Method of producing aluminum composite material

a composite material and aluminum alloy technology, applied in the direction of manufacturing tools, foundry patterns, foundry moulding apparatus, etc., can solve the problems of oxidation-loss of activated charcoal and graphite, the application of aluminum alloy is limited to a sliding portion of the structure, and the inability to prevent the oxidation of charcoal and graphi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

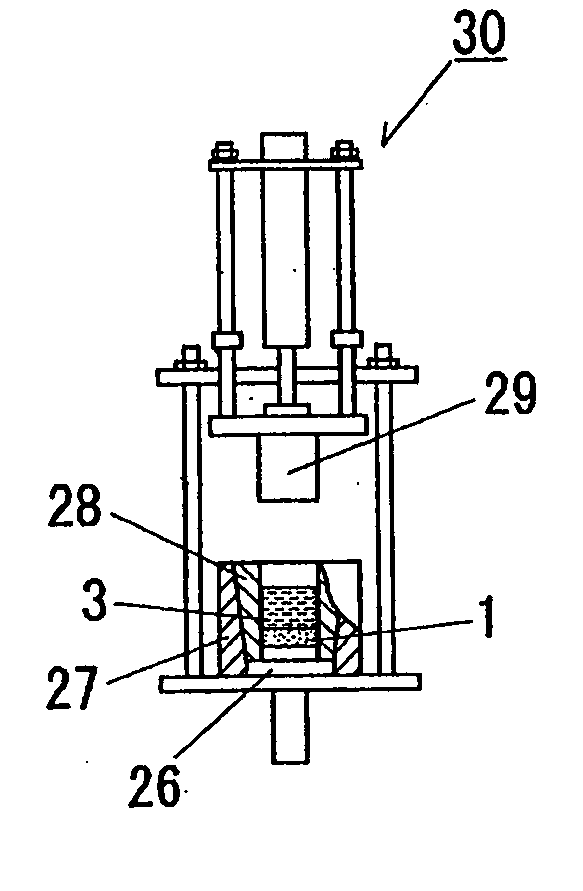

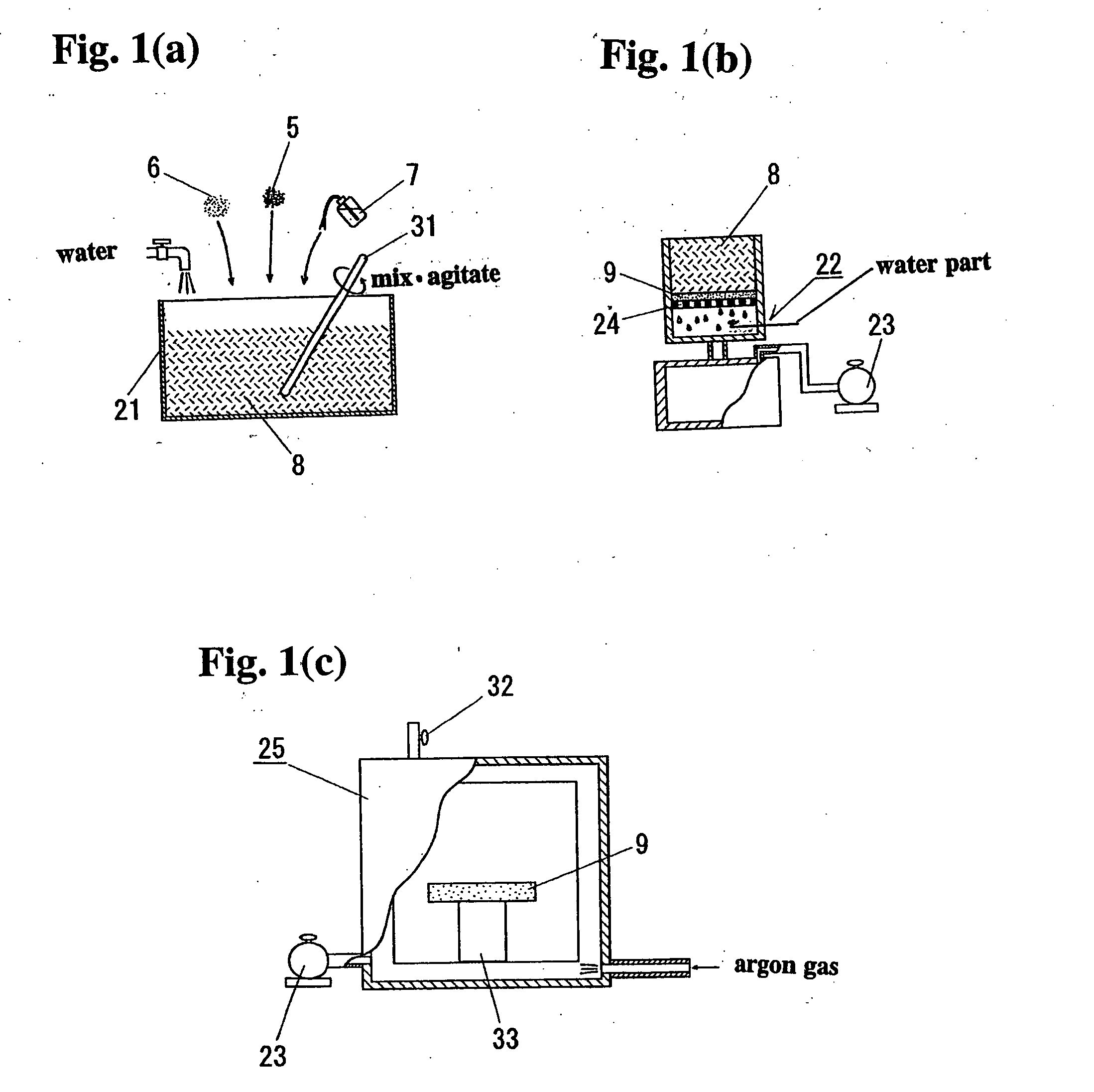

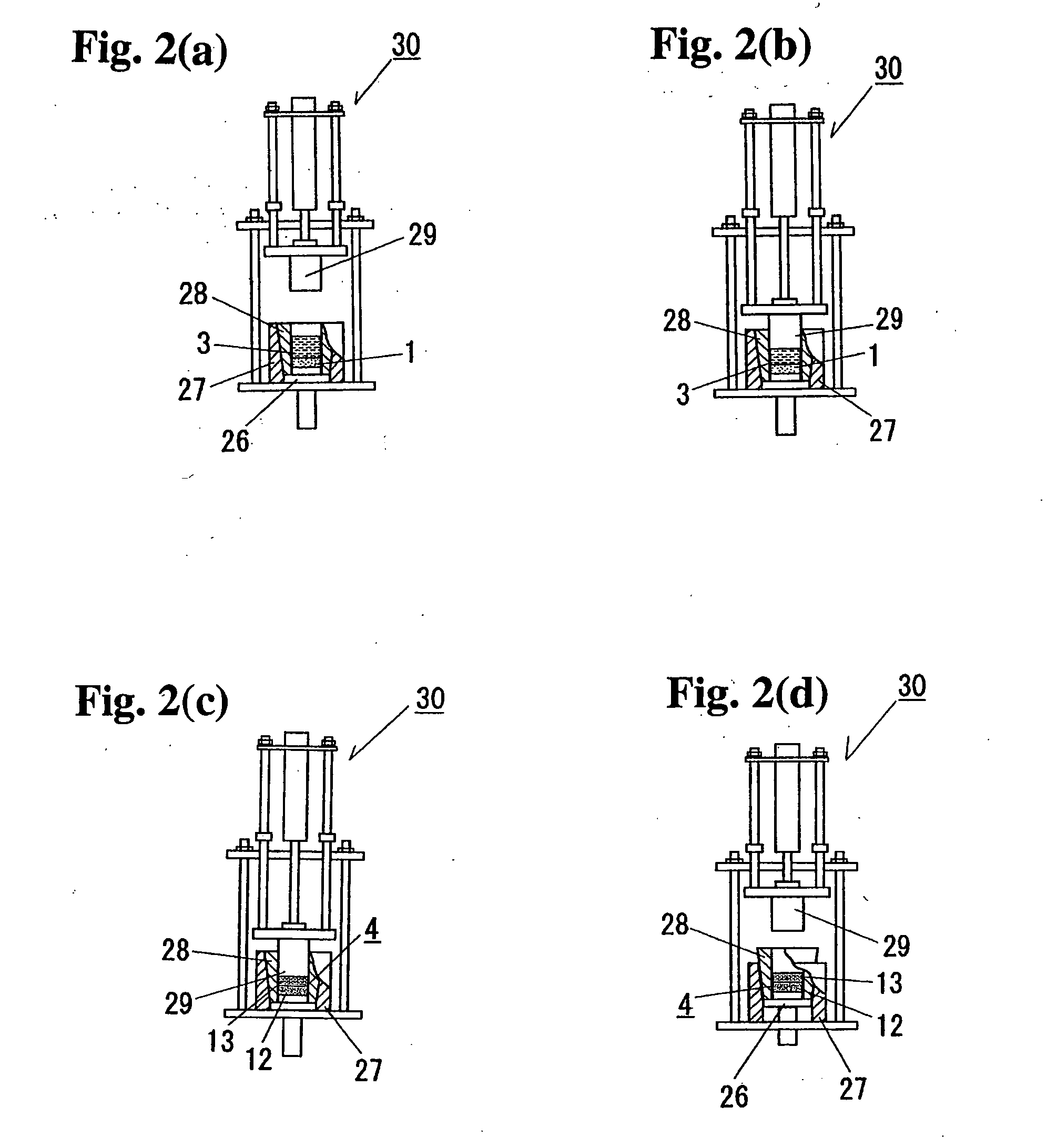

[0026] Referring to FIG. 1(a), alumina fiber 5 and powder of graphite 6 were mixed by stirring with stirring rod 31 in water in designated vessel 21. Alumina sol as an inorganic binder was added to water in which alumina fiber 5 and graphite 6 were being mixed. Alumina fiber 5 used had approximately 3 μm of average diameter, 50 cc / 5 gf of an average length, chemical composition composed of approximately 95% of Al2O3 and approximately 5% of SiO2, and graphite 6 used had approximately 20 μm of average diameter and chemical composition composed of 97% of C and approximately 3% of Al2O3 and SiO2. Alumina sol 7 used was approximately 11% of Al2O3.

[0027] Aqueous solution 8 in which alumina fiber 5, powder of graphite 6 and alumina sol 7 being mixed was transferred to suction-forming device 22 from vessel 21. Suction-forming device 22 was connected to vacuum pump 23 and referring to FIG. 1(b), suctions water of aqueous solution 8 by vacuum pump 23 through filter 24. Accordingly, dehydrate...

embodiment 2

[0031] According to embodiment 2, a manufacturing method relates to sintering in hydrogen gas as a reducing gas in the preform forming process. After dehydrated-formed base material 9 which was formed according to embodiment 1 was well dried, it was put into heating oven 25 in which the inside was at 1×10−3 Torr under vacuum. Then nitrogen gas was introduced to substitute and after substitution, heating the inside of the oven was started. When the temperature reached to 400° C., approximately 100 cc / min of hydrogen gas was introduced and the inside temperature of the oven was held for 2 hours at approximately 1000° C. Hydrogen gas over flown from leak valve 32 was burnt using a pilot burner to prevent filling and explosion in the inside. Then the oven was cooled down to room temperature to form preform 1. Further during cooling down flow of hydrogen gas was stopped at approximately 400° C. and instead, nitrogen gas was flown. According to aluminum impregnating process as described i...

embodiment 3

[0032] According to embodiment 3, a manufacturing method relates to sintering under vacuum in the preform forming process. Dehydrated-formed base material 9 which was formed according to embodiment 1 was put into heating oven 25 in which the inside was at 1×10−4 Torr under vacuum. Vacuum condition of the inside of the oven was held and the oven was heated up to approximately 1000° C., and the temperature of approximately 1000° C. was held for 2 hours and the oven was cooled down to room temperature to form preform 1. According to aluminum impregnating process as described in embodiment 1, hot solution 3 of aluminum alloy 2 was impregnated to preform 1 and aluminum composite material 4e composed of aluminum composite layer 12e and aluminum alloy layer 13 was obtained. Volumetric percentage (%) of graphite 6 was 15% of aluminum composite layer 12d of aluminum composite material 4d, volumetric percentage (%) of alumina fiber 5 was 6.5% and the rest was for aluminum alloy 2. According t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameters | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com