Porous biodegradable stent and preparation method thereof

A biodegradable and biodegradable technology, applied in the field of porous biodegradable scaffolds and their preparation, can solve problems such as failure to realize commercialization, and achieve a non-immune rejection, high continuity, and good biodegradability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

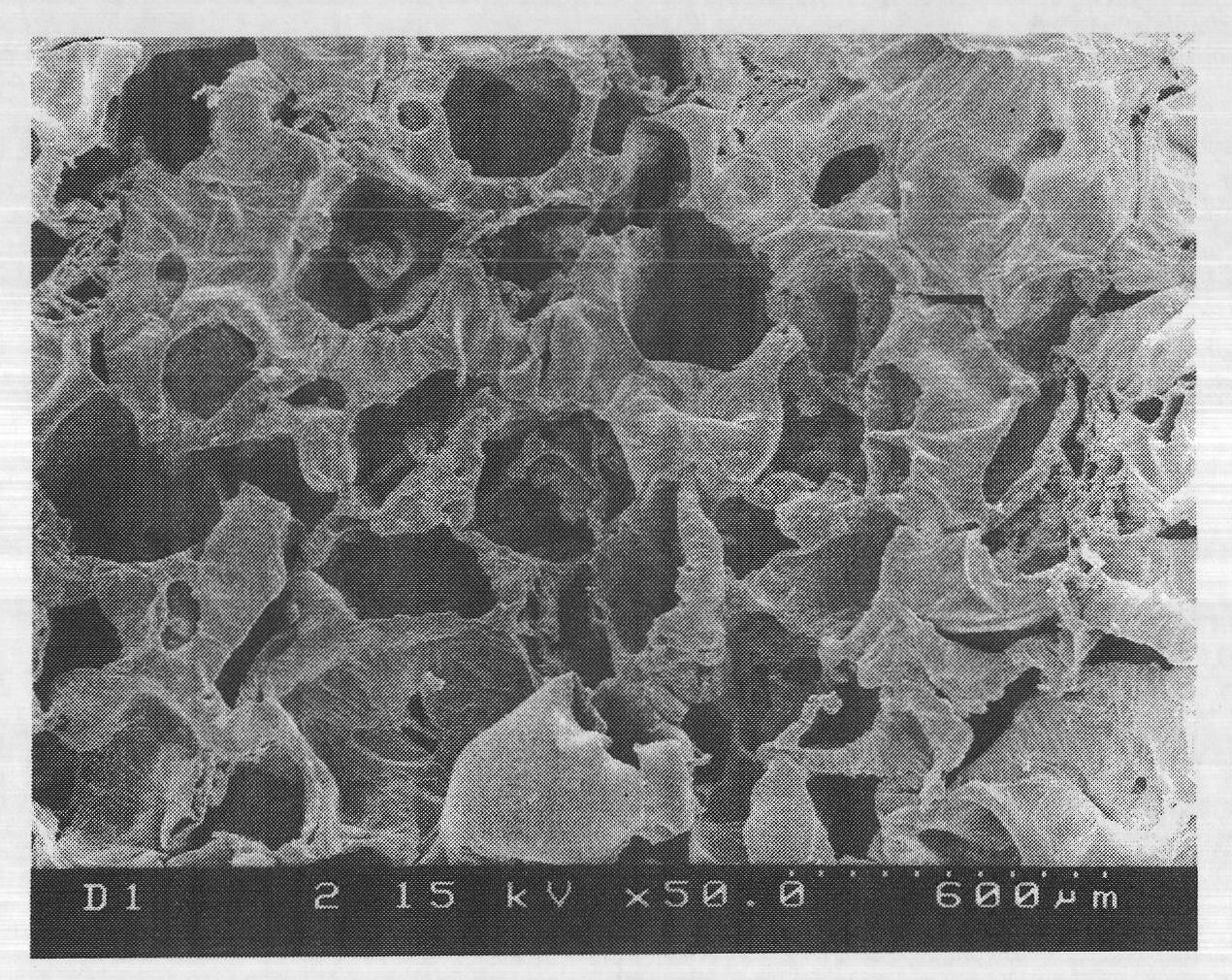

Image

Examples

Embodiment 1

[0039] (1) At room temperature, dissolve PLGA (75PLA:25PGA) with a molecular weight of 5000 (75PLA:25PGA) at a weight percentage of 20:80 in an organic solvent prepared from dichloromethane for 2 hours to form a highly viscous solution;

[0040] (2) Add sodium chloride according to the weight ratio of sodium chloride to biodegradable polymer at 1:5, stir uniformly at room temperature, and mix and stir for 1 minute to form biodegradable polymer, organic solvent and chlorine Then quickly fill the paste mixture into a plastic mold and press 345 kPa for 10 minutes to form a semi-finished product;

[0041] (3) Dry the semi-finished product at 29°C for 24 hours to remove the organic solvent to form a molded product;

[0042] (4) Use purified water to continuously remove sodium chloride from the molded product for 30 hours, resulting in a sodium chloride concentration of less than 3 μg / ml;

[0043] (5) After removing sodium chloride, put the molded product into an ultra-low temperature stora...

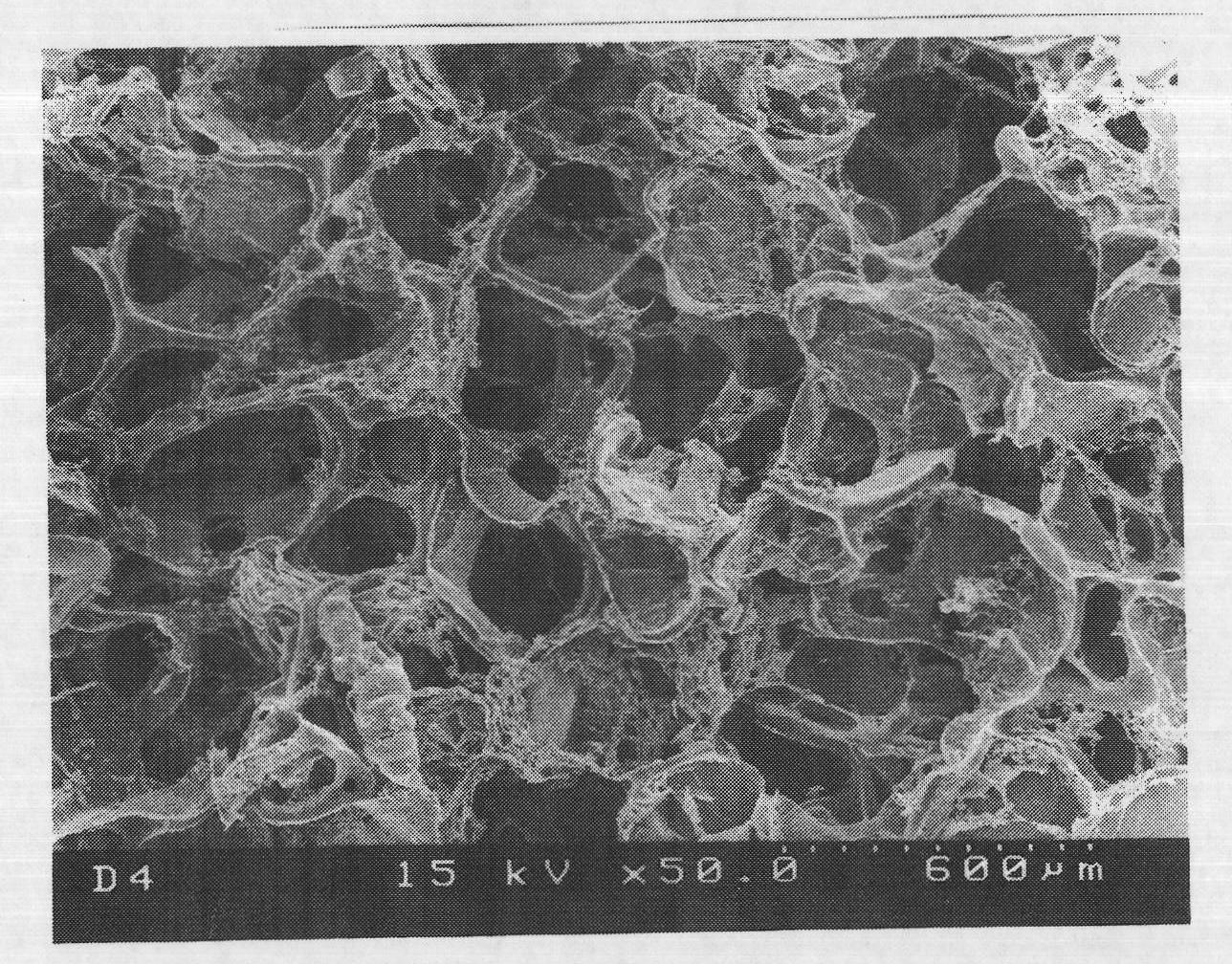

Embodiment 2

[0046] (1) At room temperature, dissolve PLGA (65PLA:35PGA) with a molecular weight of 200,000 at a weight percentage of 30:70 in an organic solvent prepared from dichloromethane and acetone at a weight percentage of 50:50 for 2.5 hours to form a high Viscous solution

[0047] (2) Add potassium chloride according to the weight ratio of potassium chloride to biodegradable polymer at 1:10, stir uniformly at room temperature, and mix and stir for 2 minutes to form biodegradable polymer, organic solvent and chlorine The paste mixture of potassium sulfide is then quickly filled into the plastic mold and pressed at 414 kPa for 9 minutes to form a semi-finished product;

[0048] (3) Dry the semi-finished product at 28°C for 30 hours to remove the organic solvent to form a molded product;

[0049] (4) Use purified water to continuously remove potassium chloride from the molded product for 24 hours, resulting in a potassium chloride concentration of less than 3 μg / ml;

[0050] (5) After remov...

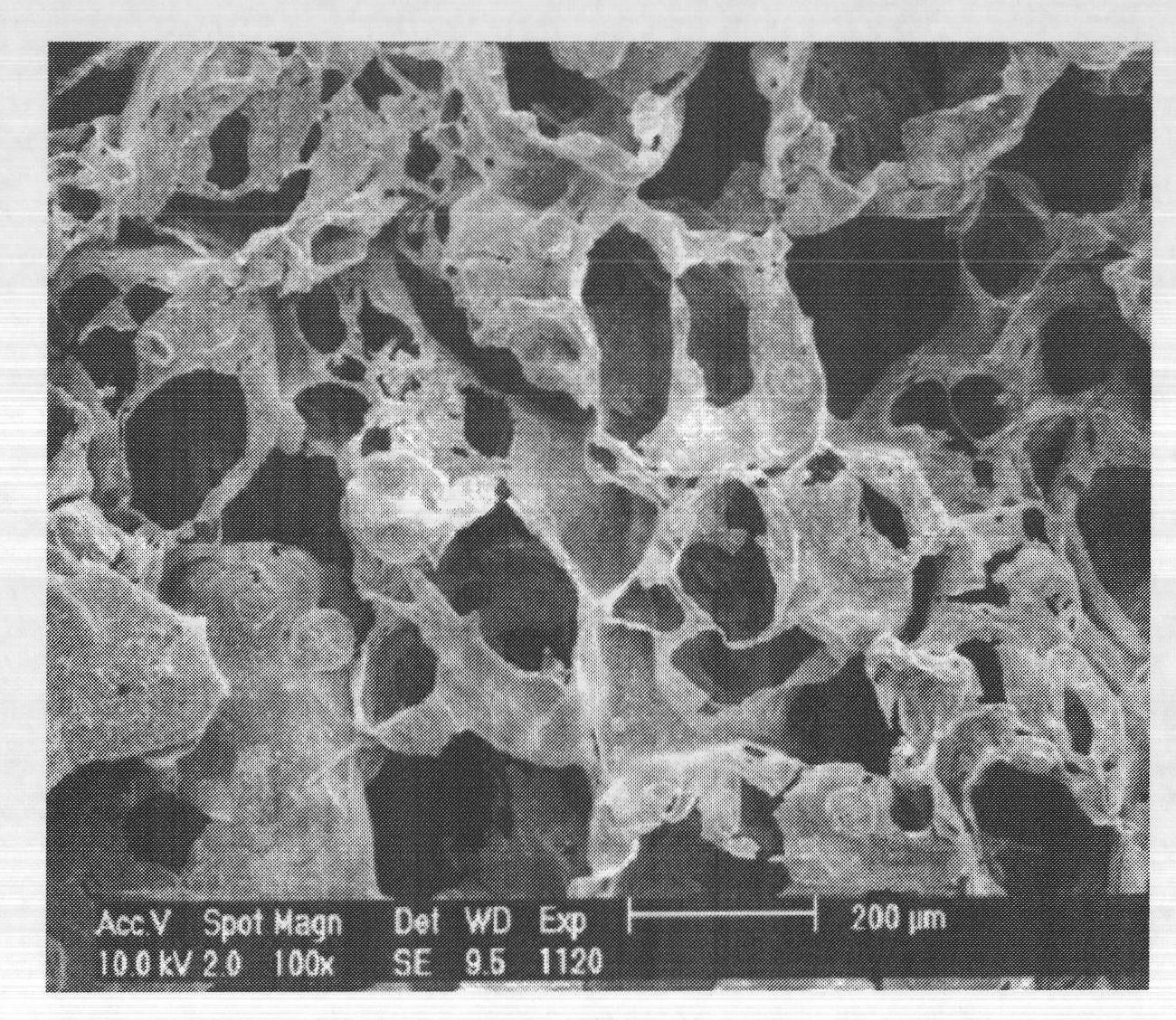

Embodiment 3

[0053] (1) At room temperature, dissolve PLGA (50PLA:50PGA) with a molecular weight of 350,000 at a weight percentage of 35:65 in an organic solvent prepared from acetone for 3 hours to form a highly viscous solution;

[0054] (2) Add potassium nitrate according to the weight ratio of potassium nitrate to biodegradable polymer at 1:15, stir uniformly at room temperature, and mix and stir for 2 minutes to form a biodegradable polymer, organic solvent and potassium nitrate Paste mixture, then quickly fill the paste mixture into a plastic mold, press 483 kPa for 8 minutes to form a semi-finished product;

[0055] (3) Dry the semi-finished product at 27°C for 35 hours to remove the organic solvent to form a molded product;

[0056] (4) Use purified water to continuously remove potassium nitrate from the molded product for 48 hours, resulting in a potassium nitrate concentration of less than 3 μg / ml;

[0057] (5) After removing potassium nitrate, put the molded product into an ultra-low te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com