Preparation method for ceramic particle reinforced metallic matrix space lattice composite material

A technology of ceramic particles and metal matrix, which is applied in the field of composite materials, can solve the problems of ceramic skeleton fracture and stress concentration, and achieve the effects of preventing crack expansion, improving service life, and being easy to infiltrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Preparation of high manganese steel matrix composite material.

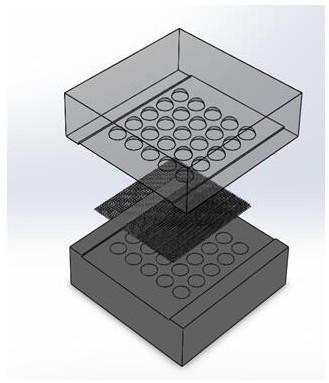

[0033] (1) Machining is used to manufacture a metal mold including a plurality of spherical cavities arranged in a plane lattice, wherein the diameter of the spherical cavity is 5 mm, and the distance between adjacent spherical cavities is 1 mm; the mold can be divided into upper and lower parts, There is a metal mesh between the upper and lower parts (such as figure 1 shown);

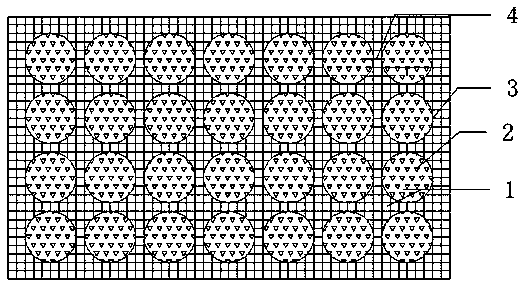

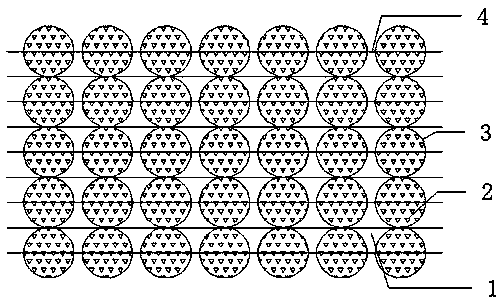

[0034] (2) Mix 60-mesh ZTA (zirconia toughened alumina) ceramic particles and water glass to make a slurry. The amount of water glass added is 3% of the mass of the ZTA ceramic particles; pour it into a metal mold, compact it, and then Put it into a heating furnace and heat it to 450°C for 0.5h, then heat it to 900°C for 1h to ensure a certain strength, and make a single-layer prefabricated body. The ceramic balls in the single-layer prefabricated body are arranged in a plane lattice (such as figure 2 shown);

[0035...

Embodiment 2

[0037] Example 2: Preparation of an aluminum alloy matrix composite material.

[0038] (1) Machining is used to manufacture a metal mold including a plurality of spherical cavities arranged in a plane lattice, wherein the diameter of the spherical cavity is 3 mm, and the distance between adjacent spherical cavities is 3 mm; the mold can be divided into upper and lower parts, There is a metal mesh between the upper and lower parts;

[0039] (2) Put 250-mesh TiC ceramic particles and 200-mesh WC ceramic particles into a ball mill with a mass ratio of 3:2 for 0.5 hours to make them fully mixed, and then add silica sol. The amount of silica sol added is the total mass of TiC and WC 10% of the slurry, continue to ball mill for 0.5h to make a slurry; pour it into a metal mold, compact it, and then put it into a heating furnace and sinter at 800°C for 1.5h to ensure a certain strength, and make a single-layer prefabricated body, single-layer The ceramic balls in the preform are arra...

Embodiment 3

[0042] Example 3: Preparation of copper alloy matrix composite material.

[0043] (1) Machining is used to manufacture a metal mold including a plurality of spherical cavities arranged in a plane lattice, wherein the diameter of the spherical cavity is 10 mm, and the distance between adjacent spherical cavities is 5 mm; the mold can be divided into upper and lower parts, There is a metal mesh between the upper and lower parts;

[0044] (2) SiC 100 mesh, TiN 150 mesh and ZrO 80 mesh 2 Put the mixture into a ball mill to make it fully mixed evenly, and then add aluminum metaphosphate, the amount of aluminum metaphosphate added is SiC, TiN and ZrO 28% of the total mass, continue ball milling to make slurry; pour it into a metal mold, compact it, then heat it to 400°C, keep it warm for 1h, continue heating to 600°C, keep it warm for 1h, and after cooling with the furnace, make a single-layer prefabrication body, the ceramic balls in the single-layer prefabricated body are arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com