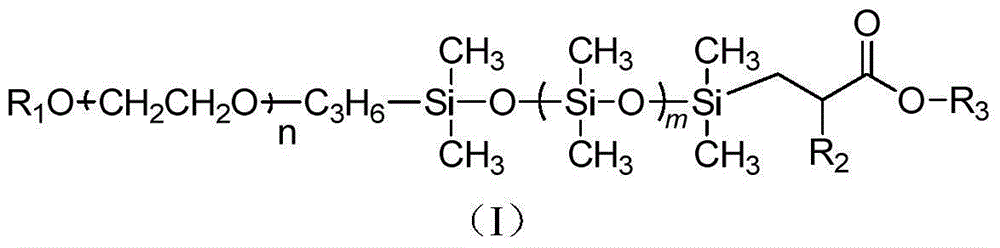

Block polysiloxane polymer and pigment dispersant containing same

A technology of polysiloxane and polymer, which is applied in the field of pigment dispersants, can solve the problems of unsatisfactory organic pigment effects, achieve the effects of shortening the grinding time, good dispersion effect, improvement of fluidity and tinting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

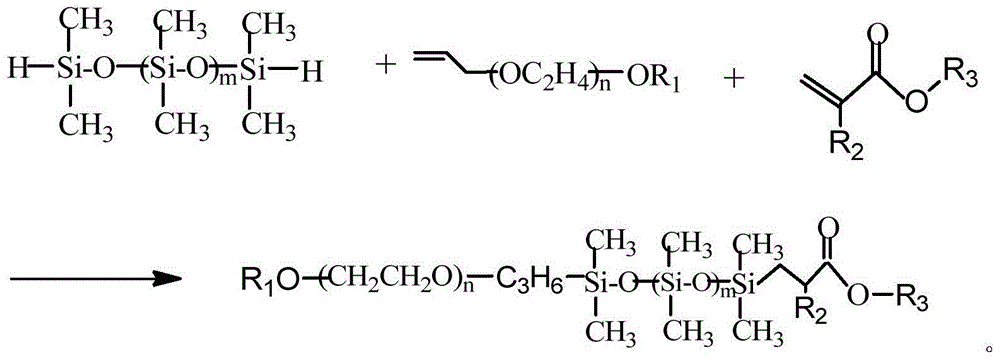

Method used

Image

Examples

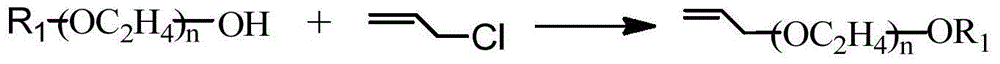

preparation example 1

[0043]10.00g polyethylene glycol (n=20), 8.00g sodium hydroxide, 0.8059g tetrabutylammonium bromide, 5.00g dichloromethane are placed in the four-necked flask that mechanical stirring and thermometer are housed, 15.33g Allyl chloride was slowly added dropwise to the reaction liquid, and after the dropwise addition was completed, the temperature was raised to 60°C and kept for 6 hours. After the reaction is complete, filter under reduced pressure to remove excess sodium hydroxide and generated sodium chloride, distill methylene chloride under reduced pressure to obtain a light yellow transparent liquid, dissolve it with ethyl acetate, and add an equal mass of deionized water , saturated saline and washed twice respectively, take the supernatant, add anhydrous sodium sulfate to dry, remove ethyl acetate by distillation under reduced pressure to obtain light yellow allyl polyoxyethylene ether A-1, the test data of its infrared spectrum As follows.

[0044] IR (tablet method): 34...

preparation example 2

[0046] 10.00g polyethylene glycol (n=20), 1.83g sodium hydroxide, 0.1612g tetrabutylammonium bromide, 4.50g dichloromethane are placed in the four-necked flask that mechanical stirring and thermometer are housed, 3.13g Allyl chloride was slowly added dropwise to the reaction liquid, and after the dropwise addition was completed, the temperature was raised to 60°C and kept for 6 hours. After the reaction is complete, filter under reduced pressure to remove excess sodium hydroxide and generated sodium chloride, distill methylene chloride under reduced pressure to obtain a light yellow transparent liquid, dissolve it with ethyl acetate, and add an equal mass of deionized water and saturated saline twice, take the supernatant, add anhydrous sodium sulfate to dry, remove ethyl acetate by distillation under reduced pressure to obtain light yellow allyl polyoxyethylene ether A-2, the test data of its infrared spectrum As follows.

[0047] IR (tablet method): 3449.59 (s, υ-OH), 2889....

preparation example 3

[0049] 10.00g polyethylene glycol (n=20), 10.00g sodium hydroxide, 0.8059g tetrabutylammonium bromide, 7.00g dichloromethane are placed in the four-necked flask that mechanical stirring and thermometer are housed, 19.13g Allyl chloride was slowly added dropwise to the reaction liquid, and after the dropwise addition was completed, the temperature was raised to 60°C and kept for 6 hours. After the reaction is complete, filter under reduced pressure to remove excess sodium hydroxide and generated sodium chloride, distill methylene chloride under reduced pressure to obtain a light yellow transparent liquid, dissolve it with ethyl acetate, and add an equal mass of deionized water , saturated saline and washed twice respectively, take the supernatant, add anhydrous sodium sulfate to dry, remove ethyl acetate by distillation under reduced pressure to obtain light yellow allyl polyoxyethylene ether A-3, the test data of its infrared spectrum As follows.

[0050] IR (tablet method): ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com