Patents

Literature

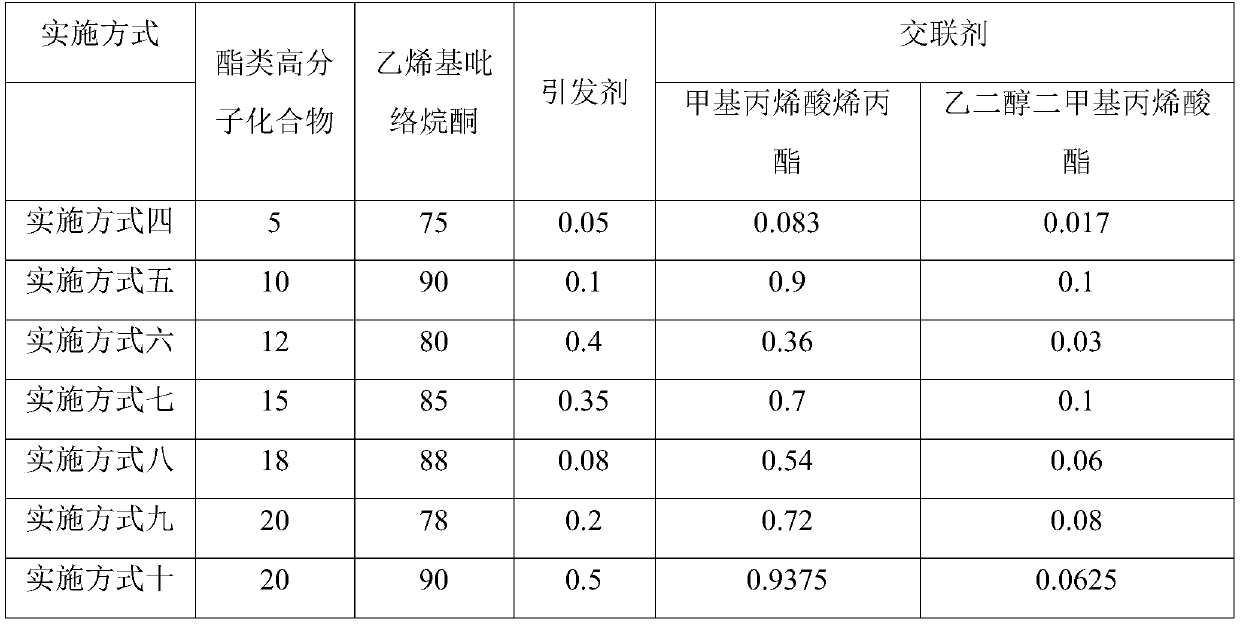

30results about How to "Fast wetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for purifying gibberellin GA3 and preparing water-soluble pulvis of gibberellin GA3

InactiveCN102246756AImprove finenessPromote precipitationBiocidePlant growth regulatorsAcetic acidEthyl ester

The invention provides a method for purifying gibberellin GA3 and preparing water-soluble pulvis of gibberellin GA3. The invention brings forward control of purity and particle size of gibberellin GA3 and utilization of complex formulation to prepare water-soluble pulvis of gibberellin GA3. According to the invention, a mixed solvent of tetrahydrofuran / ethyl acetate / water is used for recrystallization of a crude product of gibberellin GA3, which enables a reasonable process and simple operation and enables purity of the product in one operation to be more than 98.5% and yield of the product to be more than 90%; the technology of complex formulation is employed and gibberellin GA3 is made to be rapidly dissolved in a water phase and to form a stable disperse phase through using of accessories like an acidic buffer reagent, a dispersant and a surfactant, thereby enabling gibberellin GA3 to be easier to store and transport and more convenient to use and drug effects and the utilization rate to be improved.

Owner:JIANGXI LIFENG BIOLOGICAL TECH

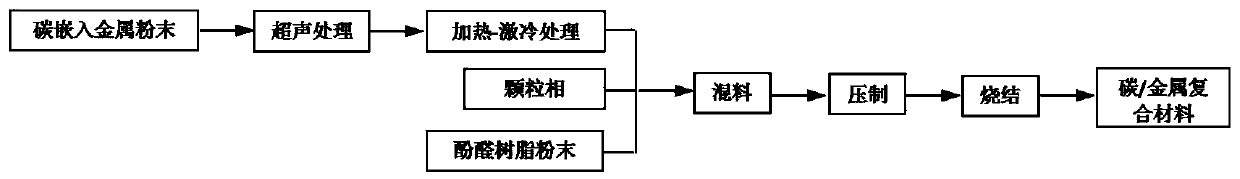

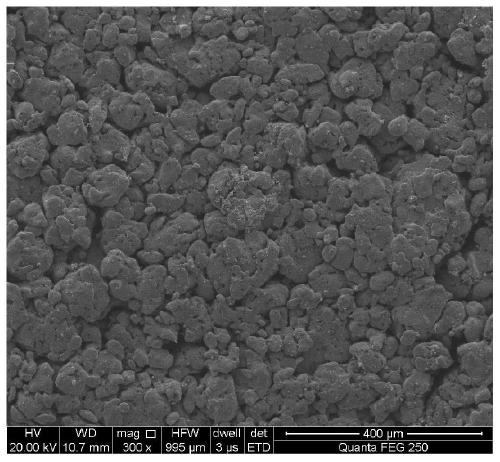

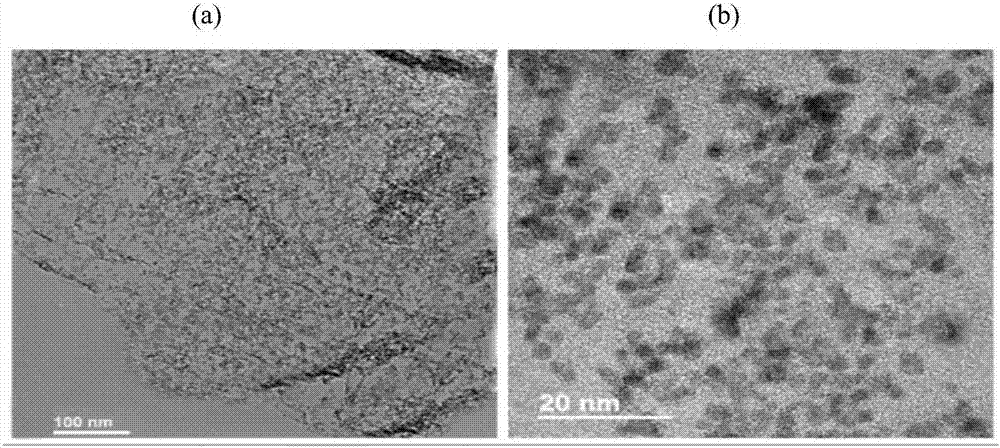

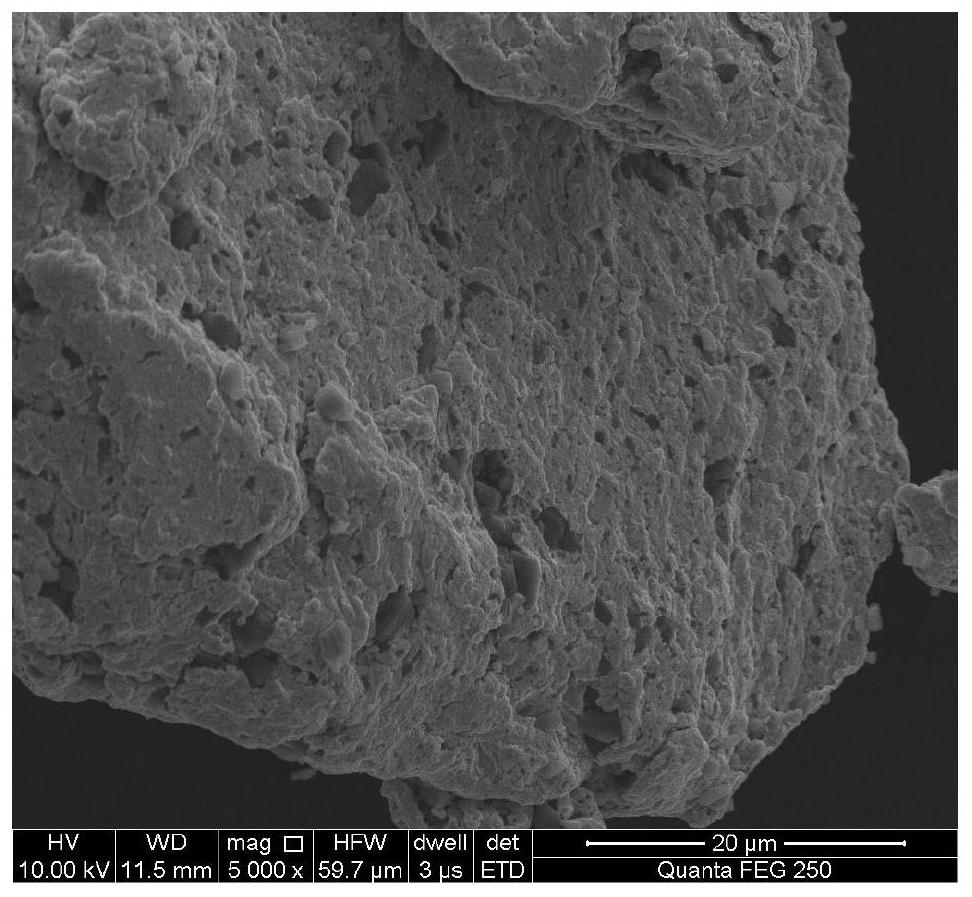

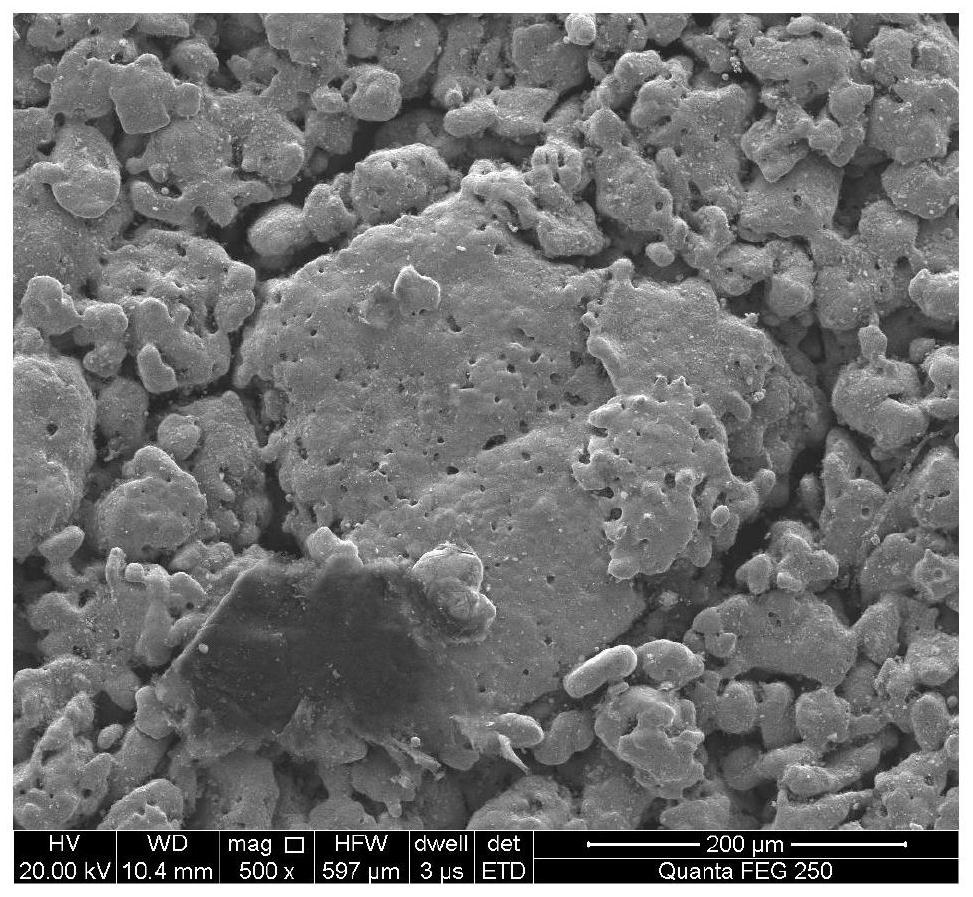

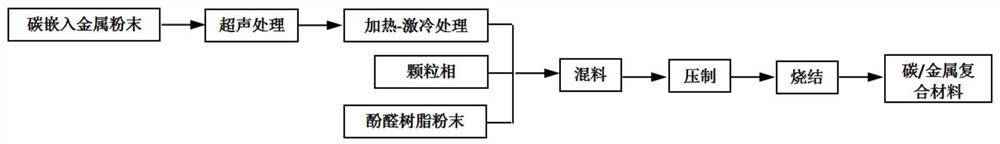

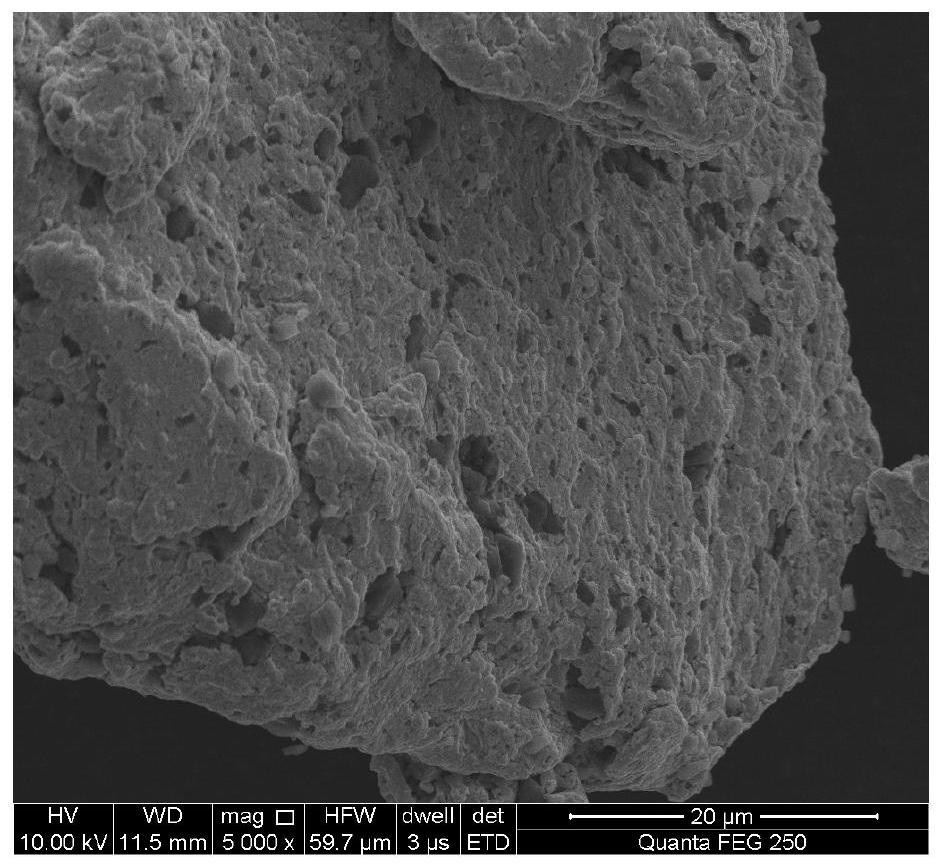

Preparation method of metal material or metal composite material

The invention relates to a preparation method of metal material or metal composite material, and in particular to a method for preparing metal material or metal composite material by adding phenolic resin powder. The preparation method comprises two sets of schemes; the first scheme comprises the following steps of uniformly mixing raw materials, and pressing and sintering to obtain the metal material, wherein the raw materials comprise metal powder and phenolic resin powder; and the second scheme comprises the following steps of ball milling reinforcing bodies and matrix metal A to obtain metal powder with the reinforcing bodies embedded in the surface and the interior, carrying out ultrasonic treatment, low-temperature heating and chilling on the metal powder embedded with the reinforcing bodies to remove reinforcing particles on the surface of the metal powder to obtain a standby material, mixing the standby material with the phenolic resin powder for pressing and sintering, or mixing the standby material with the phenolic resin powder and granular phase B for pressing and sintering to obtain carbon / metal composite material. The method has the advantages that the preparation process is simple, obtained products are excellent in performance, and the method is convenient for large-scale application.

Owner:CENT SOUTH UNIV

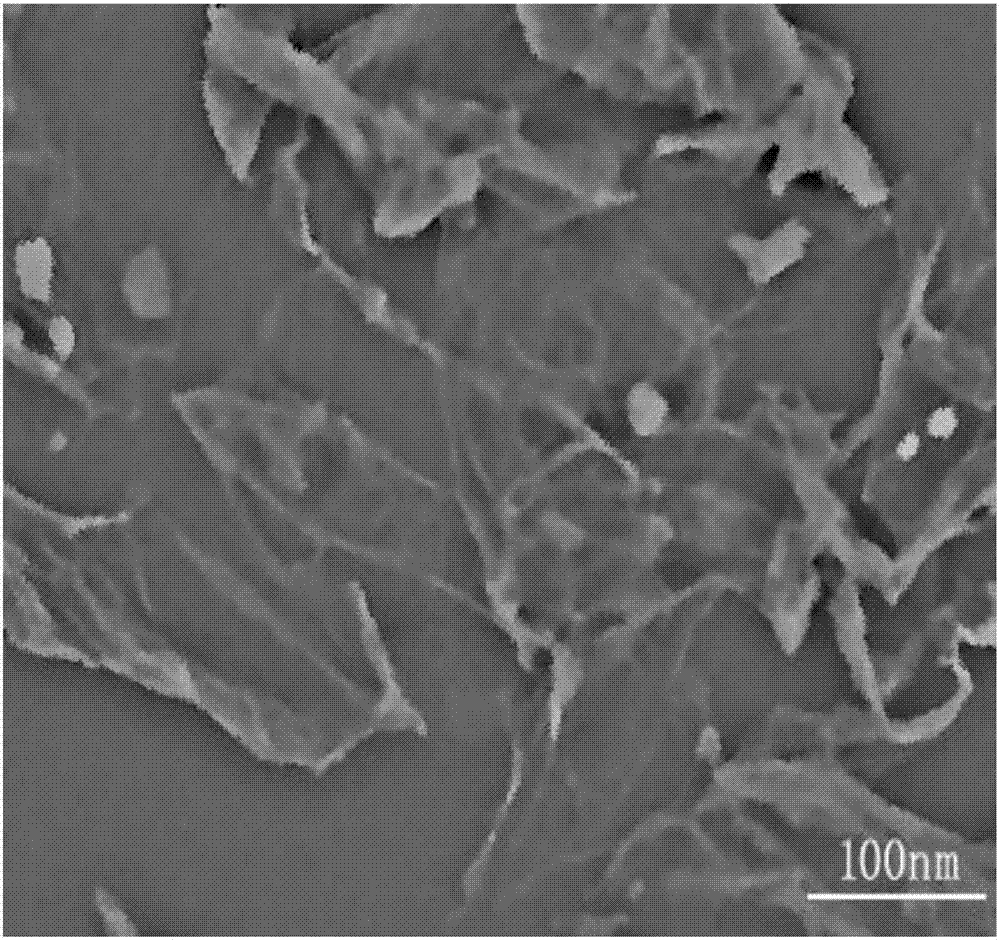

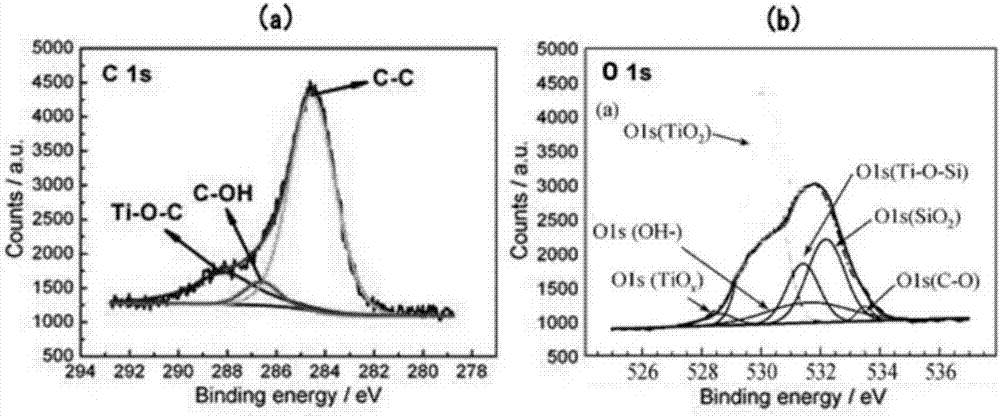

Preparation method of electrostatic-assist nano-titanium polymer coated by graphene intercalation

InactiveCN107090205AEfficient coatingImprove densification performanceFireproof paintsAnti-corrosive paintsEpoxyPolymer science

The invention discloses a preparation method of an electrostatic-assist nano-titanium polymer coated by graphene intercalation, and belongs to the field of polymer preparation. The method includes the steps of 1, blending graphite powder with titanium powder according to a certain mass proportion in an electrostatic mode; 2, putting the powder material blended well in the step 1 with epoxy resin E44, low-molecular polysiloxane, DPM-30, epoxy-group siloxane and solvent into a stainless steel reaction still for reaction, then finishing the preparation of the electrostatic-assist nano-titanium polymer coated by graphene intercalation. The obtained electrostatic-assist nano-titanium polymer coated by graphene intercalation has the advantages of being able to substantially improve the formation of steady covalent bonding and molecular bonding on the surfaces of steel and concrete base materials, thereby substantially enhancing the adhesive force of coatings and the adhesive force of wet films, uprating the comprehensive property of coatings, and meanwhile, reducing the content of dissociative nano-particles and preventing the occurrence of galvanic corrosion to aggravate corrosion when the coatings are abnormally damaged.

Owner:湖南邦泽科技有限公司

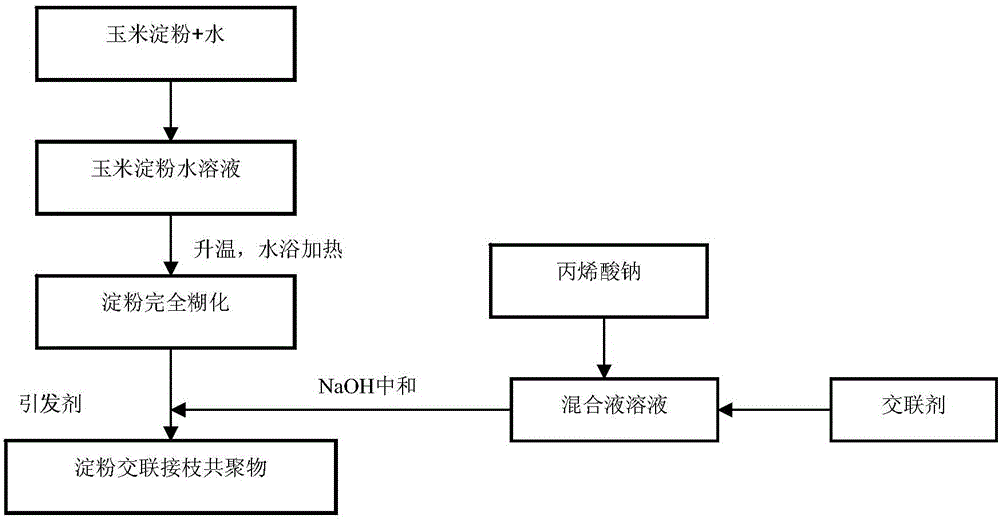

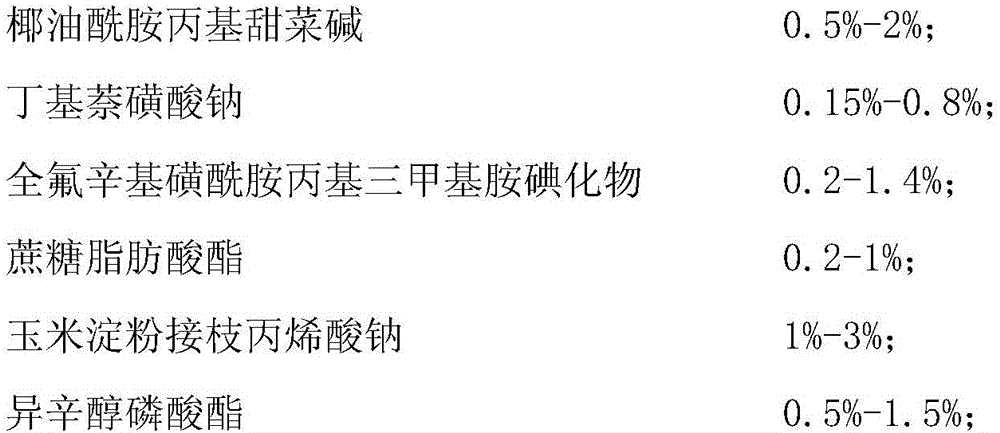

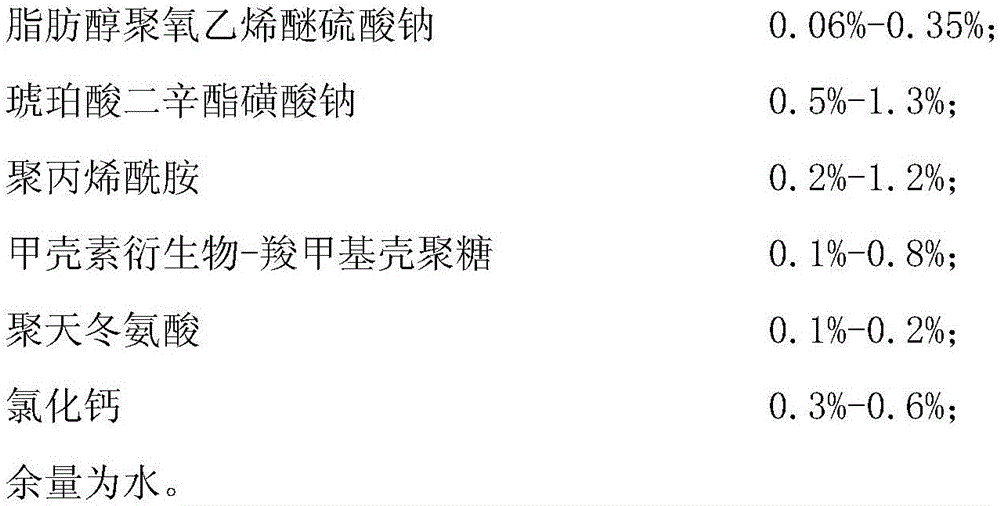

Permeability-increasing and coagulation-accelerating wetting agent for wet-type dust control

ActiveCN105778867AReduce surface tensionIncrease surface tensionOther chemical processesDust removalSucrosePhosphate

The invention discloses a permeability-increasing and coagulation-accelerating wetting agent for wet-type dust control. The permeability-increasing and coagulation-accelerating wetting agent comprises 0.5%-2% of cocamidopropyl betaine, 0.15%-0.8% of butylnaphthalenesulfonic acid sodium salt, 0.2%-1% of trimethyl-1-propanaminium iodide, 0.2%-1% of sucrose fatty acid ester, 1%-3% of corn starch grafting sodium acrylate, 0.5%-1.5% of isooctanol phosphate, 0.06%-0.35% of sodium alcohol ether sulphate, 0.5%-1.3% of sodium diethylhexyl sulfosuccinate, 0.2%-1.2% of polyacrylamide, 0.1%-0.8% of chitin derivative-carboxymethyl chitosan, 0.1%-0.2% of polyaspartic acid, 0.3%-0.6% of calcium chloride and the balance water. The ermeability-increasing and coagulation-accelerating wetting agent for wet-type dust control has the advantages that wetting ability of water for coal is enhanced and water molecules can wrap coal dust particles quickly, so that coagulation and falling of the coal dust particles are facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

Silicon steel pickling promoter and preparation method thereof

The invention specifically relates to a silicon steel pickling promoter and a preparation method thereof. According to a technical scheme in the invention, the silicon steel pickling promoter is prepared from 0.1 to 5.0 wt% of a corrosion inhibitor, 10.0 to 50.0 wt% of an inorganic salt reducing agent, 0.1 to 5.0 wt% of an emulsifier, 5.0 to 20.0 wt% of an organic metal ion chelating agent, 0.1 to 5.0 wt% of a defoaming agent, 0.1 to 5.0 wt% of a synergist and 20.0 to 80.0 wt% of water through uniform mixing at normal temperature with stirring. The silicon steel pickling promoter provided by the invention has the characteristics of convenience in usage, high pickling efficiency, low cost, environment friendliness, a good corrosion inhibition effect, etc.

Owner:WUHAN UNIV OF SCI & TECH

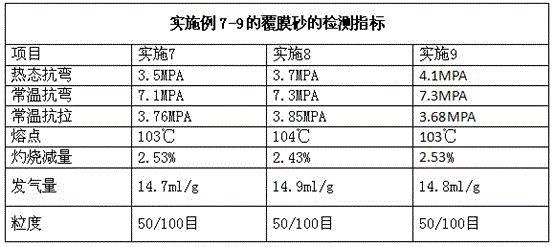

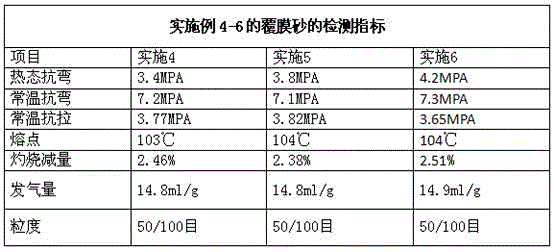

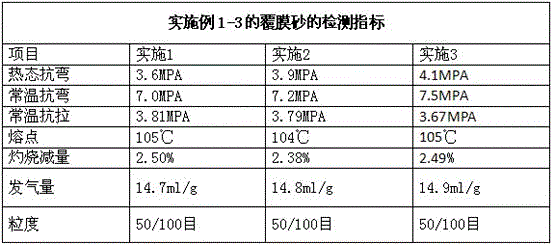

High temperature-resistant easy-collapsing precoated sand for casting

InactiveCN108971416ASimple preparation processGood value for moneyFoundry mouldsFoundry coresPolyvinyl butyralPolyvinyl alcohol

The invention discloses a high temperature-resistant easy-collapsing precoated sand for casting. The high temperature-resistant easy-collapsing precoated sand is prepared from the following componentsin parts by weight: 87 to 118 parts of raw sand, 2 to 2.5 parts of benzoxazine resin, 0.7 to 3.1 parts of polyvinyl butyral, 3.7 to 5.6 parts of inorganic polymer, 0.3 to 0.5 part of sodium alginate,3 to 11 parts of bauxite, 3 to 13 parts of mullite powder, 5 to 15 parts of diatomite, 0.3 to 0.4 part of hexamethylenetetramine, 0.1 to 0.2 part of barium stearate, 0.1 to 0. 2 part of zinc stearate, 0.15 to 0.2 part of calcium stearate, 0.45 to 3.8 parts of flake graphite, 0.7 to 3.3 parts of dolomite powder, and 0.1 to 0.3 part of potassium nitrate. The high temperature-resistant easy-collapsing precoated sand for casting has the advantages that the combination of components is optimized; especially, the decomposing temperature of the potassium nitrate is high, the heat-resistant propertyof the benzoxazine resin is high, and the components can reach the synergistic cooperation function; the preparation method is simple, the sources of the raw materials are wide, and the high temperature-resistant property and the post-casting collapsing property of the precoated sand are guaranteed.

Owner:王韶华

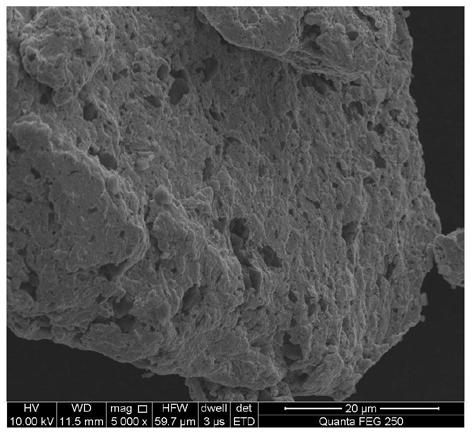

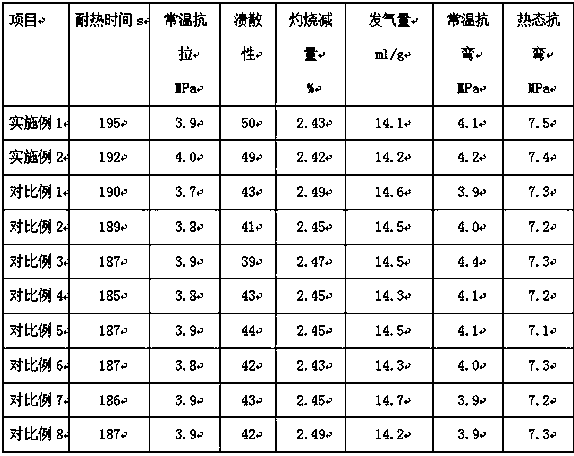

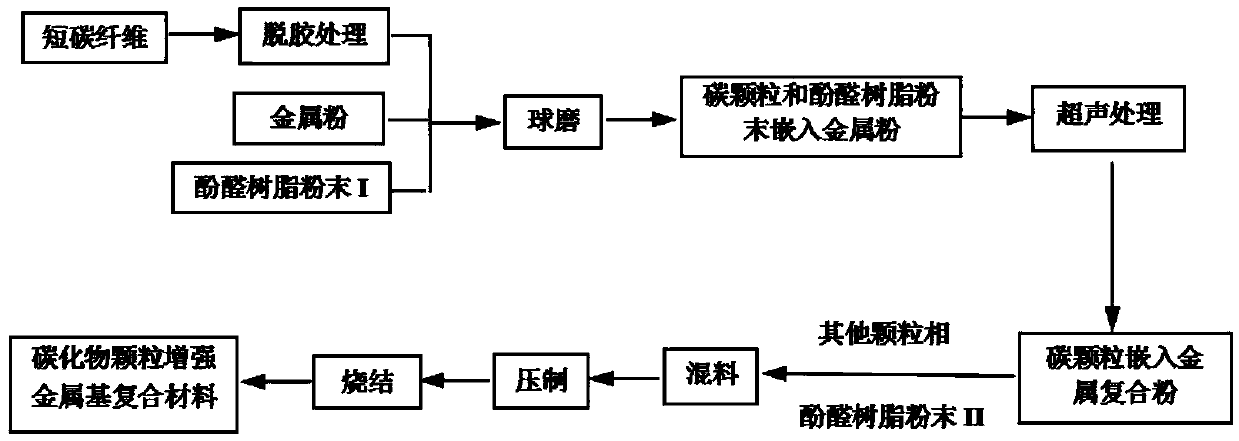

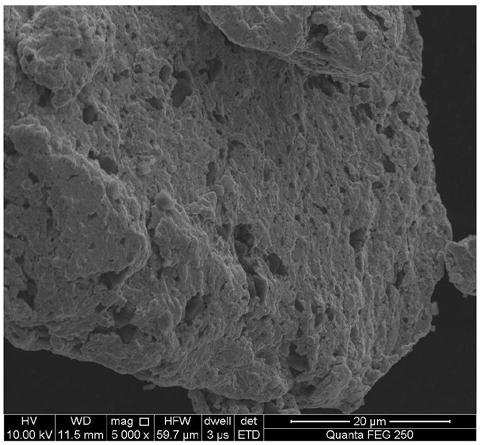

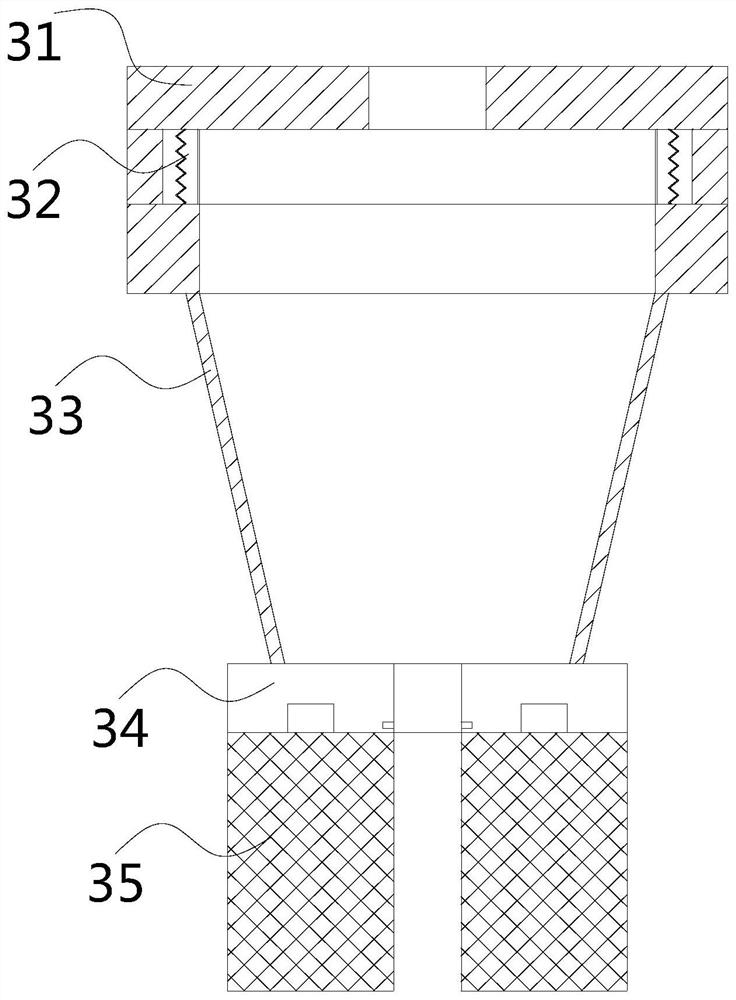

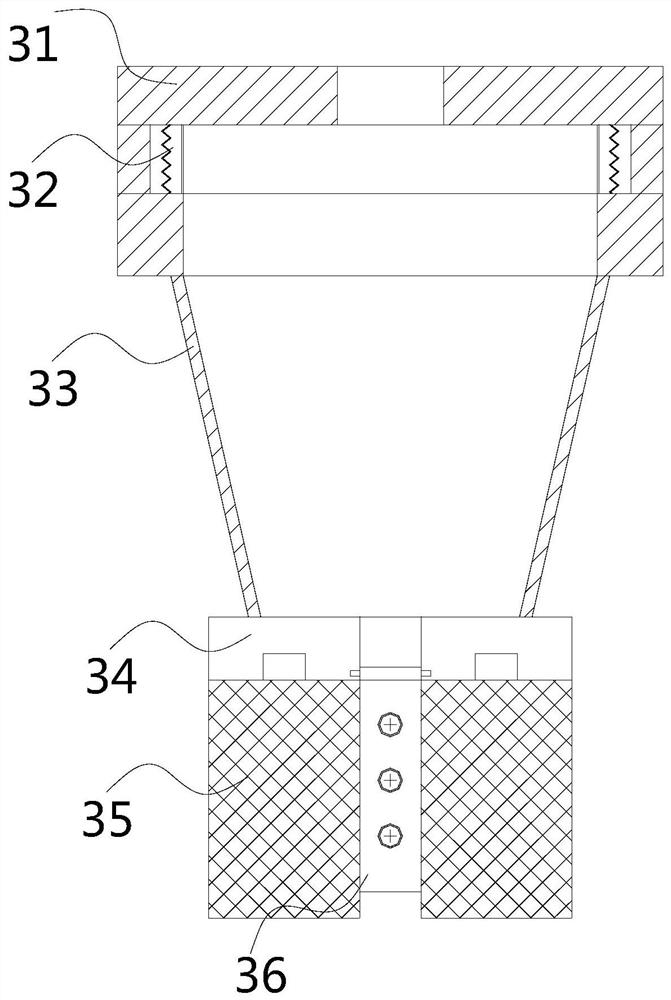

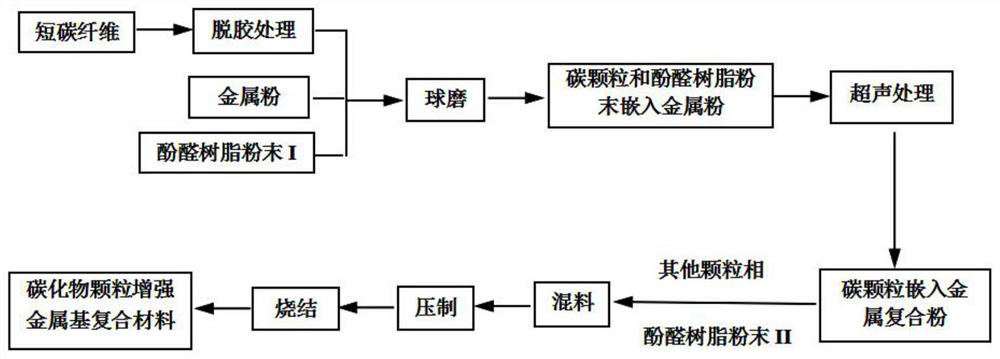

Preparation method for carbon particle reinforced metal base composite materials

The invention relates to a preparation method for carbon particle reinforced metal base composite materials, and belongs to the technical field of metal material preparation. Carbon parcel and phenolic resin uniform-embedded metal powder is obtained through high energy of degummed short carbon fibers and phenolic resin powder, is ultrasonically processed and dried to obtain surface carbon removedand carbon and phenolic resin powder embedded metal powder, and is mixed with the phenolic resin powder and other components for pressing and sintering to obtain the carbon particle reinforced metal base composite materials. The preparation method successfully solves the problem of loose interface sintering of the carbon particle embedded metal powder in the sintering process; under the precondition of realizing compact sintering of the metal powder, the mechanical performance and the wear resistance of the designed and prepared metal composite materials are greatly improved; the preparation process is simple; and the cost is low.

Owner:CENT SOUTH UNIV

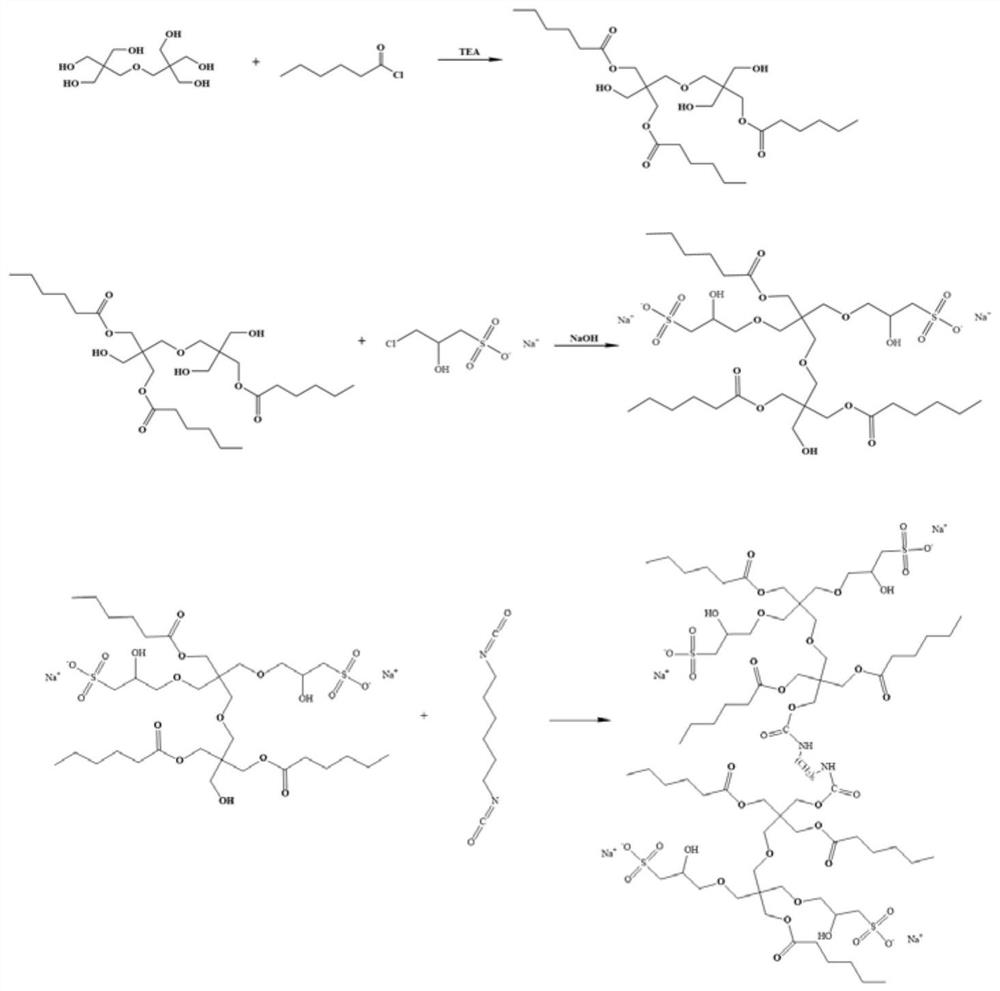

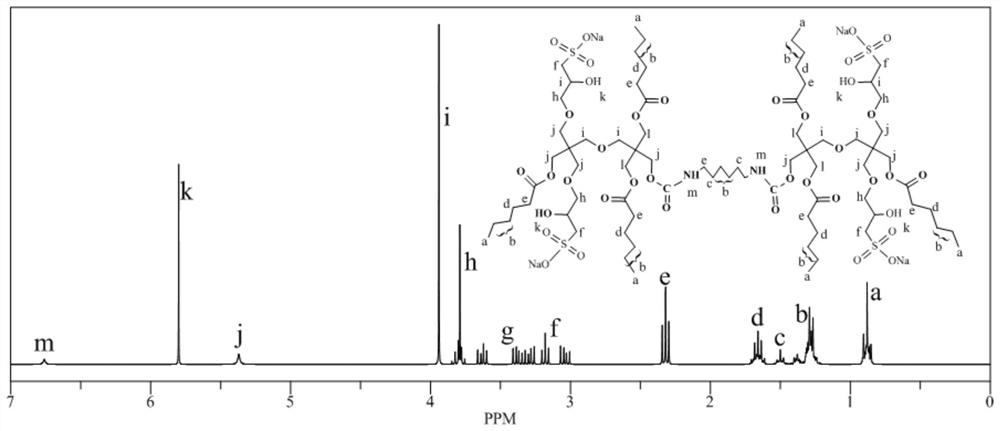

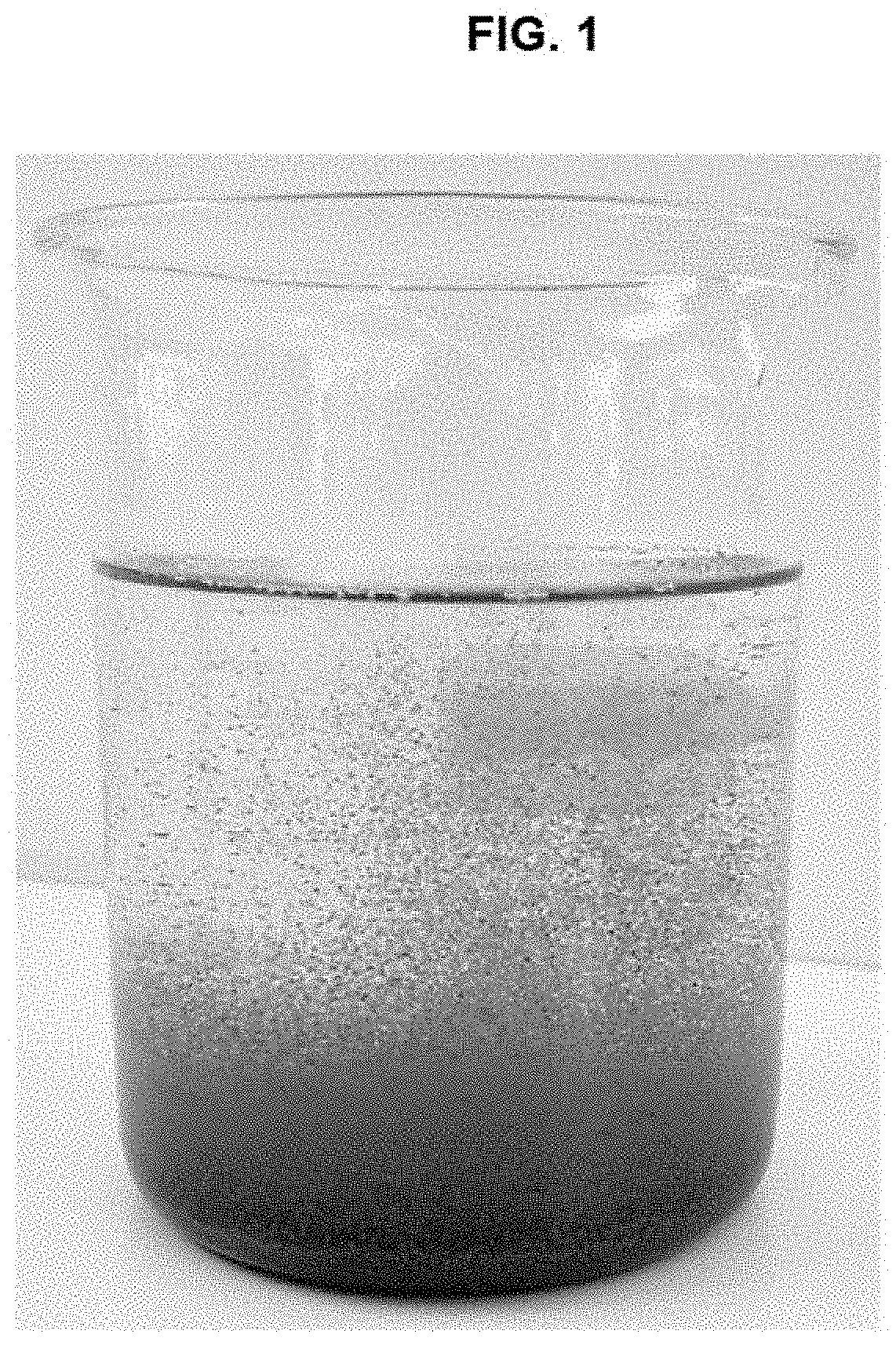

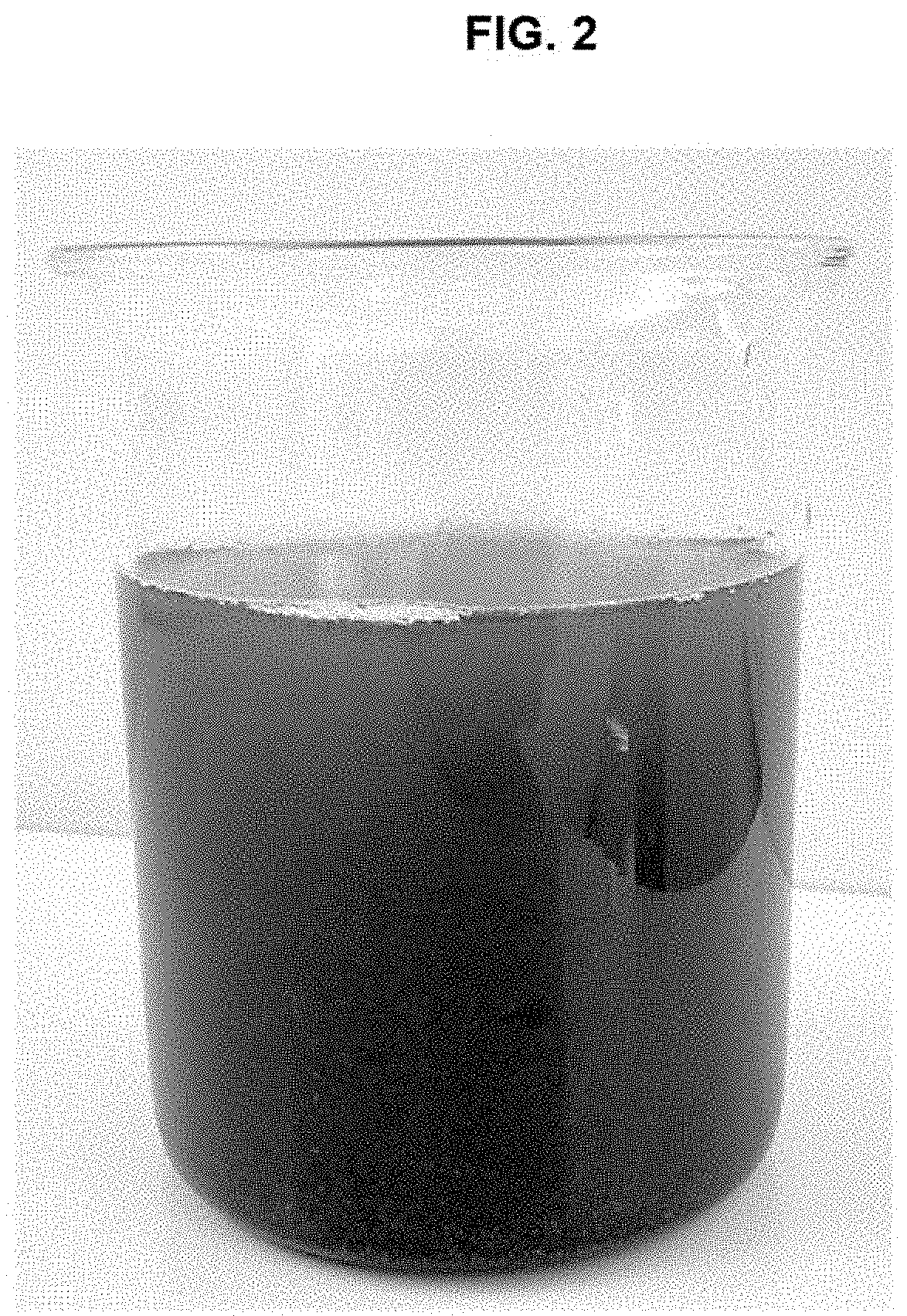

Polysulfonic acid structure surface wetting agent and preparation method thereof

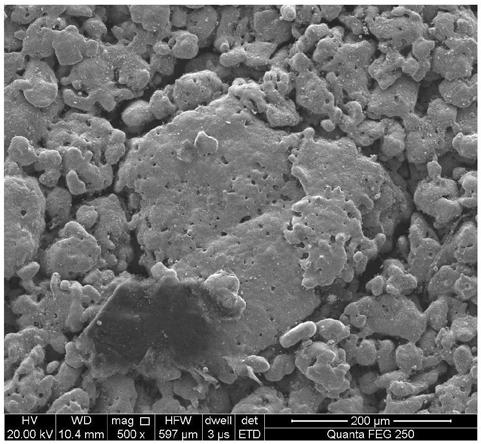

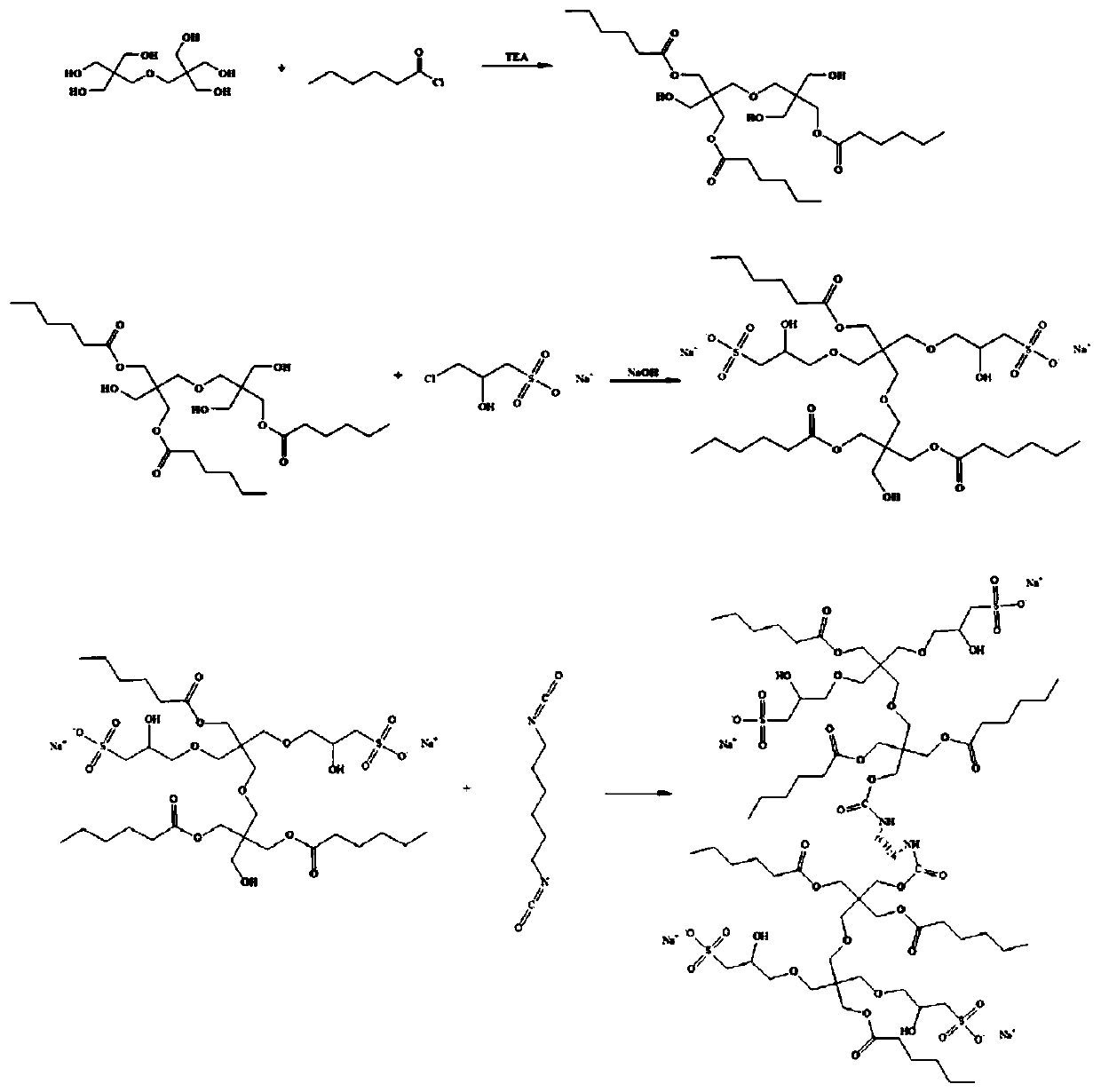

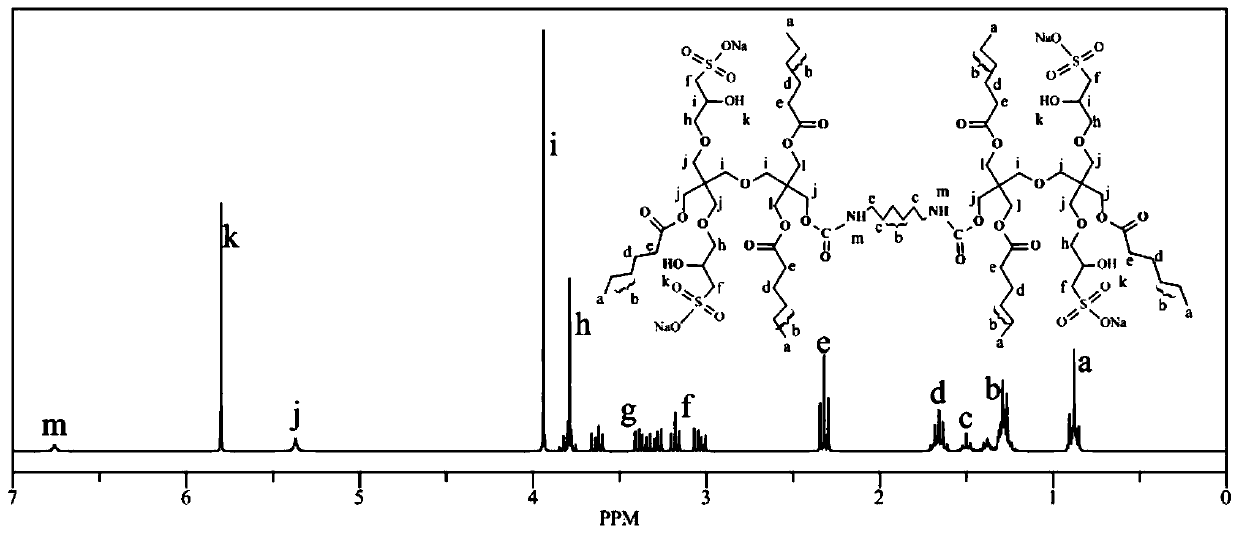

InactiveCN111559970AReduce surface tensionFast wettingOther chemical processesTransportation and packagingPhysical chemistryChloride

The invention discloses a polysulfonic acid structure surface wetting agent and a preparation method thereof. The preparation method comprises the following steps: 1) mixing dipentaerythritol and hexanoyl chloride, stirring and reacting for 2-4 h at the temperature of 30-50 DEG C, cooling to the room temperature, neutralizing, washing with water, extracting, and distilling under reduced pressure to remove the solvent to obtain a viscous liquid intermediate I; 2) adding a first solvent into the viscous liquid intermediate I, adding powdery sodium hydroxide after the viscous liquid intermediateis completely dissolved, stirring and reacting for 0.5-1 h at 25-35 DEG C, then adding sodium 3-chloro-2-hydroxypropyl propanesulfonate into the solution, heating to 80-90 DEG C, reacting for 5-7 h, and carrying out suction filtration to obtain a solid product intermediate II; and 3) adding the solid product intermediate II into a second solvent, adding hexamethylene diisocyanate under magnetic stirring, heating to 40-50 DEG C, reacting for 3-5 h, carrying out suction filtration, and drying to obtain the polysulfonic acid structure surface wetting agent. The preparation method solves the problem of poor spreadability of water on the solid surface.

Owner:宁夏宇航油田工程有限公司

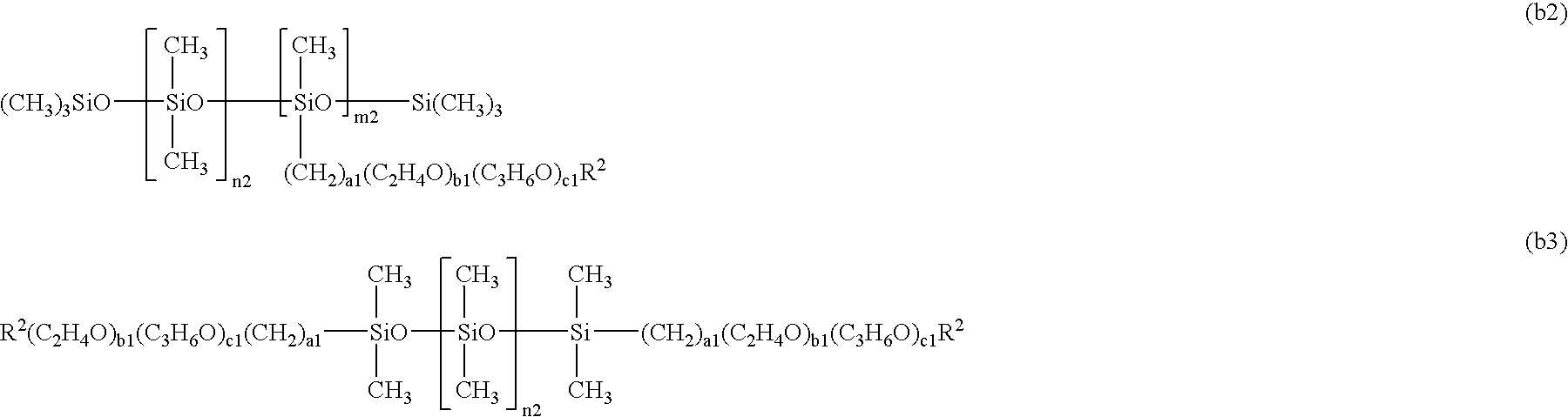

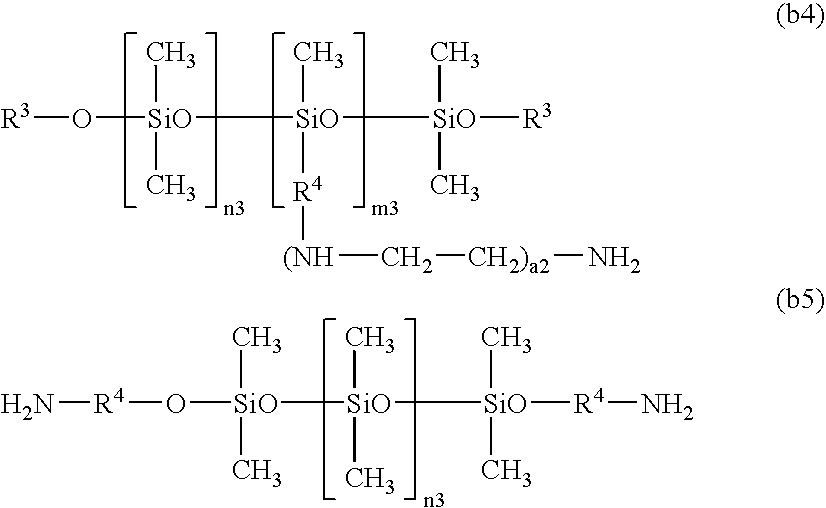

Hair treatment method

InactiveUS20080138306A1Fast wettingImprove feelCosmetic preparationsHair cosmeticsHair characteristicsAlcohol

A hair treatment method in which a hair treatment agent including (A) water, (B) a hydrophobic silicone, (C) 0.5% by weight or more of a lower alcohol and (D) a surfactant is applied to the hair, and immediately thereafter the hair is bundled and secured with a holding device.

Owner:KAO CORP

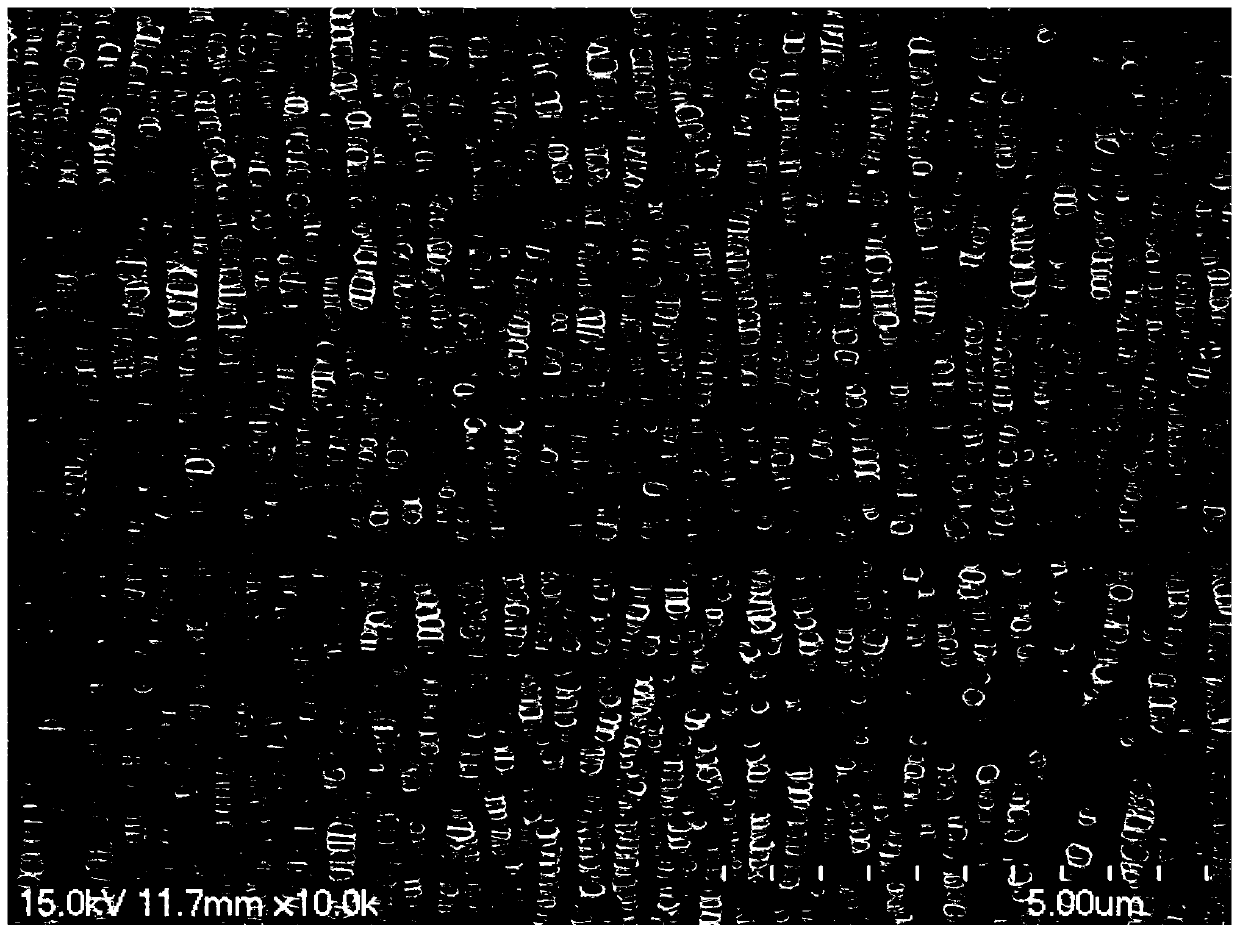

Lithium ion battery diaphragm with high electrolyte wettability and preparation method of lithium ion battery diaphragm

InactiveCN109742302AReduced risk of short circuitsFast wettingCell component detailsPolyolefinPhysical chemistry

The invention belongs to the field of lithium ion battery diaphragms, and particularly relates to a lithium ion battery diaphragm with high electrolyte wettability and a preparation method of the lithium ion battery diaphragm. The lithium ion battery diaphragm comprises a polyolefin microporous membrane matrix, and a lipophilic polymer coating covering the surface of the polyolefin microporous membrane matrix, wherein the wetting speed of the electrolyte on the diaphragm is greatly increased, the wetting uniformity of the electrolyte on the diaphragm is improved, the diaphragm wrinkling causedby poor electrolyte wetting in a lithium ion battery assembling process is prevented, and the risk of short circuit of a lithium ion battery is reduced.

Owner:JIANGSU ANREDA NEW MATERIAL

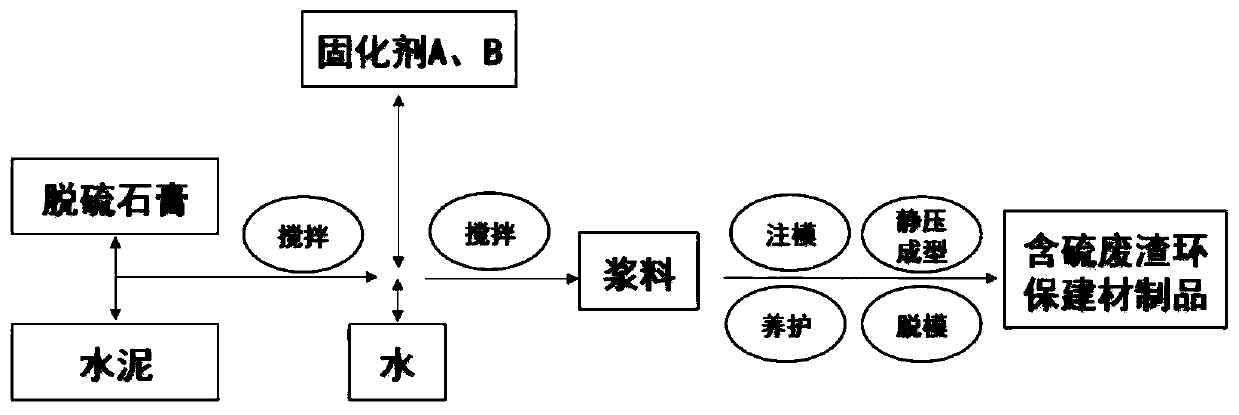

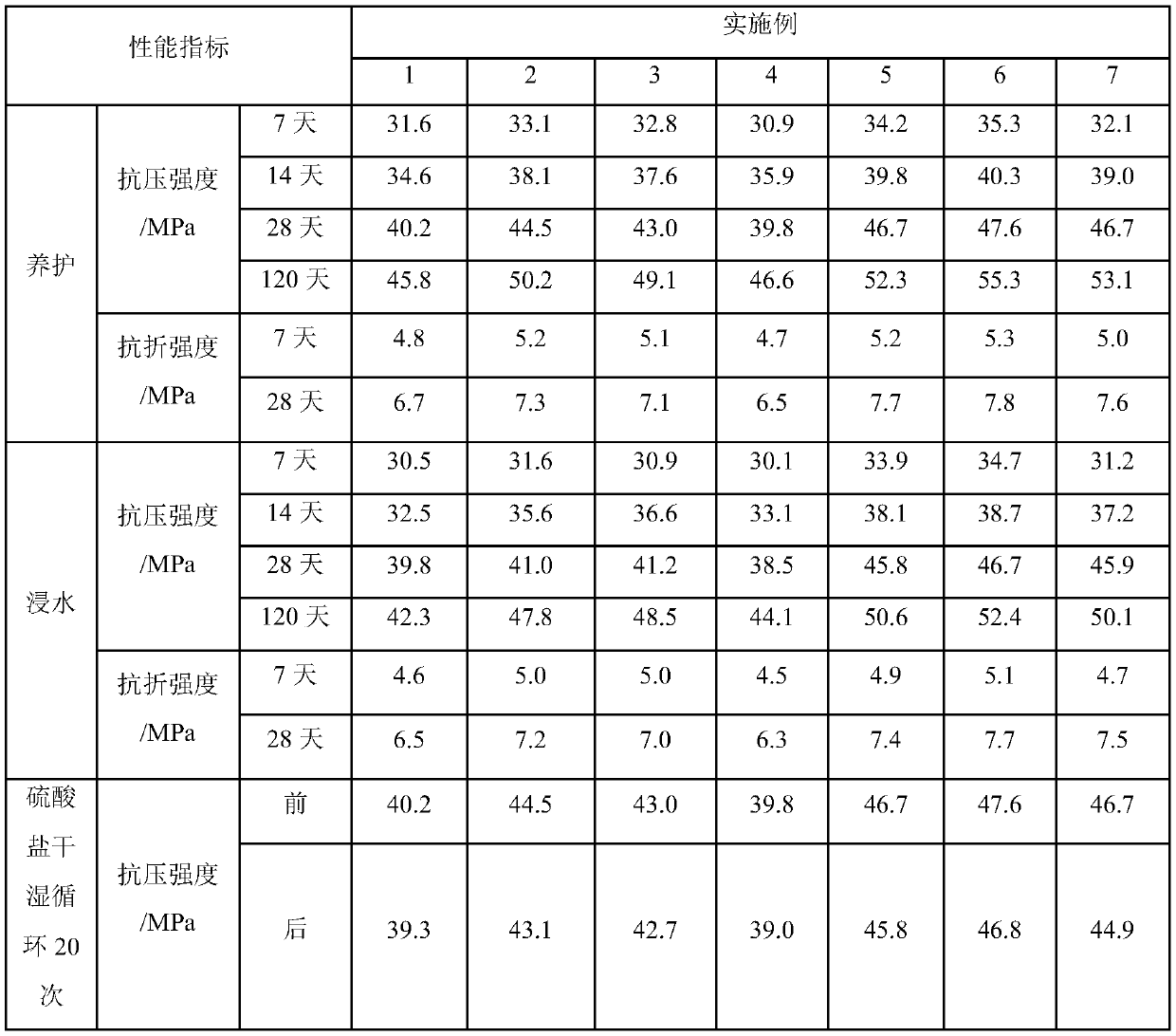

Sulfur-containing waste residue environment-friendly building material product and preparation method thereof

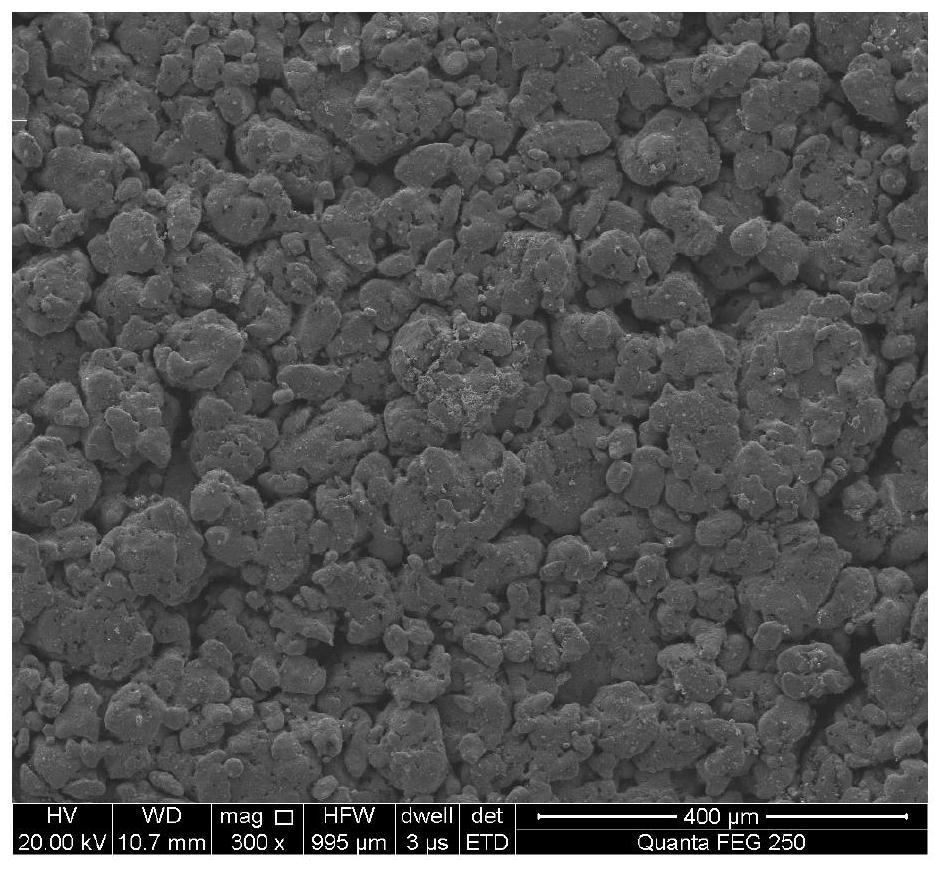

InactiveCN111393126ASmall particle sizeLarge specific surface areaCeramic shaping apparatusSocial benefitsEconomic benefits

The invention discloses a sulfur-containing waste residue environment-friendly building material product and a preparation method thereof. The formula comprises the following components by weight: 75-95 parts of desulfuration gypsum, 5-25 parts of cement, 0.1-0.6 part of a curing agent A, 0.1-0.6 part of a curing agent B and 6-15 parts of water. The preparation method specifically include: makingthe raw materials into a slurry, mixing the prepared slurry evenly, then performing injection molding, conducting static pressure forming under a pressure of 10-60MPa to obtain a green body, and maintaining the pressure for 10s-3min; and conducting curing and demolding to obtain the sulfur-containing waste residue environment-friendly building material product. According to the invention, the burden of industrial solid waste emission on the environment is greatly reduced, the cost is reduced, resource consumption is reduced, functionalization, greenization and value increment of the product are achieved while a large amount of desulfuration gypsum is consumed, and the sulfur-containing waste residue environment-friendly building material product has good economic benefits and social benefits.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

A special coated sand for high-alloy castings

The invention discloses a special coated sand for castings made of high alloy material, which comprises raw sand, lubricant, binder, curing agent and coupling agent, and the binder accounts for 1.7-1.9% of the total mass of the raw sand %; the curing agent is 9-11% of the quality of the binder; the lubricant is 6-8% of the quality of the binder; the coupling agent is 1% of the quality of the binder -2%; the original sand includes recycled sand, pearl sand and magnetite sand; the recycled sand accounts for 50-65% of the total mass of the original sand; the pearl sand accounts for 25-35% of the total mass of the original sand %; the magnetite sand accounts for 10-15% of the total mass of the raw sand, and has various high-quality characteristics such as high temperature resistance, high strength, low expansion, low gas generation, and easy collapse, which can ensure the smooth process of high alloy castings to improve production efficiency.

Owner:西峡飞龙特种铸造有限公司

Delinting penetrant for cotton-seed processing

InactiveCN102177777BLow residual acidNo lumpsVegetable fibre separation from seedsSeed and root treatmentCoconut oilHorticulture

The invention discloses a delinting penetrant for cotton-seed processing. The delinting penetrant is prepared by the following technological processes: feeding 650-750 parts by weight of polyoxyethylene ether into a reactor with mixing function, sequentially adding 240-280 parts by weight of emulsifier TS-10 (alkyl acid polyoxyethylene alkyl ether) or 6501 (coconut oil fatty acid diethanol amide)and 30-50 parts by weight of triethanolamine, and stirring for 20-60 minutes to obtain the delinting penetrant finally. The product prepared by the process disclosed by the invention does not cake incold winter, is resistant against strong acid and strong base and has fast wetting speed and stable performance, and usage amount can be greatly reduced during seed processing; meanwhile, residual acid content in the processed seeds is low, the production cost is reduced, and the product operating requirement is met.

Owner:新疆三赢农业科技发展有限公司

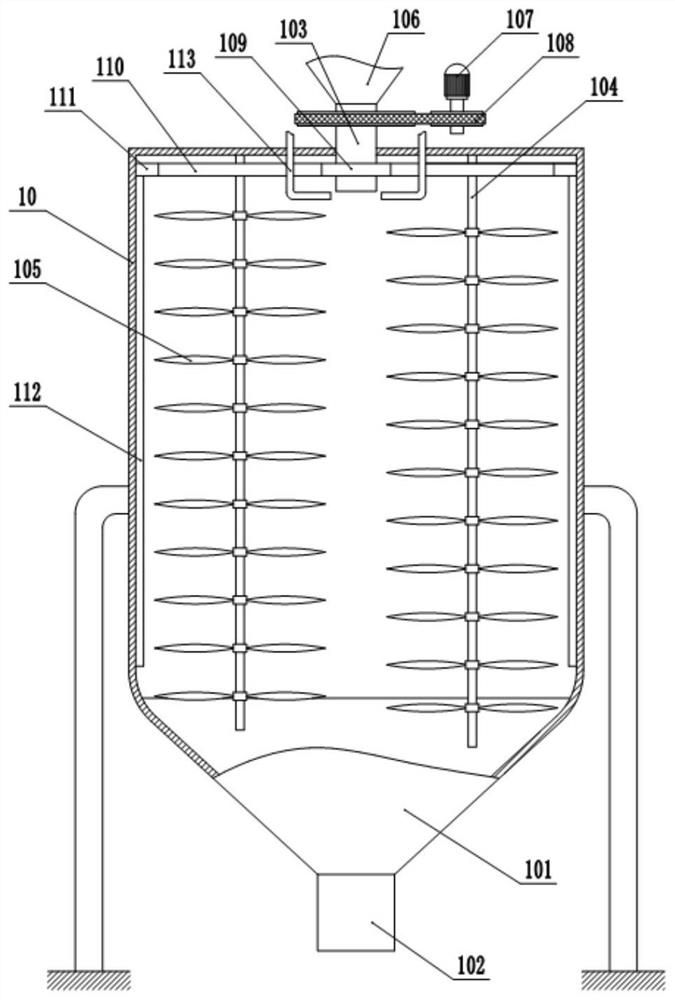

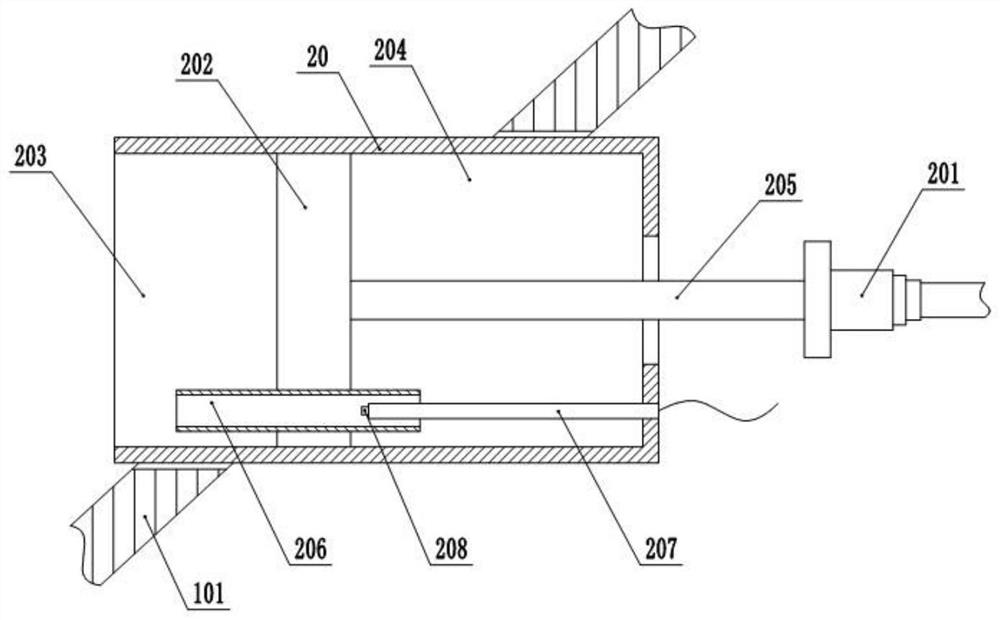

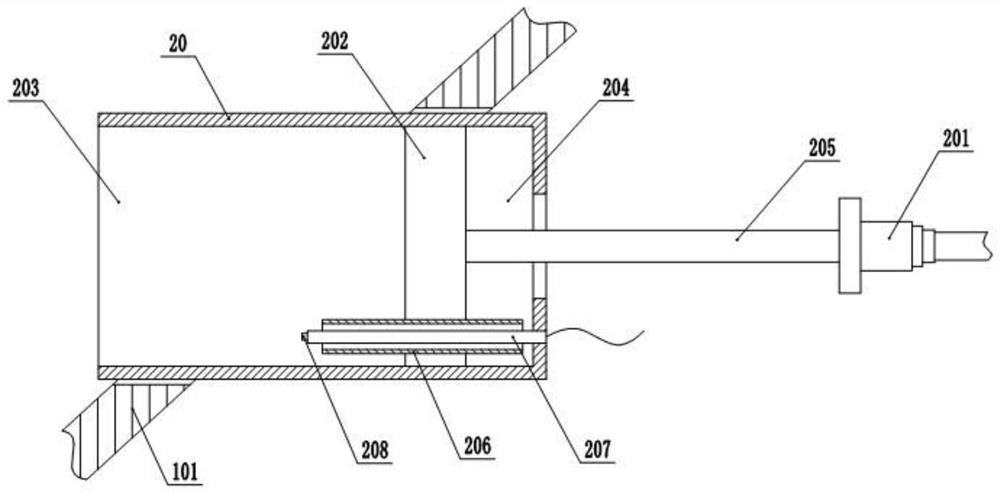

Rapid humidifying and semi-digesting method for fly ash

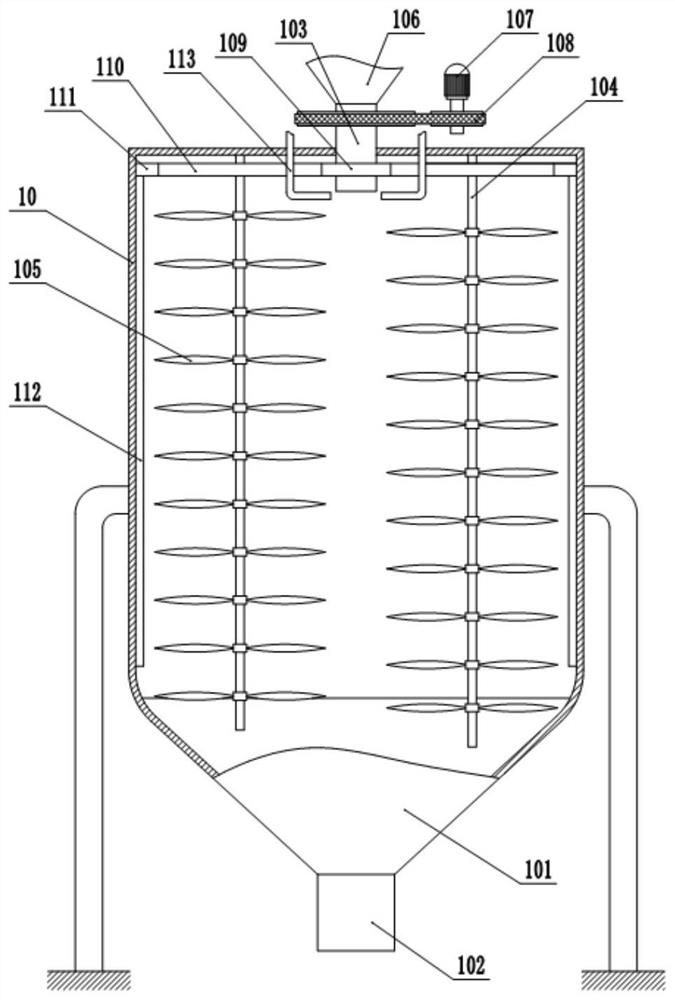

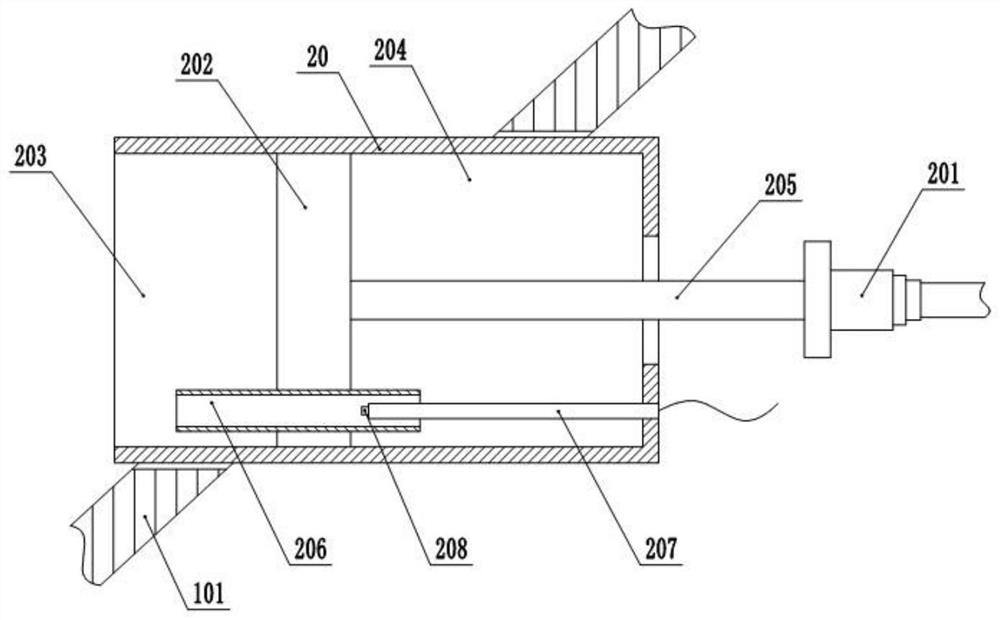

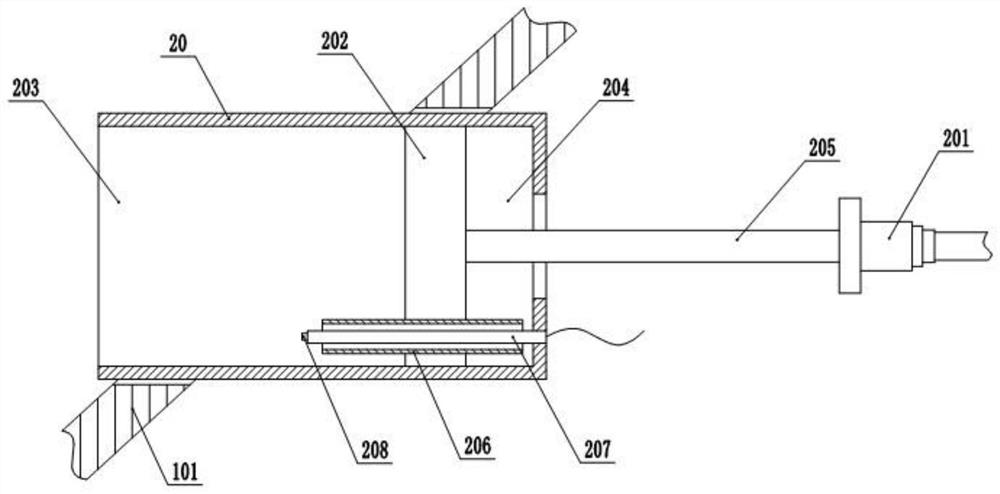

ActiveCN111676366AEasy dischargeGuaranteed dust contentProcess efficiency improvementMaterial analysisSteelmakingCalcium hydroxide

The invention relates to the technical field of resource recovery, and particularly discloses a rapid humidifying and semi-digesting method for fly ash. The method includes the following steps that 1,sampling is conducted, the mass ratio of calcium oxide in the steelmaking fly ash is determined, and the water amount X required by the complete reaction of calcium oxide to calcium hydroxide; 2, thesteelmaking fly ash is added into a stirring tank, water is sprayed into the stirring tank, the steelmaking fly ash entering the stirring tank makes contact with the water, then is mixed by a stirring mechanism in the stirring tank for semi-digestion, and finally is discharged from a discharging pipe at the bottom of the stirring tank, and the total mass of the added water is 20%-60% of X in thestep 1. According to the technical scheme, the steelmaking fly ash can be rapidly humidified and semi-digested, then iron oxide scale or magnetic separation powder and a binding agent are added and mixed together for a chemical reaction, and later reaction and ball pressing procedures are facilitated.

Owner:CHONGQING ZHONGZHA METALLURGY RENEWABLE RESOURCESCO

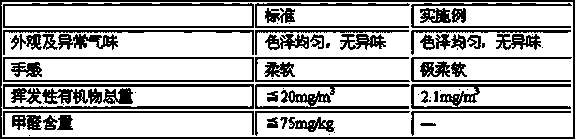

A kind of island super fiber leather processing technology

ActiveCN107675508BAppropriate coloring speedUniform colorGrip property fibresNonwoven fabricMicrofiber

The invention discloses a sea-island microfiber leather processing process which includes a step S1 of spinning sea-island microfiber, adopting a figured sea-island method to spin sea-island microfibers; a step S2 of preparing sea-island microfiber non-woven fabrics, causing the sea-island microfibers to undergo opening, carding, lapping, pre-needling and needling, to obtain the sea-island microfiber non-woven fabrics; a step S3 of performing ultrasonic softening treatment on the sea-island microfiber non-woven fabrics; a step S4 of impregnating and curing the sea-island microfiber non-woven fabrics, impregnating the sea-island microfiber non-woven fabrics in resin liquid, performing repeated squeezing, and performing ultrasonic processing through an ultrasound instrument and drying through a drying oven, to obtain a sea-island microfiber leather base; and a step S5 of performing decrement, softening, expanding drying forming, skin kneading and dyeing, to obtain finished sea-island microfiber leather. According to the sea-island microfiber leather processing process, process arrangement is reasonable, organic matter volatilization in the production process is less, the sea-island microfiber leather processing process is environmentally friendly and is easily impregnated, the coloring speed is appropriate, and the prepared sea-island microfiber leather is uniform in color and good in softness.

Owner:TIANSHOU FUJIAN SUPERFIBER TECH

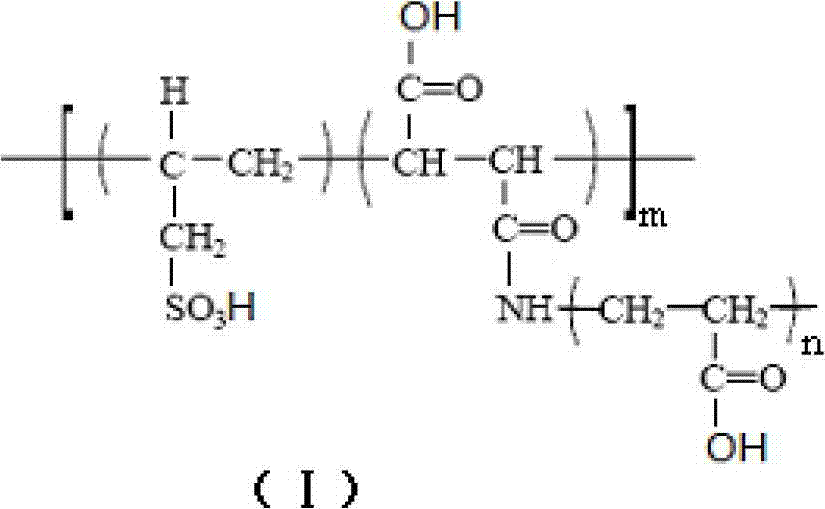

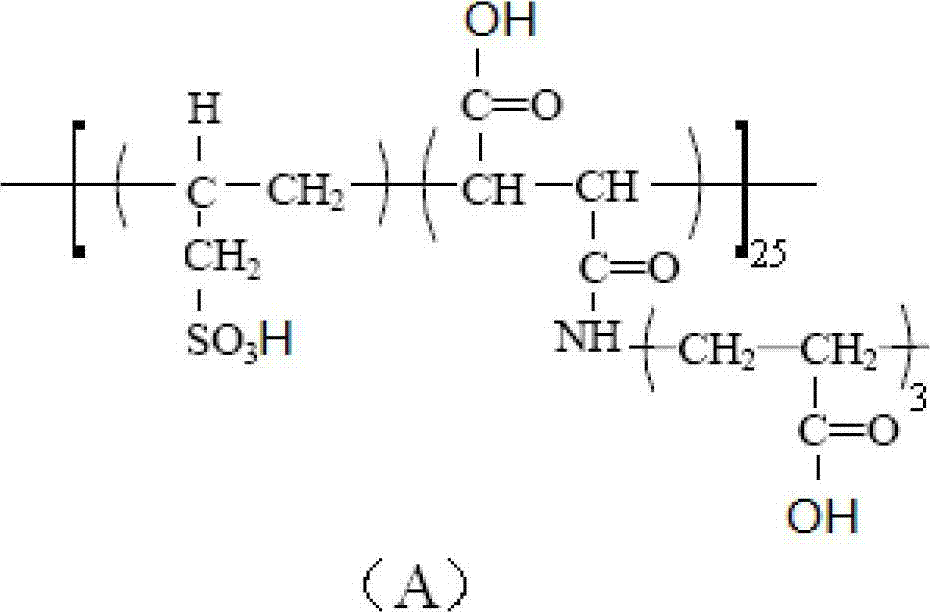

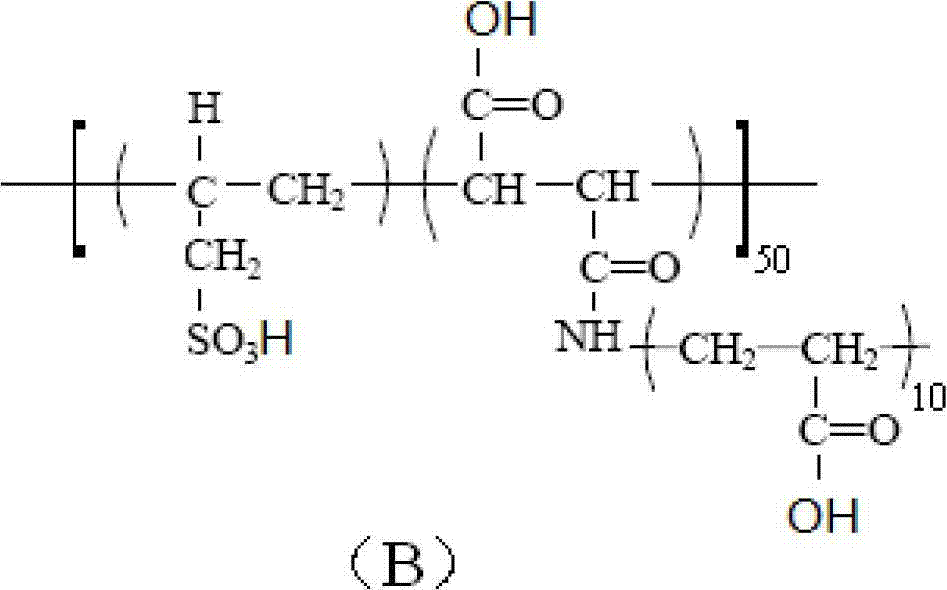

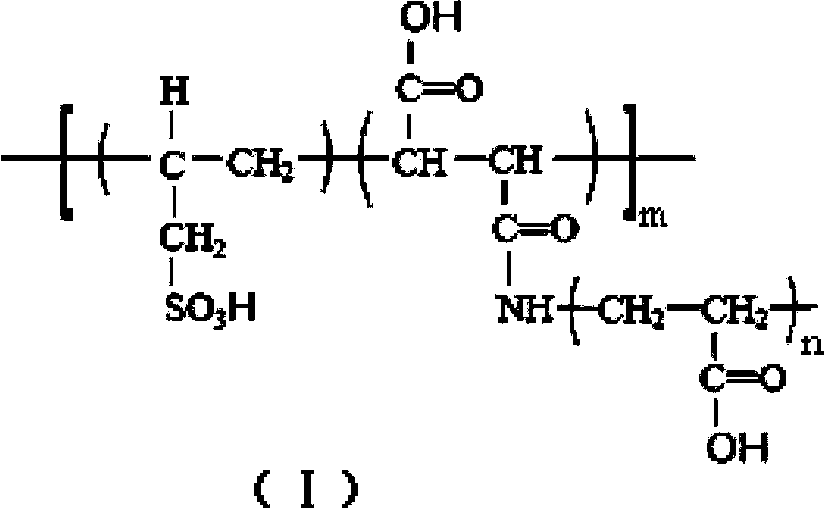

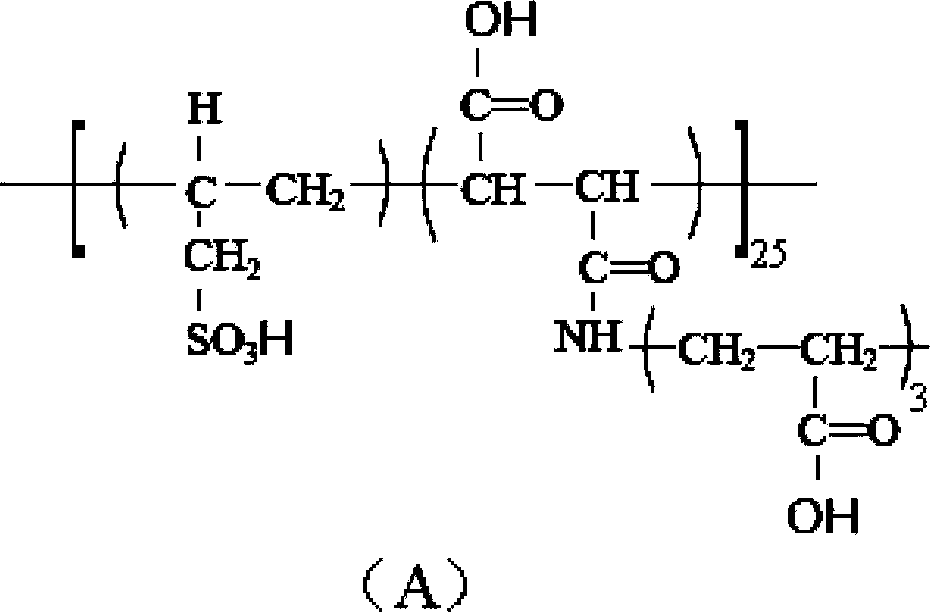

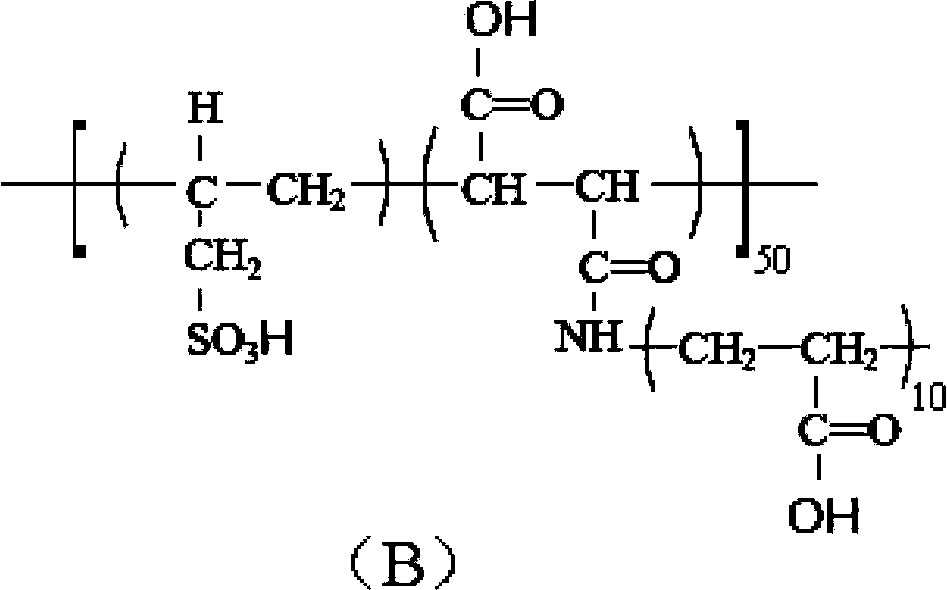

Method for preparing special compound water reducing agent for fireproof material

The invention discloses a method for preparing a special compound water reducing agent for a fireproof material. The method comprises the following steps of 1, polycarboxylic acid synthesizing: mixing 50-60 parts by weight of polyethylene glycol PEG100, 15-20 parts by weight of methacrylic acid, 5-10 parts by weight of ammonium persulfate solution with 5 percent of mass fraction and 18-25 parts by weight of mercapto ethanol solution with 10 percent of mass fraction, and polymerizing and reacting at 1-2 barometric pressure and 60-100 DEG C to obtain a polycarboxylic acid mixed solution; 2, carrier slurry control: using alumina micro powder as a carrier to be fully stirred with the obtained polycarboxylic acid mixed solution, controlling the solid content of the slurry to be 50-80 percent and the viscosity of the slurry to be 100-1000 mPa.S; and 3, carrier spraying and drying: atomizing and drying the mixed slurry. The compound water reducing agent prepared by the method has the advantages of easiness in dispersion, fast wetting, high water reducing rate, no bleeding, improved high-temperature performance and the like.

Owner:湖北斯曼新材料股份有限公司

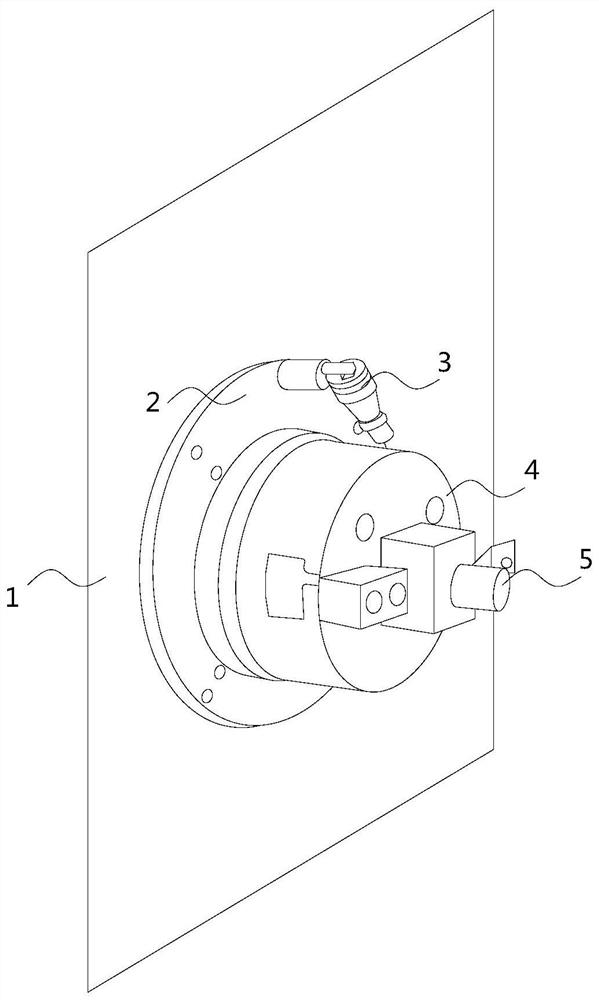

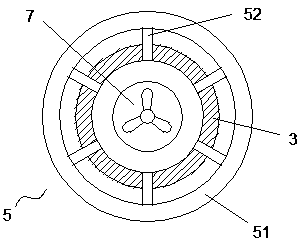

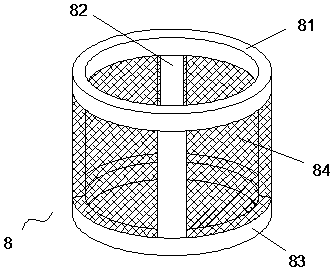

A Robot-Assisted Intelligent CNC Turning Processing System

ActiveCN111168396BAll-round lubricationCausing wear problemsOther manufacturing equipments/toolsMaintainance and safety accessoriesControl systemControl engineering

The invention discloses a robot-assisted intelligent numerical control turning processing system, which includes a digital control system, a servo power system, an imported power turret, and a fully automatic chip removal system. The imported power turret includes a frame, a tool seat, a lubrication mechanism, a tool There is a tool holder horizontally on the frame, and a tool holder is provided at the other end of the tool holder. The tool holder and the holder are fixed horizontally. The other end of the holder is equipped with a drill, and the drill and the holder are installed. It is fixed horizontally, and a lubricating mechanism is installed on the tool seat above the turret base. The present invention adjusts the length and angle of the sponge block through the expander and the sponge block, thereby lubricating the turret base and the drill in all aspects. The outer diameter of the inventive sponge block is equal to the diameter of the chassis, and the two are completely engaged, there will be no height difference, and there will be no edge friction during use, which will cause structural wear.

Owner:赣州博发精密机械有限公司

A kind of preparation method of carbon particle reinforced metal matrix composite material

The invention relates to a method for preparing a carbon particle reinforced metal matrix composite material, belonging to the technical field of metal material preparation. By degumming short carbon fiber and phenolic resin powder with high energy to obtain metal powder with carbon particles and phenolic resin evenly embedded, and then subjecting it to ultrasonic and drying treatment, the metal powder with internal carbon and phenolic resin powder embedded in the surface carbon removal is obtained, and then It is mixed with phenolic resin powder and other components and then pressed and sintered to obtain a carbon particle reinforced metal matrix composite material. The invention successfully solves the problem of non-dense interface sintering of the metal powder embedded with carbon particles in the sintering process, and realizes the mechanical properties and wear resistance of the metal composite material designed and prepared under the premise of dense sintering of the metal powder. Improvement, simple preparation process and low cost.

Owner:CENT SOUTH UNIV

A kind of preparation method of metal material or metal composite material

Owner:CENT SOUTH UNIV

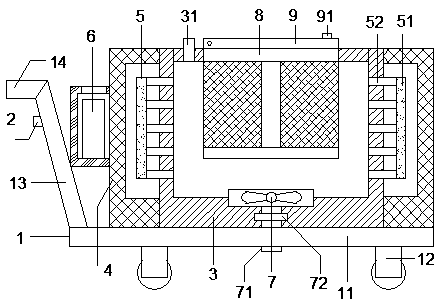

Quick humidification and semi-digestion method for dedusting dust

ActiveCN111676366BFully contactedFast wettingProcess efficiency improvementMaterial analysisSteelmakingCalcium hydroxide

The invention relates to the technical field of resource recovery, and specifically discloses a method for rapid humidification and semi-digestion of dedusting ash, including the following steps: Step 1: Sampling and detecting the mass proportion of calcium oxide in steelmaking dedusting ash, and obtaining the complete reaction of calcium oxide into calcium hydroxide The amount of water required is X; Step 2: Add the steelmaking dust removal ash into the mixing tank, and spray water into the mixing tank at the same time, so that the steelmaking dust removal ash entering the mixing tank is in contact with the water, and then mixed by the stirring mechanism in the mixing tank. Semi-digested, then discharged from the discharge pipe at the bottom of the stirring tank, wherein the total mass of water added is 20% to 60% of X in step 1. The technical solution in this patent can quickly humidify and semi-digest the steelmaking dust, and then add iron oxide scale or magnetic separation powder and binder to mix together, let it undergo a chemical reaction, which is beneficial to the later reaction and the ball pressing process. .

Owner:CHONGQING ZHONGZHA METALLURGY RENEWABLE RESOURCESCO

Composition containing propionyl brassinolide and hypersensitive protein

InactiveCN113396917APromote growthStrengthen body functionBiocidePlant growth regulatorsPolyethylene glycolBenzenesulfinic acid

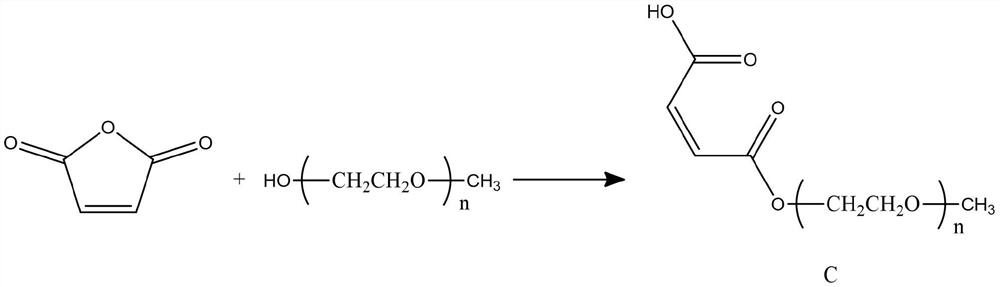

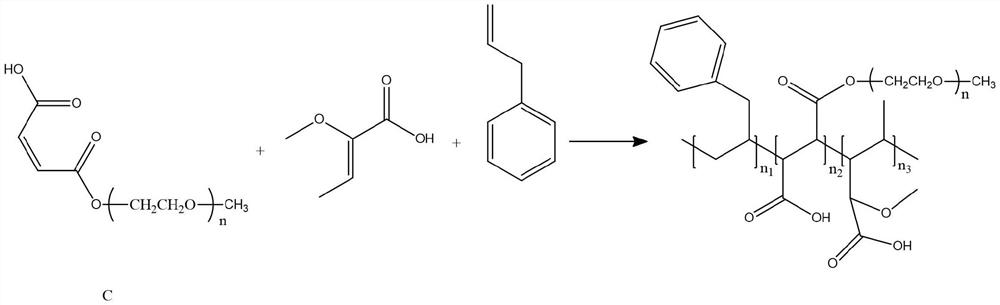

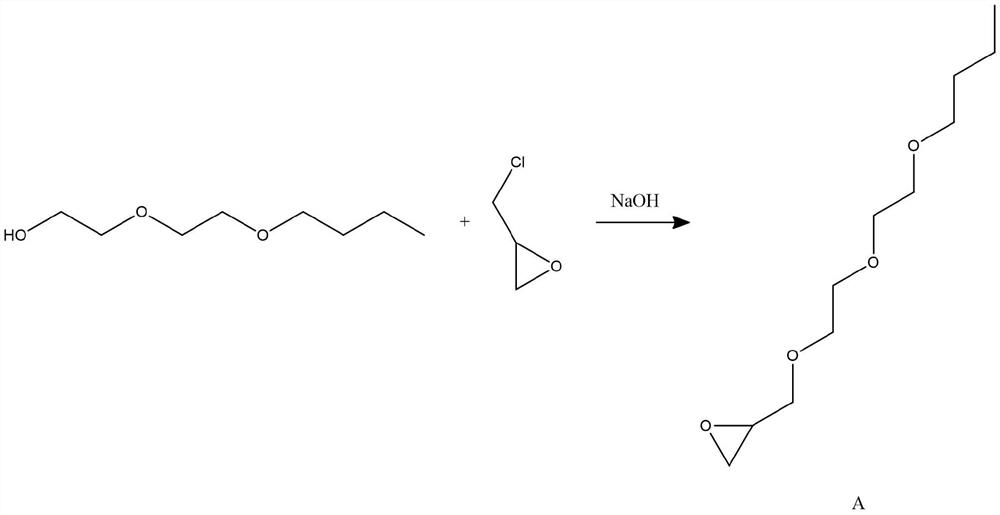

The invention discloses a composition containing propionyl brassinolide and hypersensitive protein. Maleic anhydride is added into a three-neck flask provided with a reflux condensing tube and a thermometer, polyethylene glycol monomethyl ether is added, magneton stirring is started, p-toluenesulfonic acid is added, an intermediate C is obtained, and the intermediate C and allyl benzene are added into a four-neck flask. The propionyl brassinolide and the hypersensitive protein are reasonably compounded, so that the growth of plants can be regulated, the growth of the plants is promoted, the yield of crops is increased, the stability of the pesticide is improved by adding the dispersing aid, the pesticide is not easy to settle, and the absorption efficiency of the plants is improved by adding the surface active aid, so that the purposes of high-efficiency pesticide use, environment protection and soil pressure reduction are achieved.

Owner:安徽润农腾辉生物科技有限公司

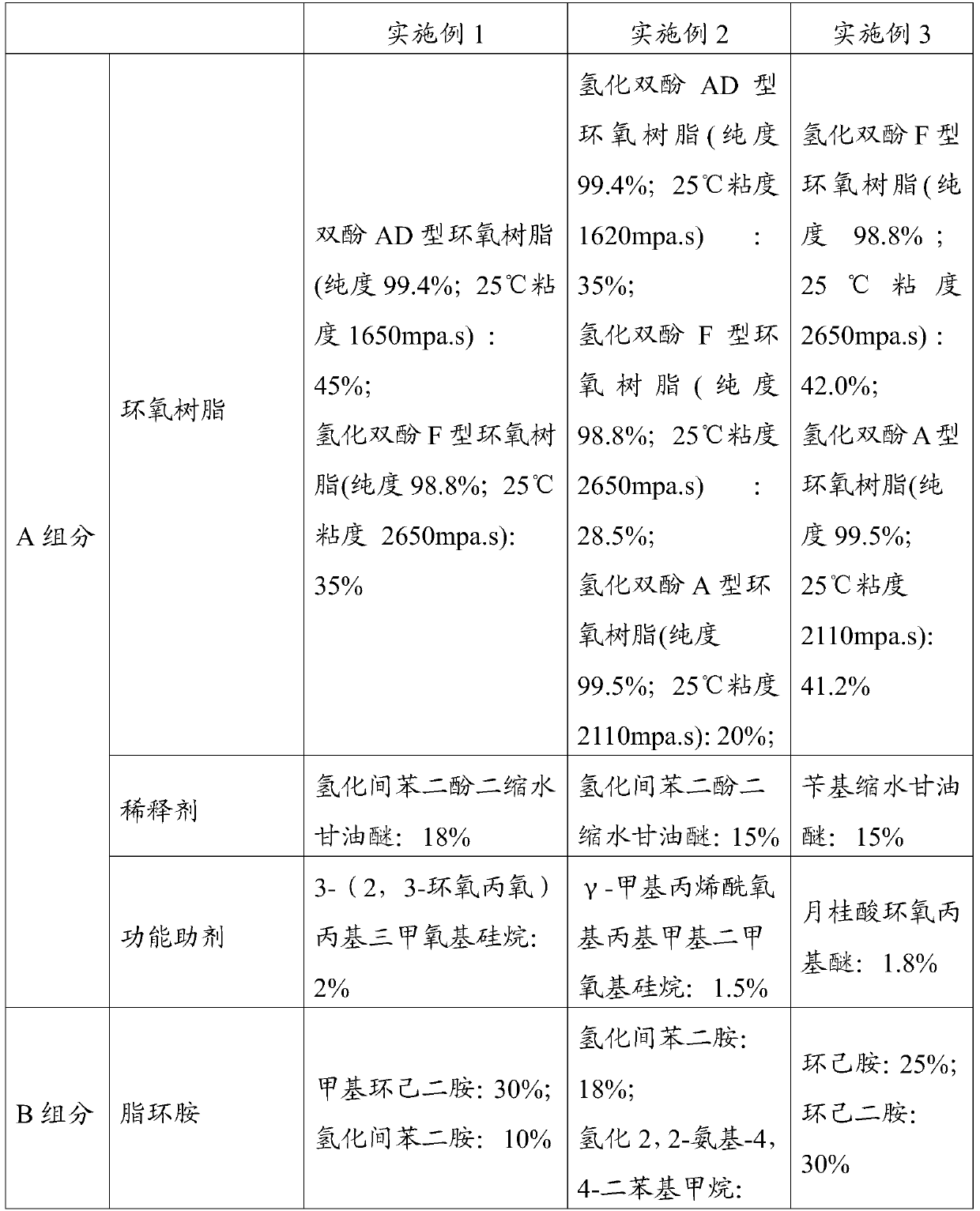

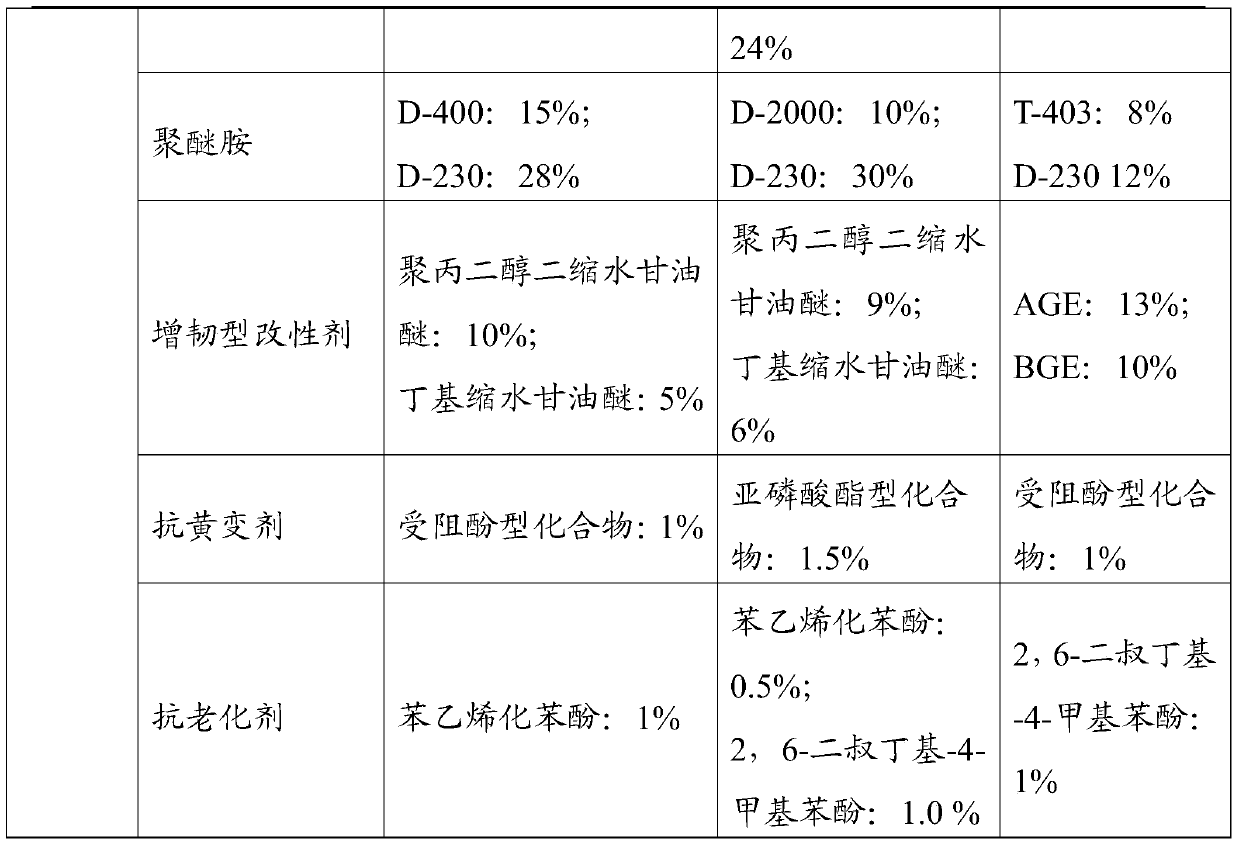

Epoxy resin system and preparation method thereof

The invention relates to an epoxy resin system and a preparation method thereof. The epoxy resin system comprises a component A and a component B, and the component A comprises 80-85% of epoxy resin, 14-19% of a diluent and 0.1-3% of a functional assistant; and the component B comprises 40-60% of alicyclic amine, 20-45% of polyetheramine and 10-30% of a toughening modifier, wherein the epoxy resin is one or more of bisphenol AD epoxy resin, hydrogenated bisphenol AD epoxy resin, hydrogenated bisphenol A epoxy resin and hydrogenated bisphenol F epoxy resin The epoxy resin system has a fast wetting speed and a good infiltrating effect on carbon fibers, can realize rapid solidification and good heat resistance, and has excellent technological operationality and excellent mechanical properties; and a solidified material can be baked at a high temperature or used outdoor without efflorescence or yellowing phenomena, can be used to make unmanned planes, and meets unmanned planes' performance requirements of composite materials.

Owner:GUANGZHOU POCHELY NEW MATERIAL TECH CO LTD

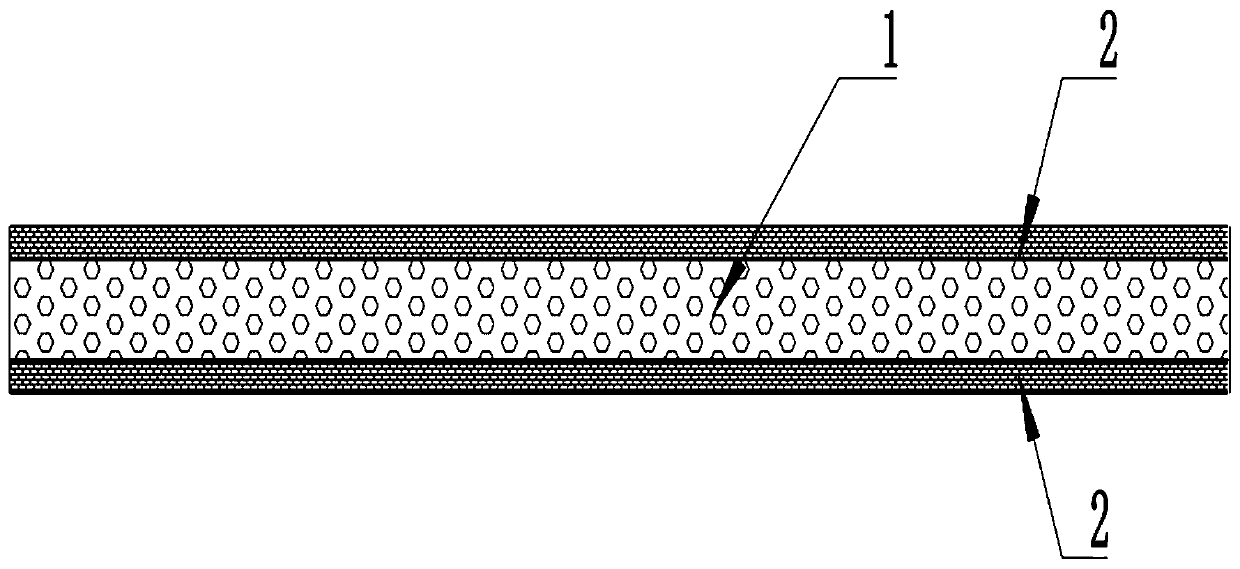

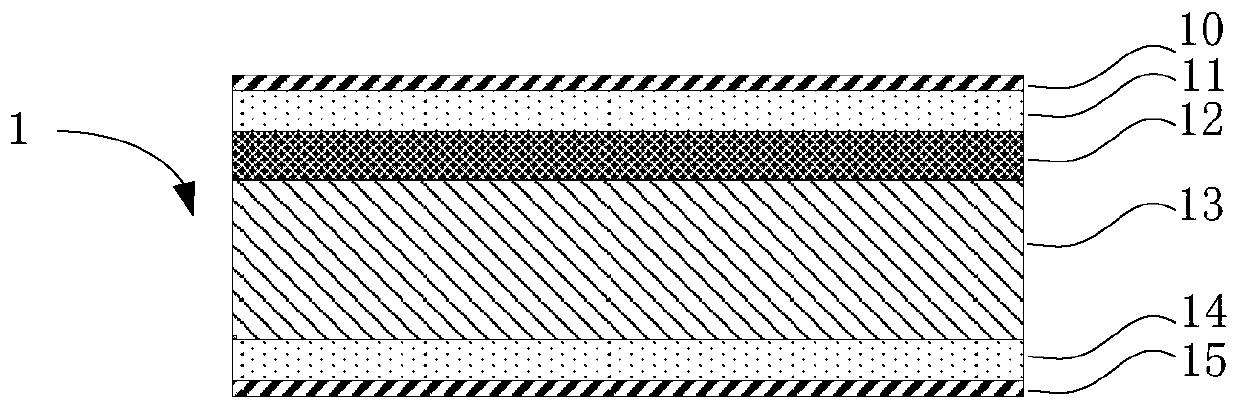

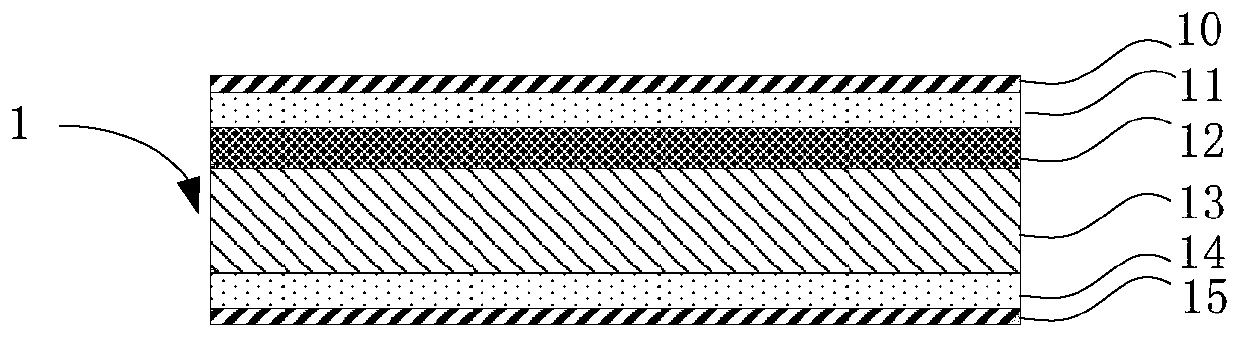

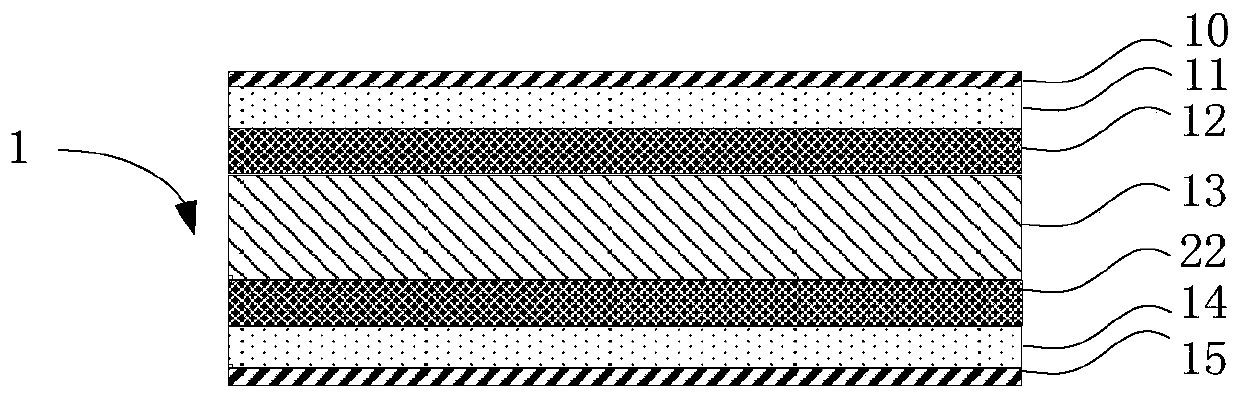

Rubber-based easy-to-pull adhesive and preparation method thereof

InactiveCN110183987AStrong initial adhesionImprove initial tackFilm/foil adhesivesMacromolecular adhesive additivesAdhesiveAbsorption effect

The invention provides a rubber-based easy-to-pull adhesive and a preparation method thereof. The rubber-based easy-to-pull adhesive comprises: a first release film, a first face adhesive layer located on the first release film, a first wetting layer located on the first face adhesive layer and used for increasing a wetting speed of the first face adhesive layer, a base film layer located on the first wetting layer, a second face adhesive layer located on the base film layer, and a second release film located on the second face adhesive layer. The provided rubber-based easy-to-pull adhesive isless affected by an ambient temperature when being used, and especially in a low temperature condition such as winter, has the advantages of being more convenient and efficient, and at the same time,because the wetting layer has the characteristics of foam cotton, the rubber-based easy-to-pull adhesive has a certain buffer and shock-absorption effect.

Owner:新纶电子材料(常州)有限公司

A kind of polysulfonic acid structure surface wetting agent and preparation method thereof

InactiveCN111559970BReduce surface tensionFast wettingOther chemical processesTransportation and packagingPhysical chemistryChloride

The invention discloses a surface wetting agent with polysulfonic acid structure and a preparation method thereof. The preparation method comprises: 1) mixing dipentaerythritol and hexanoyl chloride, stirring and reacting at 30-50°C for 2-4 hours, cooling to room temperature; neutralizing , washed with water, extracted, and the solvent was distilled off under reduced pressure to obtain a viscous liquid intermediate I; 2) Add the first solvent to the viscous liquid intermediate I, and after it is completely dissolved, add powdered sodium hydroxide and stir at 25-35°C React for 0.5-1h, then add 3-chloro-2-hydroxypropylpropanesulfonate sodium into the solution, raise the temperature to 80-90°C, react for 5-7 hours, and obtain the solid product intermediate II by suction filtration; 3) the solid Add the product intermediate II into the second solvent, add hexamethylene diisocyanate under magnetic stirring, raise the temperature to 40-50°C, react for 3-5 hours, filter with suction and dry to obtain a surface wetting agent with polysulfonic acid structure. The preparation method solves the problem of poor spreading of water on the solid surface.

Owner:宁夏宇航油田工程有限公司

Processed product of tea in the form of particles

PendingUS20210289808A1Fast wettingQuickly dispersed in waterPre-extraction tea treatmentTea extractionBiotechnologyCollagenan

Disclosed are a processed product of tea in the form of particles and method for masking the bad taste or bad odor of collagen. In an aspect, the processed product of tea contains tea powder and collagen powder and does not contain a binder. In another aspect, the processed product of tea contains tea powder and collagen powder, and contains 10 wt % or less of fine powder having a particle diameter of 75 μm or smaller based on the total particle weight of the processed product of tea.

Owner:AMOREPACIFIC CORP

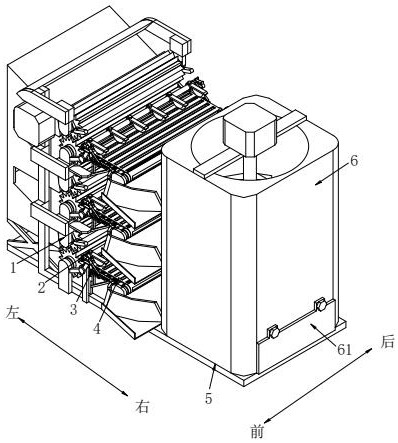

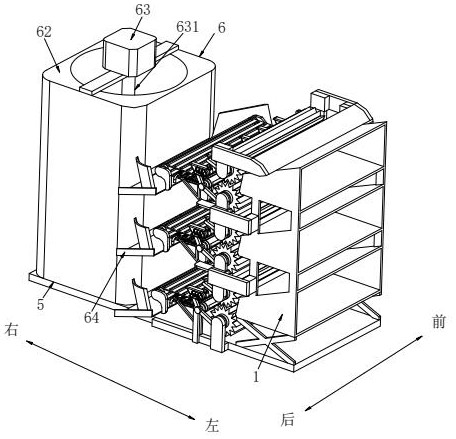

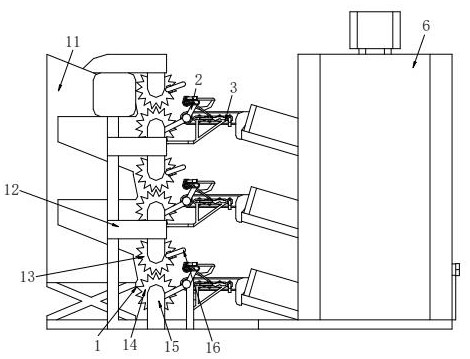

A corrugated box recycling and crushing device

ActiveCN114525695BImprove recycling efficiencyAvoid knife jamsPaper recyclingRaw material divisionCartonWater flow

The invention relates to the technical field of crushing equipment, in particular to a corrugated box recycling and crushing treatment device, comprising a bottom plate, a crushing component is fixedly connected to the right side of the upper surface of the bottom plate, and a left side of the upper surface of the bottom plate is fixedly connected with A plurality of conveying assemblies, the right sides of the plurality of conveying assemblies are rotatably connected with conveying belts, and a cutting assembly is arranged above the conveying belts, and the water outlet seats arranged on the upper and lower surfaces of the fixing frame can pass through the conveying belts. The upper and lower sides of the carton are sprayed at the same time, so that the carton is sprayed more thoroughly and the speed of wetting is faster. During the process, it shakes up and down to make the water seat spray more evenly, and at the same time, the pressure of the water flow on the carton is not constant, so that the water seat is sprayed more evenly.

Owner:江苏互憓通包装有限公司

Method for purifying gibberellin GA3 and preparing water-soluble pulvis of gibberellin GA3

InactiveCN102246756BIncrease dissolution rateImprove solubilityBiocidePlant growth regulatorsAcetic acidWater soluble

The invention provides a method for purifying gibberellin GA3 and preparing water-soluble pulvis of gibberellin GA3. The invention brings forward control of purity and particle size of gibberellin GA3 and utilization of complex formulation to prepare water-soluble pulvis of gibberellin GA3. According to the invention, a mixed solvent of tetrahydrofuran / ethyl acetate / water is used for recrystallization of a crude product of gibberellin GA3, which enables a reasonable process and simple operation and enables purity of the product in one operation to be more than 98.5% and yield of the product to be more than 90%; the technology of complex formulation is employed and gibberellin GA3 is made to be rapidly dissolved in a water phase and to form a stable disperse phase through using of accessories like an acidic buffer reagent, a dispersant and a surfactant, thereby enabling gibberellin GA3 to be easier to store and transport and more convenient to use and drug effects and the utilization rate to be improved.

Owner:JIANGXI LIFENG BIOLOGICAL TECH

Method for preparing special compound water reducing agent for fireproof material

The invention discloses a method for preparing a special compound water reducing agent for a fireproof material. The method comprises the following steps of 1, polycarboxylic acid synthesizing: mixing 50-60 parts by weight of polyethylene glycol PEG100, 15-20 parts by weight of methacrylic acid, 5-10 parts by weight of ammonium persulfate solution with 5 percent of mass fraction and 18-25 parts by weight of mercapto ethanol solution with 10 percent of mass fraction, and polymerizing and reacting at 1-2 barometric pressure and 60-100 DEG C to obtain a polycarboxylic acid mixed solution; 2, carrier slurry control: using alumina micro powder as a carrier to be fully stirred with the obtained polycarboxylic acid mixed solution, controlling the solid content of the slurry to be 50-80 percent and the viscosity of the slurry to be 100-1000 mPa.S; and 3, carrier spraying and drying: atomizing and drying the mixed slurry. The compound water reducing agent prepared by the method has the advantages of easiness in dispersion, fast wetting, high water reducing rate, no bleeding, improved high-temperature performance and the like.

Owner:湖北斯曼新材料股份有限公司

Equipment for wetting forage for cows in gestation period

InactiveCN111345246AFast wettingImprove wetting effectAnimal feeding devicesWater heatersAnimal scienceGestation period

The invention discloses equipment for wetting forage for cows in a gestation period and belongs to the technical field of livestock breeding. The equipment comprises a push device, a control switch and a wetting tank, wherein the wetting tank is of a columnar cavity structure; a heating tank is connected with the outer side wall of the wetting tank; a heating part is arranged in the inner cavity of the heating tank; the heating part is connected with the side wall of the wetting tank; a power supply protection box is connected with the left side of the heating tank; a battery is mounted in thepower supply protection box; and a water injection hole is formed in the left side of the top wall of the wetting tank. By adopting the equipment, the wetting speed can be increased, the wetting effect can be improved, the forage can be wetted and heated, demands of the cows in the gestation period on water can be increased, meanwhile, the cows can be prevented from eating cold forage, intestinesand stomachs of the cows can be protected, occurrence of gastrointestinal diseases of the cows in the gestation period can be reduced, growth and development of fetuses can be improved, and the calving rate of the cows can be increased.

Owner:徐州宇鑫农业发展有限公司

Cooling liquid for diamond wire cutting

The invention provides a cooling liquid for diamond wire cutting. The cooling liquid comprises the following components in percentage by weight: 16-26% of a stabilizer, 0.5-2% of a water-soluble lubricant, 1-4% of an extreme pressure agent, 3-8% of a preservative, 1-4% of a wetting agent, 0.01-0.04% of a defoaming agent and the balance of deionized water. The cooling liquid has the advantages of high efficiency, low toxicity and good water solubility, and can effectively inhibit the damage of microbial growth to the stability of the cooling liquid.

Owner:江苏德比新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com