Ultraviolet light chain type initiated self-reaction low-viscosity high-thickness full-curing glue

A self-reaction, ultraviolet light technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of material reaction speed and material performance fluctuations, cumbersome operation steps, etc., to achieve exempt performance Fluctuation, good wetting performance, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 10 parts of polyurethane methacrylate (molecular weight about 3000g / mol) synthesized from polytetrahydrofuran diol, hydroxyethyl methacrylate and isophorone diisocyanate, ethoxylated trimethylolpropane trimethacrylate 10 parts of ester, 30 parts of tricyclodecane dimethanol dimethacrylate, 50 parts of phenoxyethyl methacrylate, 30 parts of dicyclopentenyl methacrylate, 2.0 parts of photoinitiator benzoin dimethyl ether , 1.0 parts of 2,4,6-trimethylbenzoyl diphenylphosphine oxide, 0.6 parts of Tego931 defoamer (Evonik, Germany).

[0047] 1. Weigh the above components according to their mass composition, mix them, and let them stand for defoaming. At 25°C, its viscosity was tested to be 67mPa.s.

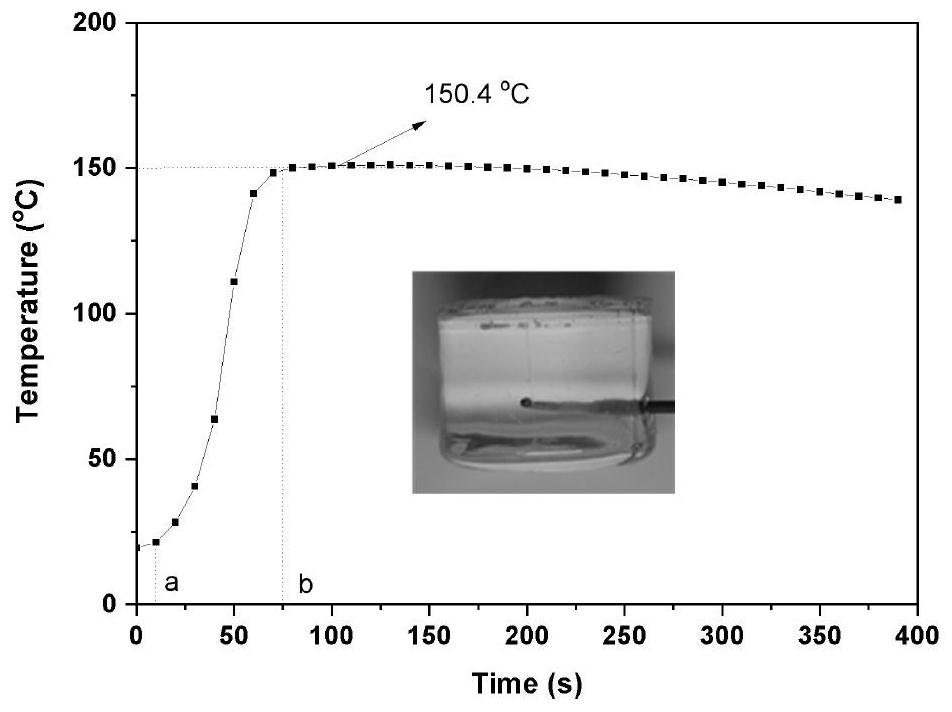

[0048] 2. Pour it into a polyethylene mold with a diameter of about 30mm and a height of 35mm, and control the actual height of the poured glue not to exceed 30mm. Under the irradiation of 1000W mercury lamps (2 pieces, with a wavelength of 350-450nm), measure the temperature...

Embodiment 2

[0056] Polyethylene glycol propylene glycol copolymerized glycol, 30 parts of polyurethane acrylate (molecular weight about 500g / mol) synthesized from hydroxyethyl acrylate and toluene diisocyanate, 5 parts of diethylene glycol diacrylate phthalate, acrylic acid 30 parts of isobornyl ester, 20 parts of N-vinyl caprolactam, 20 parts of hydroxyethyl acrylate, 0.05 parts of benzophenone, 0.05 parts of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide, Junlei 8310 defoamer (Zhengzhou Junlei Chemical Industry) 0.1 part.

[0057] 1. Weigh the above components according to their mass composition, mix them, and let them stand for defoaming. At 25°C, its viscosity was tested to be 61mPa.s.

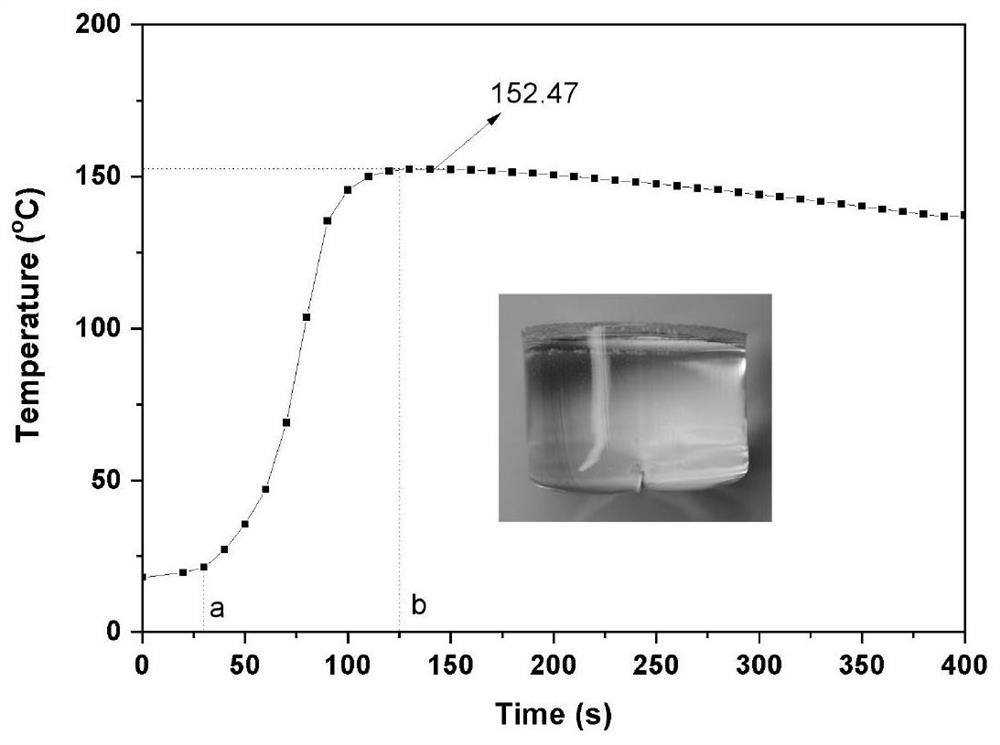

[0058] 2. Pour it into a polyethylene mold with a diameter of about 30mm and a height of 35mm, and control the actual height of the poured glue not to exceed 30mm. Under the irradiation of a 1000W mercury lamp (wavelength 350-450nm), measure the temperature at the center of the glue block with a t...

Embodiment 3

[0073] 15 parts of polyurethane methacrylate (molecular weight about 2000g / mol) synthesized from polybutylene adipate, hydroxyethyl methacrylate and diphenylmethane diisocyanate, 5 parts of propoxylated glycerin trimethacrylate Parts, 5 parts of 1,6-hexanediol dimethacrylate, 10 parts of triethylene glycol dimethacrylate phthalate, 35 parts of hydroxyethyl methacrylate, o-phenylphenoxyethyl methyl 30 parts of acrylic acid ester, 2.0 parts of 1-hydroxycyclohexyl phenyl ketone, 0.2 parts of ethyl 2,4,6-trimethylbenzoylphenyl phosphonate, Sago-1655 defoamer (Guangzhou Situ Source Chemical Co., Ltd.) 0.3 parts.

[0074] 1. Weigh the above components according to their mass composition, mix them, and let them stand for defoaming. At 25°C, its viscosity was tested to be 64mPa.s.

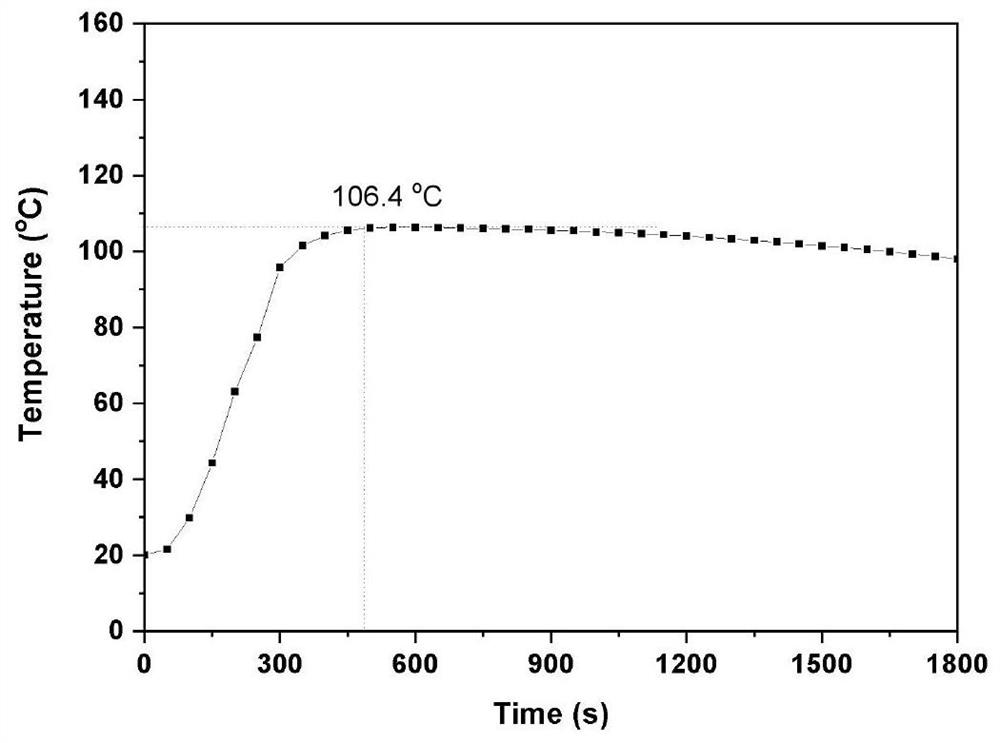

[0075] 2. Pour it into a polyethylene mold with a diameter of about 30mm and a height of 35mm, and control the actual height of the poured glue not to exceed 30mm. Under the irradiation of 45W LED lamp ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com