Preparation method and application of rare earth modified Keggin-type heteropolyacid supported catalyst

A supported catalyst and rare earth modification technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, and preparation of liquid hydrocarbon mixtures, can solve the problems of loss of activity, difficult recovery, and difficulty in separating catalysts from products, etc. Stability and activity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a rare earth modified Keggin type heteropolyacid supported catalyst, and its preparation method is as follows:

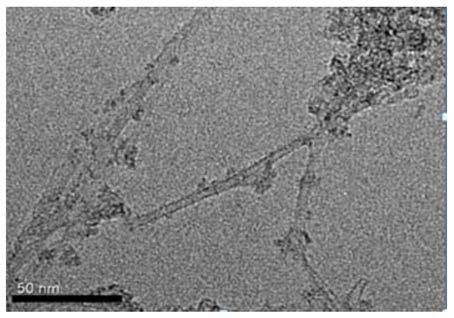

[0033] Add 0.1g single-walled carbon nanotubes and 10mL 0.1mol / L AlCl to the beaker 3 The solution was stirred evenly with a glass rod, and then 20 mL of 60 wt % ethanol was added, and ultrasonic wave was used for 4 minutes to uniformly disperse the single-walled carbon nanotubes in the solution. After ultrasonication, add 1 mL of 0.1 mol / L dilute hydrochloric acid solution dropwise to the solution. After 3 minutes of microwave action, wash repeatedly with deionized water until the pH of the system is neutral, filter, and put the obtained filter residue in an oven to dry at 120°C. 3min, obtain hydroxylated single-walled carbon nanotube powder;

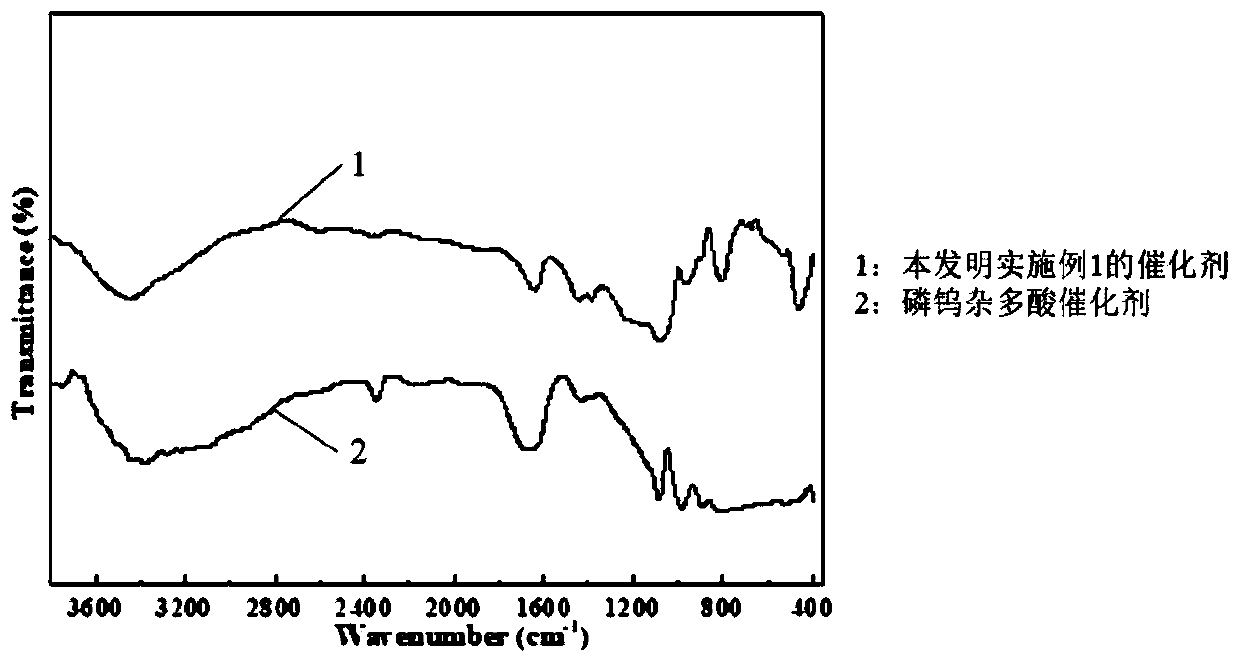

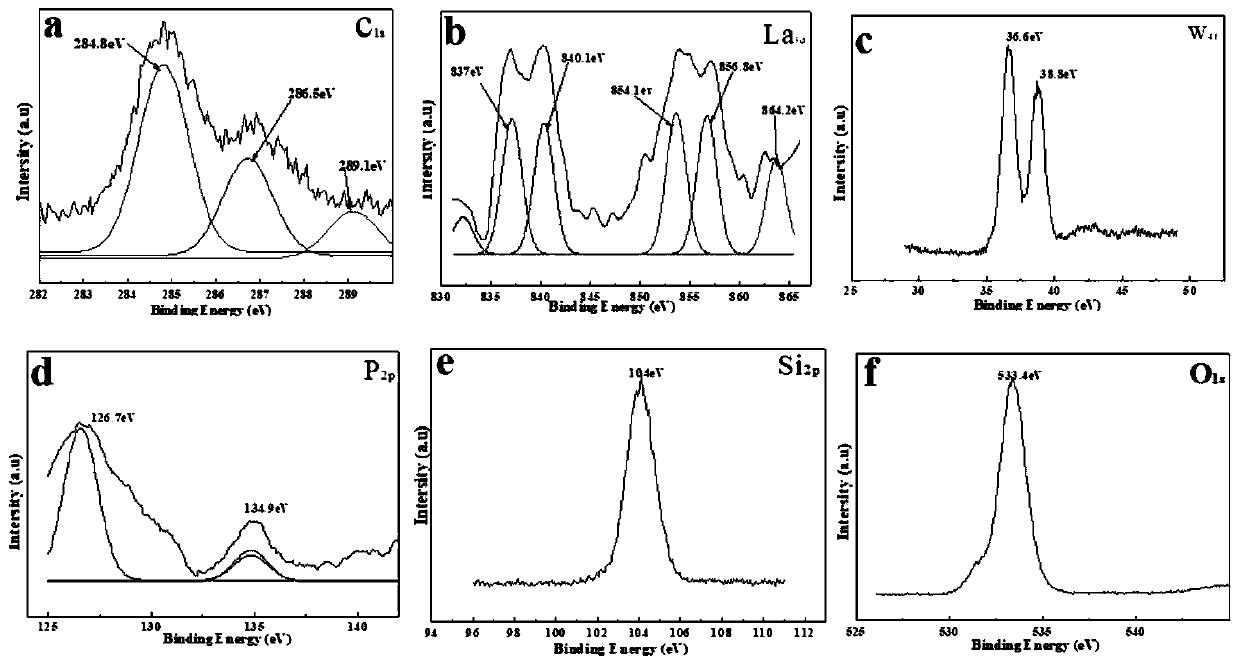

[0034] Add 4g of tetraethyl orthosilicate to 2mL of ethanol, stir evenly; then add 10mL of dilute nitric acid (C H + =1mol / L), 0.1g La(NO 3 ) 3 , 2g of phosphotungstic heteropolyacid and ...

Embodiment 2

[0037] This embodiment provides a rare earth modified Keggin type heteropolyacid supported catalyst, and its preparation method is as follows:

[0038] Add 0.2g multi-walled carbon nanotubes and 10mL 0.2mol / L MgCl to the beaker 2 The solution was stirred evenly with a glass rod, and then 20 mL of 70 wt % ethanol was added, and the multi-walled carbon nanotubes were uniformly dispersed in the solution by ultrasonication for 3 minutes. After the ultrasonic wave is finished, add 2 mL of 0.1 mol / L dilute hydrochloric acid solution dropwise to the solution. After 3 minutes of microwave action, wash repeatedly with deionized water until the pH of the system is neutral, filter, and put the obtained filter residue in an oven to dry at 120°C 3min, obtain hydroxylated multi-walled carbon nanotube powder;

[0039] Add 3g of ethyl orthosilicate to 1.5mL of ethanol, stir evenly; then add 8mL of dilute nitric acid (C H + =1mol / L), 0.125g La(NO 3 ) 3 , 2.5g of phosphotungstic heteropoly...

Embodiment 3

[0042] This embodiment provides a rare earth modified Keggin type heteropolyacid supported catalyst, and its preparation method is as follows:

[0043] Add 0.1g single-walled carbon nanotubes and 10mL 0.2mol / L MgCl to the beaker 2 The solution was stirred evenly with a glass rod, and then 20 mL of 70 wt % ethanol was added, and the single-walled carbon nanotubes were uniformly dispersed in the solution by ultrasonication for 3 minutes. After the ultrasonication is over, add 2 mL of 0.1 mol / L dilute nitric acid solution dropwise to the solution. After microwave action for 3 minutes, wash repeatedly with deionized water until the pH of the system is neutral, filter, and put the resulting filter residue in an oven to dry at 110°C. 3min, obtain hydroxylated single-walled carbon nanotube powder;

[0044] Add 3g of ethyl orthosilicate to 2mL of ethanol, stir evenly; then add 10mL of dilute nitric acid (C H + =1mol / L), 0.2g La(NO 3 ) 3 , 2.5g of phosphotungstic heteropolyacid an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com