Glass cover plate cleaning agent and cleaning method thereof

A technology for glass cover plates and cleaning agents, which is applied in the directions of cleaning methods and utensils, cleaning methods using liquids, detergent compositions, etc. Cleaning efficiency and cleaning yield, process yield and efficiency, and the effect of surface transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A glass cover cleaning agent, the glass cover cleaning agent includes an acidic cleaning agent and an alkaline cleaning agent;

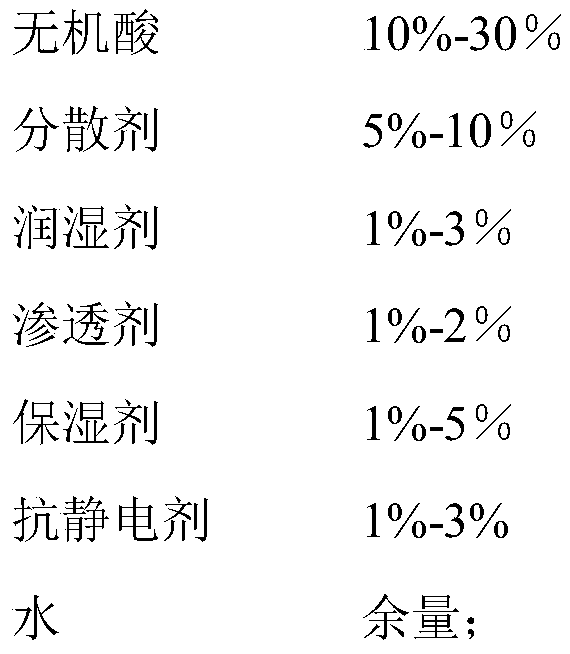

[0036] Described acid cleaning agent is made up of the raw material of following weight portion:

[0037]

[0038] Described alkaline cleaning agent is made up of the raw material of following weight portion:

[0039]

[0040] The inorganic acid is a mixture of phosphoric acid, sulfuric acid and glacial acetic acid in a volume ratio of 1:1.5:1; the dispersant is an acrylic acid-sulfonic acid copolymer.

[0041]The wetting agent is nonylphenol polyoxyethylene ether or octylphenol polyoxyethylene ether.

[0042] The penetrating agent is potassium perfluorohexyl sulfonate or sodium ethylenediamine di-o-phenylacetate.

[0043] The humectant is ethylene glycol or propylene glycol; the antistatic agent is monolauryl phosphate.

[0044] The inorganic base is a mixture of sodium hydroxide and potassium hydroxide at a volume ratio of 1:1; the ...

Embodiment 2

[0049] A glass cover cleaning agent, the glass cover cleaning agent includes an acidic cleaning agent and an alkaline cleaning agent;

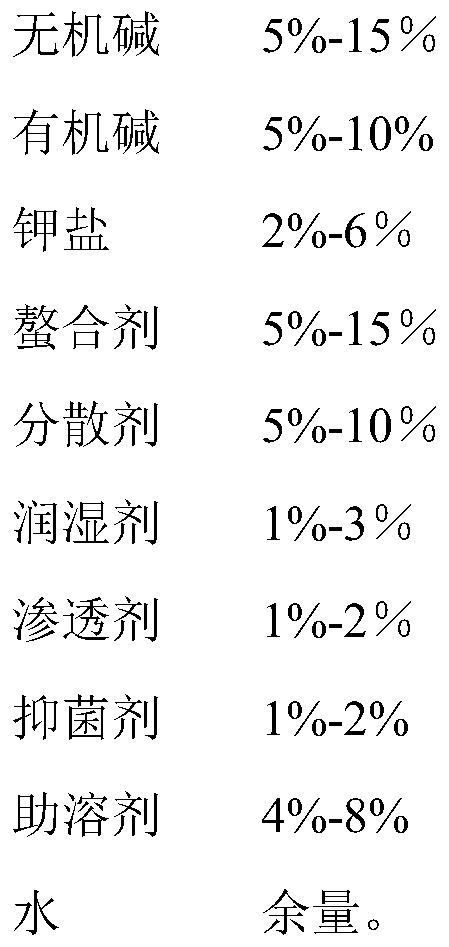

[0050] Described acid cleaning agent is made up of the raw material of following weight portion:

[0051]

[0052] Described alkaline cleaning agent is made up of the raw material of following weight portion:

[0053]

[0054] The inorganic acid is a mixture of phosphoric acid, sulfuric acid and glacial acetic acid in a volume ratio of 1.5:1.8:1; the dispersant is sodium polyacrylate.

[0055] The wetting agent is benzylphenol polyoxyethylene ether, phenylethylphenol polyoxyethylene ether or phenethylphenol polyoxypropylene polyoxyethylene ether.

[0056] The penetrant is fatty acid methyl ester ethoxylate sulfonate or sodium ricinoleol sulfonate.

[0057] The moisturizing agent is glycerol; the antistatic agent is N-dodecyl diquaternary ammonium salt.

[0058] The inorganic base is a mixture of sodium hydroxide and potassium hydroxid...

Embodiment 3

[0063] A glass cover cleaning agent, the glass cover cleaning agent includes an acidic cleaning agent and an alkaline cleaning agent;

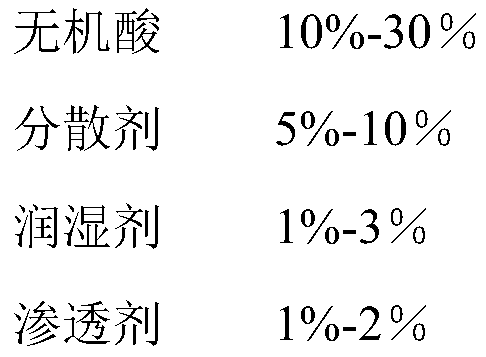

[0064] Described acid cleaning agent is made up of the raw material of following weight portion:

[0065]

[0066] Described alkaline cleaning agent is made up of the raw material of following weight portion:

[0067]

[0068] The inorganic acid is a mixture of phosphoric acid, sulfuric acid and glacial acetic acid in a volume ratio of 2:2:1; the dispersant is maleic acid-acrylic acid sodium salt.

[0069] The wetting agent is styrene ethylphenol polyoxypropylene polyoxyethylene ether or fatty alcohol polyoxyethylene ether.

[0070] The penetrating agent is sodium dodecyl sulfonate or sodium dodecylbenzene sulfonate.

[0071] The humectant is diethylene glycol methyl ether; the antistatic agent is cocamidopropyl betaine.

[0072] The inorganic base is a mixture of sodium hydroxide and potassium hydroxide at a volume ratio of 1.5:1; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com