Patents

Literature

121results about How to "Easy to impregnate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium Secondary Battery

InactiveUS20030190530A1Excellent cycle characteristicsPrevent materialCell seperators/membranes/diaphragms/spacersOrganic electrolyte cellsHydrofluoric acidOrganic base

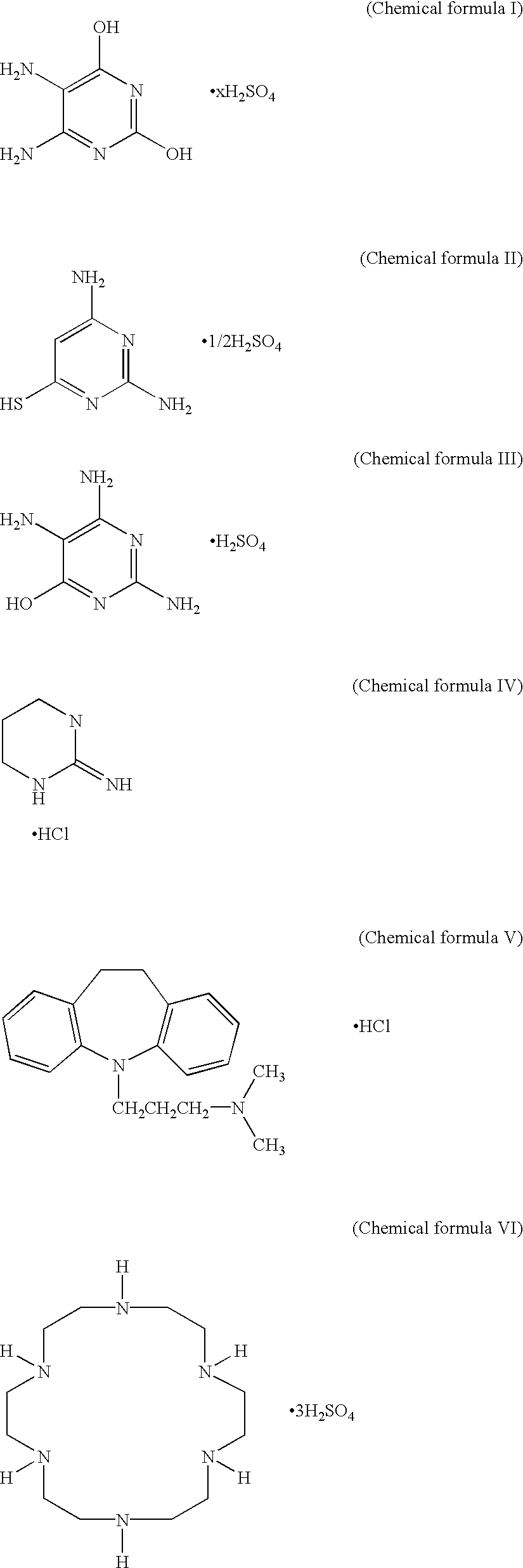

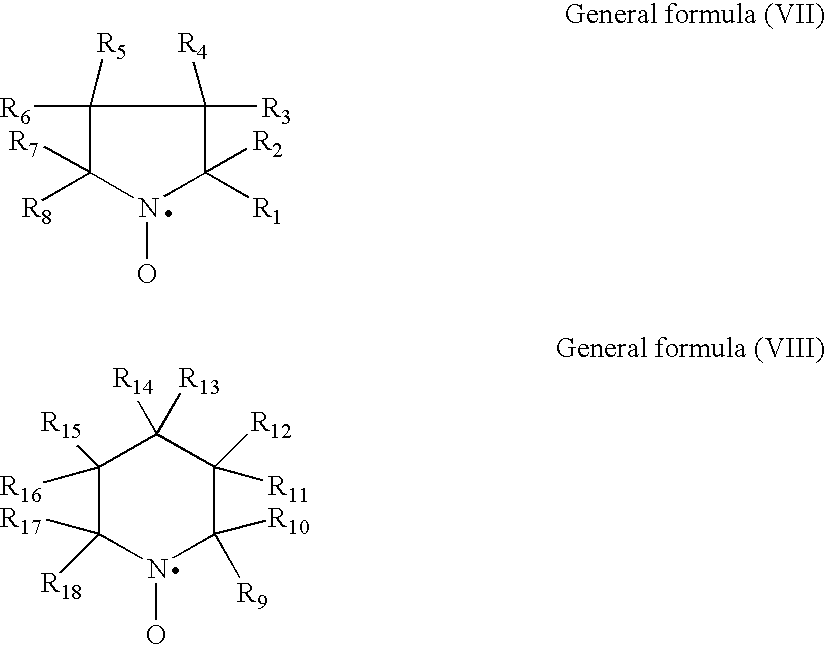

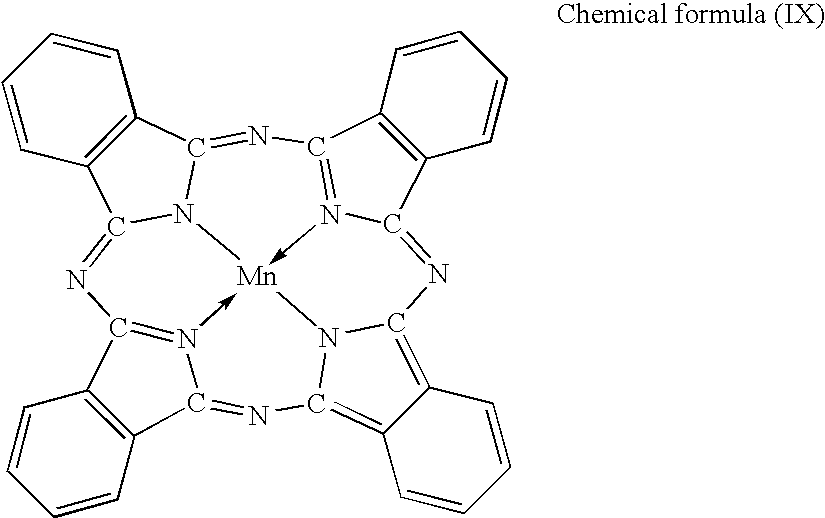

A lithium secondary battery includes: an electrode body having a positive electrode, a negative electrode, and a separator, the positive electrode and the negative electrode being wound or laminated by means of the separator; and a nonaqueous electrolyte solution containing a lithium compound as a electrolyte. At least one of the positive electrode, the negative electrode, the separator, the nonaqueous electrolyte solution contains at least one of: (a) an organic and / or inorganic inhibitor, which functions as a Cu-corrosion inhibitor or a Cu-trapping agent, (b) a compound having an organic base and an inorganic acid which are unitarily combined in a molecule, (c) a cyclic compound containing a N-O radical in a molecular structure, (d) a cyclic compound which becomes a Mn<2+> supplier in the nonaqueous electrolyte solution, (e) a compound containing an atom showing Lewis acidity and an atom showing Lewis basisity in one molecule, (f) a three-dimensional siloxane compound, and (g) a nonionic surfactant; or the nonaqueous electrolyte solution contains: (h) a water-extracting agent, or (i) a hydrofluoric acid-extracting agent. This lithium secondary battery exhibits an excellent effect that self-discharge property, cycle characteristics, long period stability and reliability can be planned.

Owner:NGK INSULATORS LTD

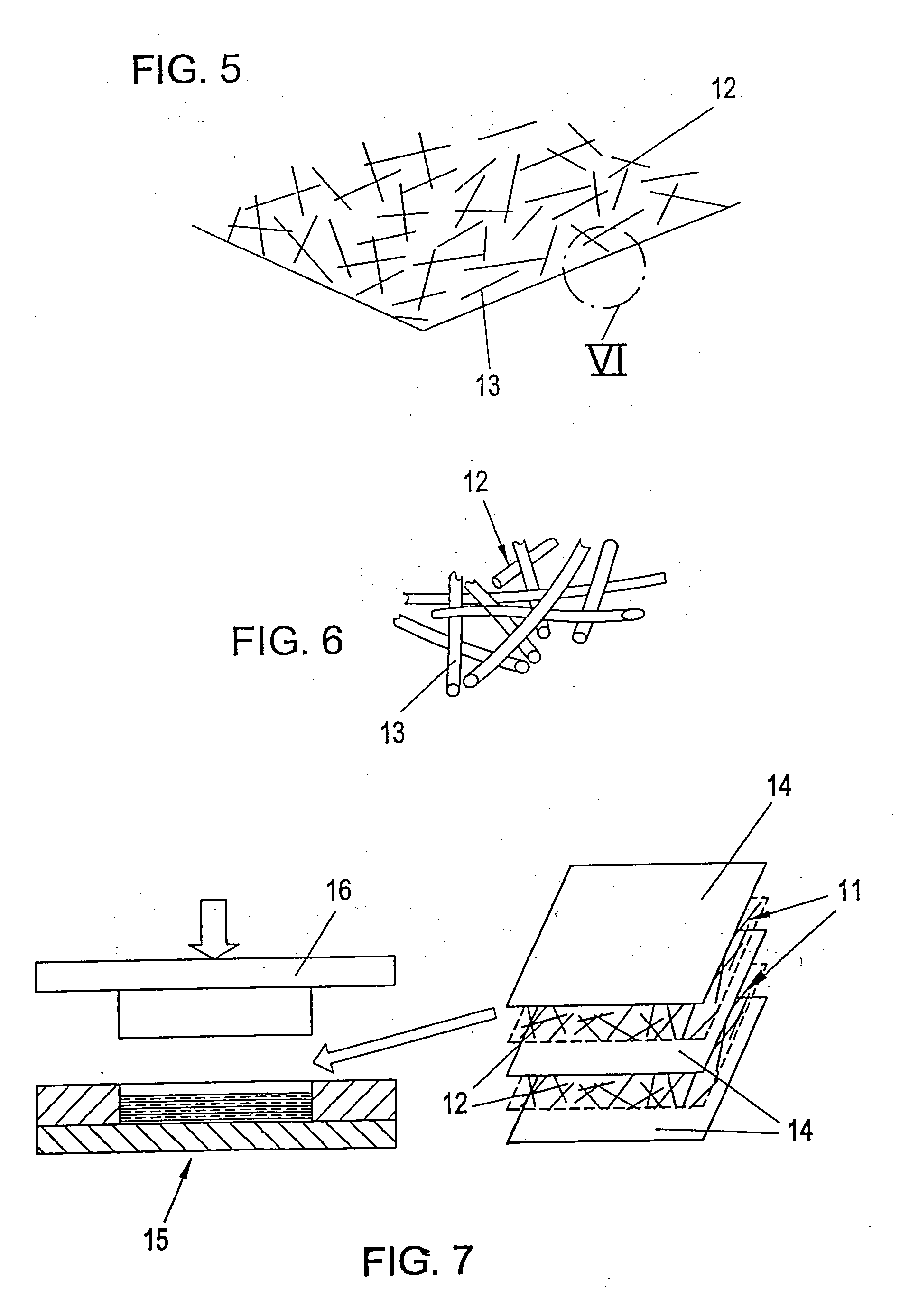

Random mat and fiber-reinforced composite material

ActiveUS8946342B2Good surface appearanceIncreasing the thicknessSpecial tyresWood working apparatusFiber bundleSingle fiber

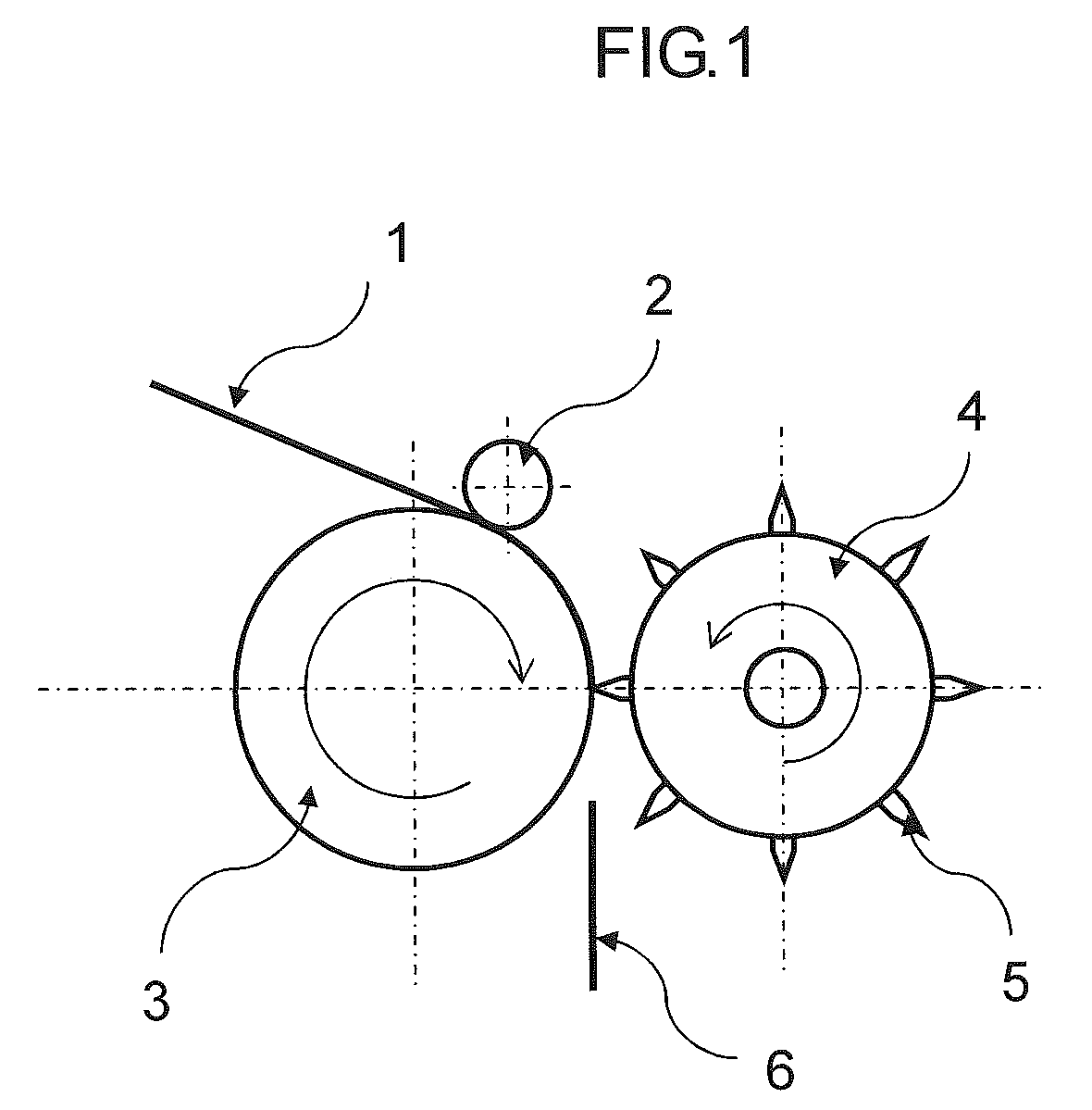

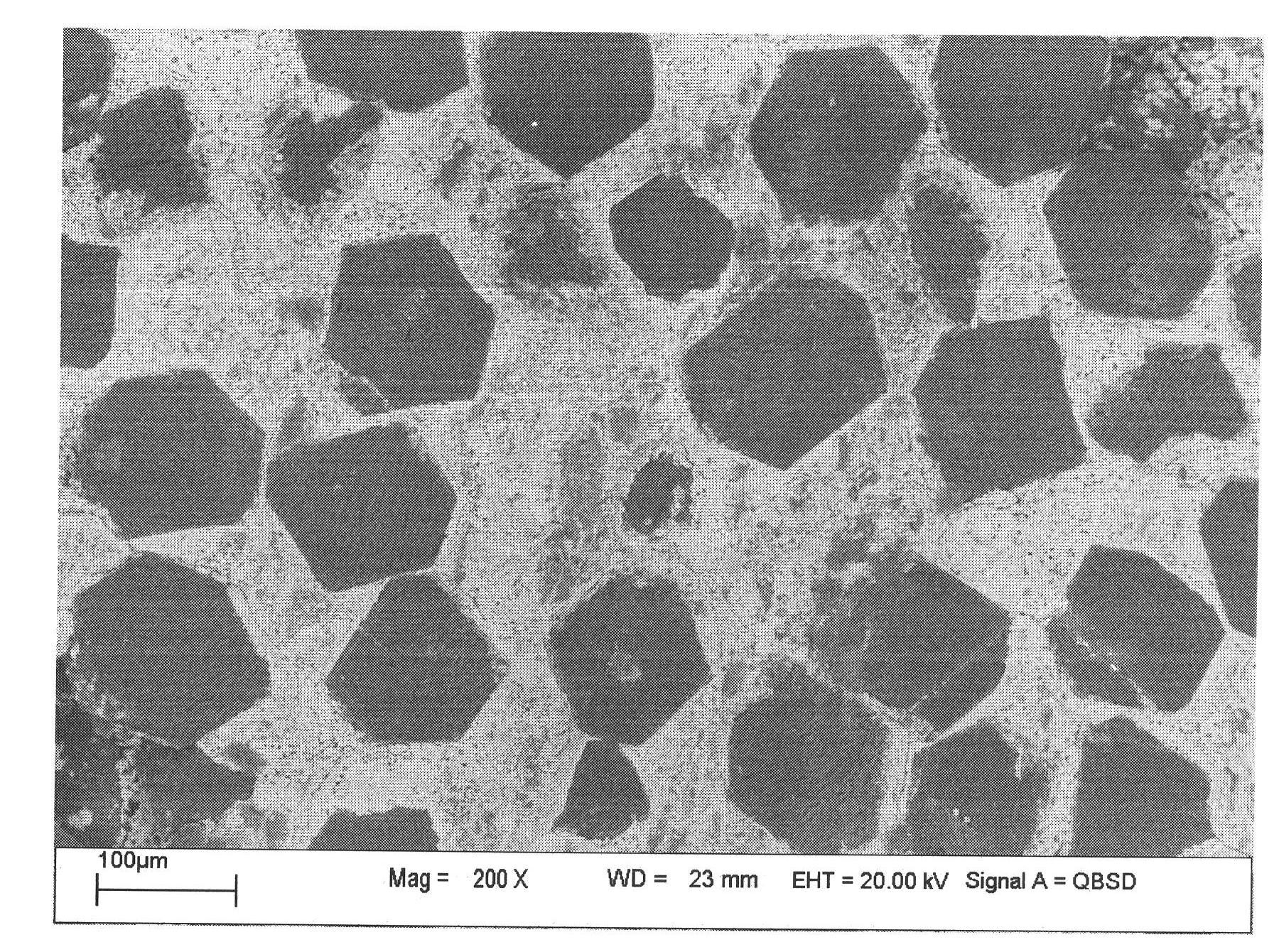

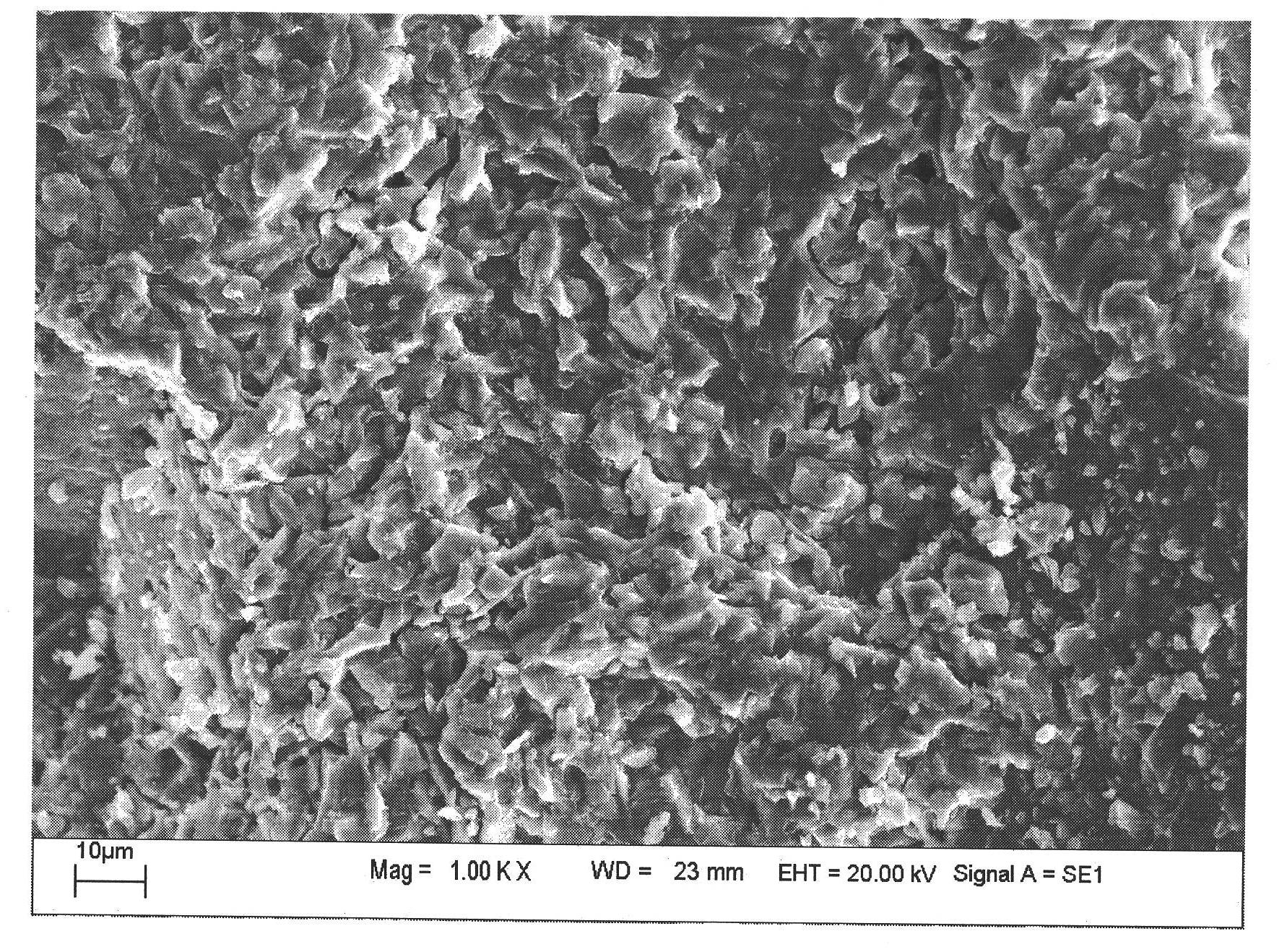

There is provided a random mat of the present invention including: reinforcing fibers having an average fiber length of 5 to 100 mm; and a thermoplastic resin,wherein a fiber areal weight of the reinforcing fibers is from 25 to 3,000 g / m2, for a reinforcing fiber bundle (A) including the reinforcing fibers equivalent to or more than a critical single fiber number defined by formula (1), a ratio of the reinforcing fiber bundle (A) to a total amount of the reinforcing fibers in the mat is from 30 vol % to less than 90 vol %, and an average number (N) of the reinforcing fibers in the reinforcing fiber bundle (A) satisfies formula (2):Critical single fiber number=600 / D (1)0.7×104 / D2<N<1×105 / D2 (2)wherein D is an average fiber diameter (μm) of single reinforcing fibers.

Owner:TEIJIN LTD

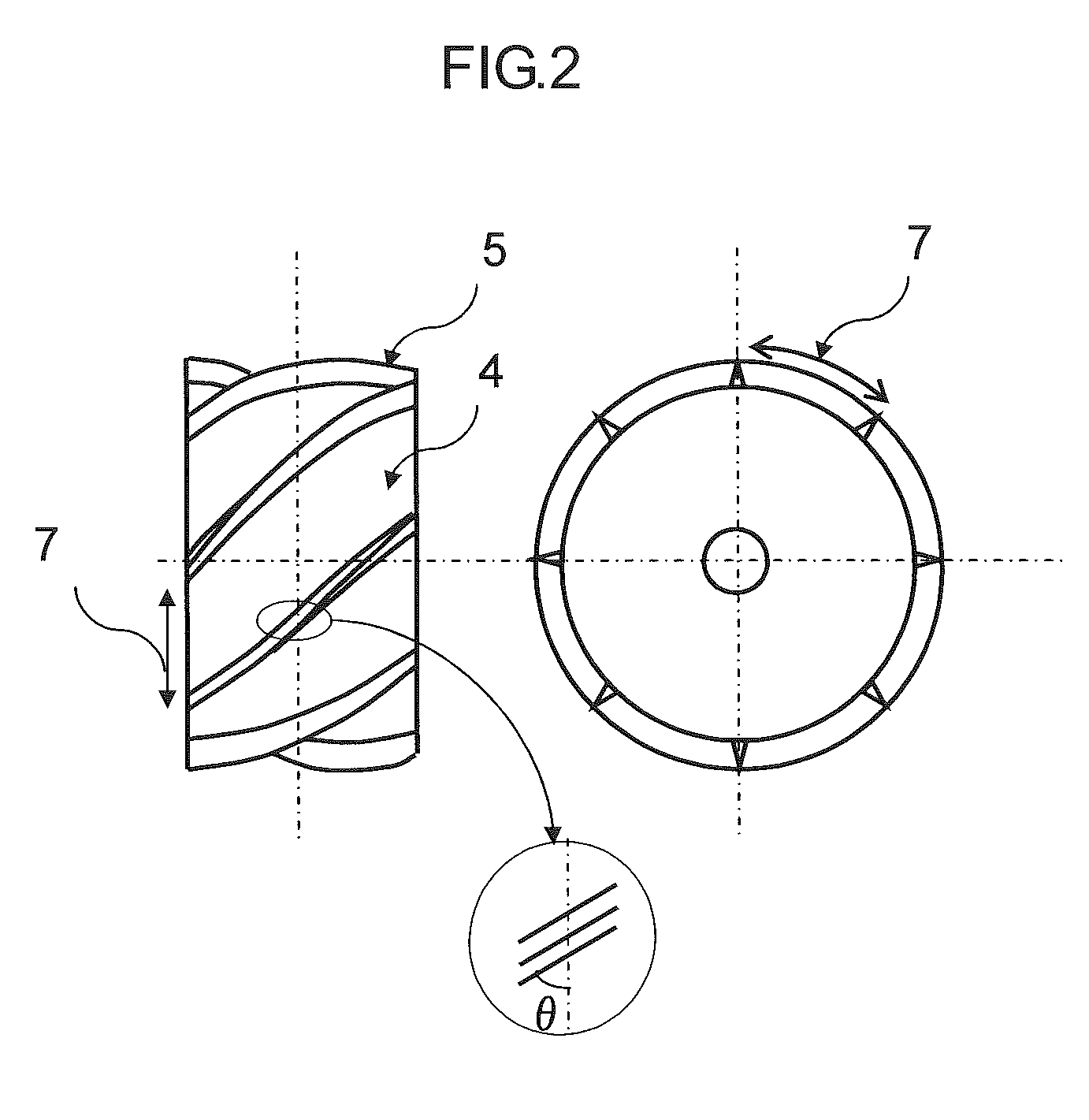

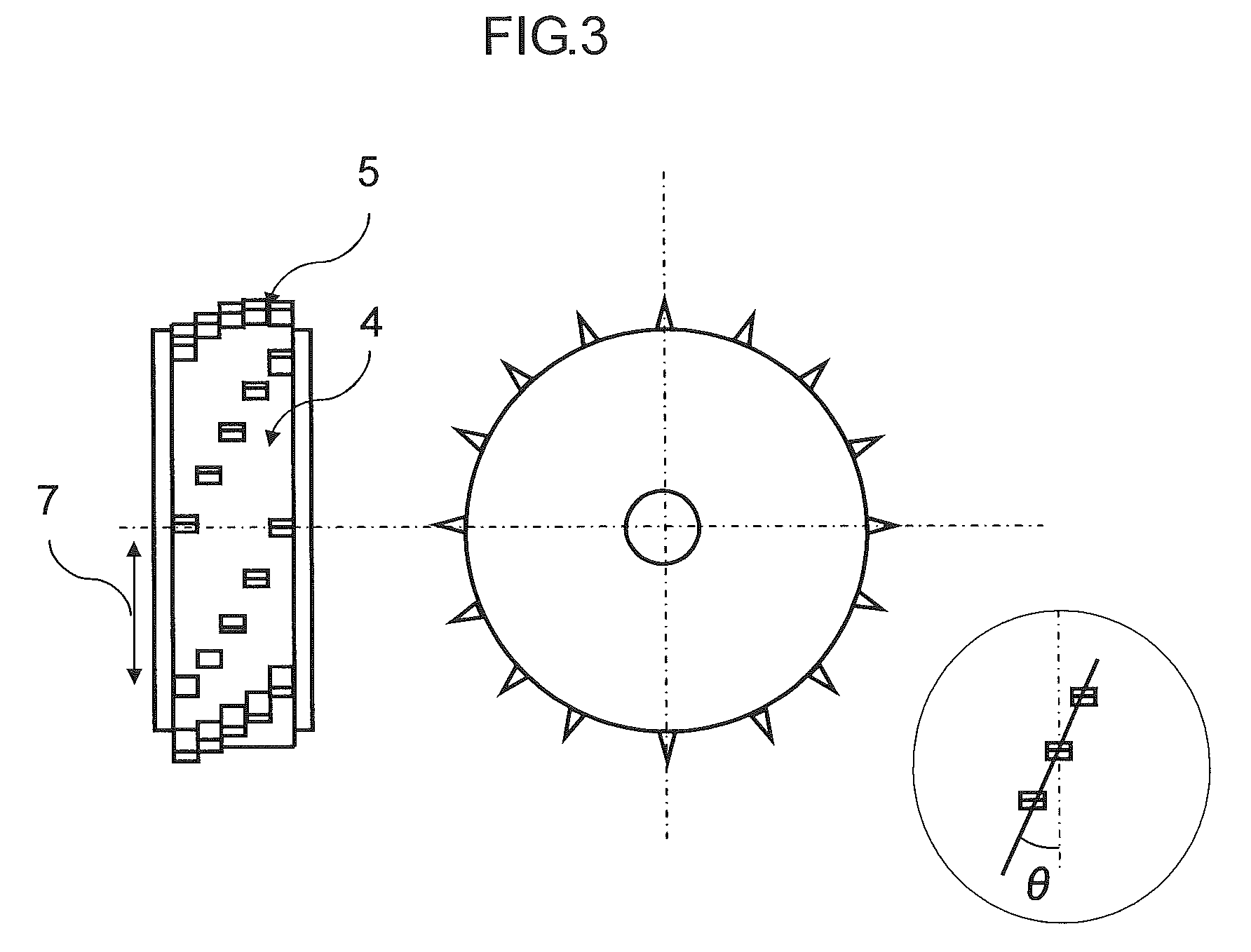

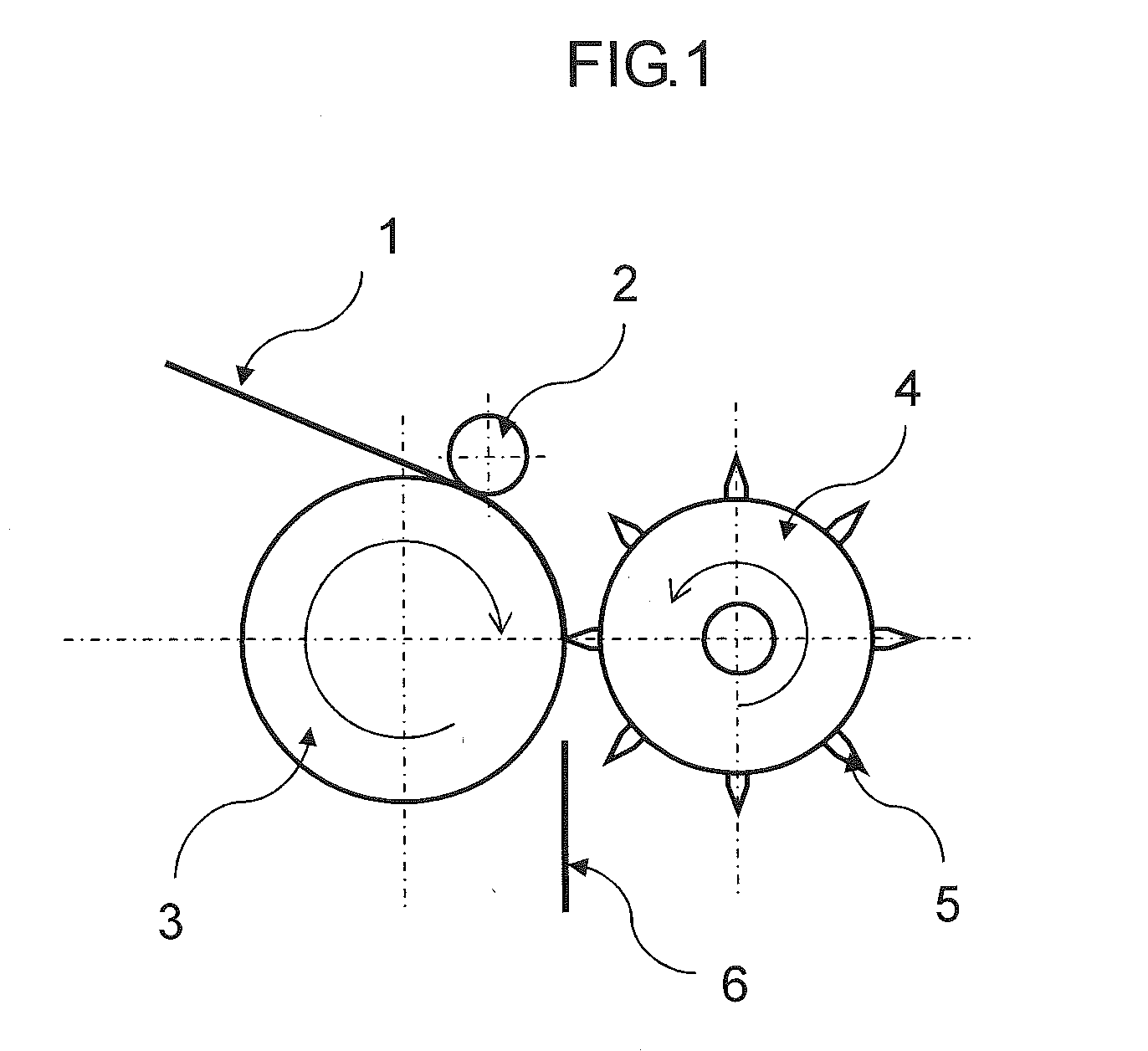

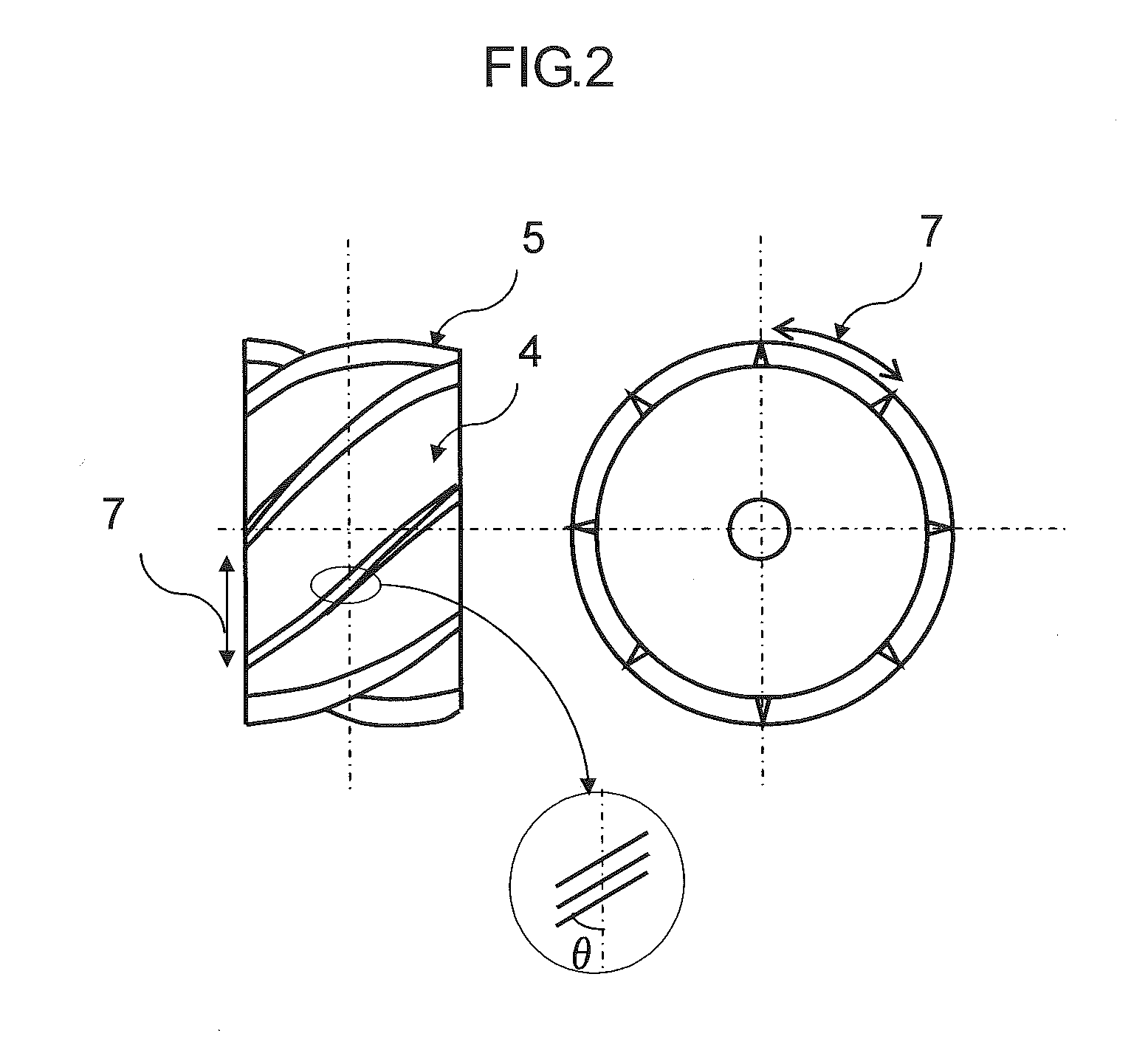

Random Mat and Fiber-Reinforced Composite Material

ActiveUS20130317161A1Good surface appearanceIncreasing the thicknessSpecial tyresWood working apparatusFiber bundleSingle fiber

There is provided a random mat of the present invention including: reinforcing fibers having an average fiber length of 5 to 100 mm; and a thermoplastic resin,wherein a fiber areal weight of the reinforcing fibers is from 25 to 3,000 g / m2, for a reinforcing fiber bundle (A) including the reinforcing fibers equivalent to or more than a critical single fiber number defined by formula (1), a ratio of the reinforcing fiber bundle (A) to a total amount of the reinforcing fibers in the mat is from 30 vol % to less than 90 vol %, and an average number (N) of the reinforcing fibers in the reinforcing fiber bundle (A) satisfies formula (2):Critical single fiber number=600 / D (1)0.7×104 / D2<N<1×105 / D2 (2)wherein D is an average fiber diameter (μm) of single reinforcing fibers.

Owner:TEIJIN LTD

Molding material, prepreg and fiber-reinforced composite material, and method for producing fiber-reinforced molding substrate

InactiveUS20100068518A1Increase productivitySatisfactory dispersionCoatingsYarnPolymer scienceFiber bundle

This invention relates to: a molding material comprising a bundle of continuous reinforcing fibers (A), a polyarylene sulfide prepolymer (B) comprising at least 50% by weight of cyclic polyarylene sulfide and having the weight average molecular weight of less than 10,000 or polyarylene sulfide (B′) having the weight average molecular weight of 10,000 or greater and the degree of dispersion of 2.5 or lower, and thermoplastic resin (C); a prepreg comprising a resin composition comprising the polyarylene sulfide prepolymer (B) impregnated into a reinforcing fiber; and a method for producing a fiber-reinforced molding substrate comprising step (I) of continuously feeding a bundle of continuous reinforcing fibers, step (II) of combining cyclic polyarylene sulfide with the reinforcing fiber bundle, step (III) of heating the composite obtained in step (II) to subject the cyclic polyarylene sulfide to ring-opening polymerization to convert into polyarylene sulfide, and step (IV) of cooling the composite obtained in step (III) and withdrawing the same.

Owner:TORAY IND INC

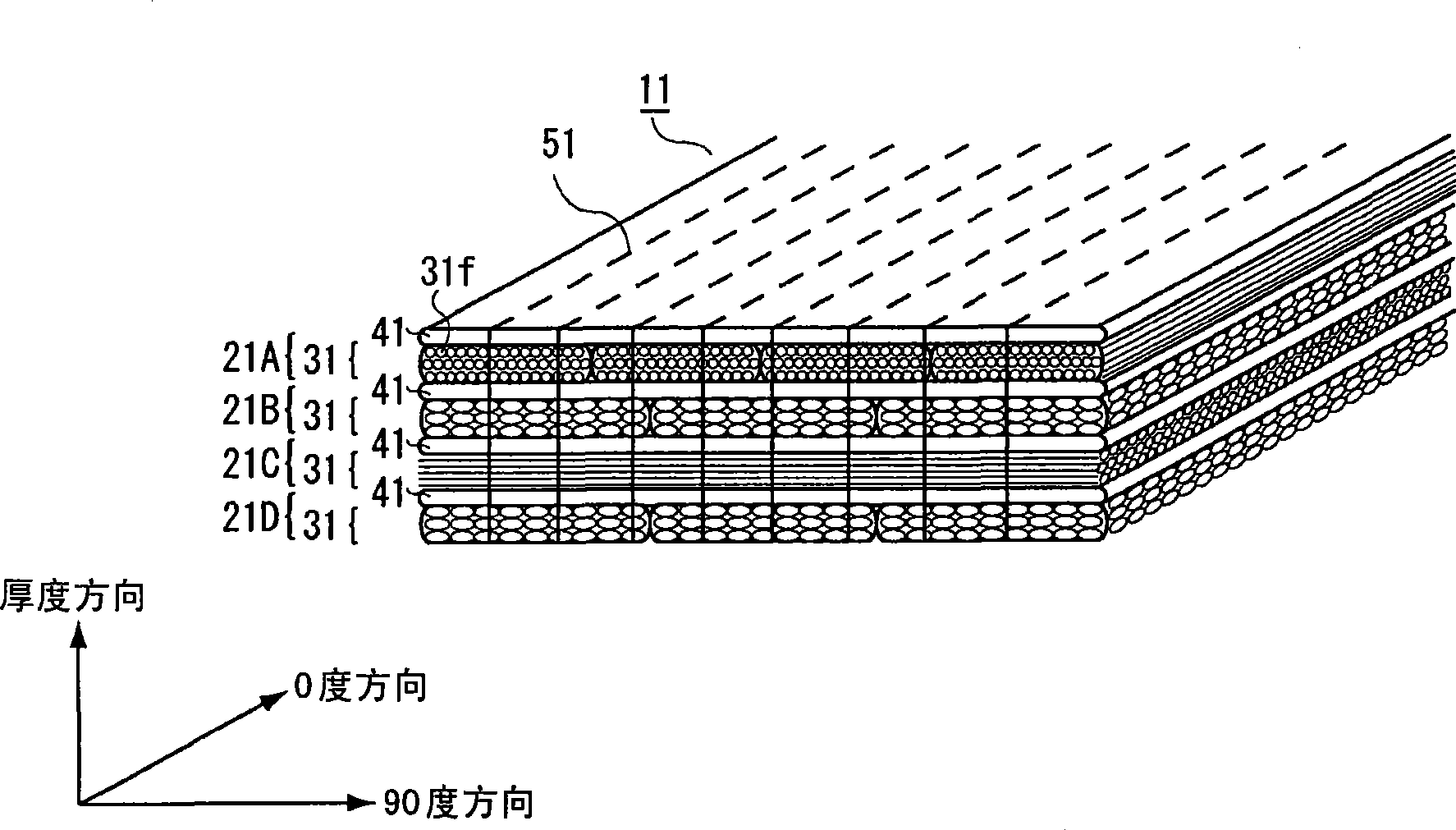

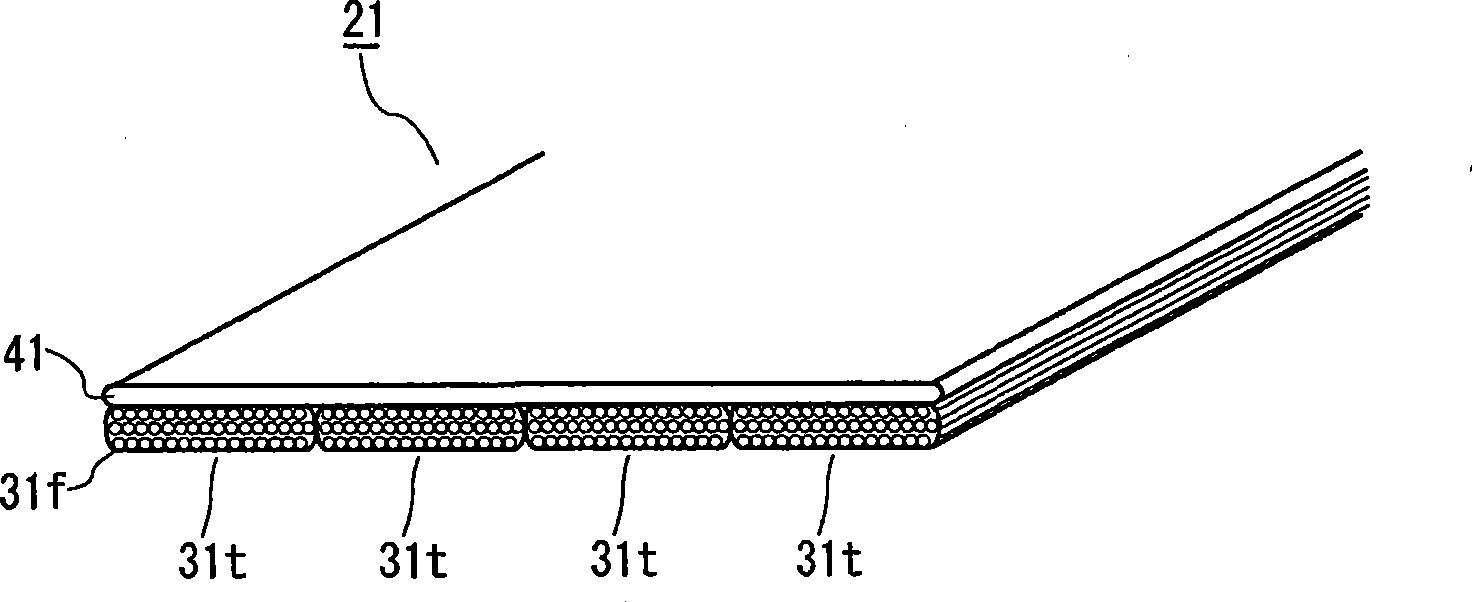

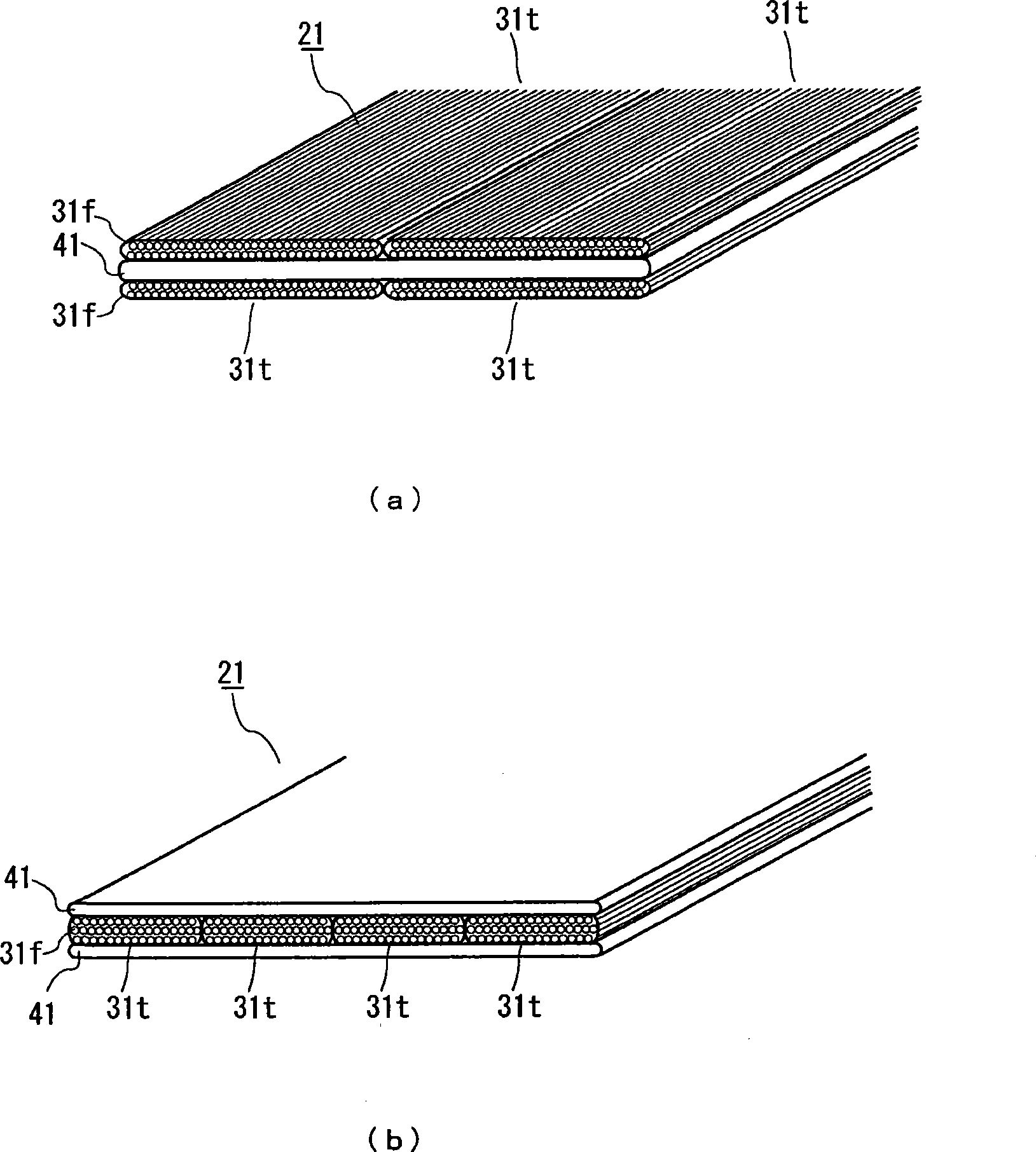

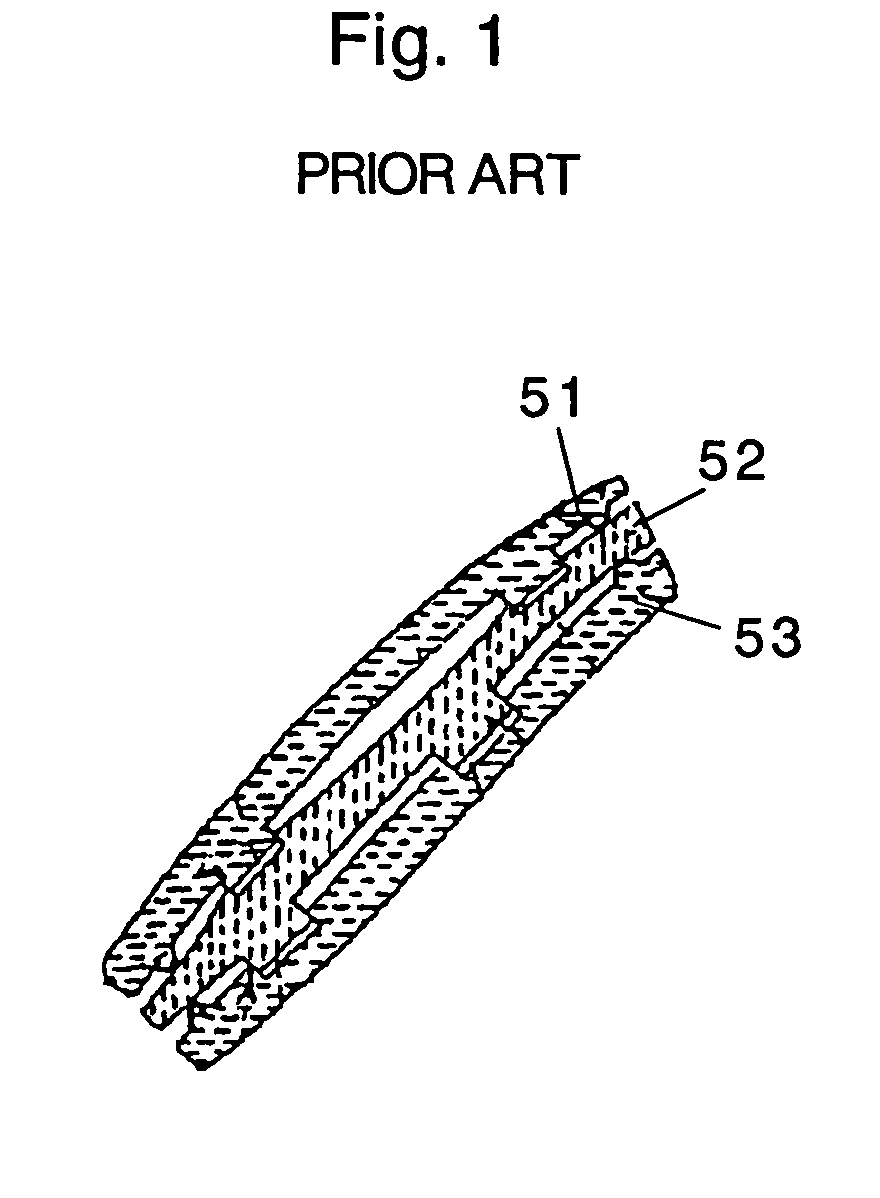

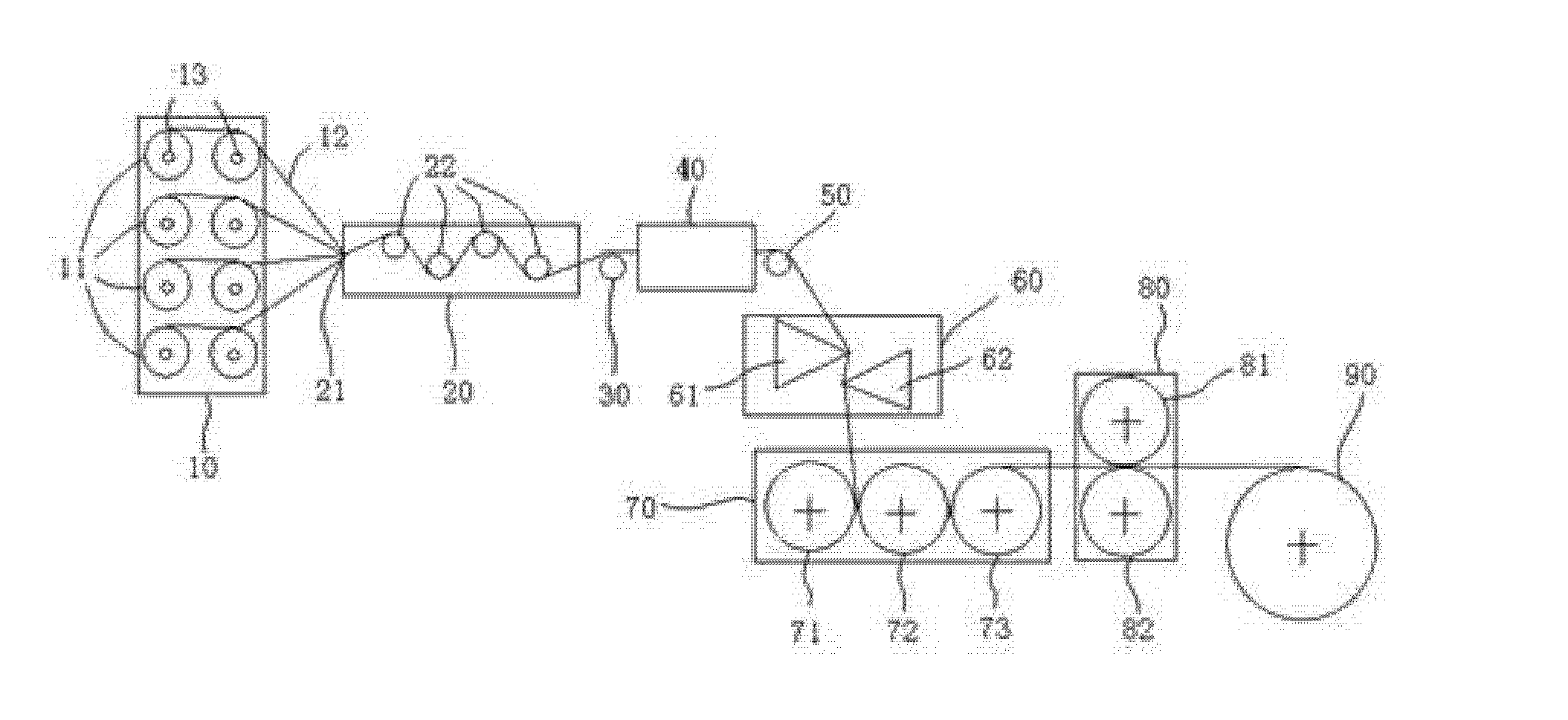

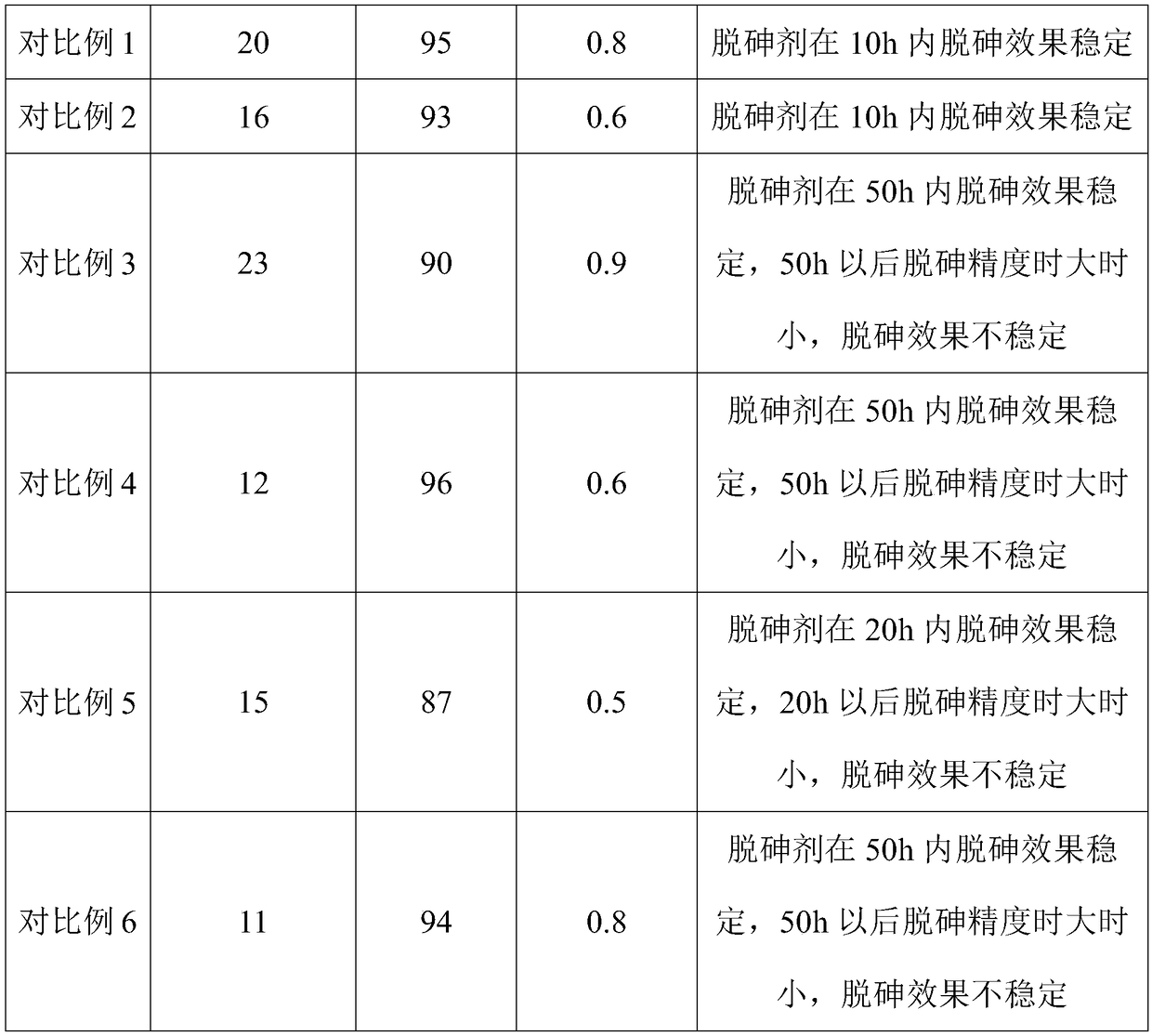

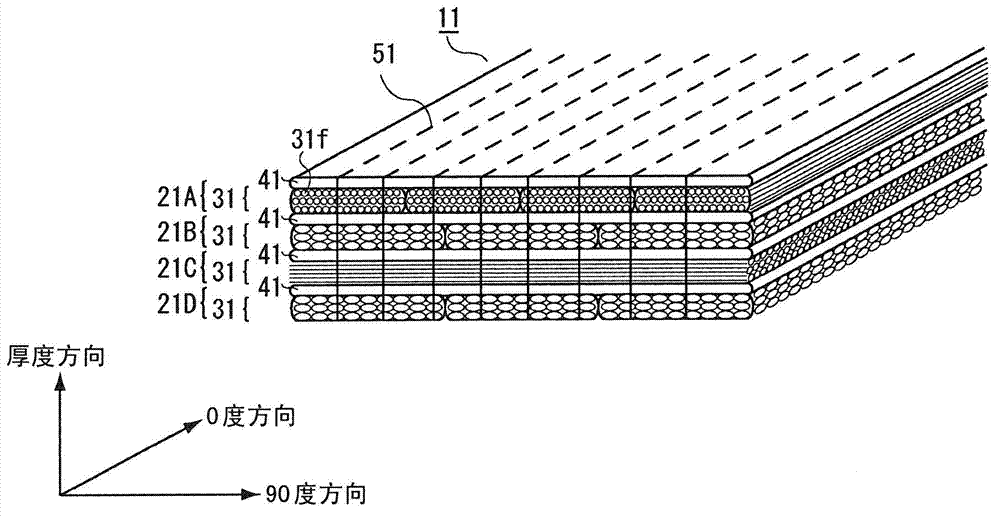

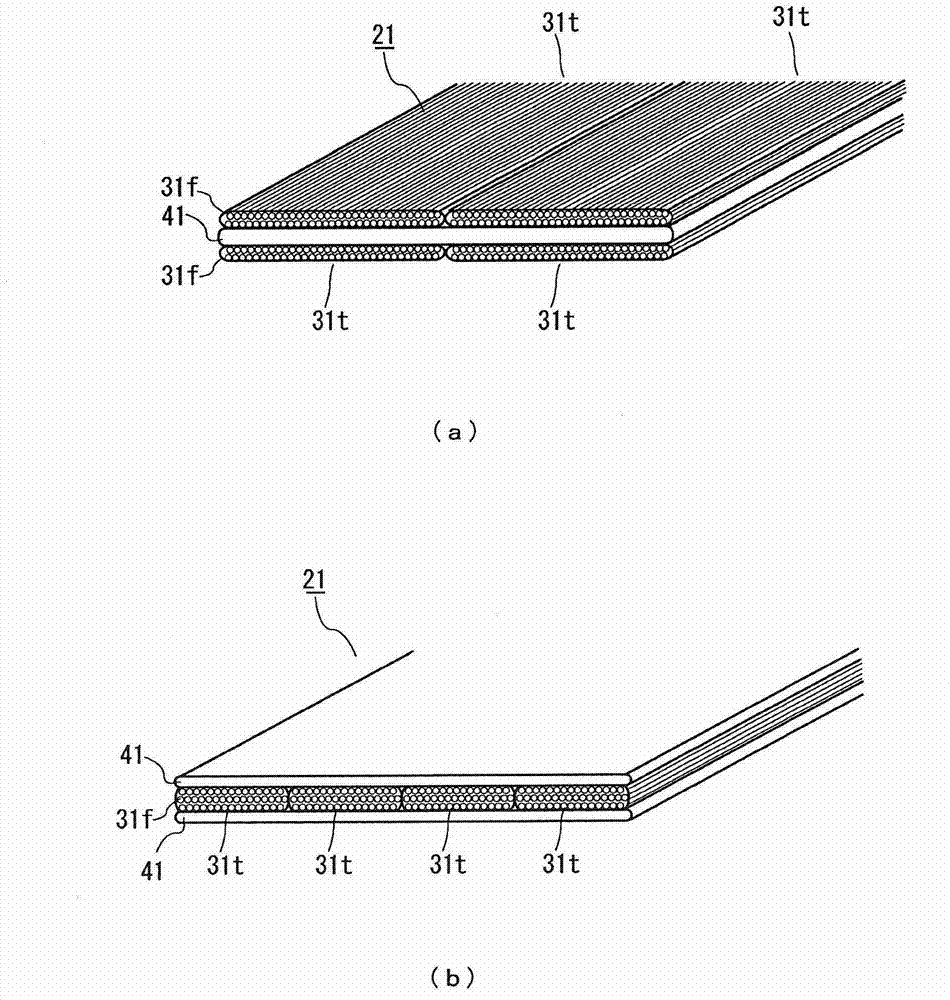

Thermalplastic resin multi-layer reinforced sheet, production method thereof and forming method for thermalplastic resin composite material forming article

ActiveCN101466535AEasy to impregnateGood dispersionSynthetic resin layered productsWoven fabricsFiber bundleMechanical property

A reinforced thermoplastic-resin multilayer sheet material which includes , as a matrix, a thermoplastic resin excellent in suitability for recycling and impact resistance and which has high quality and is excellent in mechani cal properties and draping properties. Also provided are: a process for effi ciently producing the reinforced thermoplastic-resin multilayer sheet materi al in a short time; and a reinforced thermoplastic-resin multilayer molding obtained by forming the reinforced thermoplastic-resin multilayer sheet mate rial and retaining the high quality and mechanical properties. The reinforce d thermoplastic-resin multilayer sheet material (11) comprises reinforcing t hermoplastic-resin sheet materials (21A) to (21D) superposed together which each is composed of a reinforcing fibrous sheet material (31) obtained by pa ralleling reinforcing fibers (31f) in a given direction and forming them int o a sheet and a thermoplastic-resin sheet material (41) adherent to one side of the reinforcing fibrous sheet material (31), the sheet materials (21A) t o (21D) having been united together by stitching with a thermoplastic-resin fiber bundle (51) for uniting which is made of the same material as the ther moplastic-resin sheet materials (41). The reinforcing fibrous sheet material s (31) have been superposed so that their reinforcing directions are multi-a xial.

Owner:FUKUI PREFECTURE

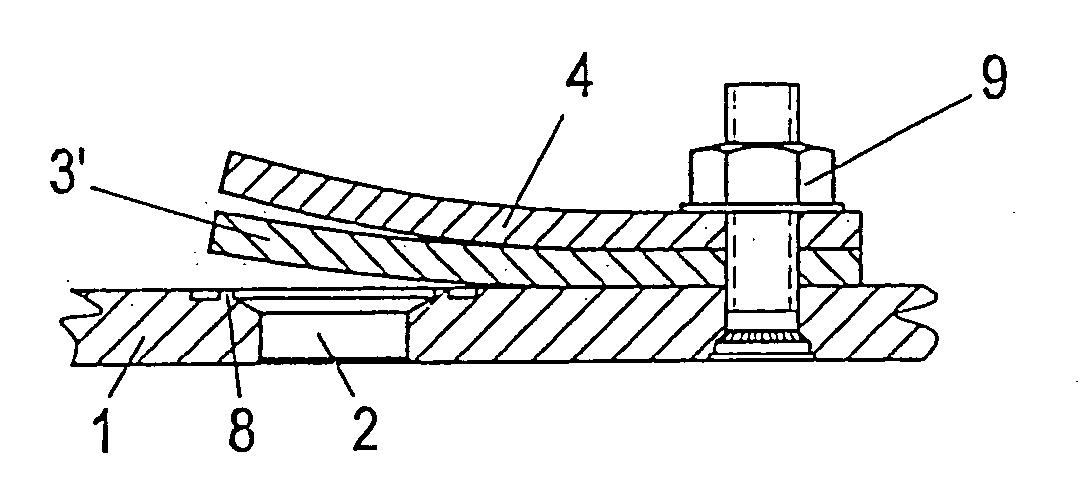

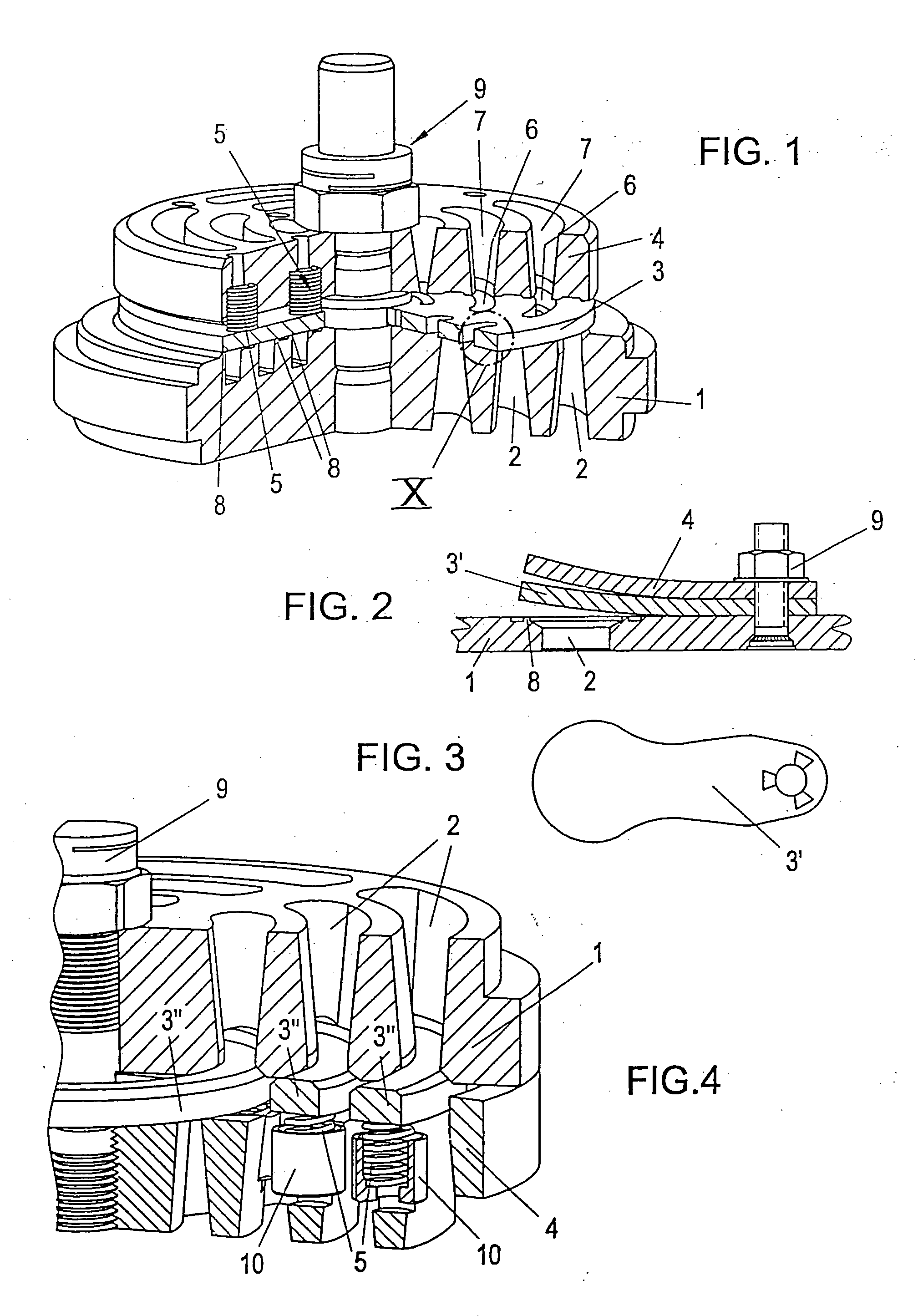

Sealing elements for compressor valves

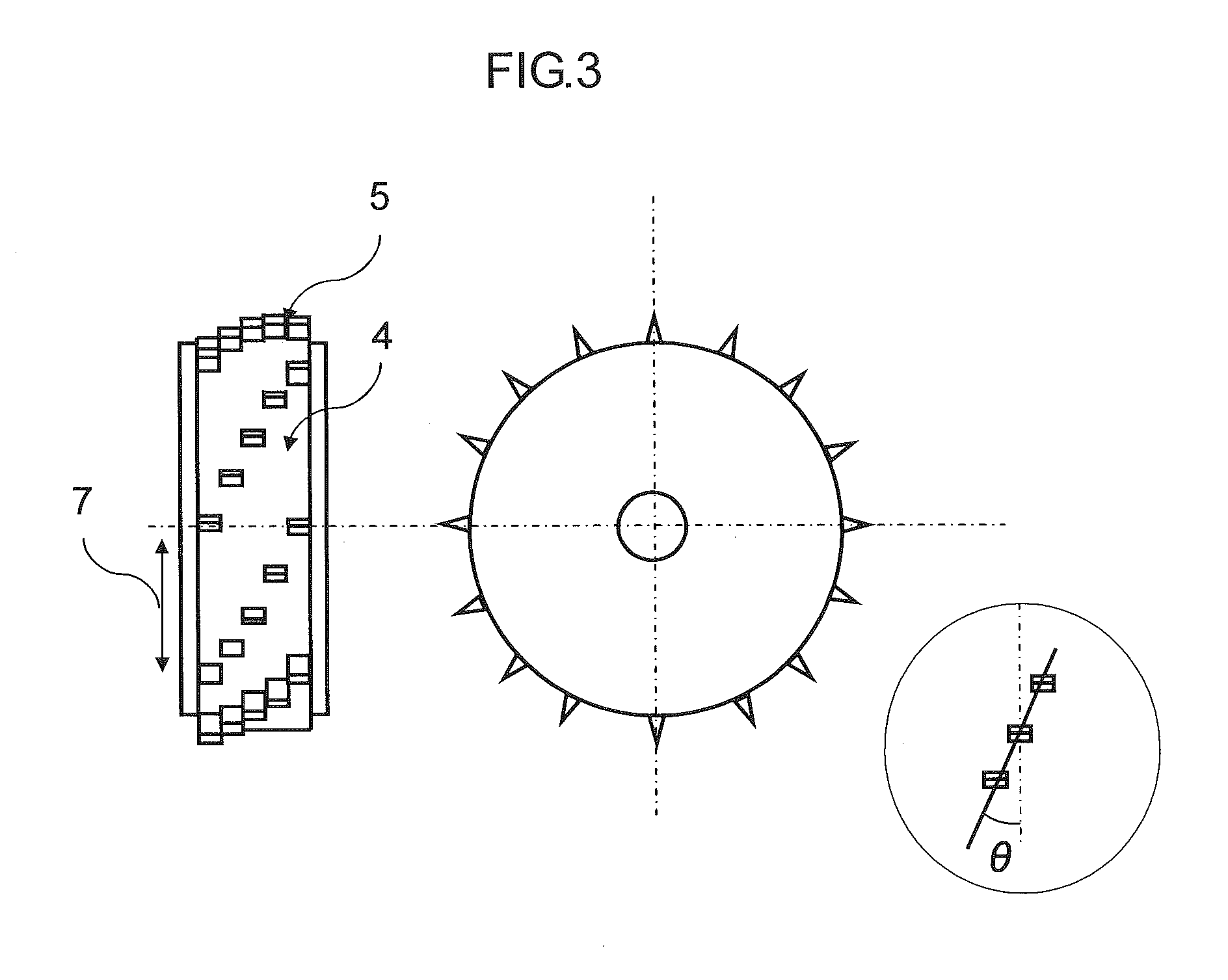

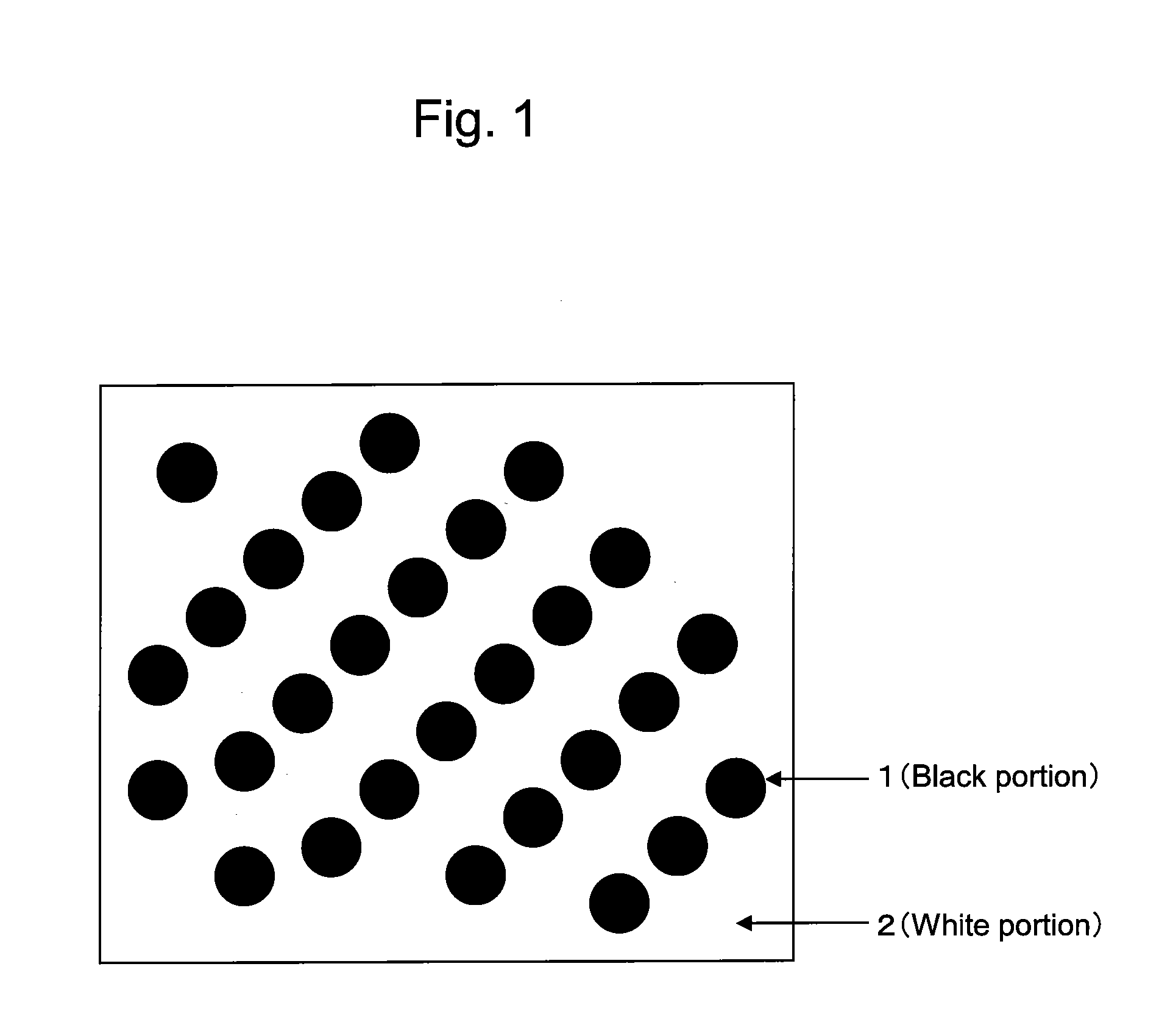

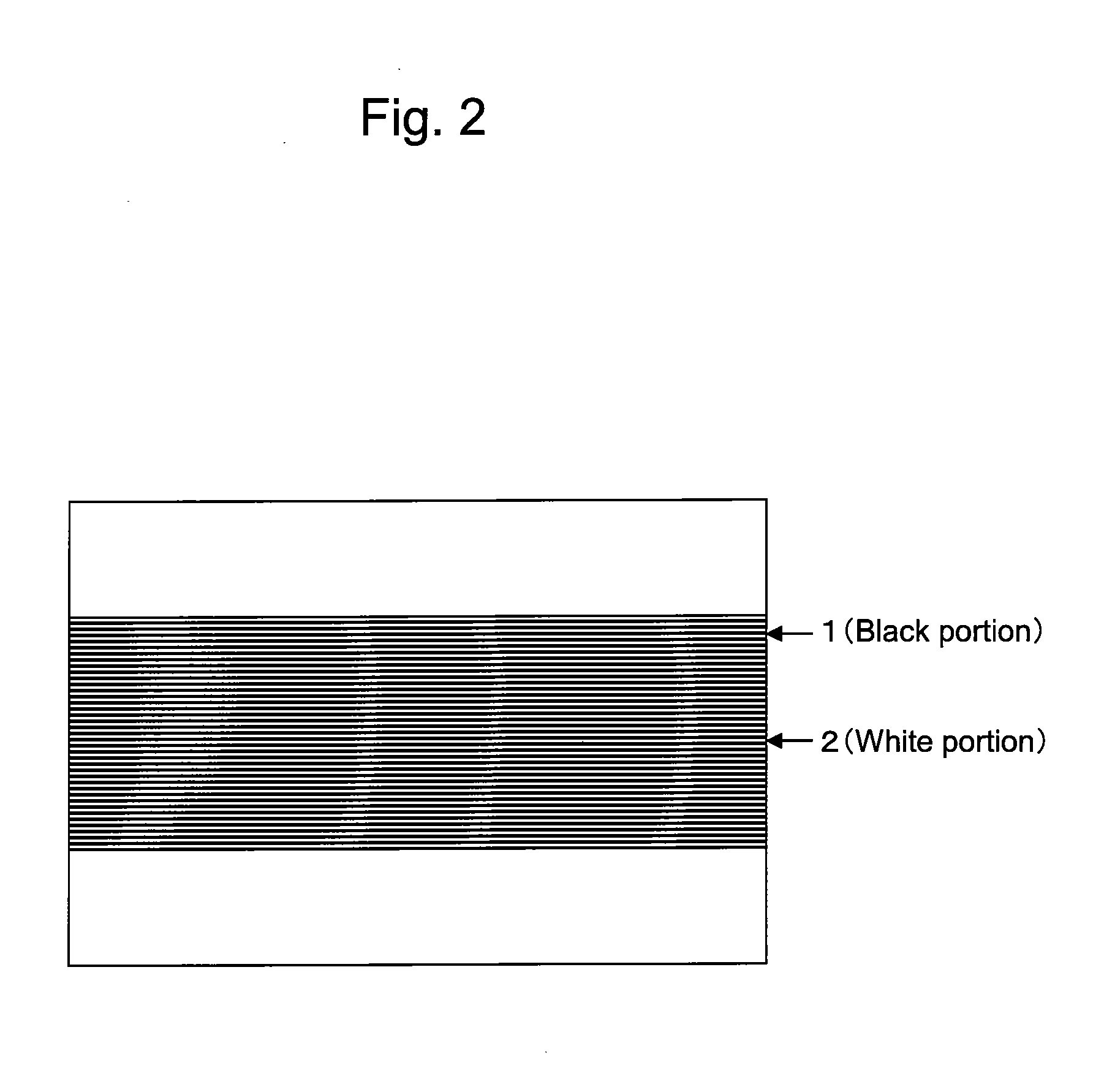

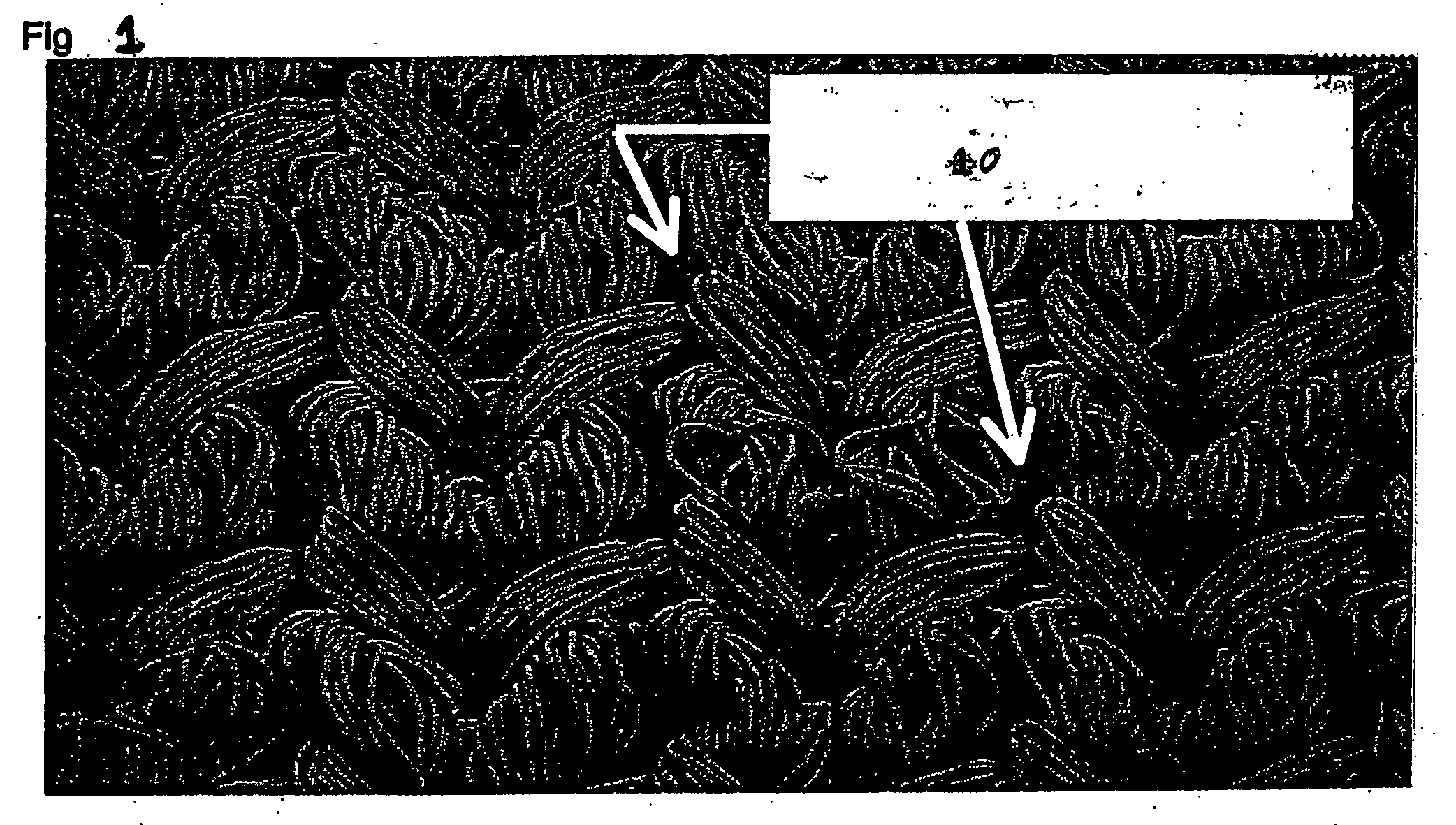

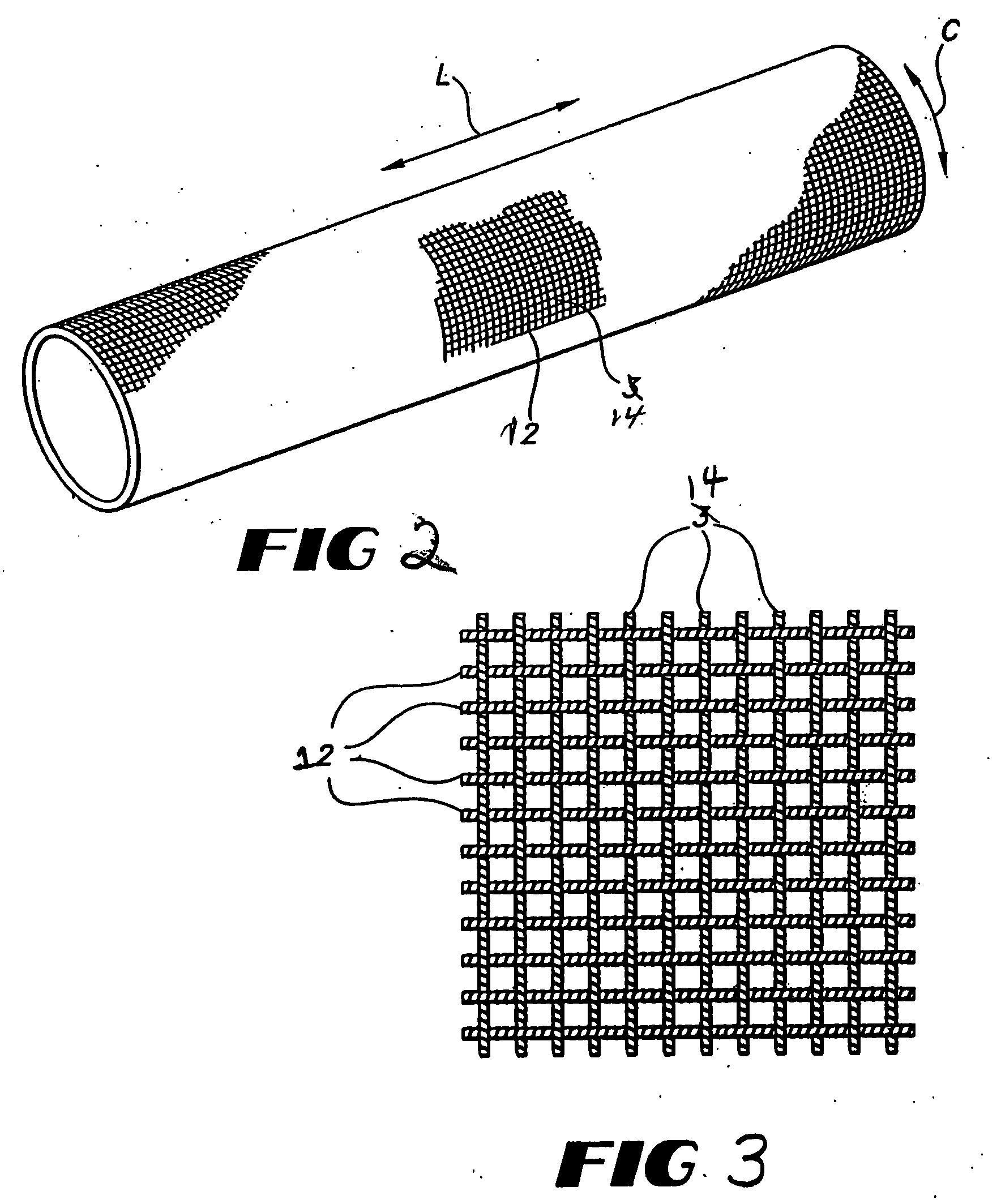

InactiveUS20060102240A1High effectFavorable characteristicPositive displacement pump componentsCheck valvesEngineeringFiber orientation

In sealing elements (3, 3′, 3″) made of synthetic material (14) having embedded fiber reinforcement (11), as it has been used for some time for automatic compressor valves, the fiber reinforcement (11) consists of at least one piece of an essentially flat, non-woven fiber fabric (12), which has, at least in its plane, a directionally independent (random) fiber orientation. Disadvantages of short-fibered reinforced synthetic materials can thereby be avoided, as well as the ones for synthetic materials reinforced by means of long-fibered fabrics, and sealing elements (3, 3′, 3″) may be obtained thereby having a very high durability.

Owner:HORBIGER VENTILWERKE

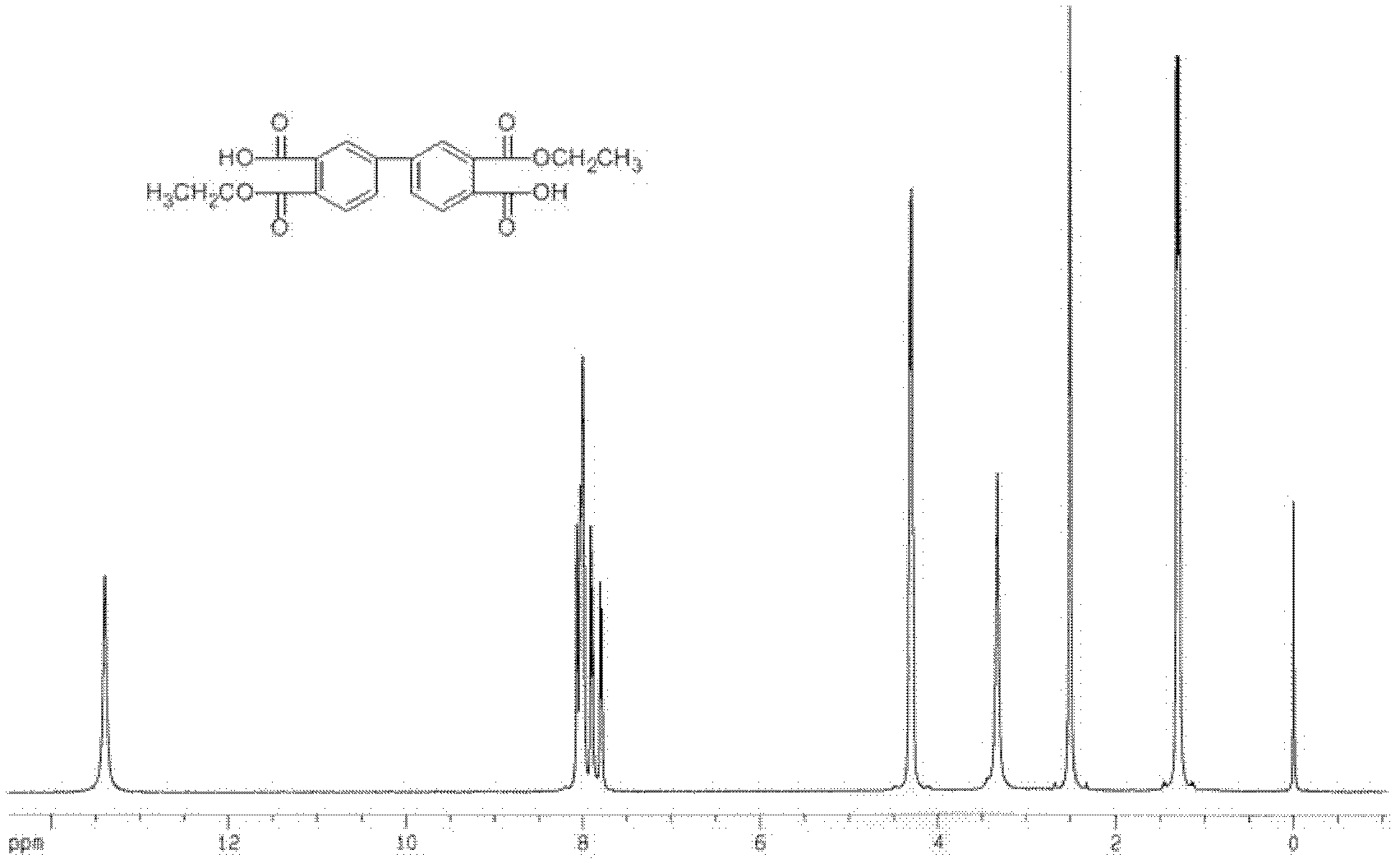

Polyimide resin as well as preparation method and application thereof

The invention discloses polyimide resin with low melt viscosity and high toughness as well as a preparation method of a composite material of the polyimide resin. The resin is high in solid content, low in solution viscosity and is easy to steep carbon fibers to prepare a high-quality carbon fiber prepreg (a belt or cloth); a melt resin formed by heating and melting the resin has the characteristics of low melt viscosity and wide melting temperature; a resin condensate formed by heating and solidifying is high in toughness and high in Tg (glass-transition temperature). The resin is suitable for steeping reinforced fibers to prepare prepregs, and a carbon fiber reinforced composite material prepared by the autoclave and the hot hubbing forming process is excellent in impact-resistant toughness, comprehensive mechanical property and high-temperature resistant performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

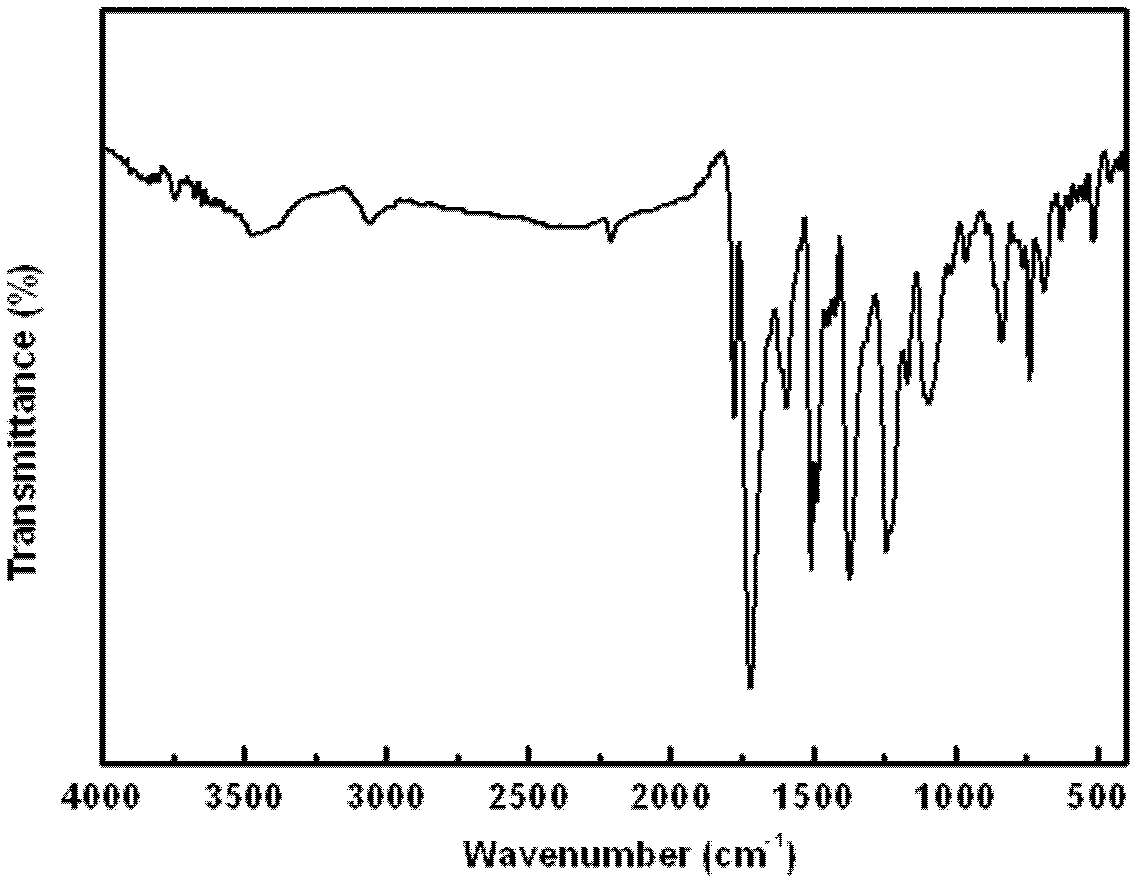

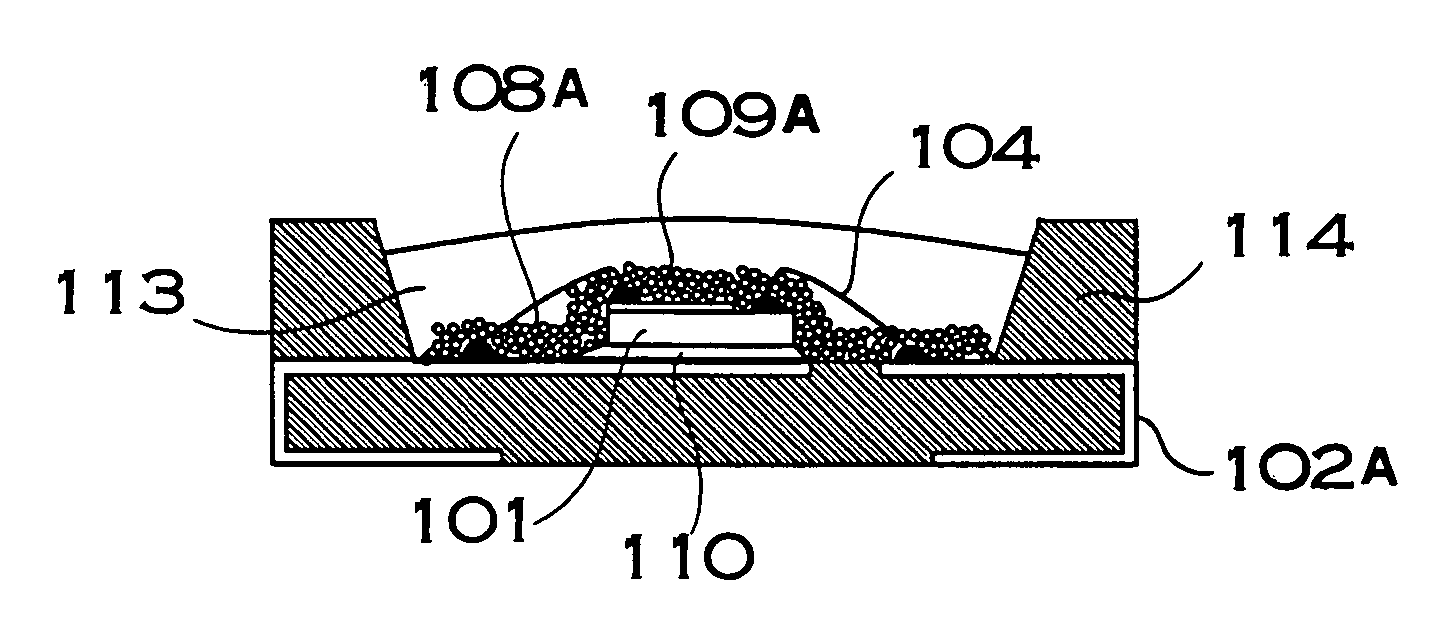

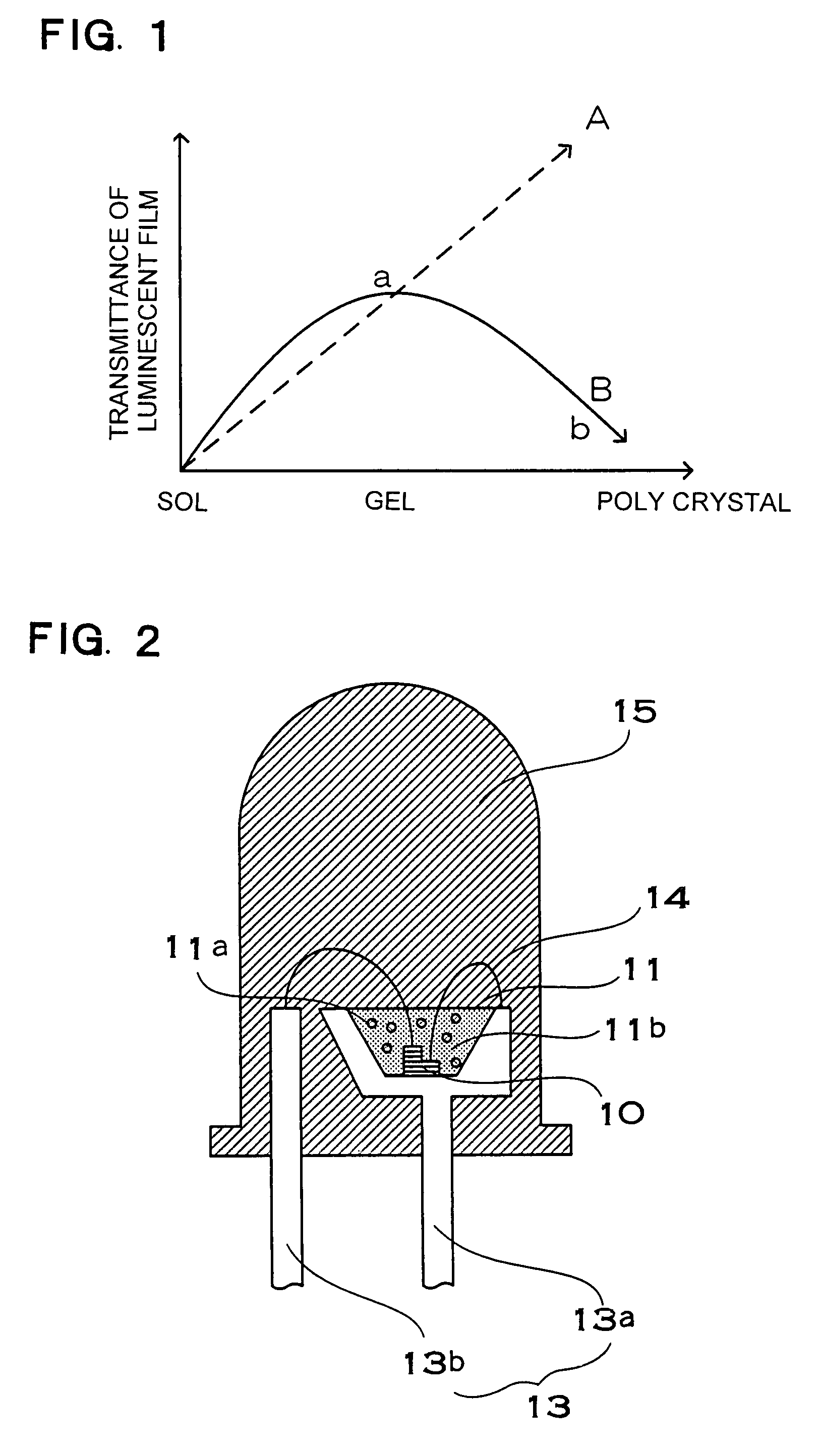

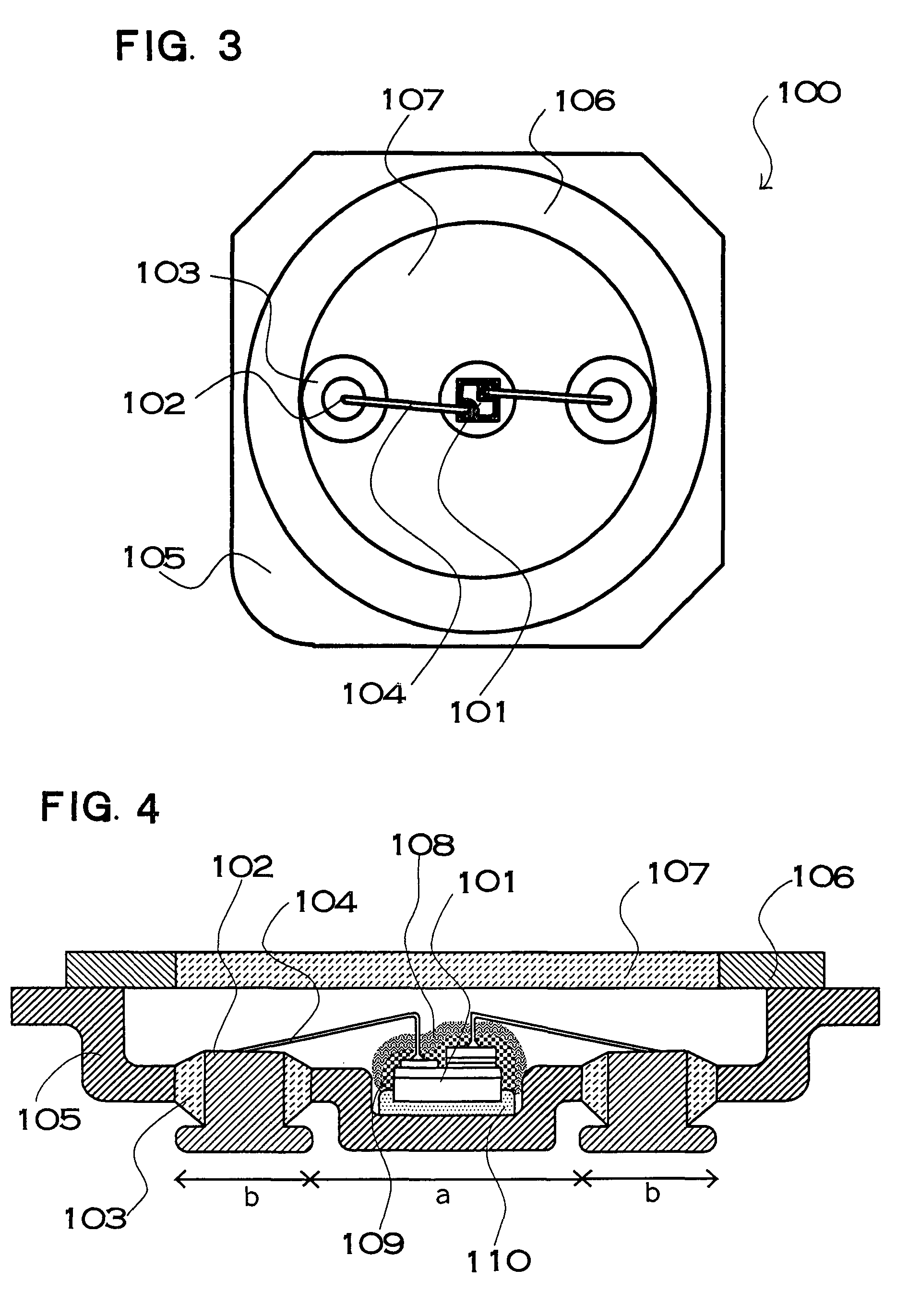

Light emitting film, luminescent device, method for manufacturing light emitting film and method for manufacturing luminescent device

InactiveUS7923918B2Easy to impregnateDischarge tube luminescnet screensLamp detailsFluorescenceLight emitting device

The present invention provides a reliable, long-life phosphor, or the like, which is prevented from darkening due to aging. A light emitting apparatus has a light emitting element and a phosphor layer. The phosphor layer has a phosphor excited by light from the light emitting element, and a binder which binds the phosphor. The binder is hydroxide oxide gel obtained by curing sol of a hydroxide oxide mixed with sol containing at least one metallic element selected from the group consisting of Al, Y, Gd, Lu, Sc, Ga, In, and B. Transmittance of hydroxide oxide in a gel state is higher than the transmittance in the polycrystal state where the sol-gel reaction is proceeded. In addition, the content of hydroxyl group or water of crystallization in the hydroxide oxide is 10% or less by weight.

Owner:NICHIA CORP

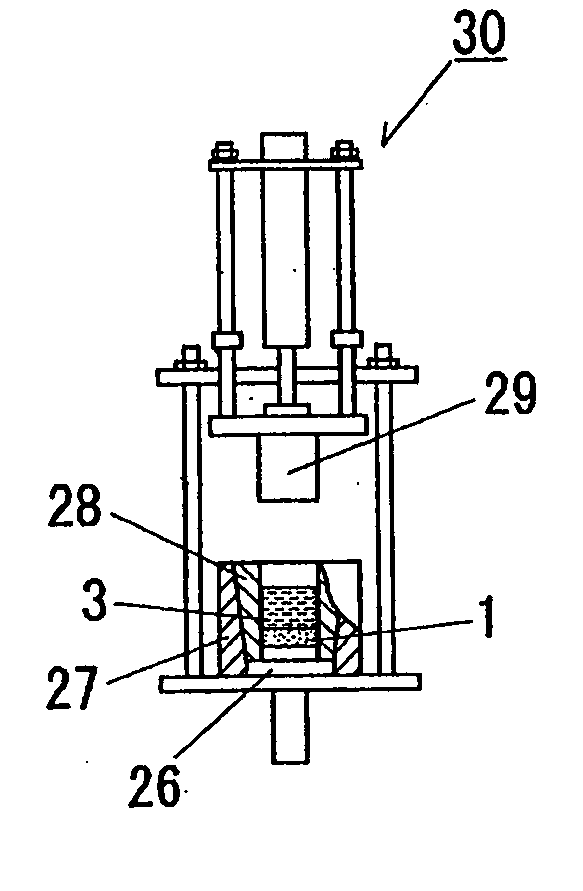

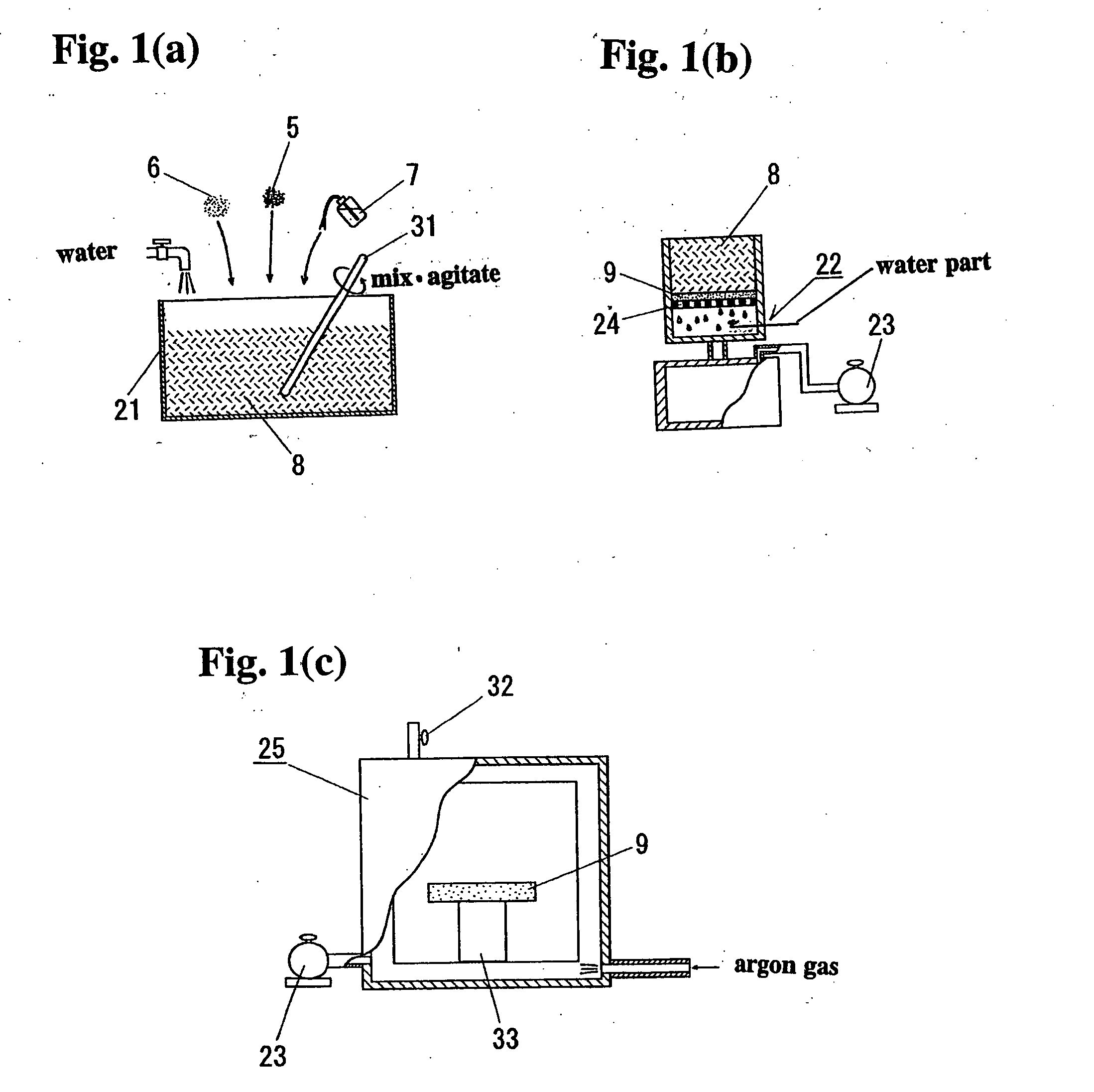

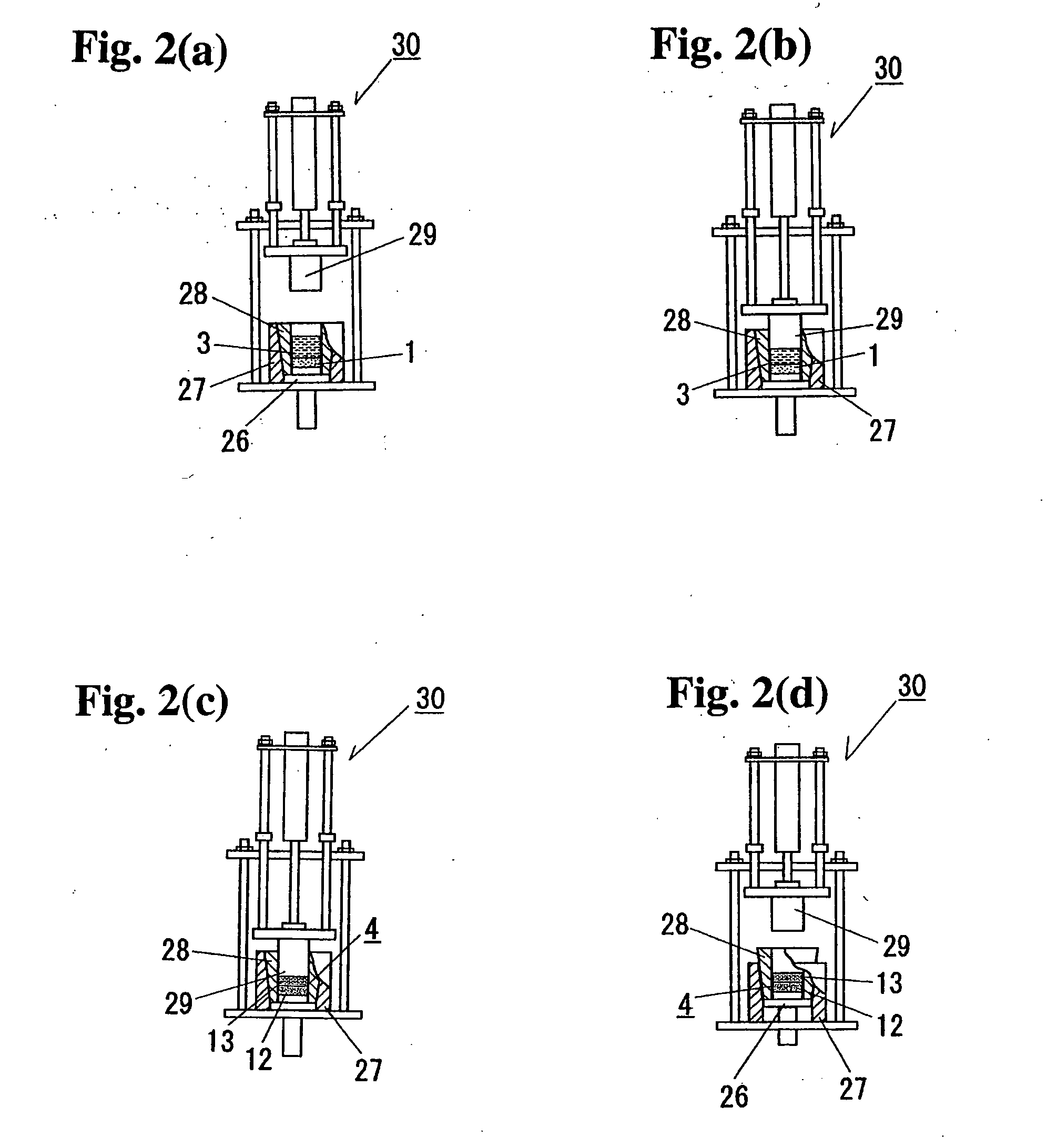

Heat-resistant ceramic core with three-dimentional shape and method of manufacturing cast by the same

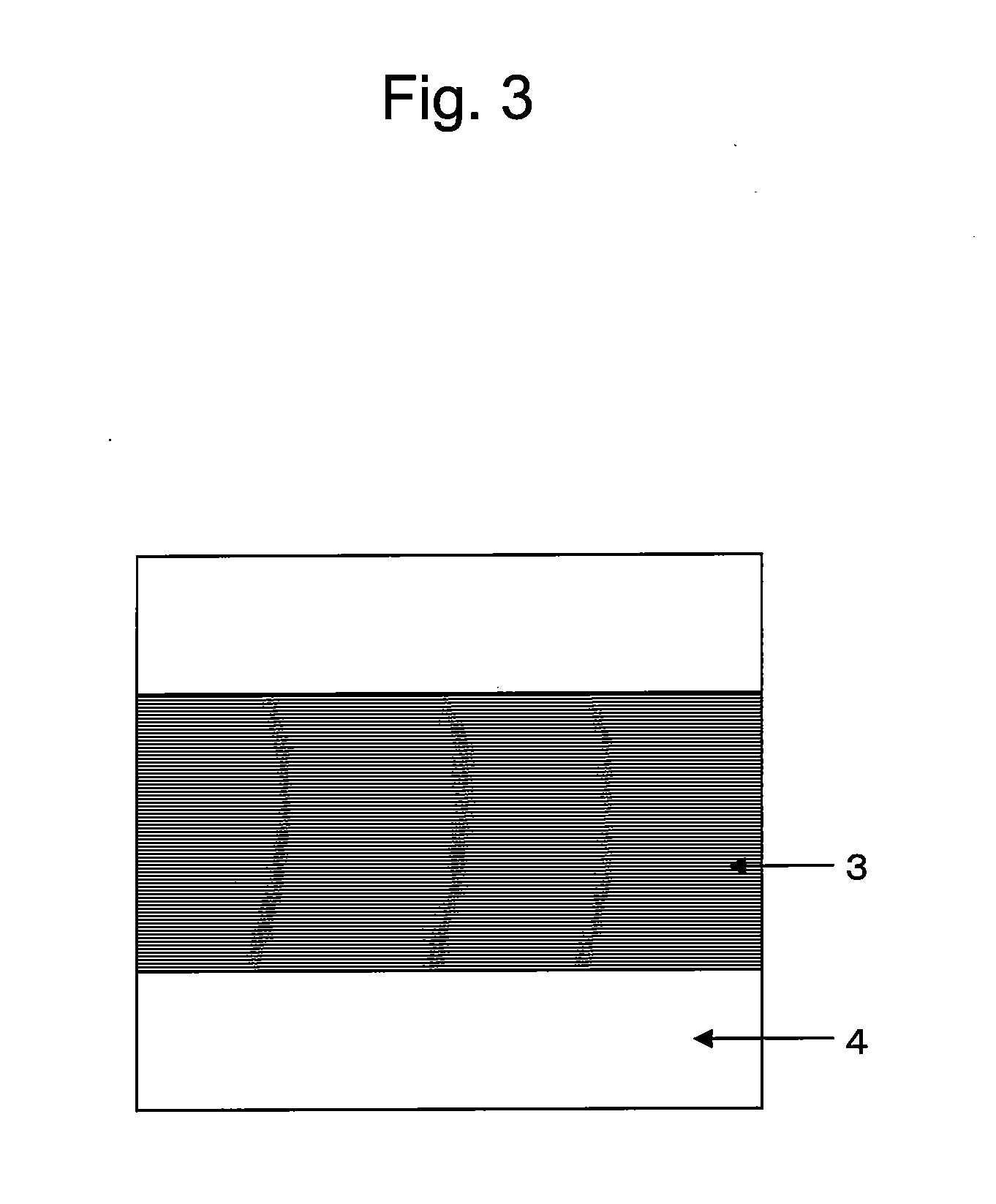

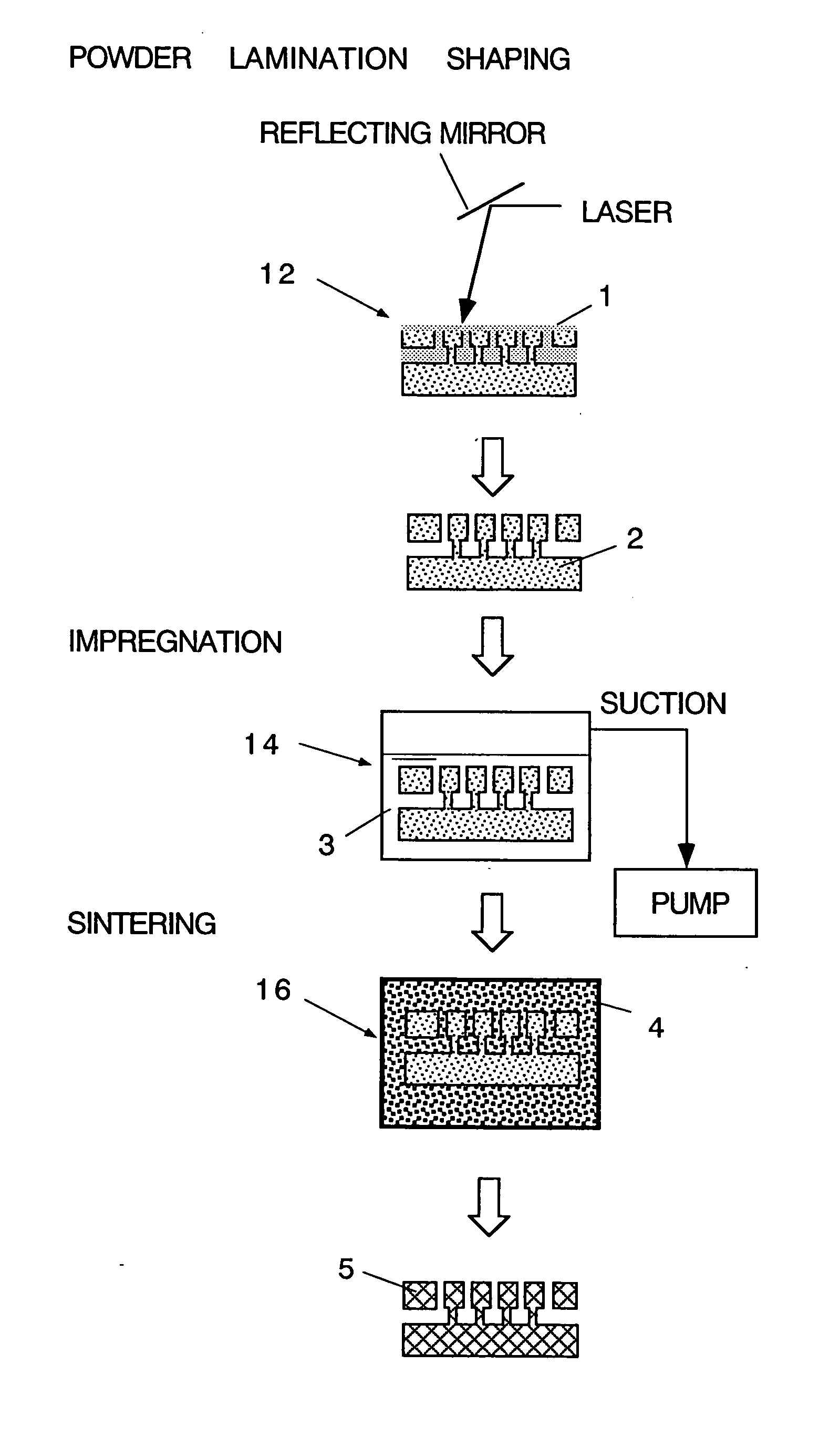

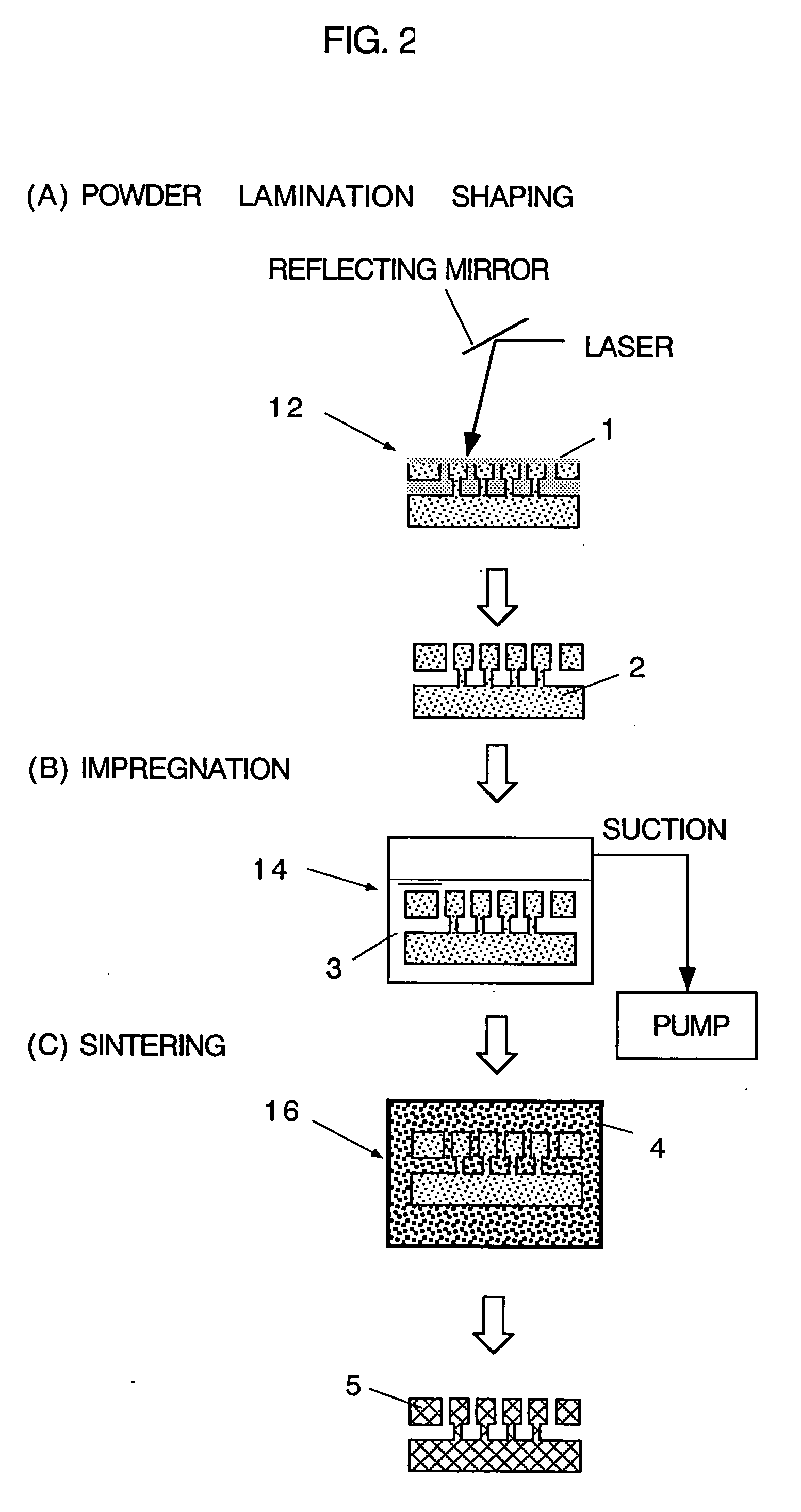

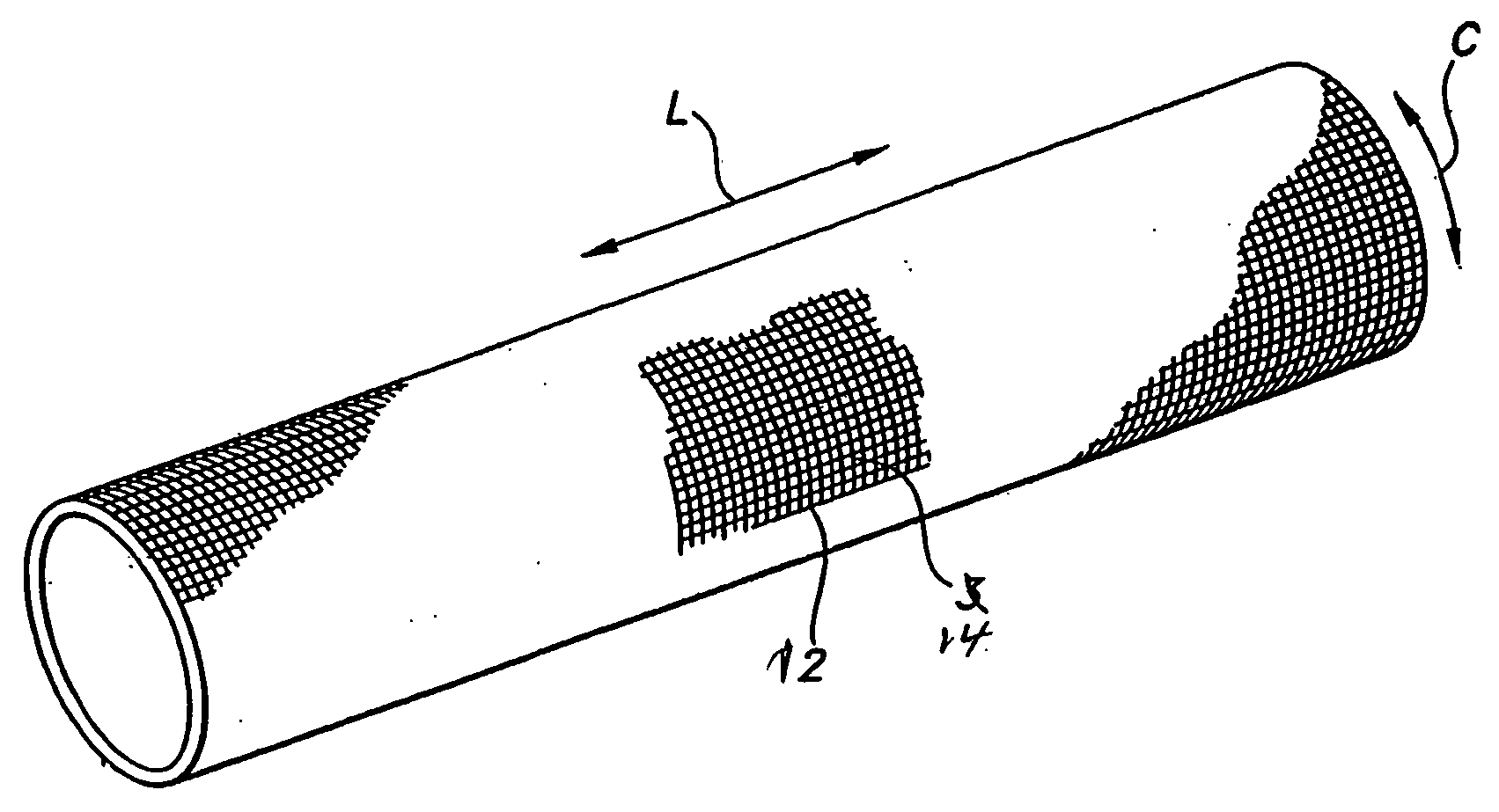

InactiveUS20050035501A1Improve heat resistanceEasy to manufactureFoundry mouldsAuxillary shaping apparatusHeat resistanceThree dimensional shape

A method of manufacturing a heat-resistant ceramic core with a three-dimensional shape, which is used to cast a hollow flow passage inside by precision casting. The method includes a powder lamination shaping step for forming ceramic core 2 with a three-dimensional shape from resin-covered ceramic powder 1, an impregnation step for impregnating ceramics reinforcing liquid 3 into the formed ceramic core 2, and a sintering step for sintering the impregnated ceramic core 2 to improve the heat resistance thereof.

Owner:IHI CORP

Catalysts for oxidation of mercury in flue gas

InactiveUS7776780B1Superior mercury adsorption propertyLow costGas treatmentIsotope separationParticulatesIridium

Two new classes of catalysts for the removal of heavy metal contaminants, especially mercury (Hg) from effluent gases. Both of these classes of catalysts are excellent absorbers of HCl and Cl2 present in effluent gases. This adsorption of oxidizing agents aids in the oxidation of heavy metal contaminants. The catalysts remove mercury by oxidizing the Hg into mercury (II) moieties. For one class of catalysts, the active component is selected from the group consisting of iridium (Ir) and iridum-platinum (Ir / Pt) alloys. The Ir and Ir / Pt alloy catalysts are especially corrosion resistant. For the other class of catalyst, the active component is partially combusted coal or “Thief” carbon impregnated with Cl2. Untreated Thief carbon catalyst can be self-activating in the presence of effluent gas streams. The Thief carbon catalyst is disposable by means of capture from the effluent gas stream in a particulate collection device (PCD).

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

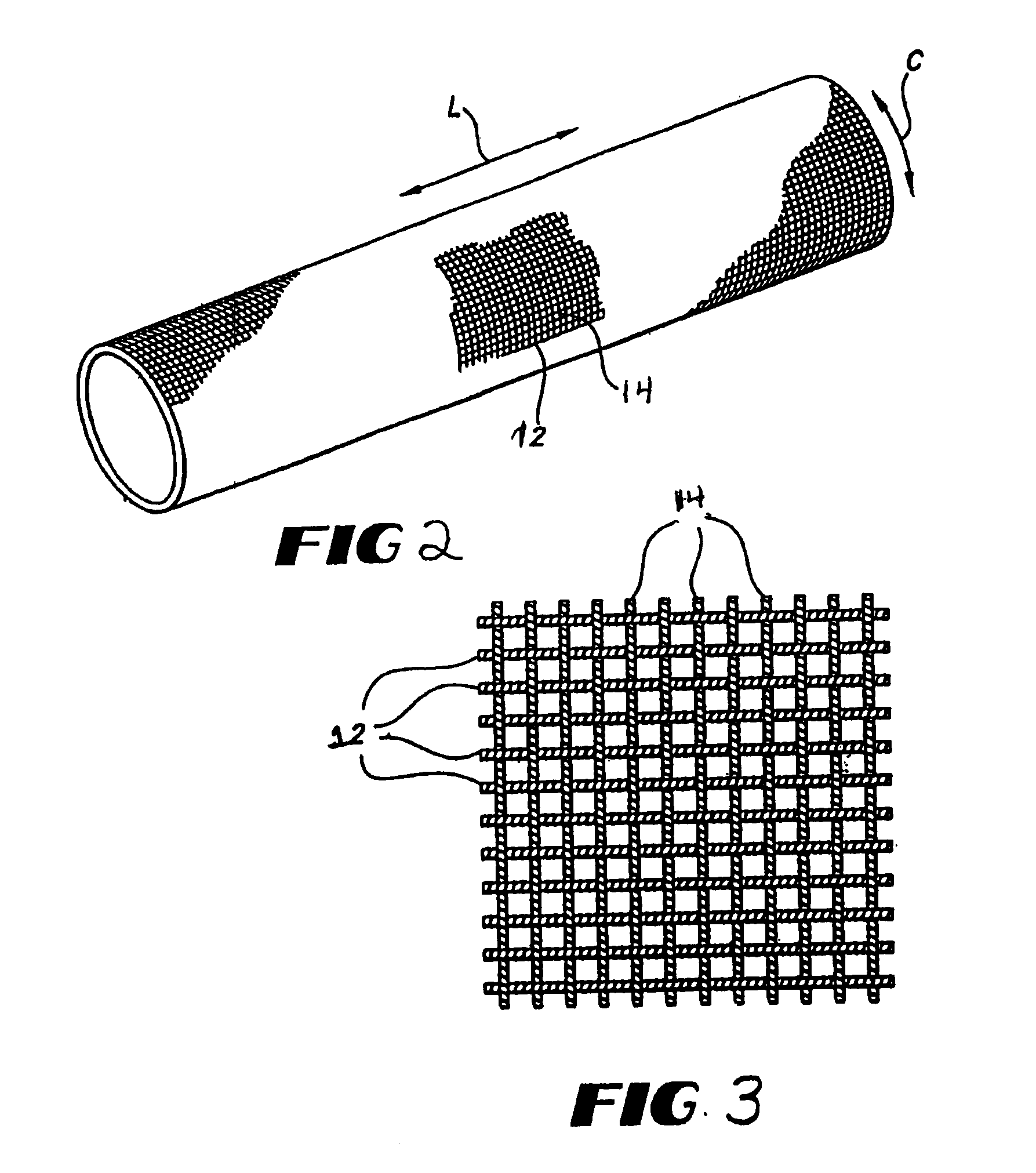

Blood-tight implantable textile material and method of making

An unmodified textile material is combined with a mixture including a non-colloidal polysaccharide slurry to form a blood-tight implantable textile material. A substantially porous unmodified textile material is impregnated with a biocompatible, bioresorbable slurry to make an implantable textile material, preferably in the form of a vascular graft. Sodium alginate is a preferred polysaccharide to use in the mixture, which serves as a viable alterative to collagen impregnation and coatings of vascular grafts.

Owner:LIFESHIELD SCI

Method for preparing diamond/silicon carbide ceramic matrix composite material

The invention discloses a method for preparing a diamond / silicon carbide ceramic matrix composite material, and belongs to the field of ceramic materials. The diamond / silicon carbide ceramic matrix composite material is characterized by being prepared from the following raw materials in percentage by weight: 5 to 15 percent of adhesive, 15 to 45 percent of silicon carbide powder, and 40 to 80 percent of diamond particle. The method comprises the following steps of: wet-mixing the raw materials for 8 to 24 hours, performing die forming under the pressure of 75 to 250MPa to obtain a blank of the composite material, oxidizing the blank in the air at the temperature of 200DEG C for 6 to 10 hours, sintering under the protection of nitrogen at the temperature of between 800 and 1,200DEG C for 8 to 15 hours, and cooling together with a furnace; and performing vacuum impregnation, oxidation, sintering and cooling, and circulating for 3 to 7 times to obtain the compact diamond / silicon carbide ceramic matrix composite material, wherein the oxidation temperature is 200DEG C, the oxidation time is 6 to 10 hours, the sintering is performed at the temperature of between 800 and 1,200DEG C for 8 to 15 hours under the protection of nitrogen, and the product is cooled together with the furnace. The method has low equipment requirement, is low in cost and can prepare the complicated-shaped compact diamond / silicon carbide ceramic matrix composite material.

Owner:UNIV OF SCI & TECH BEIJING

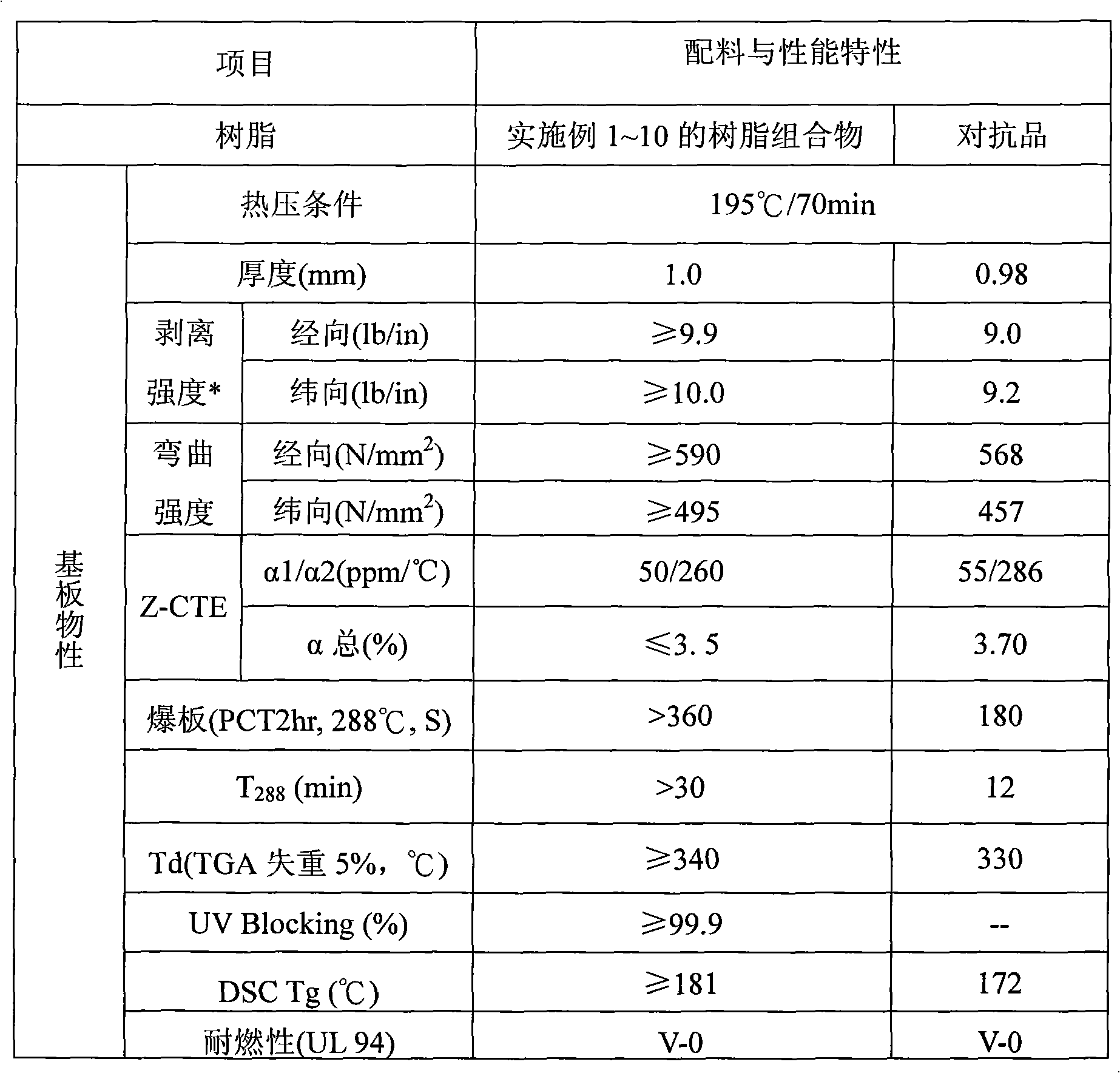

Epoxy resin composition for printed circuit copper-clad plate

ActiveCN101864146AHigh glass transition temperatureImprove heat resistanceCircuit susbtrate materialsMetal layered productsHeat resistanceThermal expansion

The invention discloses an epoxy resin composition for a printed circuit copper-clad plate, which consists of the following components in part by weight: 130 to 140 parts of butane solution containing modified epoxy resin, 60 to 70 parts of composite phenolic aldehyde curing agent or 4.5 to 6.5 parts of dicyandiamide curing agent, 0.02 to 0.04 part of curing catalyst, 30 to 40 parts of solvent and 25 to 30 parts of filler, wherein the butane solution containing the modified epoxy resin is prepared by modifying bis-functional epoxy resin, brominated bisphenol epoxy resin, multi-functional novolac epoxy resin and linear novolac epoxy resin. The epoxy resin composition has the characteristics of low viscosity, easy impregnation, convenient operation, good reactivity and high Tg; and the printed circuit copper-clad plate made of the epoxy resin composition has good reliability and workability, excellent heat resistance and Z-axis thermal expansion coefficient and other comprehensive performance.

Owner:EPOXY BASE ELECTRONICS MATERIAL

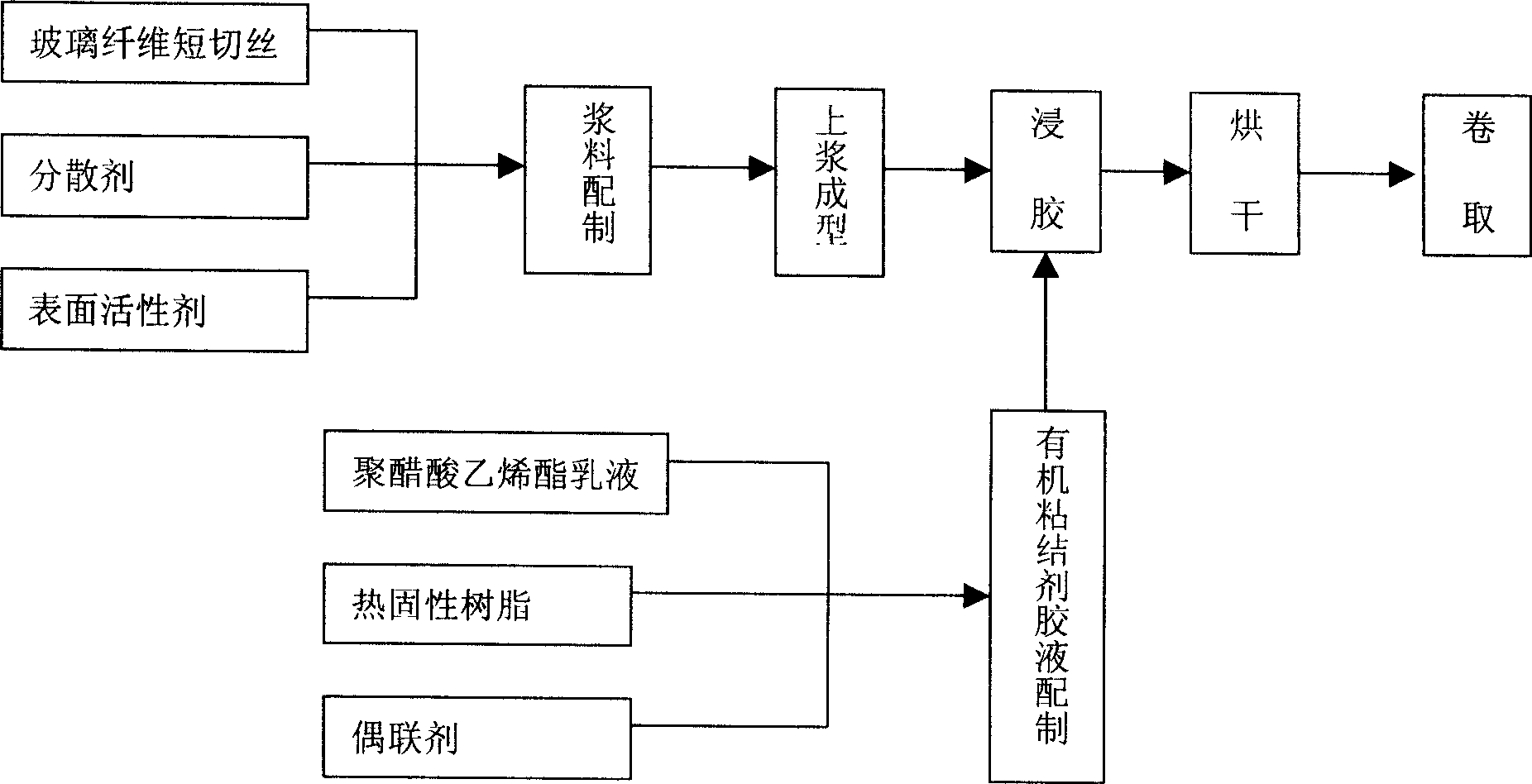

Glass fiber thin felt for plastic floor leather base material and preparation method thereof

The invention discloses a thin felt with glass fiber for the substrate of plastic floor ant the manufacturing method, comprising short-cut silk of glass fiber, dispersant, surfactant and organic binder. Said short-cut silk of glass fiber is middle-alkali or non-alkali, the diameter is 9-10 mum and the length is 6-12mm. Said dispersant is thickener belonging to cellulose acetate. Said surfactant is quaternary ammonium cationic surfactants. The organic binder is the mixture of polyethylene acetate emulsion thermosetting resin, KH560 coupling agent and water. Said thin felt with glass fiber is produced by wet technology, which comprises producing stock, preparing slurry, sizing forming, dipping and drying so on. The product is provided with high compactness, even thickness, widely applied temperature, and no-deformation under high temperature. The plastic floor surface with the felt as the substrate, is provided with flat and smooth, no shrinkage deformation, no-bending, no mildewing and stable dimension.

Owner:樊福定

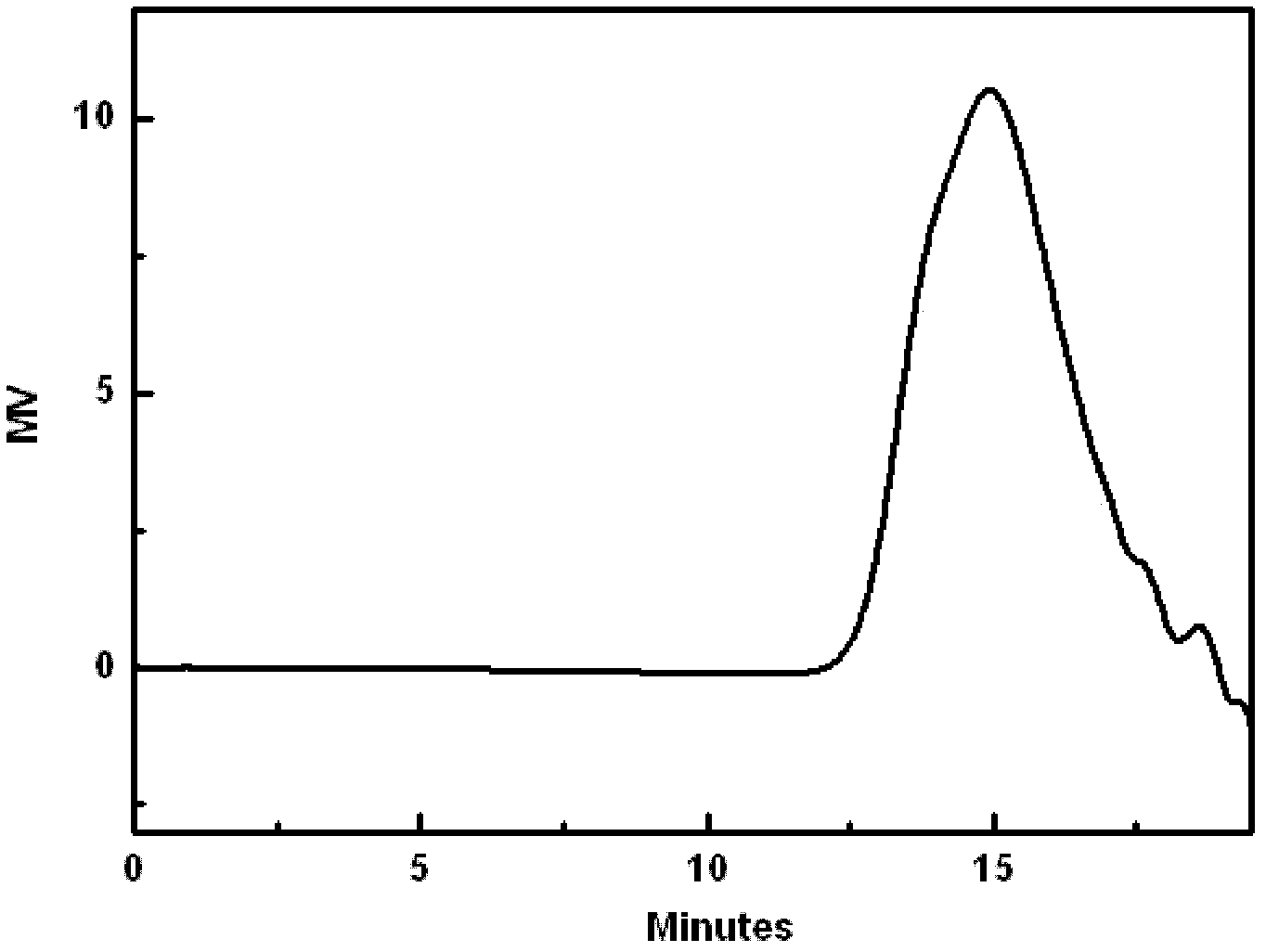

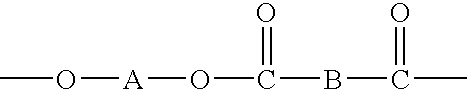

Processes for dispersing an impact modifier in a macrocyclic polyester oligomer

The invention provides macrocyclic polyester oligomer compositions containing one or more impact modifiers, methods of dispersing an impact modifier in a macrocyclic polyester oligomer, and polymers and articles produced from a macrocyclic polyester oligomer composition containing one or more impact modifiers.

Owner:CYCLICS CORP

Continuous fiber reinforce polyamide composite material prepreg tape and preparation method thereof

The invention discloses a continuous fiber reinforce polyamide composite material prepreg tape. The continuous fiber reinforce polyamide composite material prepreg tape is prepared by the following weight part components: 26-72 parts star-shaped polyamide matrix, 20-70 parts continuous fiber and 0-8 parts additive. The invention further discloses a preparation method of the continuous fiber reinforce polyamide composite material prepreg tape. Polyamide provided with a star-shaped structure is chosen by matrix resin of the prepreg tape, the liquidity of fondant is higher than the liquidity of traditional linear polyamide, dipping can be conducted easily to the continuous fiber, and dipping equipment with double intersect extrusion die heads is adopted to conduct the dipping to the continuous fiber. By means of special technology design, the continuous fiber reinforce polyamide composite material prepreg tape which is even in fiber distribution and is dipped completely is obtained, the resin content in the prepreg tape is easy to control, the fiber in the prepared continuous fiber reinforce polyamide composite material prepreg tape is guaranteed to be dipped completely, and the porosity rate is maintained not higher than 0.1%.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

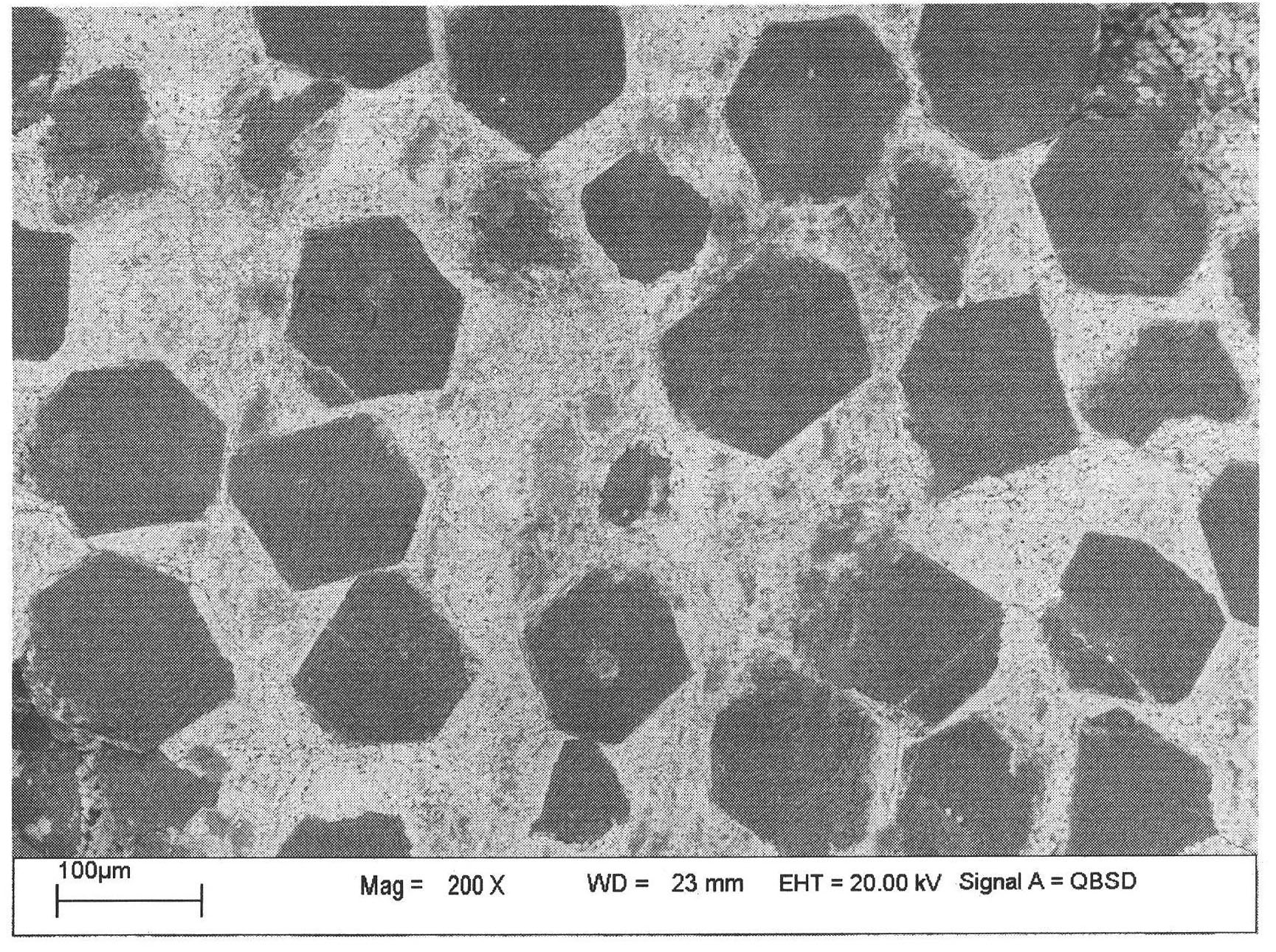

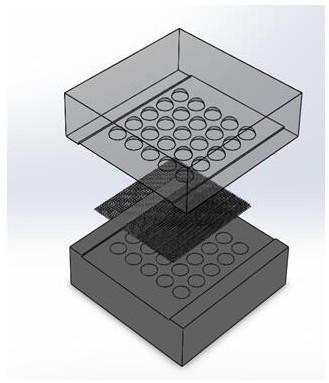

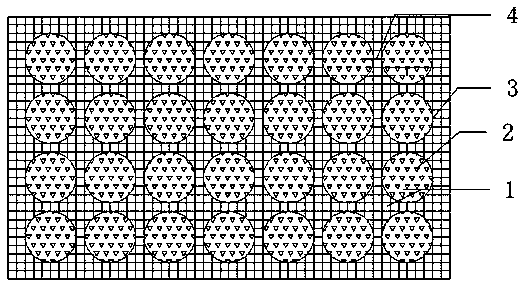

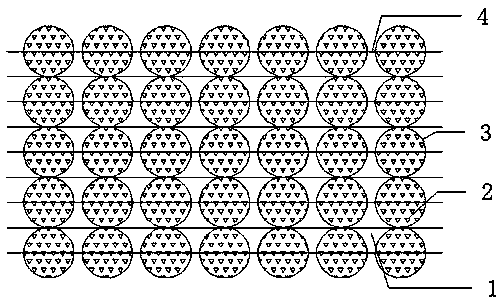

Preparation method for ceramic particle reinforced metallic matrix space lattice composite material

ActiveCN109022882ALow costSolve the problem of difficult impregnation into ceramic particlesMatrix spaceSlurry

The invention discloses a preparation method for a ceramic particle reinforced metallic matrix space lattice composite material. The preparation method comprises the following steps that (1) a metal mold comprising a plurality of globular cavities arranged in a plane lattice manner is manufactured, the mold can be divided into upper and lower parts, and a metal net is arranged between the upper and lower parts; (2) ceramic particles and a binder are mixed to prepare slurry, the metal mold is filled with the slurry, compaction and high-temperature sintering are carried out, and single-layer prefabricated bodies are manufactured; (3) metal nets are placed between the single-layer prefabricated bodies for stacking and arranging layer by layer, a binder is added for bonding, high-temperature sintering is carried out, and three-dimensional prefabricated bodies are manufactured; and (4) the three-dimensional prefabricated bodies are placed into a sand mould prepared in advance, pouring of metallic matrix melt is carried out, and infiltration is carried out to prepare the ceramic particle reinforced metallic matrix space lattice composite material. By means of the preparing method, the problem that a micron-order ceramic particle reinforced steel-based composite material is difficult to achieve ordinary pressure permeation and insufficient in toughness is solved.

Owner:KUNMING UNIV OF SCI & TECH

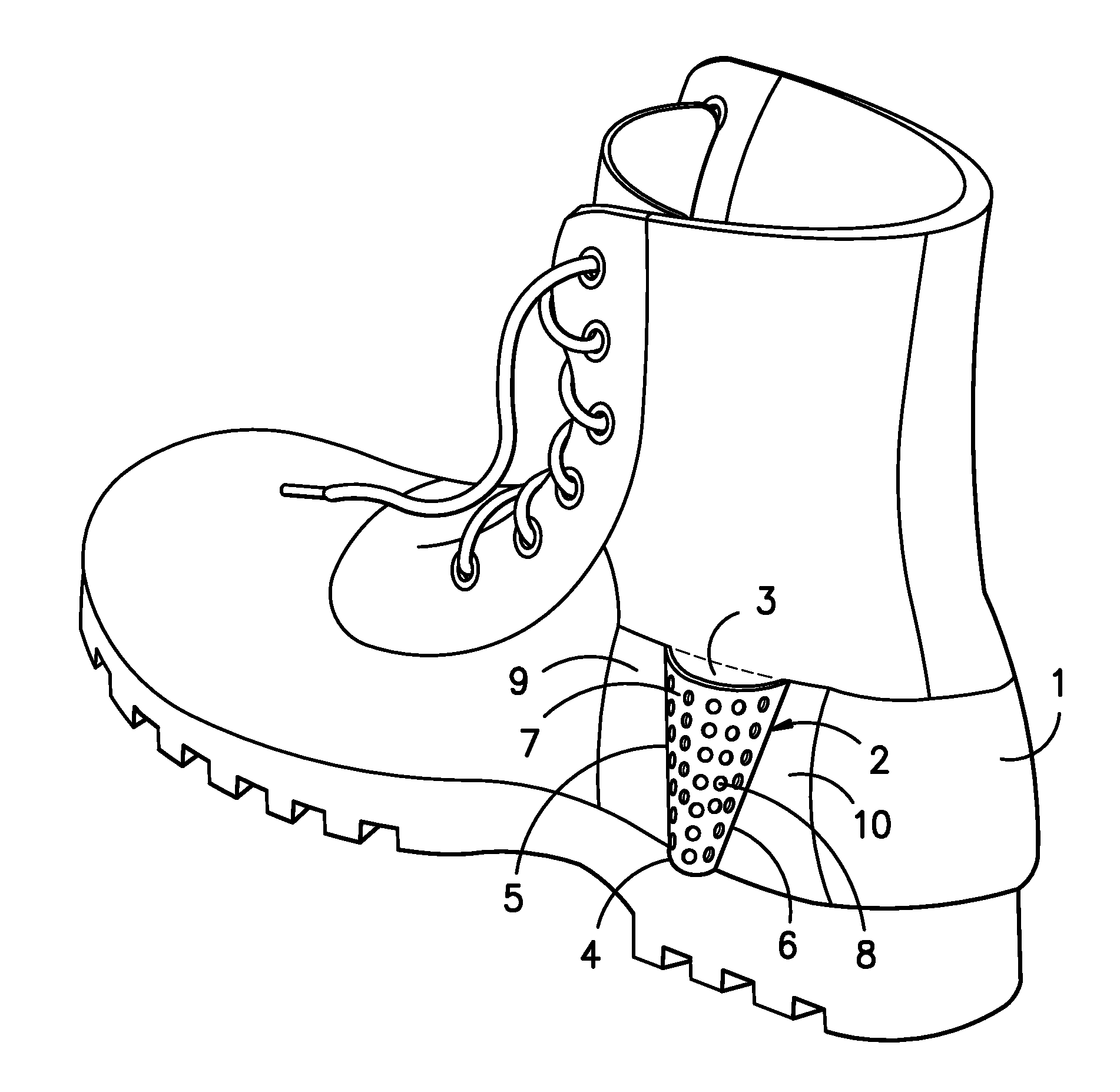

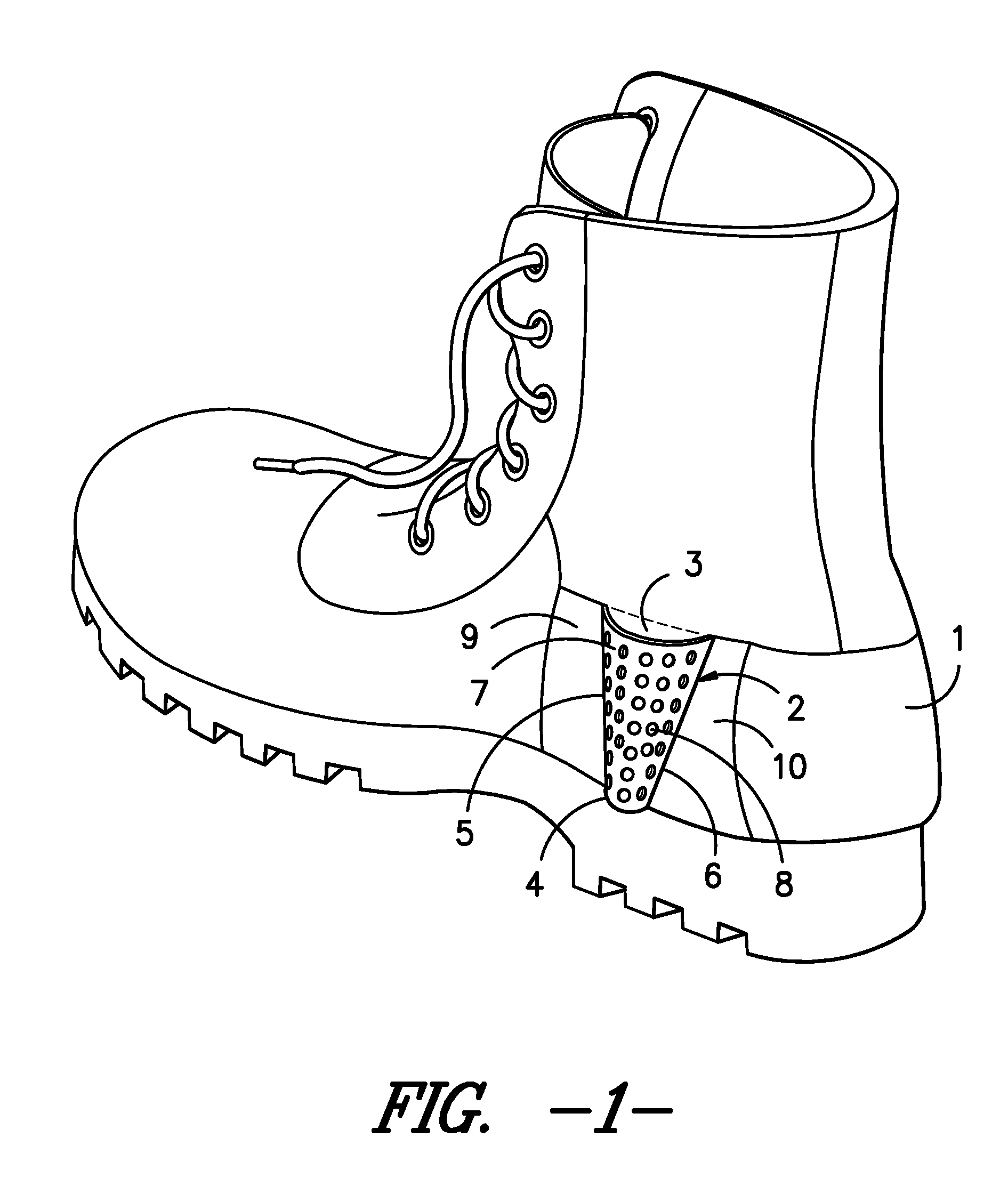

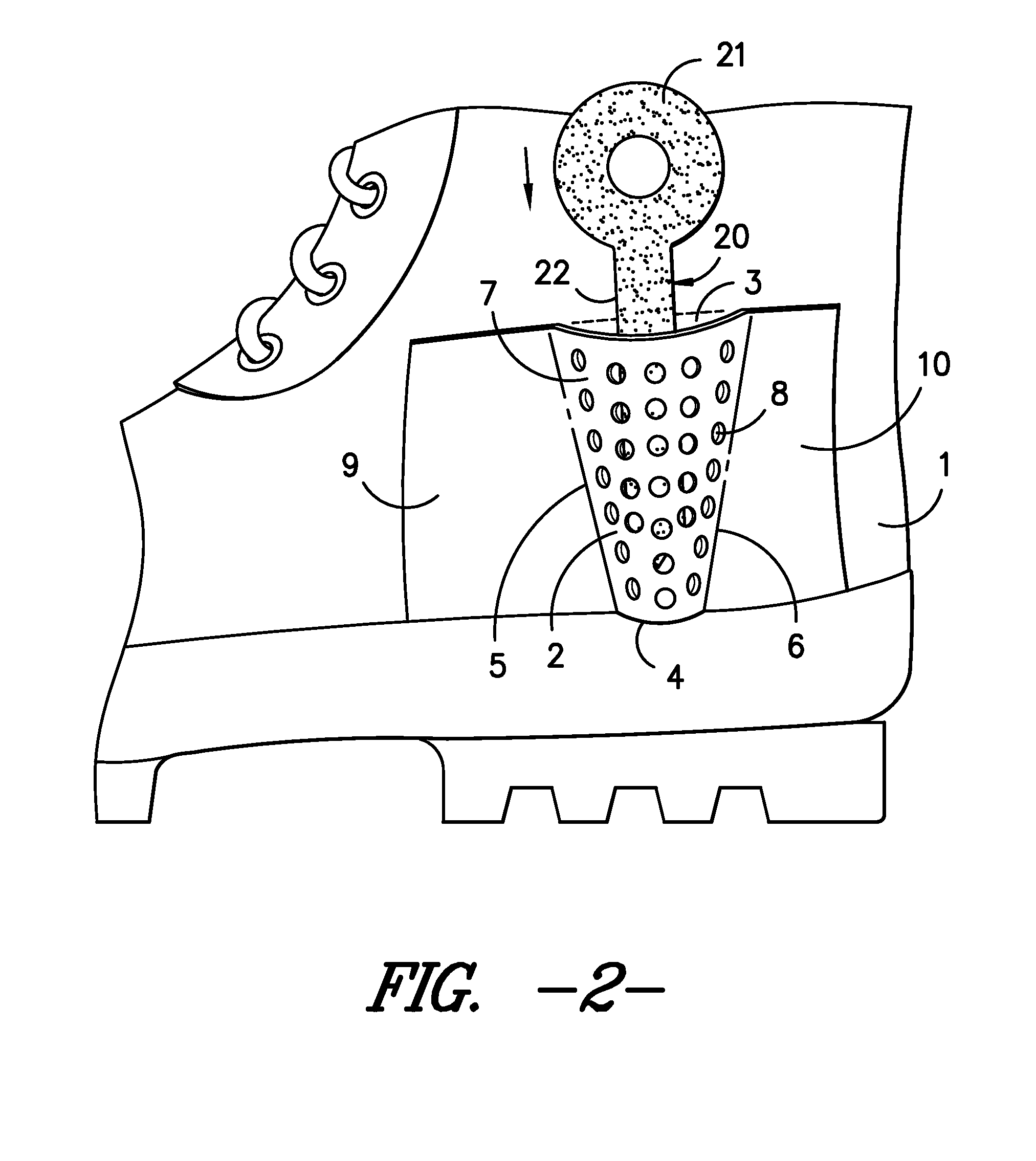

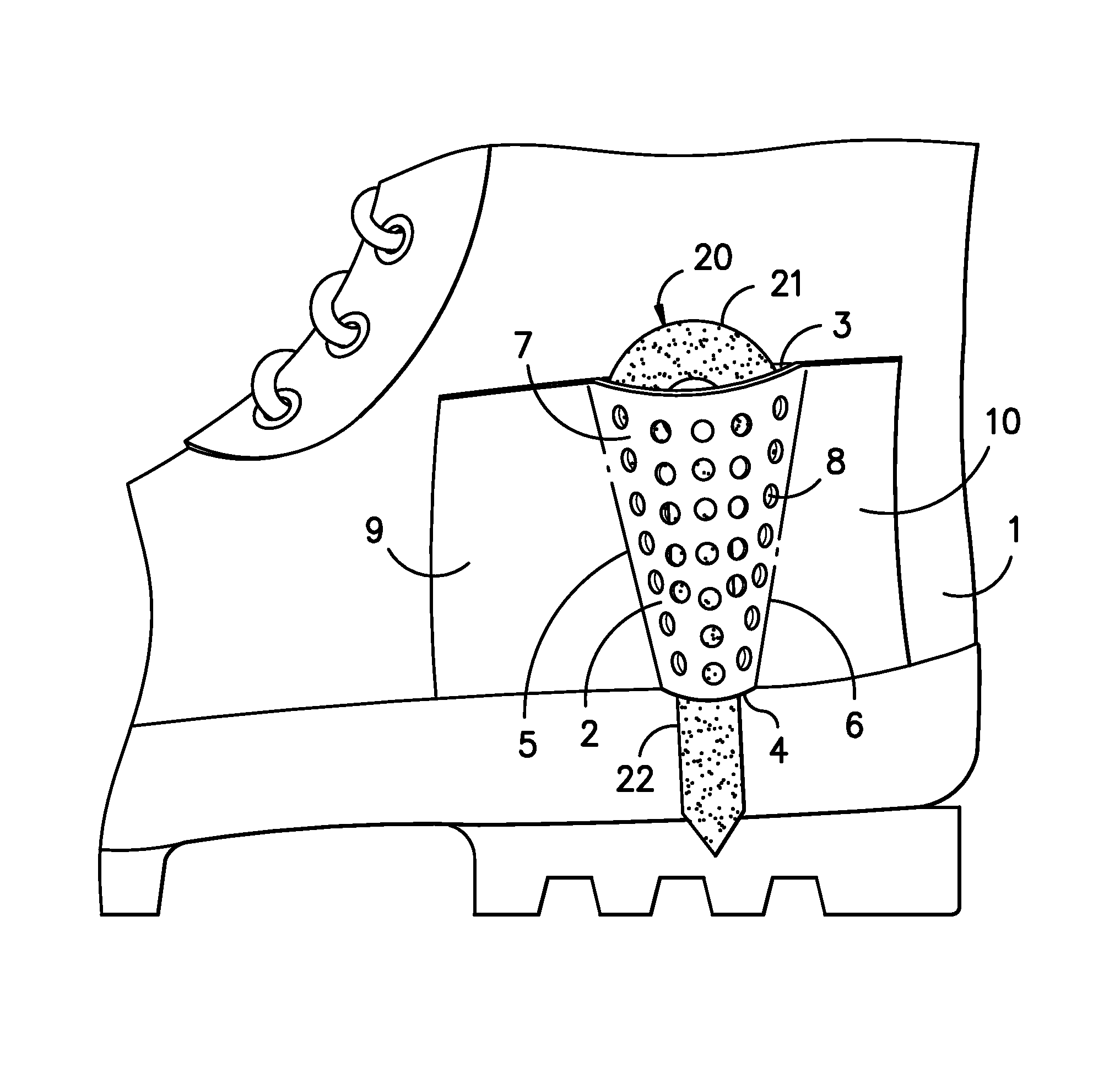

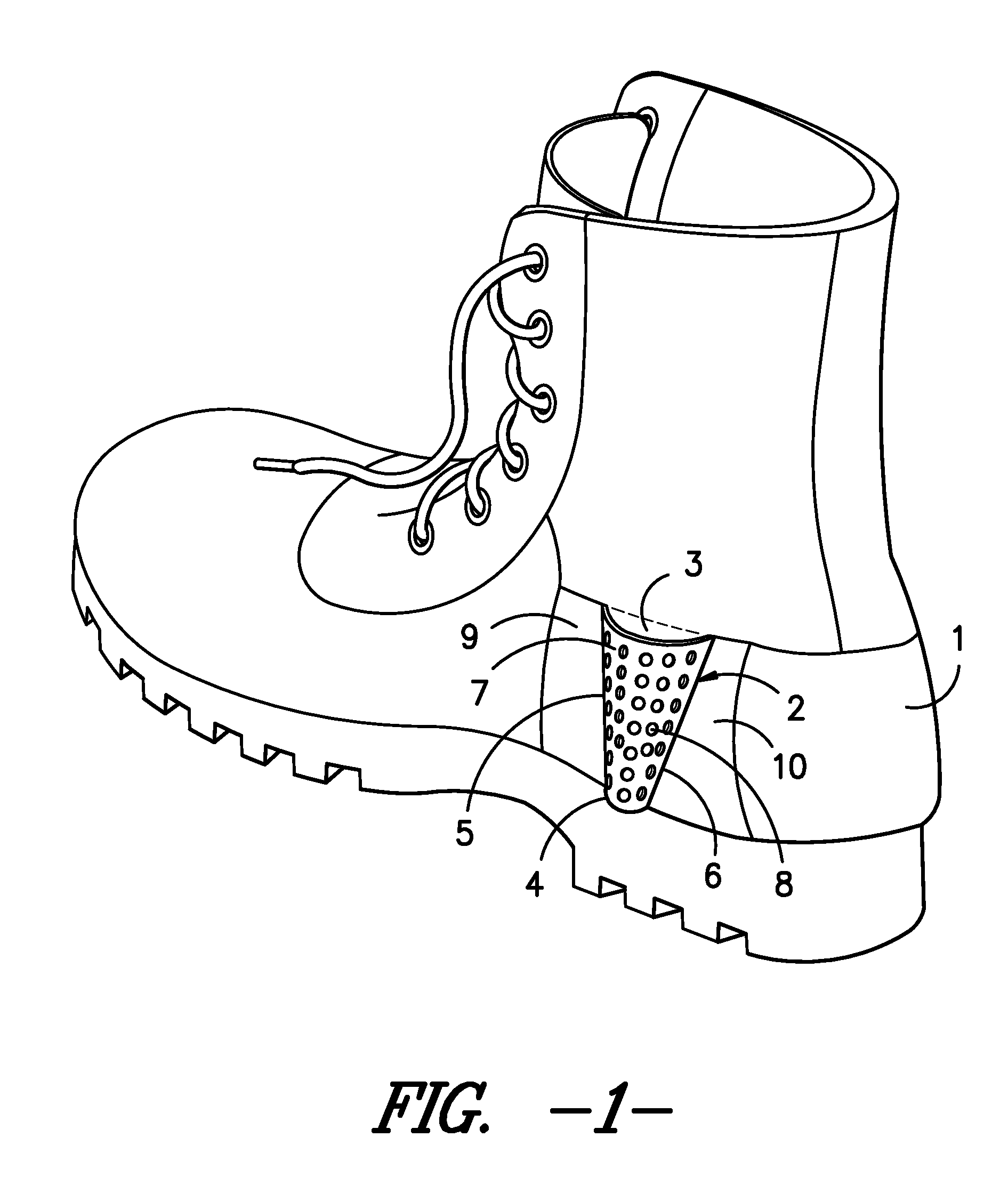

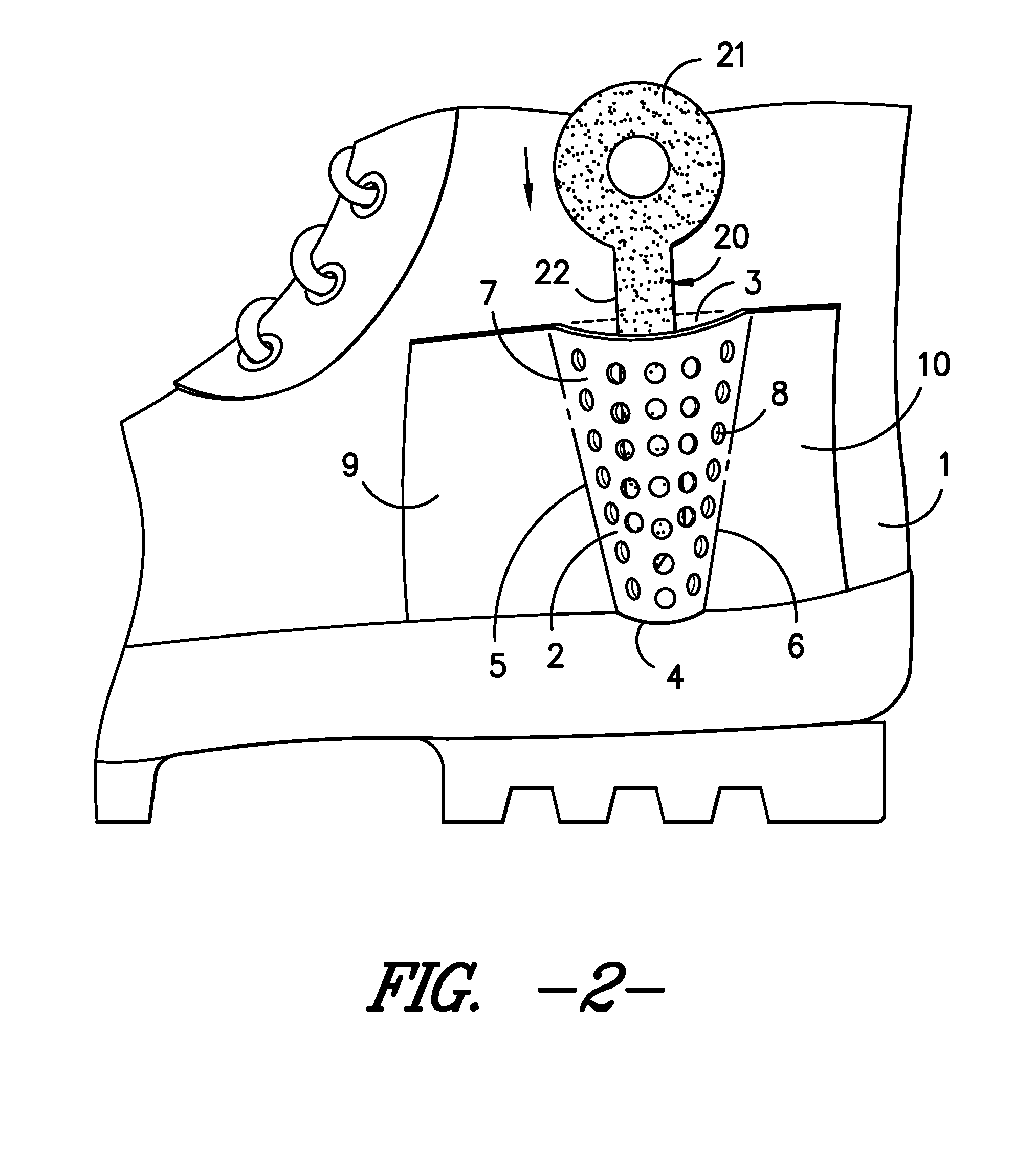

Hunting boot with pocket for scent wick

ActiveUS20140310996A1Easy to impregnateEasy to disassembleAnimal huntingFasteningsEngineeringMechanical engineering

Owner:WATERS JIMMY LEE

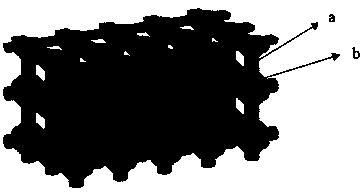

Three-dimensional shell ceramic skeleton-metal matrix composite and preparation method thereof

ActiveCN108396165AReduce manufacturing costLow costAdditive manufacturing apparatusAdditive manufacturing processesSpherical shapedMetal matrix composite

The invention discloses a three-dimensional shell ceramic skeleton-metal matrix composite and a preparation method thereof, and belongs to the field of metal matrix composites. According to the structure of the three-dimensional shell ceramic skeleton-metal matrix composite, the inside and outside of a three-dimensional shell ceramic skeleton is filled with a metal matrix, the whole three-dimensional shell ceramic skeleton is of a hollow shell structure, interpenetrating column pitch points are in a spherical, cylindrical or square shape, and the wall thickness of the three-dimensional shell ceramic skeleton is 0.5-3mm. According to the preparation method, the difficulty of infiltration of metal liquid and ceramic reinforcement is improved effectively, the inside and outside of the shell is wrapped with a pure matrix, and the plastic toughness of the composite is not lost while good wear resistance is achieved. The shape of the pitch points of the skeleton is in a spherical, cylindrical and square shape, the pitch points of the skeleton are distributed periodically, certain connection strength during sintering can be provided, and the synergistic effect of the skeleton structure and the matrix is brought maximally. The three-dimensional shell ceramic skeleton-metal matrix composite is expected to be used in the field of friction and abrasion working conditions.

Owner:KUNMING UNIV OF SCI & TECH

Method of producing aluminum composite material

InactiveUS20060169434A1Heat-contraction of the preform can be preventedHigh strengthFoundry mouldsFoundry coresFiberActivated carbon

A manufacturing method of an aluminum composite material having excellent abrasion resistant and vibration damping properties is disclosed. The aluminum composite material is manufactured by impregnating a perform with an aluminum alloy the perform is formed by mixing an alumina fiber and graphite or activated charcoal and an inorganic binder in water and sintering the resultant mixed product at a predetermined sintering temperature under vacuum, in an inert gas, or in a reducing gas.

Owner:CENTRAL MOTOR WHEEL CO LTD

A kind of hydrophilic base cloth and its manufacturing method

InactiveCN102277690AHigh bonding strengthMeet high performance requirementsPaving reinforcementsNon-woven fabricsGramUltimate tensile strength

The invention discloses hydrophilic base fabric with high tensile strength and good water permeability. The hydrophilic-group fabric is characterized in that the gram weight per unit area is 100-280g / m<2>, the thickness is 0.4-1.0mm, the tensile strength is 4000-14000N / m, the tearing strength is 130-450N, and the vertical permeation coefficient is 0.1-1.0cm / s. The manufacturing method of the hydrophilic base fabric comprises the steps of: raw material processing, net forming, impregnating and bonding, drying and sizing. The product of the hydrophilic base fabric has the characteristics of high strength, good hydrophilcity, small thermal contractibility, easiness for impregnation and the like, has high bonding strength with modified asphalt, is easy for construction, and completely meets the requirements of high-grade highways on high performance of materials.

Owner:HUNAN NONWOVEN CNNC

Novel copper-based dip brazing alloy for drilling bit

InactiveCN101890588AReasonable typeReasonable contentWelding/cutting media/materialsSoldering mediaChemical compositionBraze alloy

The invention discloses a novel copper-based dip brazing alloy used in drilling bit production. Cutting drill teeth and a drill body form a whole by dip brazing. The dip brazing copper alloy has excellent mechanical property and high strength, toughness and abrasion resistance. A brazing process is simple and convenient and suitable for brazing drill bits of multiple types. When the brazing temperature is between 900 and 1,000 DEG C, the alloy comprises the following chemical components in percentage by weight: 5 to 10 percent of Ni, 3 to 9 percent of Mn, 3 to 5 percent of Fe, 7 to 13 percent of Sn, 0.1 percent of sigma RE and the balance of Cu. When the brazing temperature is between 950 and 1,150 DEG C, the alloy comprises the following chemical components in percentage by weight: 8 to 15 percent of Ni, 10 to 13 percent of Mn, 5 to 10 percent of Zn, 1 to 2 percent of Fe, 0.05 to 0.1 percent of Ce and the balance of Cu. When the brazing temperature is between 1,100 and 1,250 DEG C, the alloy comprises the following chemical components in percentage by weight: 15 to 20 percent of Ni, 5 to 10 percent of Mn, 3 to 5 percent of Fe, 0.05 to 0.1 percent of sigma RE and the balance of Cu.

Owner:TIANJIN SANTIAOSHI NONFERROUS METAL FOUNDRY

Complex fiber roadbed thin felt

The present invention discloses a complex fiber roadbed thin felt, including 40% to 60% of glass fiber short cutting silk by weight, 20% to 40% of polyester fiber short cutting silk by weight, and 18% to 30% of organic binder. The complex fiber roadbed thin felt is made from the glass fiber short cutting silk, the polyester fiber short cutting silk and the organic binder through a wet process, thus the felt is integrated with the advantage of the glass fiber thin felt and the polyester fiber thin felt, has adequate intensity, good flexibility, uniform thickness, easy impregnation, and high collapse property; the complex fiber roadbed thin felt is not only suitable for wide temperature range, also has low expansion coefficient, good stability, strong capacity for penetrating bitumen; a structural layer is formed after absorbing a bituminous material, thus the felt has water-proof, heat-proof and corrosion-proof physical characteristics, and very good associativity and is not liable to separate. The felt is suitable for building and reconstructing an old cement concrete pavement asphalt pavement; the repair maintenance of asphalt pavement facial cleft.

Owner:樊福定

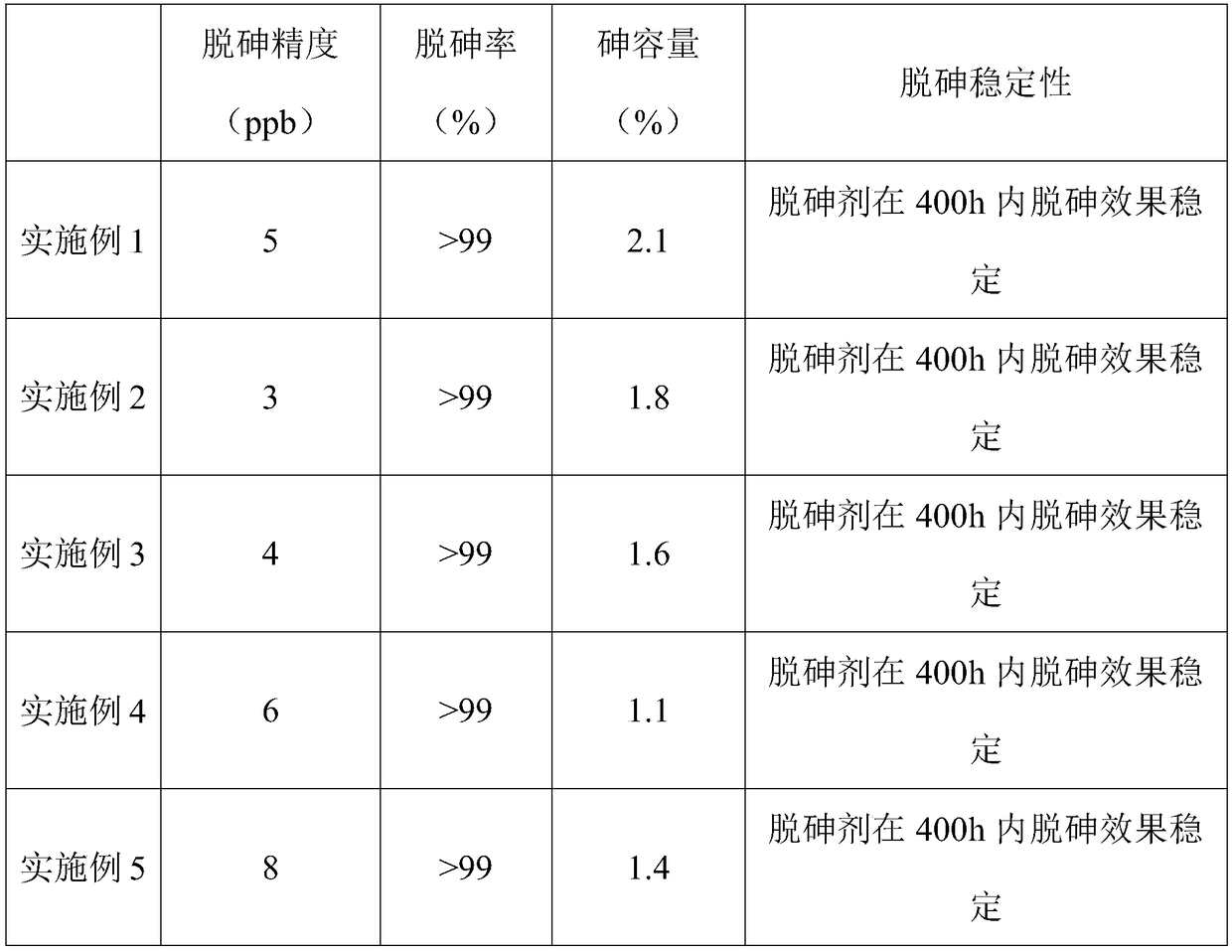

Arsenic removal agent, and preparation method and use thereof

ActiveCN109251764AHigh precision of arsenic removalImprove stabilityRefining with metal oxidesProcess efficiency improvementActivated carbonActive component

Owner:昆山市精细化工研究所有限公司

Reinforced thermoplastic-resin multilayer sheet material, process for producing the same, and method of forming molded thermoplastic-resin composite material

InactiveCN102815062AEasy to impregnateGood dispersionSynthetic resin layered productsLaminationFiberShock resistance

Owner:FUKUI PREFECTURE

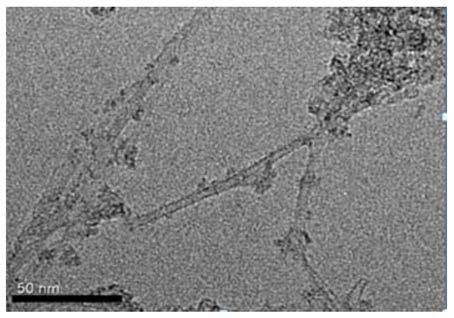

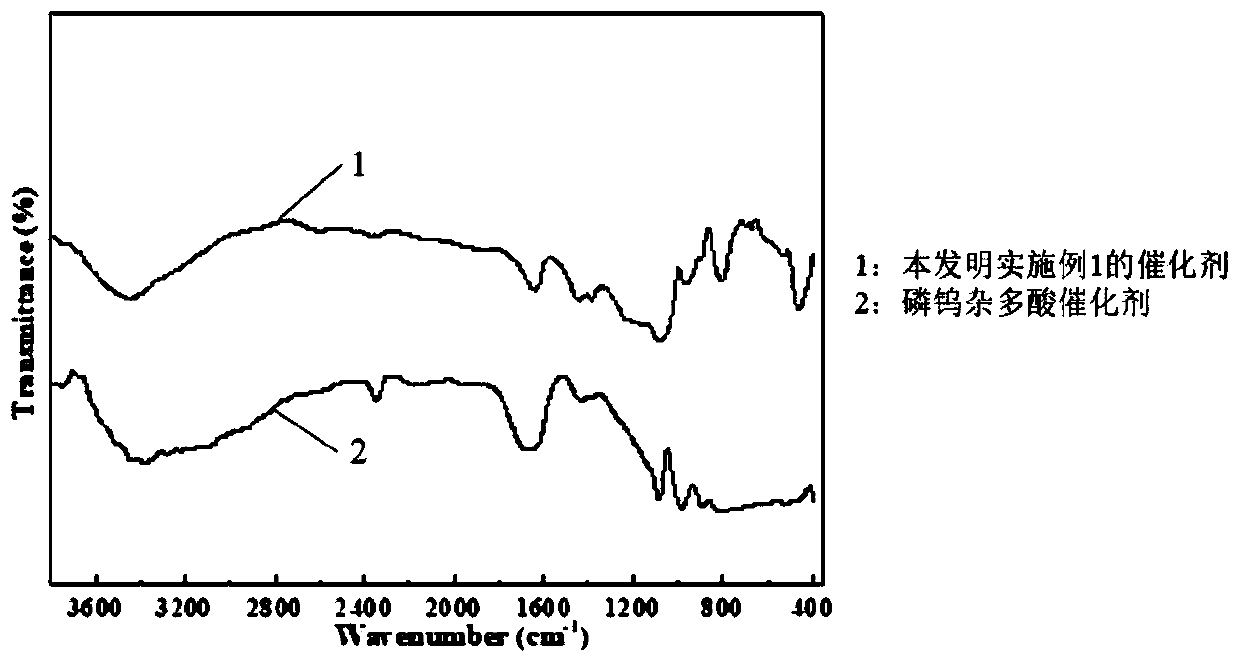

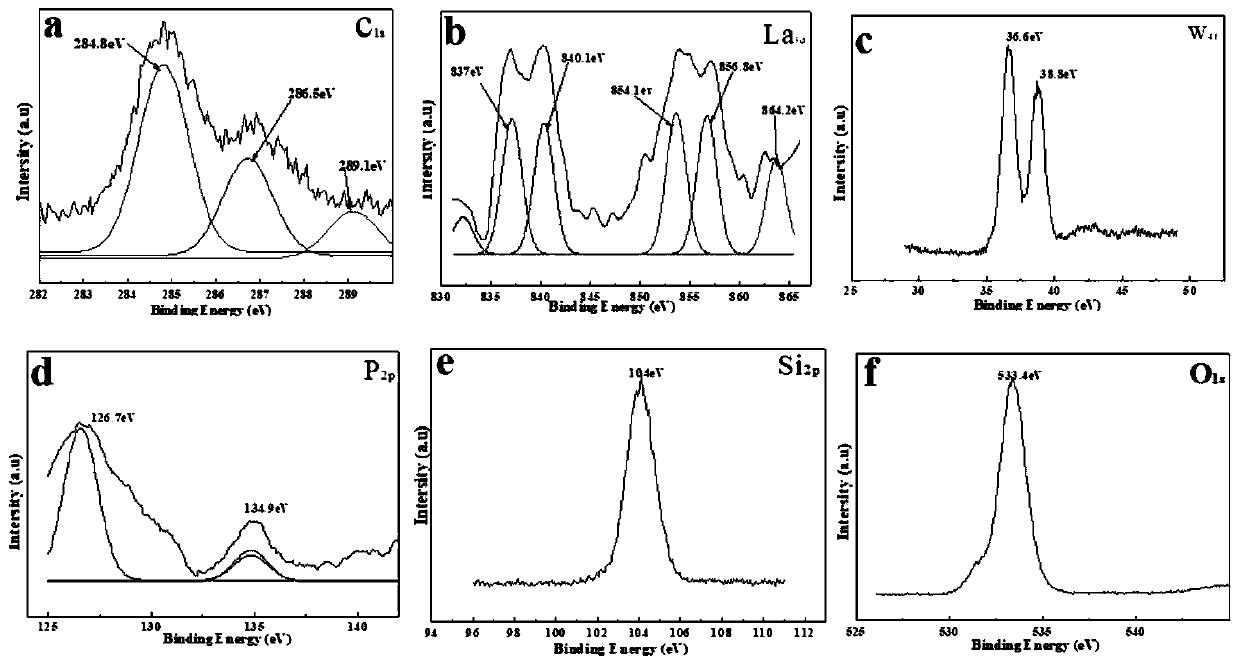

Preparation method and application of rare earth modified Keggin-type heteropolyacid supported catalyst

ActiveCN109876836AHigh activityImprove stabilityBiofuelsCatalyst activation/preparationMetal chlorideAlcohol

The invention relates to the technical field of preparation of catalysts, and discloses a preparation method of a rare earth modified Keggin-type heteropolyacid supported catalyst. A carbon nanotube is used as a carrier; the carbon nanotube is subjected to oxidation opening and is cut into short pipes through an acid solution; under the action of metal chlorides and alcohol solvent, the defect sites of the tail end or (and) the side wall of the carbon nanotube are combined with hydroxy, so that a hydroxylated carbon nanotube is obtained; the surface property of the carbon nanotube is changed,so that active ingredients can be more easily and firmly adsorbed; the stability of the catalyst is improved; meanwhile, the hydroxylated carbon nanotube has a large number of highly-delocalized Pi electrons, and strong attraction to rare earth metal elements is realized, so that a Lewis acid site is favorably formed; the activity of the catalyst is improved; and meanwhile, the stability of the catalyst is also improved.

Owner:JIANGXI UNIV OF SCI & TECH

Insulating glue for lithium ion batteries and using method of insulating glue

InactiveCN102719214AMoisture-proofAcid proofNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyElectrical battery

The invention provides insulating glue for covering exposed lug metal in the electrode assembling process of coiled lithium ion batteries and a using method of the insulating glue. The insulating glue comprises the following components in mass percentage: 20-60% of epoxy resin, 12-15% of epoxy resin curing agent, 5-15% of epoxy propane butyl ether, 3-10% of triethanolamine, 15-30% of quartz powder and 5-10% of white carbon black. The insulating glue is a naturally dried artificial rubber coating which can be easily sprayed, brushed or soaked; and the insulating glue is suitable for the insulating protection of metal exposed parts of the lithium ion batteries without influencing the properties of the lithium ion batteries, low in cost, simple and easy for operation, excellent in an insulating effect, safe and reliable.

Owner:TECHNICAL INST OF LITHIUM BATTERY ENERGY SAVING TECH OF MCNAIR DONGGUAN +2

Blood-tight implantable textile material and method of making

Owner:LIFESHIELD SCI

Hunting boot with pocket for scent wick

Owner:WATERS JIMMY LEE

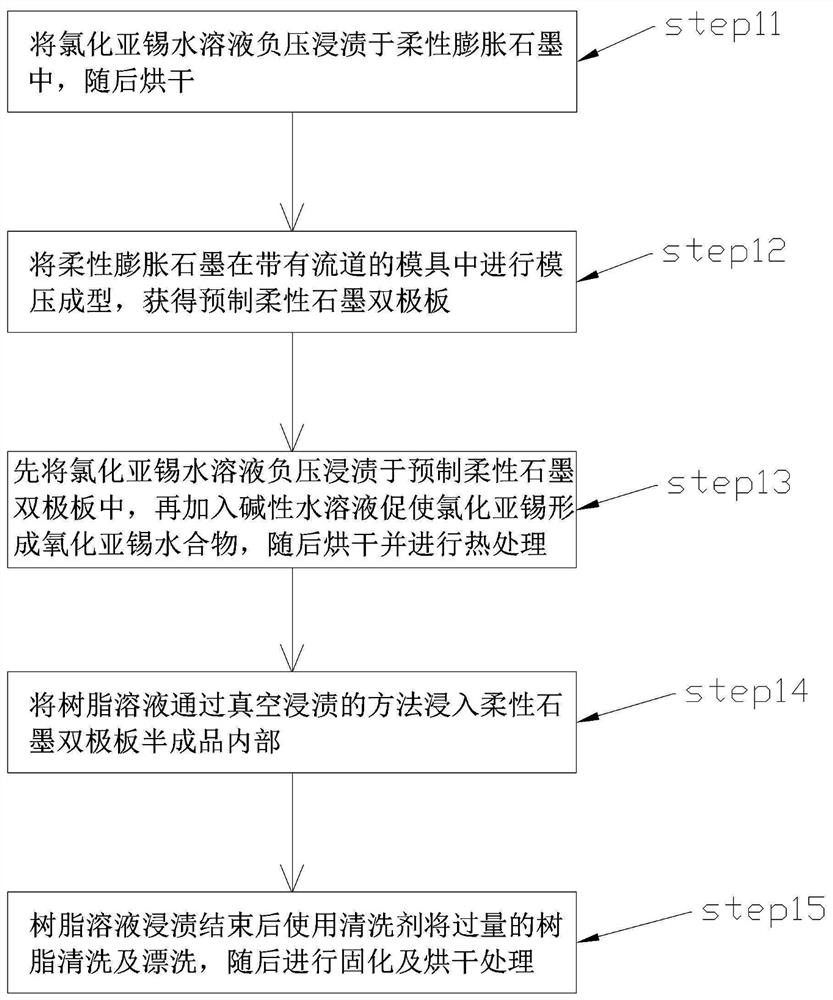

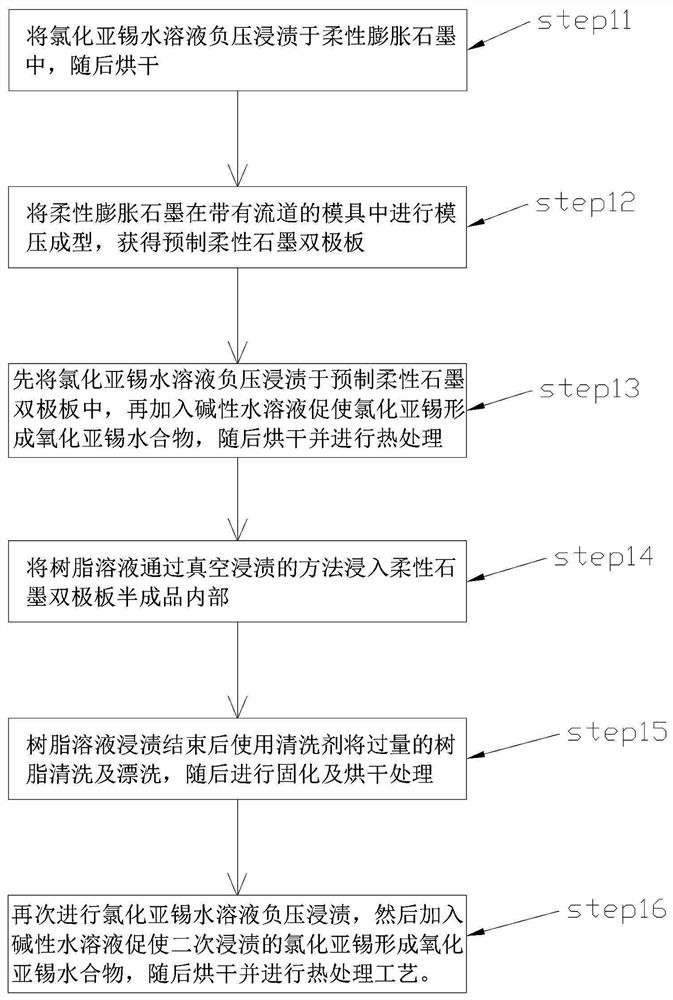

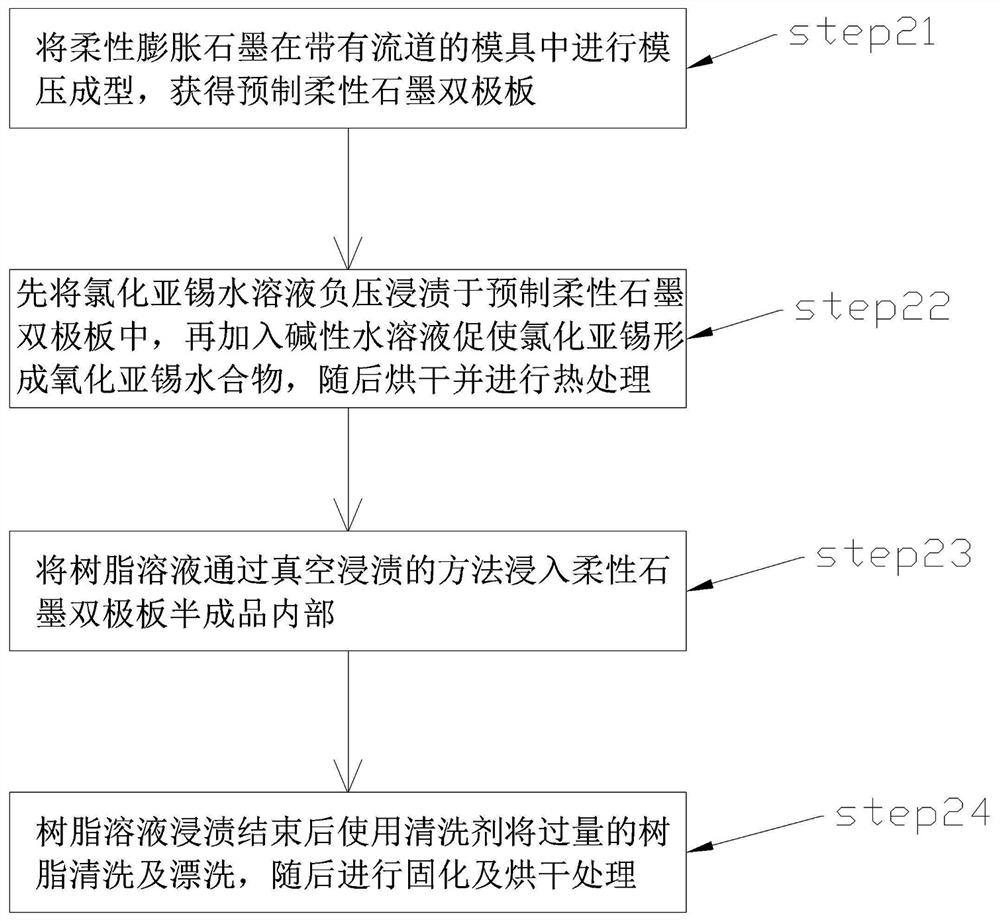

Tin dioxide doped flexible graphite bipolar plate and preparation method and application thereof

The invention discloses a stannic oxide doped flexible graphite bipolar plate and a preparation method and application thereof, stannous chloride is used as a tin source, a stannous oxide hydrate is formed under an alkaline condition, high-conductivity stannic oxide can be formed in the flexible graphite bipolar plate through high-temperature heat treatment, and the conductivity of the flexible graphite bipolar plate is improved. And tin dioxide can also improve the hydrophilicity of the graphite bipolar plate, so that the subsequent resin aqueous solution is easier to impregnate, the flexible graphite bipolar plate with high conductivity and high density is obtained, the output performance of the fuel cell is improved, and the service life of the fuel cell is prolonged. The tin dioxide doping method used in the invention is simple, low in cost, especially suitable for rapid batch processing, and suitable for popularization and application in the field of flexible graphite bipolar plates of fuel cells.

Owner:广东环华氢能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com