Method and device for cleaning material surface by microwave

A cleaning device and cleaning technology, applied in the directions of cleaning methods and utensils, cleaning flexible items, chemical instruments and methods, etc., can solve the problems of not wide application area and limited cleaning degree, achieve wide application range and improve surface work function. , the effect of optimizing electrode performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

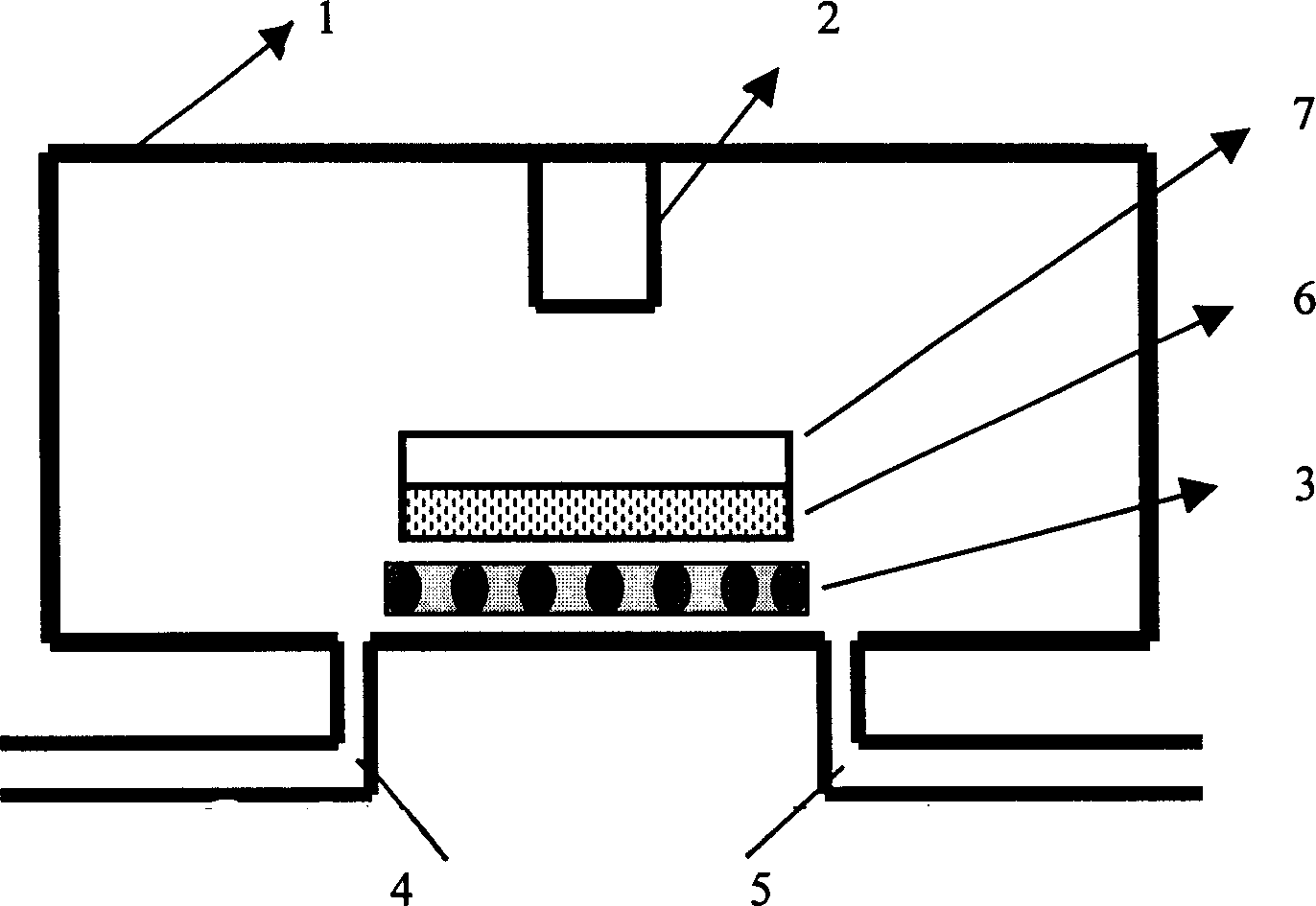

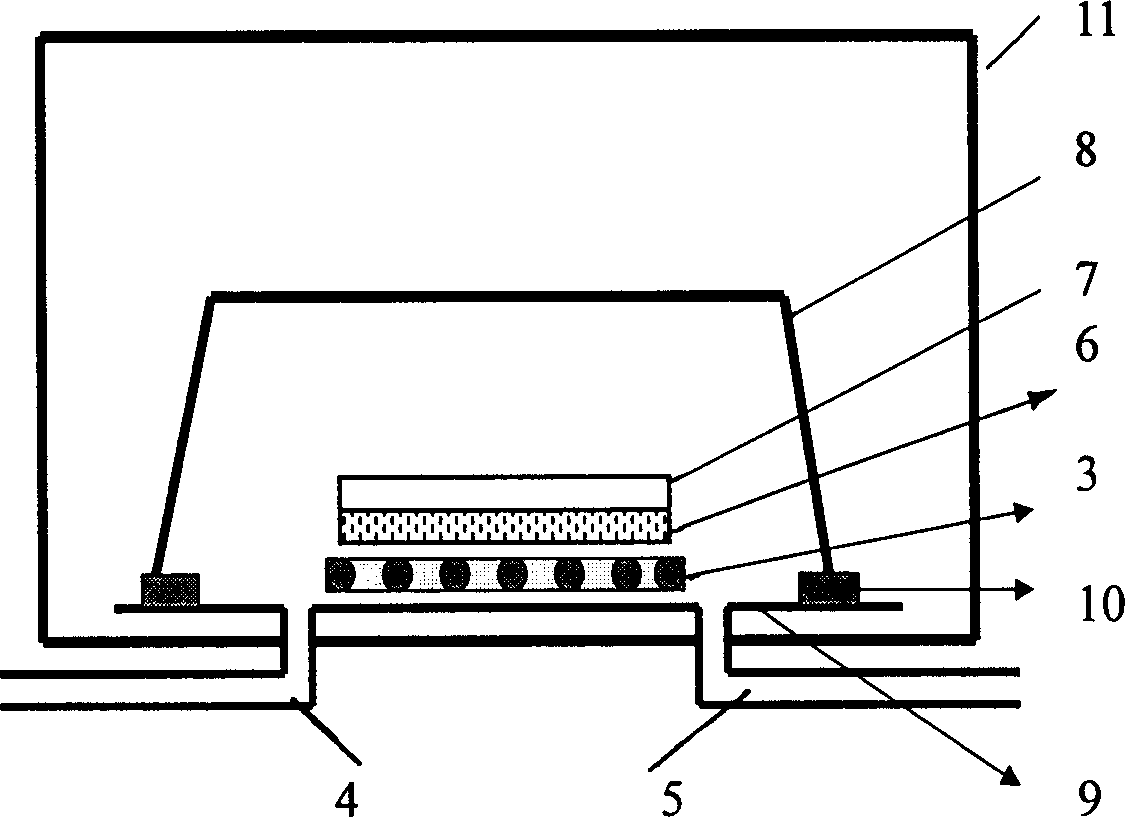

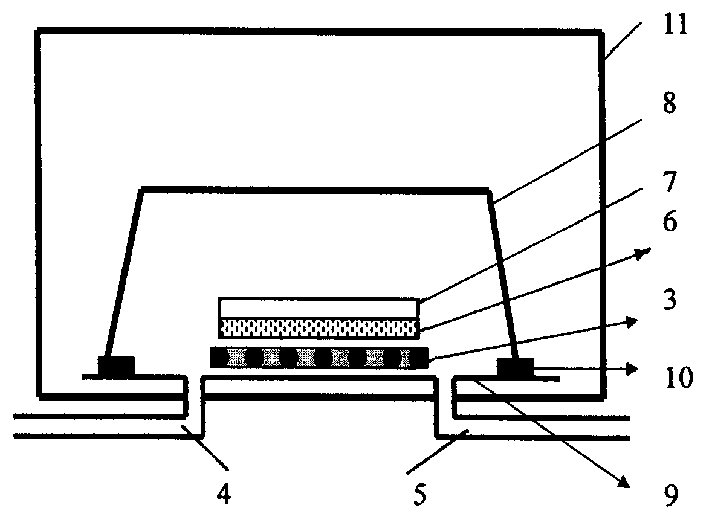

[0013] The structure of the device is as figure 2 As shown, a frequency conversion microwave oven is used to process a stainless steel chassis 9, process and prepare an ultraviolet lamp 3 without electrodes, put it on the stainless steel chassis 9, and install the stainless steel chassis at the bottom of the microwave oven cavity. 22 centimeters of glass plates 8 are buckled upside down on the stainless steel chassis 9 as a glass cover, and the edge of the glass cover is cushioned with a special rubber sealing ring 10 . Connect the gas inlet and outlet ports 4 and 5 to the rear panel of the microwave oven and to an external gas flow controller. The gas flow controller is connected to high-purity oxygen and the gas outlet is connected to a mechanical vacuum pump. In this way, the vacuum degree of the sealed chamber in the glass disc can be controlled, and the equipment can be subjected to oxygen plasma treatment (1-10Pa) by controlling the vacuum degree. More conveniently, oz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com