Tin dioxide doped flexible graphite bipolar plate and preparation method and application thereof

A technology of flexible graphite and tin dioxide, which is applied in the direction of electrochemical generators, fuel cells, collectors/separators, etc., can solve the problems of unsatisfactory electrical conductivity and achieve improved output performance and working life, high electrical conductivity, The effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

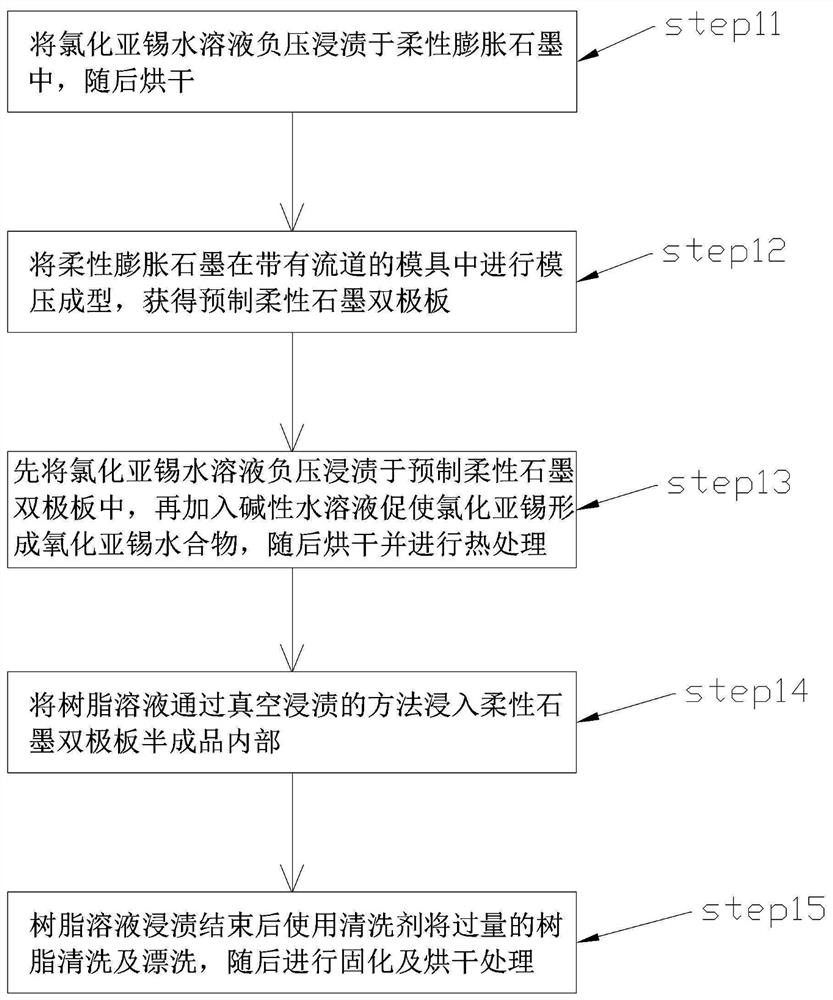

[0045] A tin dioxide-doped flexible graphite bipolar plate is prepared through the following steps.

[0046] 1) Immerse 0.10mol / L stannous chloride aqueous solution in negative pressure with a density of 0.05g / cm 3 Expanded graphite, followed by drying.

[0047] 2) The flexible expanded graphite was molded in a mold with a flow channel using a pressure of 15MPa to obtain an average density of 0.10g / cm 3 , Prefabricated flexible graphite bipolar plates with a thickness of 6mm.

[0048] 3) Immerse the 0.10mol / L stannous chloride aqueous solution in the prefabricated flexible graphite bipolar plate under negative pressure, then add 0.24mol / L sodium hydroxide aqueous solution to promote the formation of stannous oxide hydrate from the tin source, then dry and place in the A heat treatment process is performed at 500° C. to obtain a semi-finished flexible graphite bipolar plate with tin dioxide formed inside.

[0049] 4) Immerse the methanol solution of epoxy resin with a solid ...

Embodiment 2

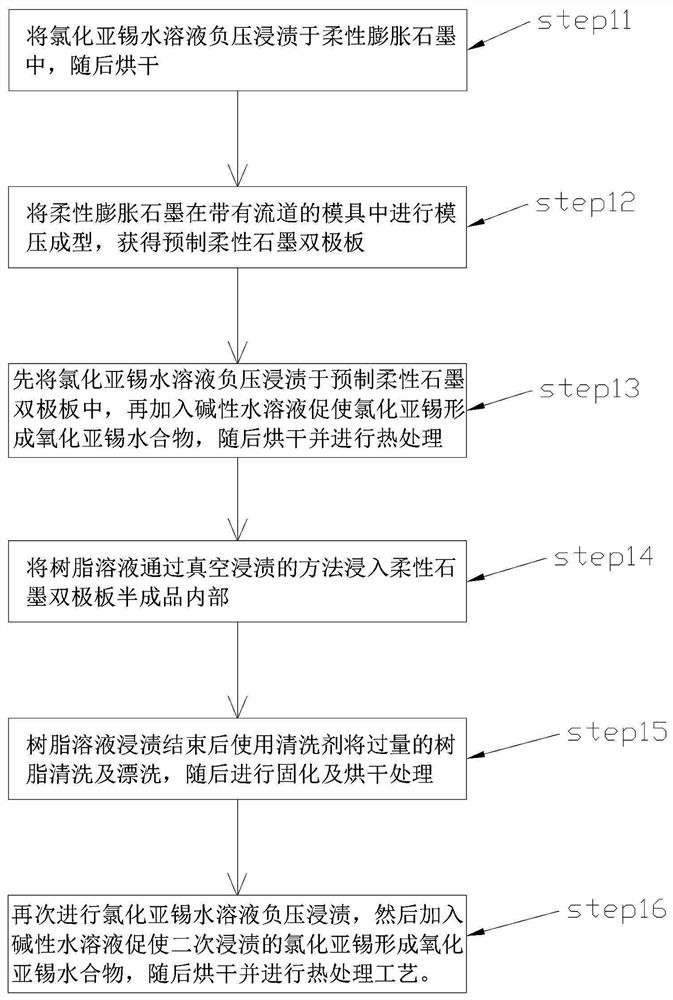

[0053] A tin dioxide-doped flexible graphite bipolar plate is prepared through the following steps.

[0054] 1) Immerse 0.04mol / L stannous chloride aqueous solution in negative pressure with a density of 0.11g / cm 3 Expanded graphite, followed by drying.

[0055] 1) The flexible expanded graphite was molded in a mold with a runner using a pressure of 24MPa to obtain an average density of 0.18g / cm 3 , Prefabricated flexible graphite bipolar plates with a thickness of 5mm.

[0056] 2) Immerse the 0.04mol / L stannous chloride aqueous solution in the prefabricated flexible graphite bipolar plate under negative pressure, then add 0.06mol / L sodium hydroxide aqueous solution to promote the formation of stannous oxide hydrate from the tin source, then dry and place in the Heat treatment process at 600°C.

[0057] 3) Immerse an ethanol solution with a solid content of 8% polyacrylic resin into the semi-finished flexible graphite bipolar plate by vacuum impregnation.

[0058] 4) After...

Embodiment 3

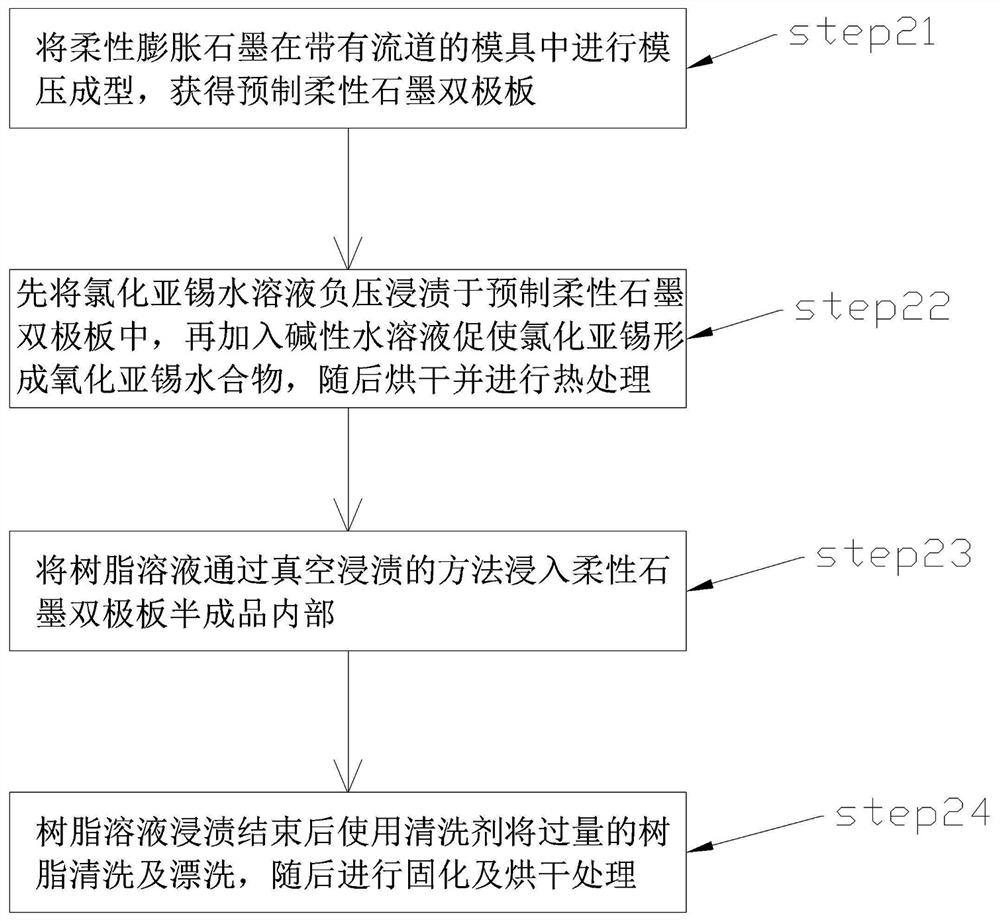

[0062] A tin dioxide-doped flexible graphite bipolar plate is prepared through the following steps.

[0063] 1) Immerse 0.16mol / L stannous chloride aqueous solution in negative pressure with a density of 0.15g / cm 3 Expanded graphite, followed by drying.

[0064] 2) The flexible expanded graphite was molded in a mold with a flow channel using a pressure of 40MPa to obtain an average density of 0.25g / cm 3 , Prefabricated flexible graphite bipolar plates with a thickness of 4mm.

[0065] 3) Immerse 0.16 mol / L stannous chloride aqueous solution in the prefabricated flexible graphite bipolar plate under negative pressure, then add 0.30 mol / L sodium hydroxide aqueous solution to promote the formation of tin oxide hydrate from the tin source, then dry and place in Heat treatment process at 400°C.

[0066] 4) Immerse a phenolic resin solution with a solvent of 50% methanol, 30% ethanol, 10% isopropanol, 10% glycerol, and a solid content of 6% into the semi-finished flexible graphit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com