Arsenic removal agent, and preparation method and use thereof

A technology for removing arsenic and carrier, which is applied in refining with metal oxides, treating hydrocarbon oil, petroleum industry, etc. It can solve the problems of unfavorable selective arsenic removal reaction, low MoO3 content, high reaction temperature, etc., and achieve good arsenic removal effect, The effect of stable arsenic removal effect and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

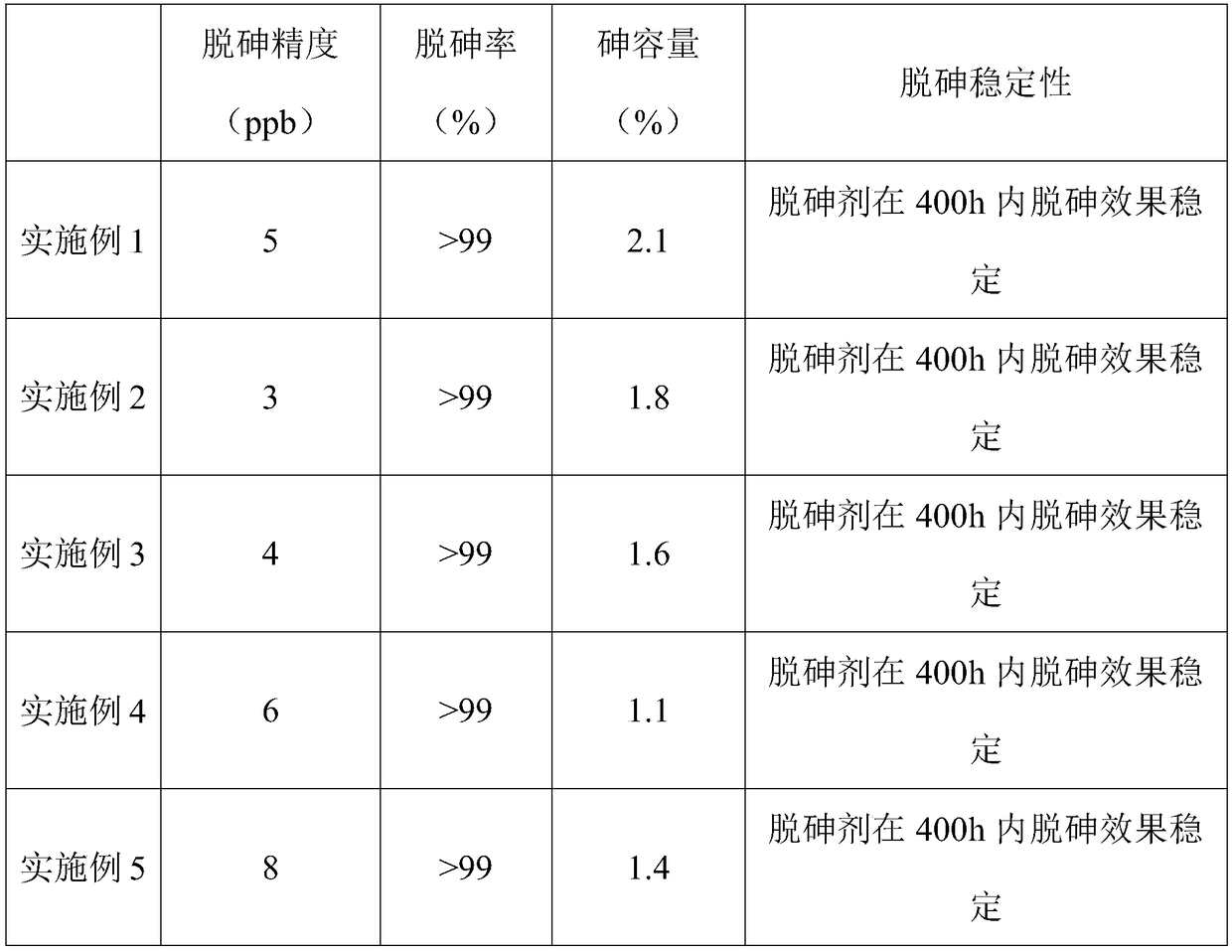

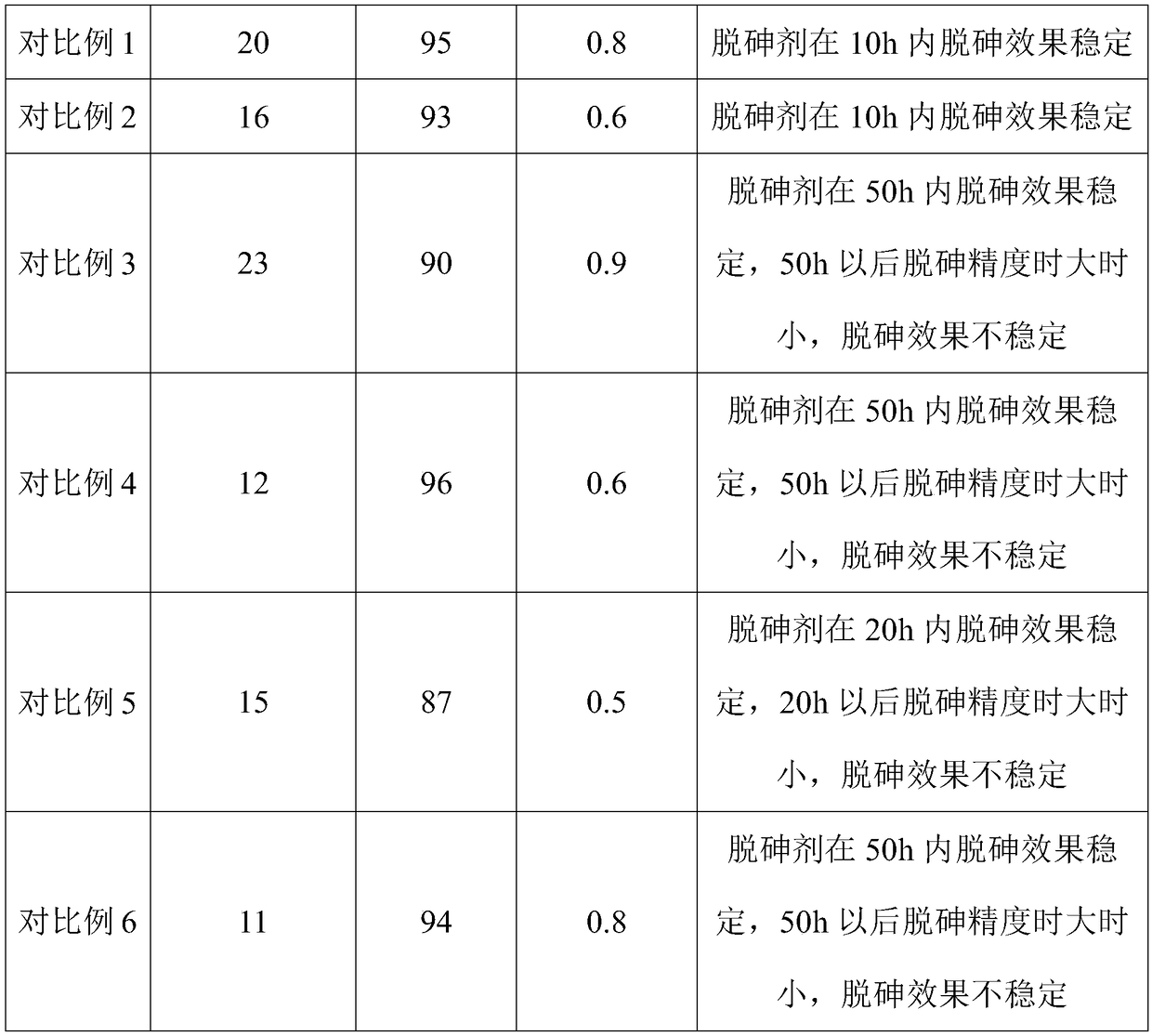

Examples

Embodiment 1

[0046] The arsenic removal agent of this embodiment includes a carrier and an active component loaded on the carrier, the carrier is a mixture of activated carbon and alumina, the mass ratio of activated carbon to alumina is 3:1, and the specific surface area of alumina is 100m 2 / g, the active component is the active component of the Ni-Cu-Mo-Co system, wherein, taking the mass of the carrier as 100%, the mass percentage of Ni is 10%, the mass percentage of Cu is 5%, and the mass percentage of Mo is 5%, and the mass percentage of Co is 2%.

[0047] The preparation method of the arsenic removal agent of the present embodiment comprises the following steps:

[0048] 1) At 40°C, use a strong oxidizing acid solution to impregnate the carrier for 1 hour, immerse the acid-treated carrier in an aqueous solution of soluble nickel salt, filter the filtrate, dry at 100°C for 3 hours, and roast at 600°C 1.5h, obtain the carrier that is loaded with Ni;

[0049] 2) immersing the Ni-lo...

Embodiment 2

[0053] The arsenic removal agent of this embodiment includes a carrier and an active component loaded on the carrier, the carrier is a mixture of activated carbon and alumina, the mass ratio of activated carbon to alumina is 1:1, and the specific surface area of alumina is 200m 2 / g, the active component is the active component of the Ni-Cu-Mo-Co system, wherein, taking the mass of the carrier as 100%, the mass percentage of Ni is 15%, the mass percentage of Cu is 8%, and the mass percentage of Mo is 3%, and the mass percentage of Co is 3%.

[0054] The preparation method of the arsenic removal agent of the present embodiment comprises the following steps:

[0055] 1) At 40°C, impregnate the carrier with a strong oxidizing acid solution for 1 hour, immerse the acid-treated carrier in an aqueous solution of soluble nickel salt, filter off the filtrate, dry at 100°C for 5 hours, and roast at 400°C 5h, obtain the carrier that is loaded with Ni;

[0056] 2) immersing the Ni-lo...

Embodiment 3

[0060] The arsenic removal agent of this embodiment includes a carrier and an active component loaded on the carrier, the carrier is a mixture of activated carbon and alumina, the mass ratio of activated carbon to alumina is 5:1, and the specific surface area of alumina is 400m 2 / g, the active component is the Ni-Cu-Mo-Co system active component, wherein, based on the mass of the carrier as 100%, the mass percentage of Ni is 20%, the mass percentage of Cu is 6%, and the mass percentage of Mo is 2%, and the mass percentage of Co is 2%.

[0061] The preparation method of the arsenic removal agent of the present embodiment comprises the following steps:

[0062] 1) At 20°C, impregnate the carrier with a strong oxidizing acid solution for 2 hours, immerse the acid-treated carrier in an aqueous solution of soluble nickel salt, filter the filtrate, dry at 120°C for 3 hours, and roast at 400°C 4h, obtain the carrier that is loaded with Ni;

[0063] 2) immersing the Ni-loaded car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com