Production method of dearsenic agent

A production method and technology for removing arsenic, applied in the direction of chemical change purification/separation, etc., can solve the problems of increased one-time filling cost of products, high manufacturing cost, reduced arsenic removal effect, etc., and achieve good arsenic removal effect and production cost. Low, wide-ranging and targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

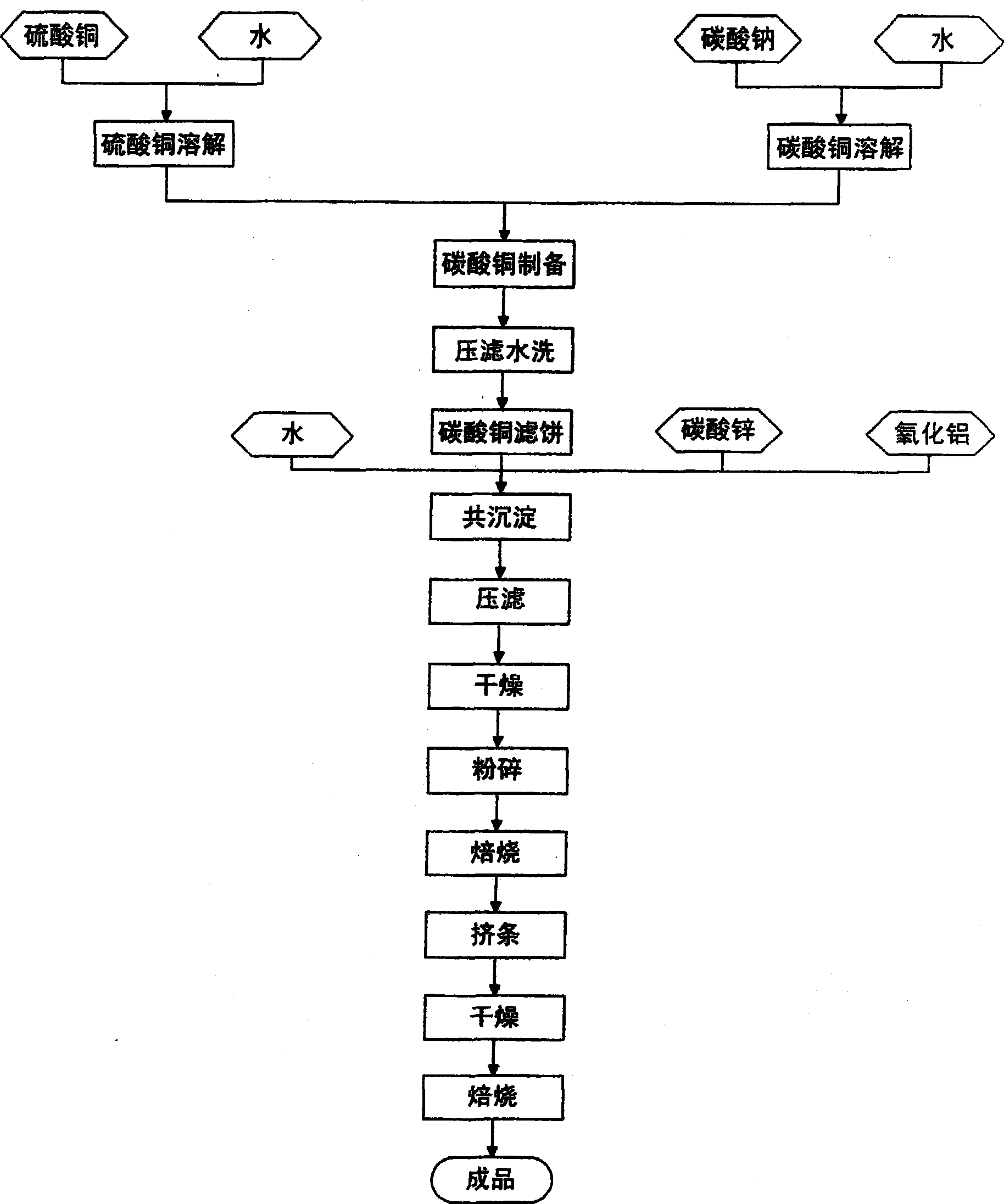

[0047] A production method of arsenic removal agent, comprising the following process steps:

[0048] 1. Preparation of copper carbonate

[0049] (1) Put 200kg of sodium carbonate in a tank or reactor, then put in 1800L of water, heat to 50-60°C, dissolve and stir for 30-40 minutes, and make a sodium carbonate solution for later use. The concentration of the sodium carbonate solution is 10%.

[0050] (2) Put 600kg of copper sulfate in a tank or reaction kettle, add 3600L of water, heat to 30-40°C, stir for 30-40 minutes, and prepare a 15% copper sulfate solution for later use.

[0051] (3) Put the above-mentioned prepared sodium carbonate solution in a tank or a reaction kettle, then add the above-mentioned prepared copper sulfate solution into the sodium carbonate solution at a flow rate of 3000L / nr, the synthesis temperature is 50-60°C, and the pH value is 8.0-9.0, after aging for 1 hour, press filter, separate the copper carbonate from the solution, and wash with water at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com