Method and device for extracting straw fibre

A technology of straw fiber and extraction method, which is applied to fiber raw materials, fiber raw material processing, textiles and papermaking, etc., can solve the problems of raw material wood shortage, environmental pollution, and lack of forest resources, so as to save transportation costs, improve efficiency, and benefit The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

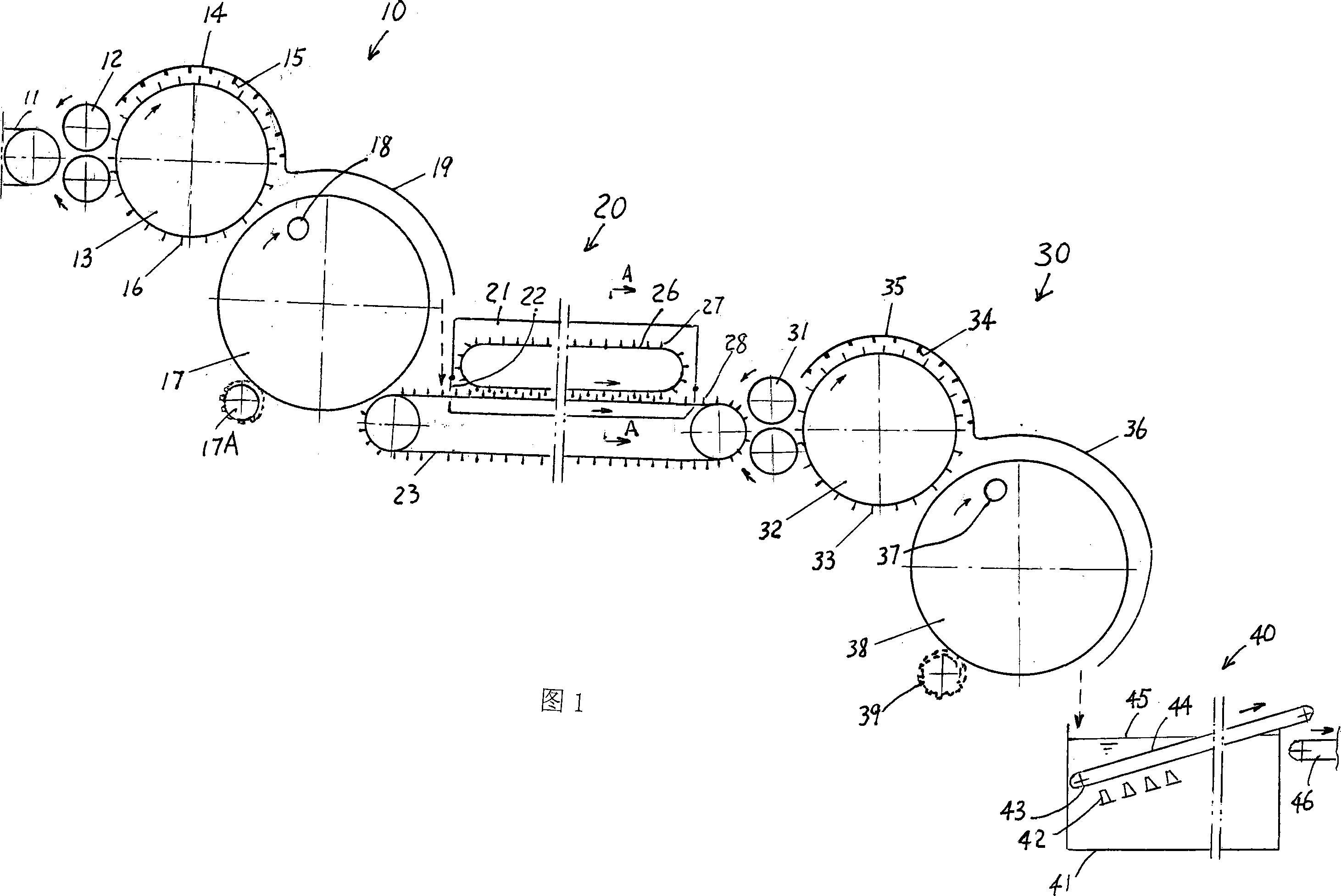

[0037] Example 1. The method of extracting rice or wheat straw fiber is an example, and is illustrated in conjunction with accompanying drawing 1:

[0038] Remove the dust and sundries from the raw material stalks and segment them; the extraction steps are:

[0039] 1) rough extraction of stalks, the threshed crop stalks are shredded into small pieces on the spot with the rough extraction device 10, and

[0040] Rough extraction to get rough straw; return impurities, dust and soil directly to the field;

[0041] 2) steam treatment, heating and moistening the crude straw through a steam treatment device for 6 minutes;

[0042] Stripping and combing are carried out in time to make the fiber in the straw rich in toughness and elasticity, and to make the attached tissue in the straw swell and soft and easy to separate;

[0043] 3) Straw fine extraction, the steam-treated crude straw is further stripped and combed with a fine extraction device to remove the attachment tissue in ...

Embodiment 2

[0047] Embodiment 2, equipment.

[0048] The equipment used is shown in FIG. 1 , including a rough extraction device 10 , a steam treatment device 20 , a fine extraction device 30 and a cleaning device 40 .

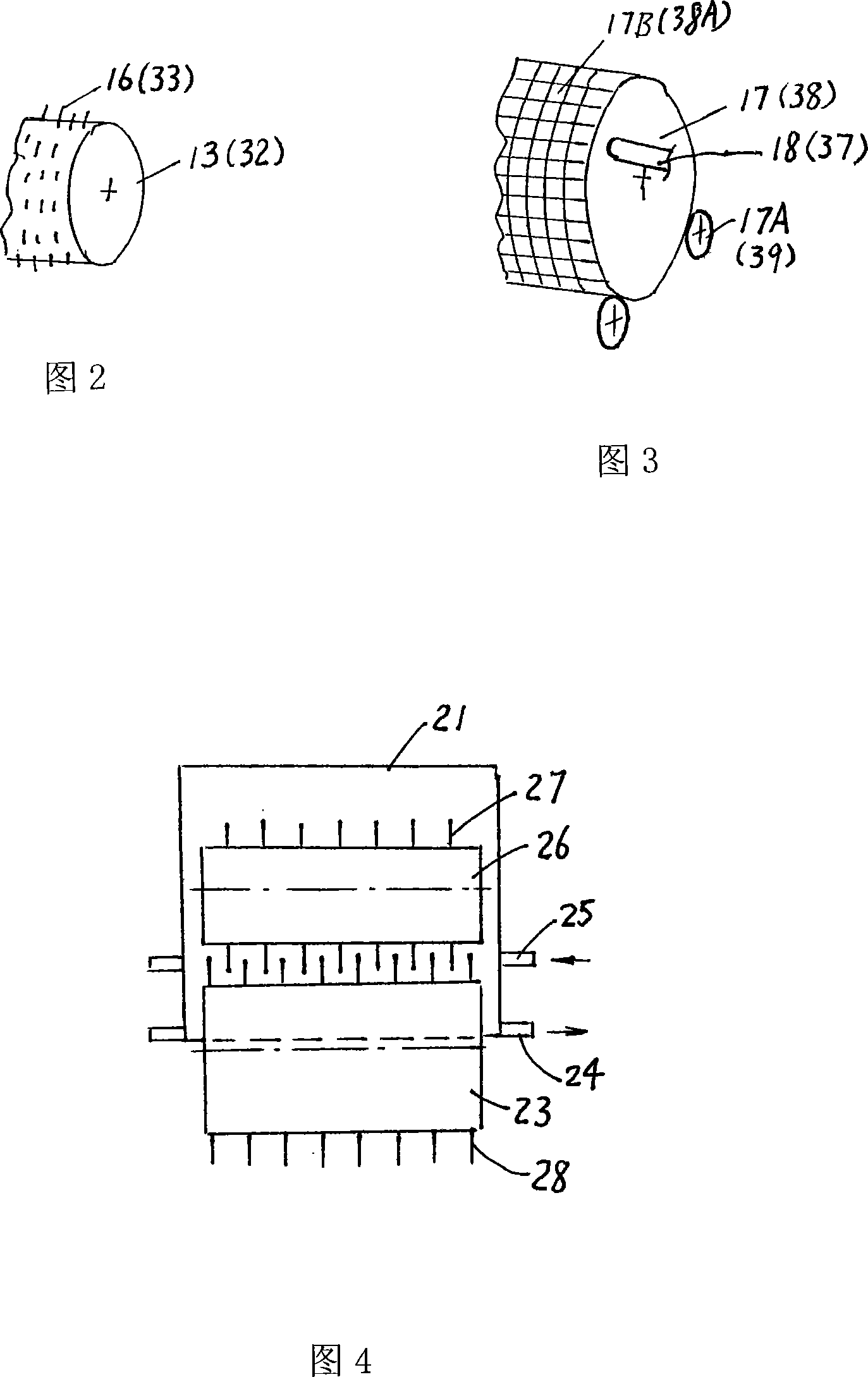

[0049] The stalk rough extracting device 10 comprises 1 pair of coarse feed rollers 12, the thick steel wire wheel 13 and the coarse screen wheel 17 that successively connect, thick steel wire wheel cover 14 and coarse screen wheel cover 19; On the coarse steel wire wheel 13 There is a wire tip 16 and a tip 15 on the coarse wire wheel cover 14; a pair of coarse feed rollers 12 are located at the feed end of the coarse wire wheel 13. Referring to FIG. 2, the thick wire wheel 13 is hollow and has a wire tip 16 on its outer surface. Referring to Fig. 3, the coarse screen wheel 17 is hollow, and its outer surface is covered with a wire mesh 17B of sieve holes, and there are 2 support gears 17A below the coarse screen wheel 17, which are driven by the support gear 17A. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com