Extinguishing material for coal mine, and production method thereof

A kind of fire extinguishing material and coal mine technology, applied in fire prevention equipment, etc., can solve the problems of not being suitable for large area filling, polluting underground air, endangering workers' health, etc., and achieves the effects of less water vapor generation, convenient material extraction, and great adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

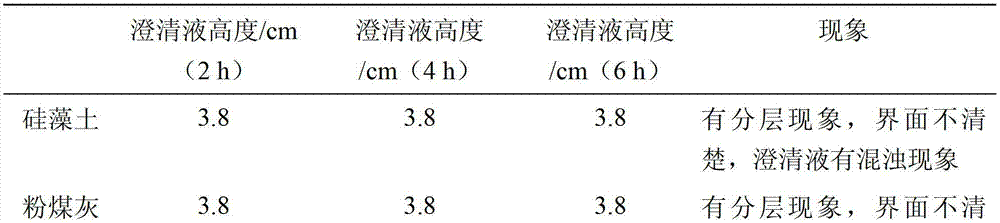

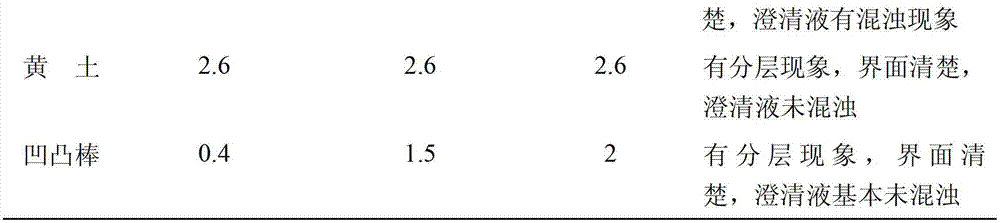

Examples

Embodiment 1

[0025] 1) Place 3 parts of acrylic acid in an ice bath, neutralize with sodium hydroxide to obtain PH=6, then add 4 parts of acrylamide to form a monomer, and sequentially add persulfuric acid that accounts for 0.25% of the total monomer mass Potassium, N,N-methylenebisacrylamide accounting for 0.25% of the total monomer mass; raise the temperature of the water bath and react at 70°C for 7h, after the reaction product is cooled, filter out the reaction product and put it in a vacuum oven, in Dry to constant weight at 50°C to obtain salt-resistant superabsorbent resin;

[0026] 2) Weigh 4g of salt-resistant super absorbent resin and mix with 40ml of tap water, fully stir for about 10min and stand by;

[0027] 3) Weigh 10g of attapulgite and mix with 46ml of tap water, fully stir for 10-50min, and carry out the next reaction after the aggregate slurry is uniform;

[0028] 4) The two slurries obtained in step 2) and step 3) are fully mixed and stirred to obtain the result.

[0...

Embodiment 2

[0031] 1) Place 3 parts of acrylic acid in an ice bath, neutralize with sodium hydroxide to obtain PH=6, then add 4 parts of acrylamide to form a monomer, and sequentially add persulfuric acid that accounts for 0.25% of the total monomer mass Potassium, N,N-methylenebisacrylamide accounting for 0.25% of the total monomer mass; raise the temperature of the water bath and react at 70°C for 7h, after the reaction product is cooled, filter out the reaction product and put it in a vacuum oven, in Dry to constant weight at 50°C to obtain salt-resistant superabsorbent resin;

[0032] 2) Weigh 2g of salt-resistant super absorbent resin and mix with 30ml of tap water, and fully stir for about 10min for use;

[0033] 3) Weigh 15g of attapulgite and mix with 53ml of tap water, fully stir for 10-50min, and proceed to the next step after the aggregate slurry is uniform;

[0034] 4) The two kinds of slurries obtained in step 2) and step 3) are fully mixed and uniformly stirred to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com