A kind of island super fiber leather processing technology

A processing technology and technology of microfiber leather, which is applied in the direction of fiber treatment, fiber type, improved hand feeling fiber, etc., can solve the problems affecting the dyeing process of sea-island microfiber leather, uneven coloring of sea-island microfiber leather, workers and users Damage and other problems, to achieve the effect of appropriate coloring speed, uniform color and fast wetting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

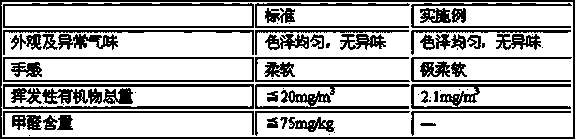

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with specific embodiments.

[0020] A sea-island microfiber leather processing technology proposed by the present invention comprises the following steps:

[0021] S1: Spinning of sea-island superfiber, the island component is polyamide, the sea component is water-based polyester, the island and the sea are added to the screw extruder according to the ratio of 60:40, and the island-fixing method is used to spin Sea-island superfibers were produced, and the number of islands was 64;

[0022] S2: Preparation of the sea-island superfiber nonwoven fabric, the sea-island superfiber prepared in the step S1 is opened, carded, laid, prepunched and needled to obtain the sea-island superfiber nonwoven fabric;

[0023] S3: Softening treatment of sea-island superfiber non-woven fabrics. Arrange the sea-island superfiber non-woven fabrics prepared in step S2 in an ultrasonic instrument filled with softeners, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com