Method for preparing special compound water reducing agent for fireproof material

A technology of composite water reducer and refractory materials, which is applied in the field of preparation of special composite water reducers for refractory materials, which can solve the problems of reducing the high-temperature performance of refractory materials, low addition amount, and more gas deflection holes, etc., so as to improve the uniformity of dispersion , Improve high temperature performance and eliminate bleeding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

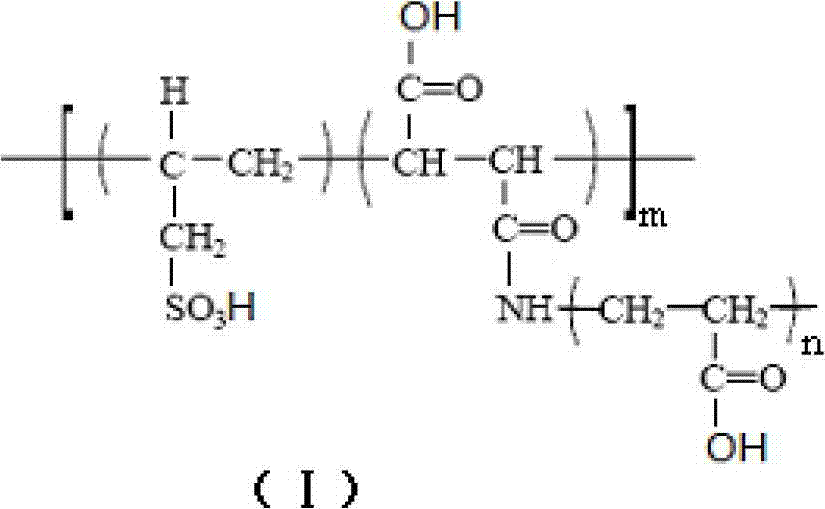

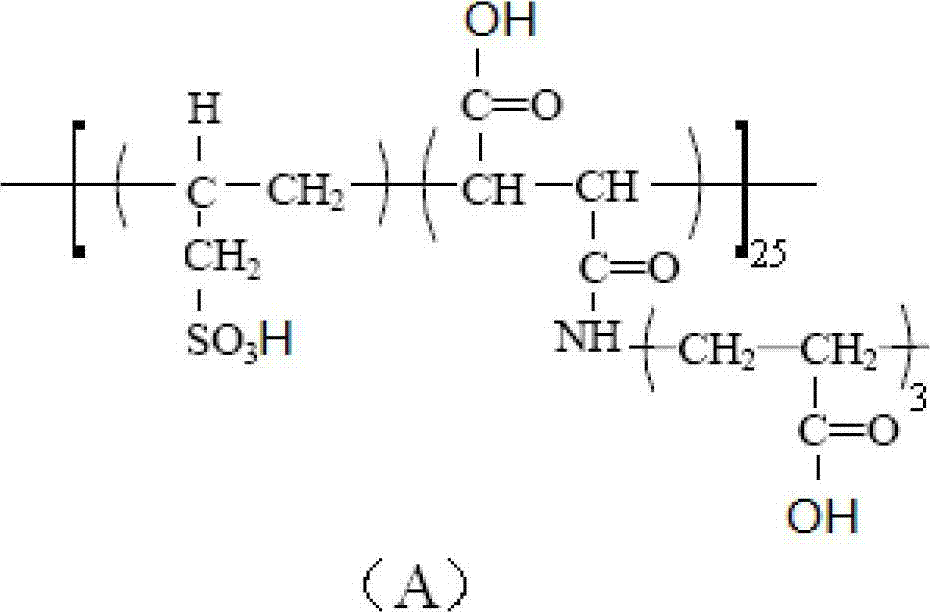

[0018] 1) Synthesis of polycarboxylic acid: the massfraction of 5% ammonium persulfate solution and 20.5 parts by weight of the massfraction of 5% ammonium persulfate solution and the massfraction of 52.5 parts by weight of polyethylene glycol PEG100, 18 parts by weight of methacrylic acid, 9 parts by weight of 10 % of mercaptoethanol solution, and polymerized under the conditions of 1~2 atmospheric pressure and 60~100°C to obtain a mixed solution containing polycarboxylic acid with the structure shown in A. The relative molecular weight of the polycarboxylic acid is 11375,

[0019]

[0020] 2) Control of the carrier slurry: take alumina micropowder as the carrier, fully stir with the mixed solution containing the polycarboxylic acid of the structure shown in A obtained in step 1), control the solid content of the slurry to be 75%, and the viscosity to be 500mPa .S;

[0021] 3) Carrier spray drying: atomize the slurry prepared in step 2) at an atomization rate of 20,000 rpm...

Embodiment 2

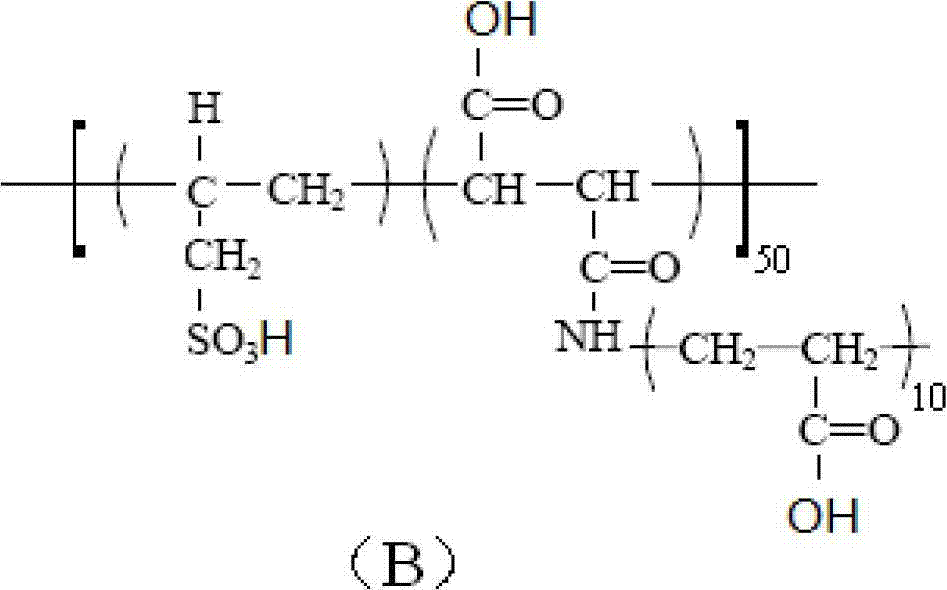

[0023] 1) Synthesis of polycarboxylic acid: the massfraction of 5% ammonium persulfate solution and 22 parts by weight of the massfraction of 5% ammonium persulfate solution and the massfraction of 22 parts by weight of the methacrylic acid of the polyethylene glycol PEG100 of 50 parts by weight, 18 parts by weight of 10 parts by weight % of mercaptoethanol solution, and polymerized under the conditions of 1~2 atmospheric pressure and 60~100°C to obtain a mixed solution containing polycarboxylic acid with the structure shown in B, the relative molecular weight of the polycarboxylic acid is 48300,

[0024]

[0025] 2) Control of the carrier slurry: with the alumina micropowder as the carrier, fully stir with the mixed solution containing the polycarboxylic acid of the structure shown in B obtained in step 1), the solid content of the control slurry is 80%, and the viscosity is at 600mPa .S;

[0026] 3) Carrier spray drying: atomize the slurry prepared in step 2) at an atomiz...

Embodiment 3

[0028] 1) Synthesis of polycarboxylic acid: the massfraction of 5% ammonium persulfate solution and 22 parts by weight of methacrylic acid, the massfraction of 7 parts by weight of the polyethylene glycol PEG100 of 55 parts by weight, the massfraction of 16 parts by weight is 10 % of mercaptoethanol solution, and polymerized under the conditions of 1~2 atmospheric pressure and 60~100°C to obtain a mixed solution containing polycarboxylic acid with the structure shown in C. The relative molecular weight of the polycarboxylic acid is 28650,

[0029]

[0030] 2) Control of the carrier slurry: take the alumina micropowder as the carrier, fully stir with the mixed solution containing the polycarboxylic acid of the structure shown in C obtained in step 1), control the solid content of the slurry to be 70%, and the viscosity to be 400mPa .S;

[0031] 3) Carrier spray drying: atomize the slurry prepared in step 2) at an atomization rate of 25,000 rpm, and dry at a drying temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com