Environment-friendly composite water treatment agent and application thereof

A water treatment agent and composite technology, applied in the field of water treatment, can solve the problems of polluted water environment, poor biodegradation performance, good scale inhibition effect, etc., and achieve good biodegradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of compound medicine: Add sodium molybdate and tetradecyldimethylbenzyl ammonium chloride to water, add polyepoxysuccinic acid (average molecular weight 1200, concentration 40%), polyglutamic acid ( The average molecular weight is 6000), sodium lauroyl sarcosinate, so that the mass percentage of each component is: polyepoxysuccinic acid 20%, polyglutamic acid 13%, sodium molybdate 25%, sodium lauroyl sarcosinate 12% %, tetradecyl dimethyl benzyl ammonium chloride 15%, mixed and stirred evenly to obtain a composite water treatment agent.

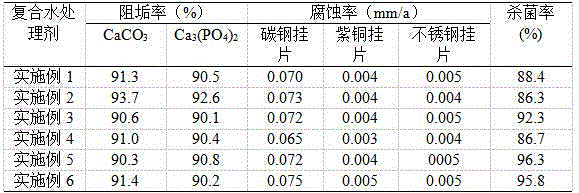

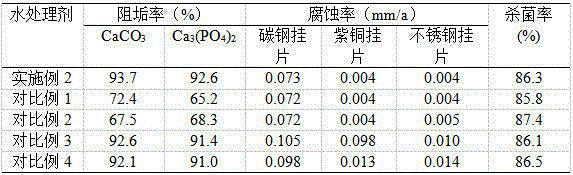

[0020] The scale inhibition, corrosion inhibition and sterilization effects of the water treatment agents provided in this example are shown in Table 1.

Embodiment 2

[0022] Preparation of compound medicine: Add sodium molybdate and tetradecyldimethylbenzyl ammonium chloride to water, add polyepoxysuccinic acid (average molecular weight 1200, concentration 55%), polyglutamic acid ( The average molecular weight is 7000), sodium lauroyl sarcosinate, so that the mass percentage of each component is: polyepoxysuccinic acid 25%, polyglutamic acid 15%, sodium molybdate 20%, sodium lauroyl sarcosinate 15% %, tetradecyl dimethyl benzyl ammonium chloride 10%, mixed and stirred evenly to obtain a composite water treatment agent. The scale inhibition, corrosion inhibition and sterilization effects of the water treatment agents provided in this example are shown in Table 1.

Embodiment 3

[0024] Preparation of compound medicine: Add sodium molybdate and tetradecyldimethylbenzyl ammonium chloride to water, add polyepoxysuccinic acid (average molecular weight 1200, concentration 55%), polyglutamic acid ( The average molecular weight is 7000), sodium lauroyl sarcosinate, so that the mass percentage of each component is: polyepoxysuccinic acid 18%, polyglutamic acid 12%, sodium molybdate 20%, sodium lauroyl sarcosinate 15% %, 20% tetradecyl dimethyl benzyl ammonium chloride, mixed and stirred evenly to obtain a composite water treatment agent.

[0025] The scale inhibition, corrosion inhibition and sterilization effects of the water treatment agents provided in this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com