Emulsion stabilizer for coconut juice beverage and preparation method of emulsion stabilizer

An emulsion stabilizer and beverage technology, applied in the field of food additives, can solve problems such as affecting the appearance and taste of products, restricting coconut milk production, flocculation and precipitation, etc., so as to improve product taste, improve emulsification stability, and improve quality and taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

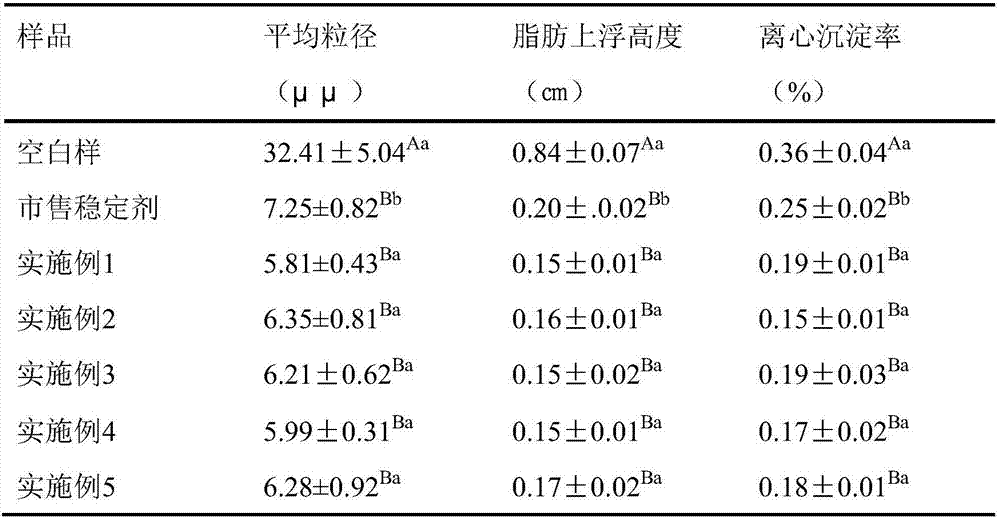

Examples

Embodiment 1

[0033] The formula of the emulsification stabilizer that is used to produce a kind of coconut milk beverage described in the present embodiment is as follows:

[0034] Glyceryl Monostearate 32% Sucrose Fatty Acid Ester 12%

[0035] Agar 3% Xanthan Gum 6%

[0036] Sodium Caseinate 40% Sodium Tripolyphosphate 7%

[0037] The preparation method of the above-mentioned emulsification stabilizer: mix the above-mentioned components such as glyceryl monostearate, sucrose fatty acid ester, agar, xanthan gum, sodium caseinate, sodium tripolyphosphate, etc. by weight, and then stir evenly, that is Obtain an emulsion stabilizer in a uniform powder state.

[0038] When preparing the coconut milk drink with the emulsion stabilizer described in the present embodiment, the weight ratio of the coconut milk drink is as follows:

[0039] 6.5% of sugar, 6.5% of coconut meat, 0.4% of the emulsification stabilizer of coconut milk drink, and the balance is water.

[0040] Now the preparation met...

Embodiment 2

[0044] The formula described in the present embodiment for producing the emulsion stabilizer of a kind of coconut milk drink is as follows:

[0045] Glyceryl Monostearate 35% Sucrose Fatty Acid Ester 10%

[0046] Agar 5% Xanthan Gum 8%

[0047] Sodium Caseinate 35% Sodium Tripolyphosphate 7%

[0048] The preparation method of the above-mentioned emulsification stabilizer: mix the above-mentioned components such as glyceryl monostearate, sucrose fatty acid ester, agar, xanthan gum, sodium caseinate, sodium tripolyphosphate, etc. by weight, and then stir evenly, that is Obtain an emulsion stabilizer in a uniform powder state.

[0049] When preparing the coconut milk drink with the emulsion stabilizer of the present invention, the weight proportion of the coconut milk drink is as follows:

[0050] 7.2% of sugar, 10.0% of coconut meat, 0.9% of the emulsification stabilizer of coconut milk drink, and the balance is water.

[0051] Now the preparation method of coconut milk drin...

Embodiment 3

[0055] The formula described in the present embodiment for producing the emulsion stabilizer of a kind of coconut milk drink is as follows:

[0056] Glyceryl Monostearate 10% Sucrose Fatty Acid Ester 5%

[0057]Agar 10% Xanthan Gum 20%

[0058] Sodium Caseinate 45% Sodium Tripolyphosphate 10%

[0059] The preparation method of the above-mentioned emulsification stabilizer: mix the above-mentioned components such as glyceryl monostearate, sucrose fatty acid ester, agar, xanthan gum, sodium caseinate, sodium tripolyphosphate, etc. by weight, and then stir evenly, that is Obtain an emulsion stabilizer in a uniform powder state.

[0060] When preparing the coconut milk drink with the emulsion stabilizer of the present invention, the weight proportion of the coconut milk drink is as follows:

[0061] 7.2% of sugar, 8.0% of coconut meat, 0.6% of the emulsification stabilizer of coconut milk drink, and the balance is water.

[0062] Now the preparation method of coconut milk drin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com