Continuous fiber reinforce polyamide composite material prepreg tape and preparation method thereof

A technology of continuous fibers and composite materials, applied in the field of polymer composite materials, can solve the problems of unfavorable fiber infiltration, increased fiber content, limited high temperature fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The prepreg tape based on continuous fiber reinforced polyamide composite material is made from components comprising the following parts by weight:

[0047] Continuous glass fiber (PPG company, 45882400tex continuous glass fiber) 50.8 parts,

[0048] 49.2 parts of star-shaped polyamide matrix;

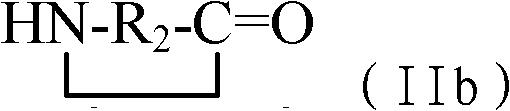

[0049] Among them, the star-shaped polyamide matrix is prepared according to the method described in French patent FR2743077, 100 parts of caprolactam (monomer II), 0.025 parts of 2,2,6,6-tetra-(β-carboxyethyl)- Cyclohexanone (multifunctional compound I) and 0.036 parts of distilled water are added into a high-pressure reactor for copolymerization. According to the standard IS01133, the melt flow index measured at 275°C under a load of 325 grams is 28g / 10min.

[0050] (1) The star-shaped polyamide matrix is plasticized and melted by an extruder to obtain a star-shaped polyamide matrix melt, which is smoothly extruded through a double-extrusion die head for use;

[0051] (2...

Embodiment 2

[0056] The prepreg tape based on continuous fiber reinforced polyamide composite material is made from components comprising the following parts by weight:

[0057] Continuous carbon fiber (Toray Fiber Research Institute, T700 24K continuous carbon fiber) 53.2 parts,

[0058] 46.8 parts of star polyamide matrix;

[0059] Among them, the star-shaped polyamide matrix is according to the method described in French patent FR2743077, 100 parts of caprolactam (monomer II), 0.031 parts of 2,2,6,6-tetra-(β-carboxyethyl)-cyclohexyl Ketone (polyfunctional compound I) and 0.036 parts of distilled water are added into a high-pressure reactor for copolymerization. According to the standard ISO1133, the melt flow index measured at 275° C. under a load of 325 grams is 47 g / 10 min.

[0060] (1) The star-shaped polyamide matrix is plasticized and melted by an extruder to obtain a star-shaped polyamide matrix melt, which is smoothly extruded through a double-extrusion die head for use;

...

Embodiment 3

[0064] The prepreg tape based on continuous fiber reinforced polyamide composite material is made from components comprising the following parts by weight:

[0065] Continuous glass fiber (PPG company, 4588 2400tex continuous glass fiber) 70 parts,

[0066] Star-shaped polyamide matrix 26 parts,

[0067] 3.5 parts of magnesium hydroxide,

[0068] Antioxidant 1098 0.25 parts,

[0069] Antioxidant 168, 0.25 part;

[0070] The preparation method, components and content of the star-shaped polyamide matrix are the same as those in Example 1.

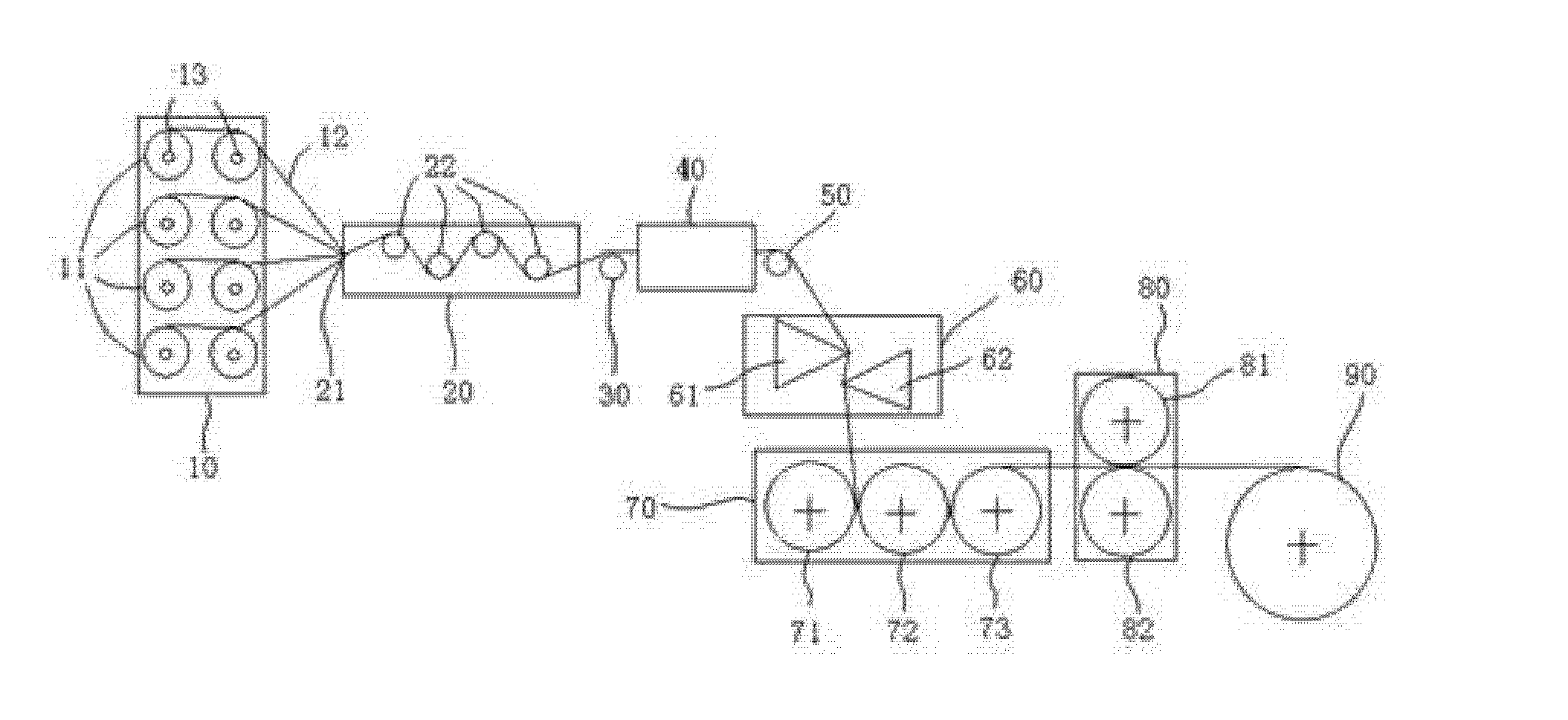

[0071] Such as figure 1 As shown, (1) the star-shaped polyamide matrix and additives are plasticized and melt-blended by an extruder to obtain a star-shaped polyamide matrix melt, and are extruded smoothly through a double extrusion die head for use;

[0072] (2) Install the continuous glass fiber roll 11 on the spindle 13 of the creel 10 to draw the continuous fiber bundles 12 arranged in parallel, carefully draw the continuous glass fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com