Environment-friendly acrylic spinning oil

A spinning oil and environment-friendly technology, applied in the field of acrylic fiber oil, can solve the problems of poor biodegradability, high fiber smoothness, insufficient saturation, etc., and achieve less coking and carbonization, high drum full rate, smoke less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

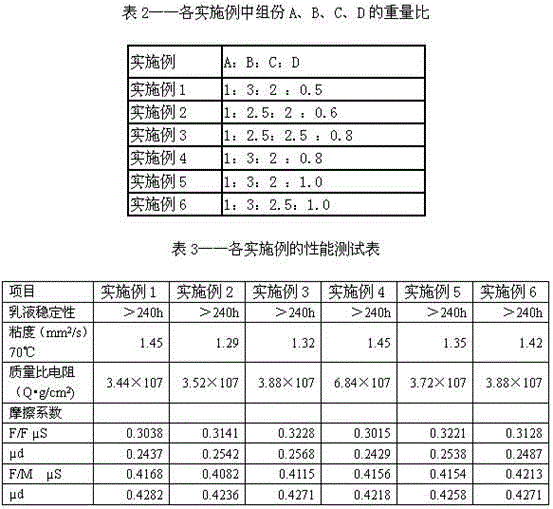

[0030]Prepare components A, B, C and D in proportion as active ingredients, and then prepare the above-mentioned active ingredients into an emulsion with warm water at 60°C. The concentration of the emulsion in the upper oil tank is controlled at 2-3 wt%. The concentration is controlled at 10-15wt%.

[0031] Embodiment 1~2 is used for the spinning oiling of 3.33dtex * 105mm acrylic fiber, embodiment 3~4 is used for the spinning oiling of 6.66dtex * 113mm acrylic fiber, and embodiment 5~6 is used for the filament of 3.33dtex The tow is spun and oiled, and the tow is passed through a multi-zone stretch breaker to make a wool top. In the embodiment, the fiber oiling rate is controlled at 0.30±0.01%, the fiber shows good spinnability and processing performance in the spinning process and the post-processing process, and the prepared fiber is soft and smooth, and has a good hand feeling.

[0032] The specific compositions of components A, B, C, and D of each embodiment are shown i...

Embodiment 1

[0037] Weight ratio, component A: component B: component C: component D=1:3:2:0.5.

[0038] Component A is 12-2-12 type Gemini (gemini) quaternary ammonium salt, also known as 12-2-12 type Gemini quaternary ammonium salt or 12-2-12 type gemini quaternary ammonium salt; component B is polyethylene glycol Alcohol (400) laurate, component C is 6,7 branched isomeric fatty alcohol polyoxyethylene ether (8), component D is N-(aminoethyl)-2-aminopropylmethyl dimethyl Oxysilane, the above products are known products.

[0039] In this example,

[0040] The chemical formula of component A: [(C 12 h 25 ) 2 N 2 (CH 3 ) 4 (C 2 h 4 )] 2+ 2Br -

[0041] Chemical formula of component B: C 12 h 25 COO(CH 2 CH 2 O) 6 h

[0042] The chemical formula of component C: (C 6 h 13 )(C 7 h 15 )O(CH 2 CH 2 O) 8 h

[0043] Chemical formula of component D: CH 3 (CH 3 0) 2 Si(CH 2 ) 3 NH(CH 2 ) 2 NH 2

[0044] The above-mentioned embodiment is especially suitable for the ...

Embodiment

[0045] In embodiment 2:

[0046] Weight ratio, component A: component B: component C: component D=1:2.5:2:0.6.

[0047] Component A is 12-3-12 type Gemini (gemini) quaternary ammonium salt, also known as 12-3-12 type Gemini quaternary ammonium salt or 12-3-12 type gemini quaternary ammonium salt, specifically refers to C12-3-C12 ▪2Br - ; Component B is polyethylene glycol (400) dilaurate, component C is 6,7 branched chain isomerized fatty alcohol polyoxyethylene ether (10), component D is N-(aminoethyl)- 2-aminopropylmethyldimethoxysilane, the above products are known products.

[0048] In this example,

[0049] The chemical formula of component A: [(C 12 h 25 ) 2 N 2 (CH 3 ) 4 (C 3 h 6 )] 2+ 2Br -

[0050] Chemical formula of component B: C 12 h 25 COO(CH 2 CH 2 O) 6 h

[0051] The chemical formula of component C: (C 6 h 13 )(C 7 h 15 )O(CH 2 CH 2 O) 10 h

[0052] Chemical formula of component D: CH 3 (CH 3 0) 2 Si(CH 2 ) 3 NH(CH 2 ) 2 NH 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com