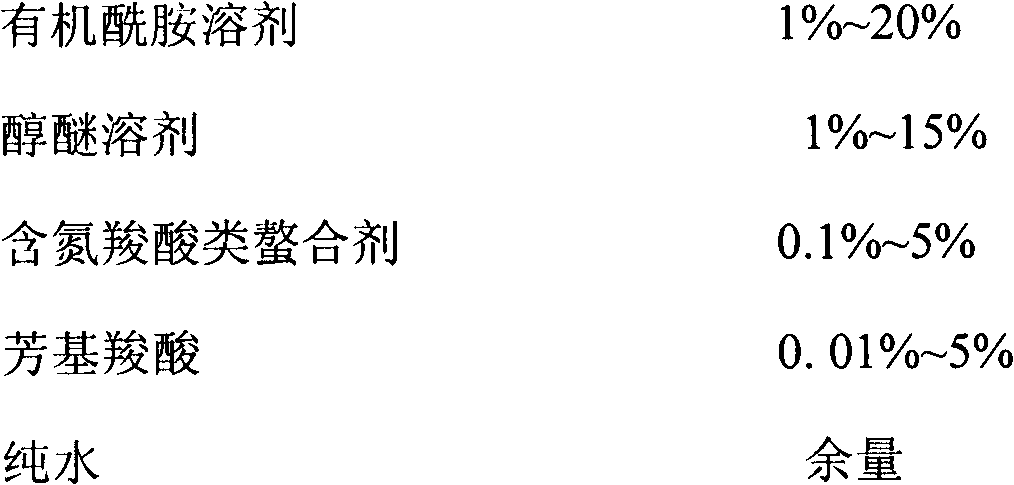

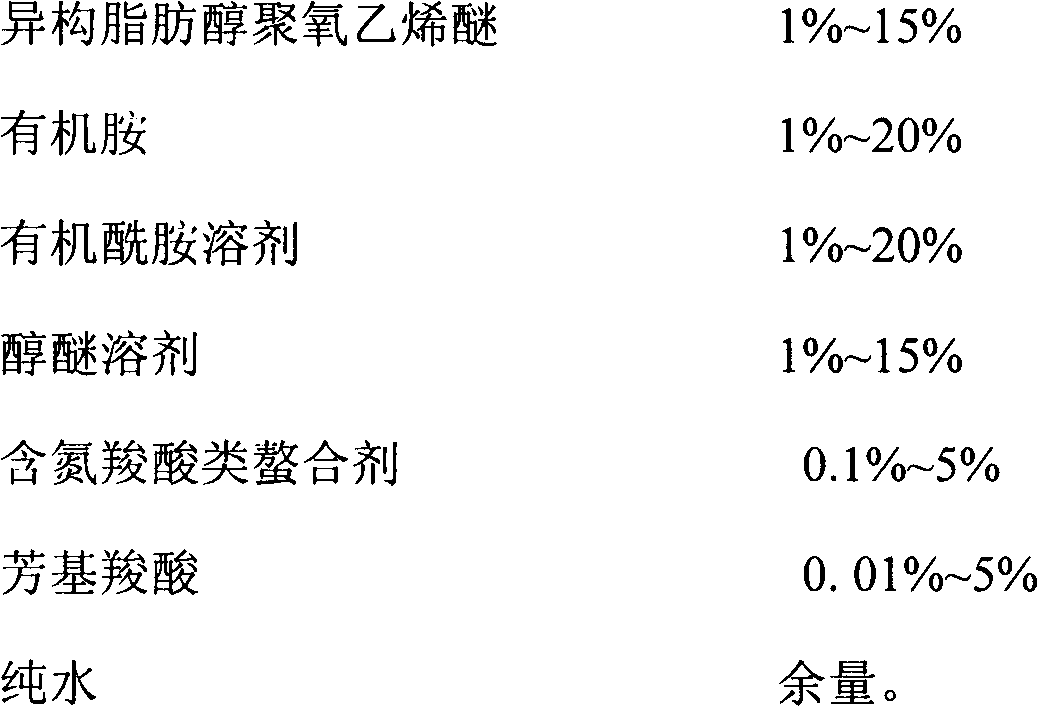

[0029] Raw material and weight percent are as follows: Isomerized fatty alcohol polyoxyethylene ether C 10 h 21 O(C 2 h 4 O) 7 H 15%, monoethanolamine 10%, N-methylpyrrolidone 20%, ethylene glycol monobutyl ether 15%, ethylenediaminetetraacetic acid 2%, benzoic acid 0.05%, pure water balance.

[0030] The cleaning method adopts the above method. Compared with the existing cleaning solution, after cleaning the surface pollutants on the LED chip, there is no residue on the chip surface, the cleaning efficiency is high, and the corrosion rate to the substrate material and metal wiring is very small.

Embodiment 2

[0032] Raw material and weight percent are as follows: Isomerized fatty alcohol polyoxyethylene ether C 10 h 21 O(C 2 h 4 O) 17 H 5%, diethanolamine 10%, N-methylpyrrolidone 5%, ethylene glycol monoethyl ether 10%, ethylenediaminetetraacetic acid sodium salt 1%, 2-ethylbenzoic acid 1%, pure water balance.

[0033] The cleaning method and cleaning effect are the same as in Example 1.

Embodiment 3

[0035] Raw material and weight percent are as follows: Isomerized fatty alcohol polyoxyethylene ether C 10 h 21 O(C 2 h 4 O) 7 H 1%, triethylamine 10%, N,N-dimethylformamide 20%, diethylene glycol monobutyl ether 10%, nitrilotriacetic acid sodium salt 1%, 3-ethylbenzoic acid 0.05% , Pure water balance.

[0036] The cleaning method and cleaning effect are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com