Patents

Literature

89results about How to "Good arsenic removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

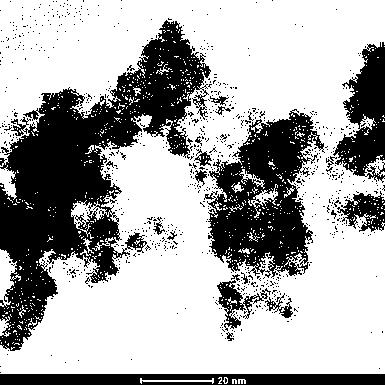

Preparation of iron-managanese compounded oxide/diatomite adsorbant, its using and regenerating method

ActiveCN101024160AImprove adsorption capacityGood arsenic removal effectOther chemical processesWater/sewage treatment by sorptionSorbentManganese oxide

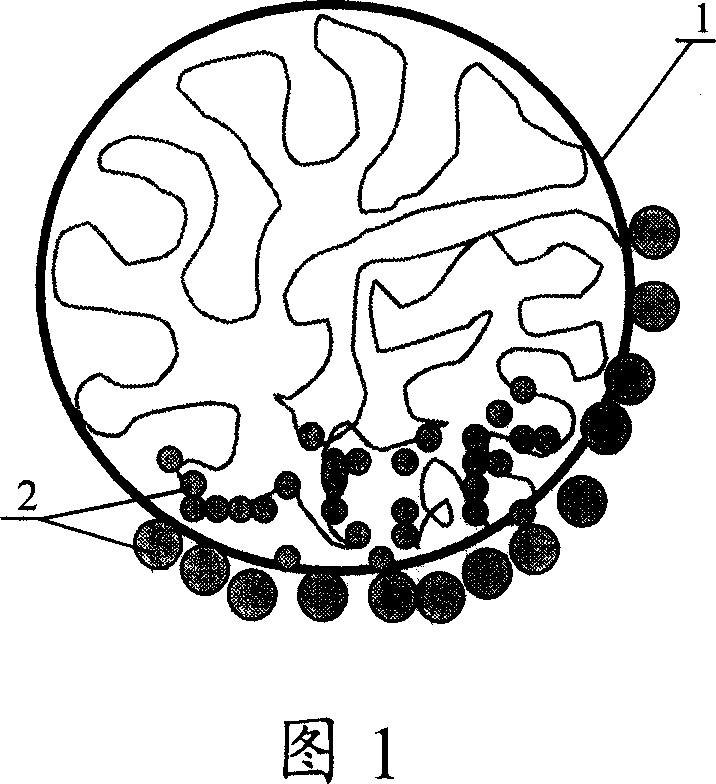

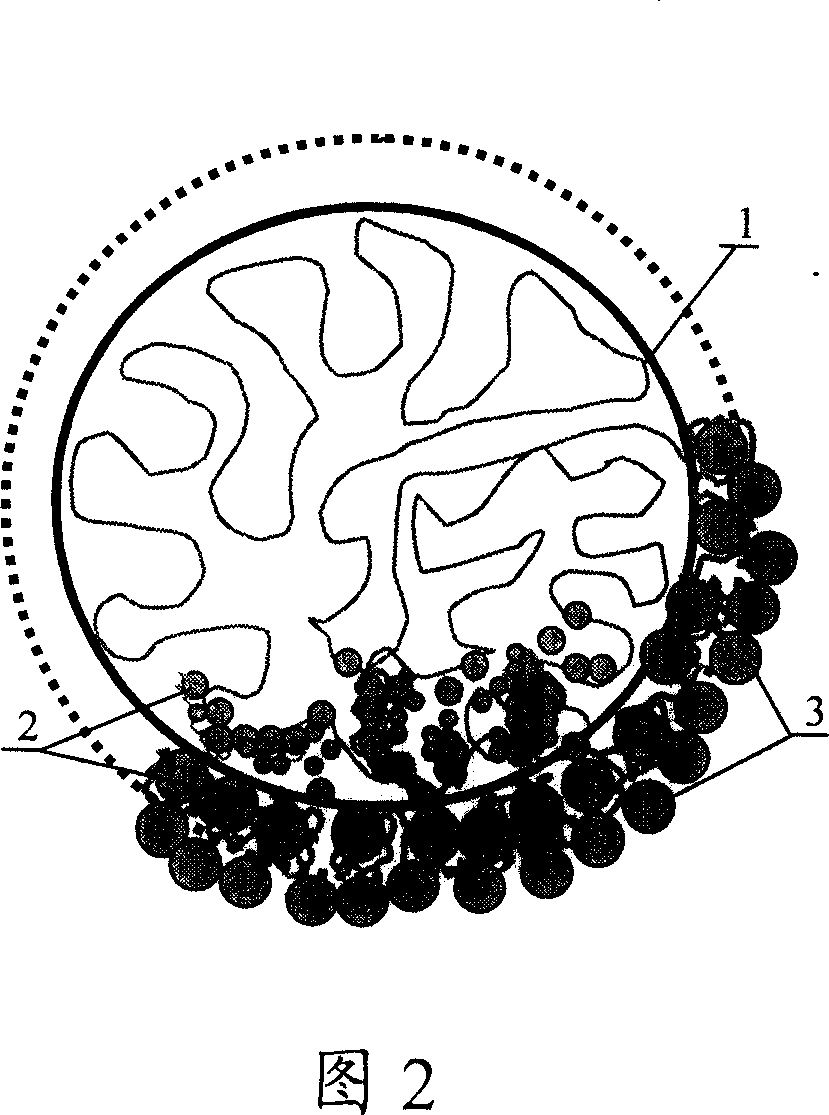

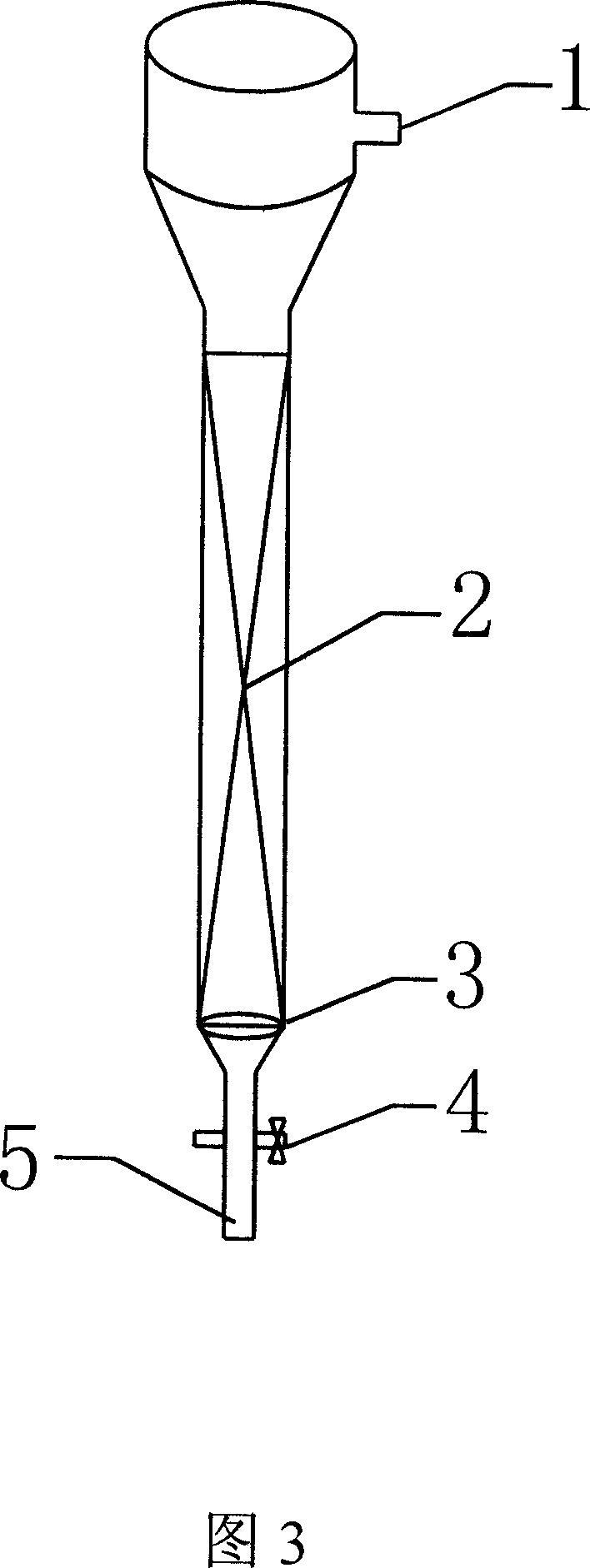

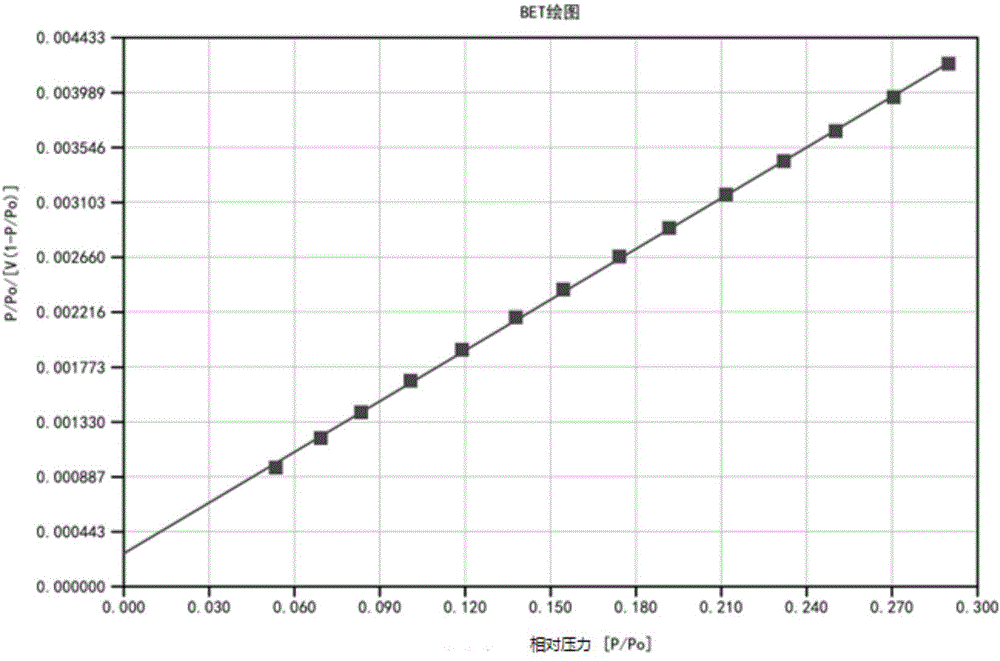

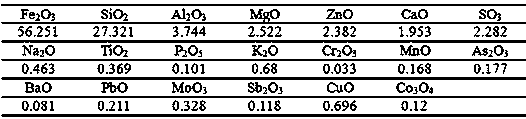

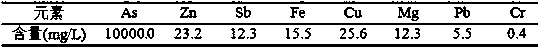

The invention supplies a new type adsorbent--mixed oxide of iron and manganese / diatomite preparation, use and regeneration method, belongs to the treatment of technology. The method used the soluble ferrous permanganate and salt as raw materials, respectively prepared the solutions, after adequate lye into permanganate solution, mixed two salt solutions, by adding diatomite particles, full oscillation, standing aging, neutralize, washing and drying to get the manganese oxide / silicon algae absorbent. The adsorbent is larger than the surface area and good adsorption properties can be used to remove arsenic in water pollutants (especially tervalence arsenic), and the adsorption surface activity of the saturated absorption of pollutants can be directly passed to load manganese oxide compound to regeneration.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Multicomponent composite flocculating setting agent and use in arsenic contamination water treatment

ActiveCN101503239AEfficient removalGood arsenic removal effectWater/sewage treatment by flocculation/precipitationArsenic pollutionEarth surface

The invention belongs to the technical field of river water body pollution control and in particular relates to a multiple-element compound flocculating settling agent and the application of the multiple-element compounded flocculating settling agent in arsenic pollution water body treatment. The multiple-element compounded flocculating settling agent is prepared by compounding malysite, aluminium salt, hypermanganate, polyacrylamide and aqueous solution. The multiple-element compounded flocculating settling agent can be applied in the arsenic pollution water body treatment to remove arsenic in the arsenic pollutant water body. The concentration of the arsenic in the treated water can meet or is superior to the specified requirement of three types of water on the arsenic concentration in the national earth surface water environment quality standard (less than 0.05 mg / L). The invention also can be used for removing heavy metals such as copper, chromium, cadmium, lead and the like in water by sedimentation. The multiple-element compounded flocculating settling agent can be used together with a multiple-element compounded metal oxide arsenic removal setting agent in static or flowing arsenic pollution water body treatment for removing the arsenic in the water body polluted by arsenic.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Liquid state petroleum hydrocarbon normal temperature dearsenicating agent and preparation method thereof

InactiveCN1923966AHigh arsenic capacityImprove water resistanceHydrocarbon oils refiningSulfideSilicon dioxide

The invention discloses a normal temperature arsenic-removing agent of liquid-oil hydrocarbon and preparing method, which consists of 50-99% middle-hole molecular sieve with arsenic-removing component and 1-50% structural moulding auxiliary material, wherein the molecular sieve is silica middle-hole molecular sieve or silicon-aluminium middle-hole molecular sieve with even aperture at 2-50nm and specific area at 100-1000m2 / g, which is selected from one or more composition of nitrate or chloride or sulfate or sulfide or oxalic compound with Cu, Fe, Mn, Ni and Si; the former of active component contains 0.01-20% metal in the arsenic-removing agent.

Owner:SHANGHAI RES INST OF CHEM IND

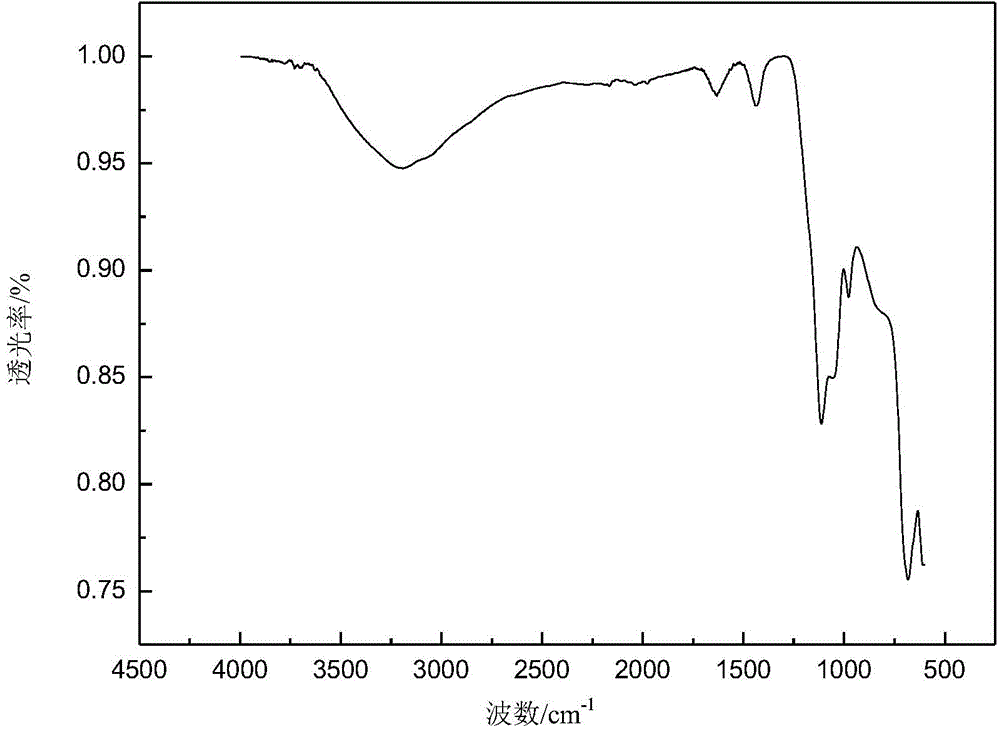

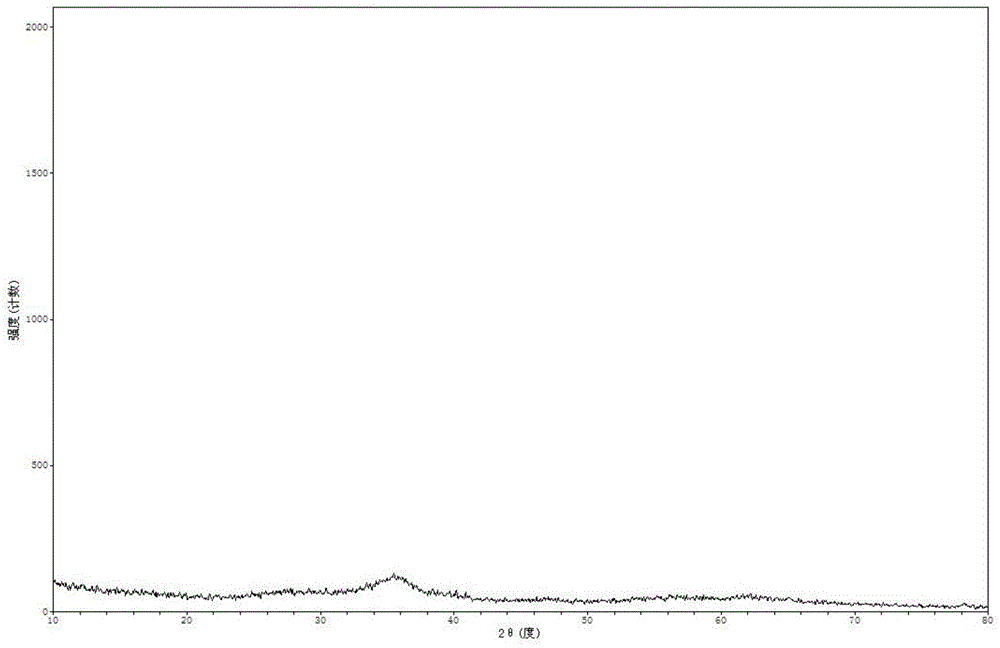

Preparation method for amorphous FeOOH water-purifying agent

InactiveCN105800762AHigh arsenic removal efficiencyEfficient removalWater/sewage treatmentAluminum IonHydrolysis

The invention provides a preparation method for an amorphous FeOOH water-purifying agent. The preparation method comprises the following steps: preparing a ferrous sulfate solution from industrial ferrous sulfate heptahydrate; adding a proper amount of sulfuric acid into the ferrous sulfate solution so as to provide an acidic environment; adding hydrogen peroxide into the solution and allowing ferrous sulfate to be oxidized into ferric sulfate under the condition of hydrolysis promotion by sulfuric acid; subjecting an industrial alkali source and the ferric sulfate solution to a precipitation reaction so as to produce iron hydroxide colloid; and dehydrating the iron hydroxide colloid under proper conditions so as to prepare the amorphous FeOOH water-purifying agent. The amorphous FeOOH water-purifying agent can effectively arsenic in water, has arsenic removal efficiency of 98% or above, does not contain aluminum ions or pose secondary pollution to a water body; after arsenic removal with the water-purifying agent, scorodite stably existing in the nature is produced, so pollution is not posed to the environment; moreover, raw materials used in the invention are of an industrial grade, and the preparation method is low in production cost and simple to operate.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

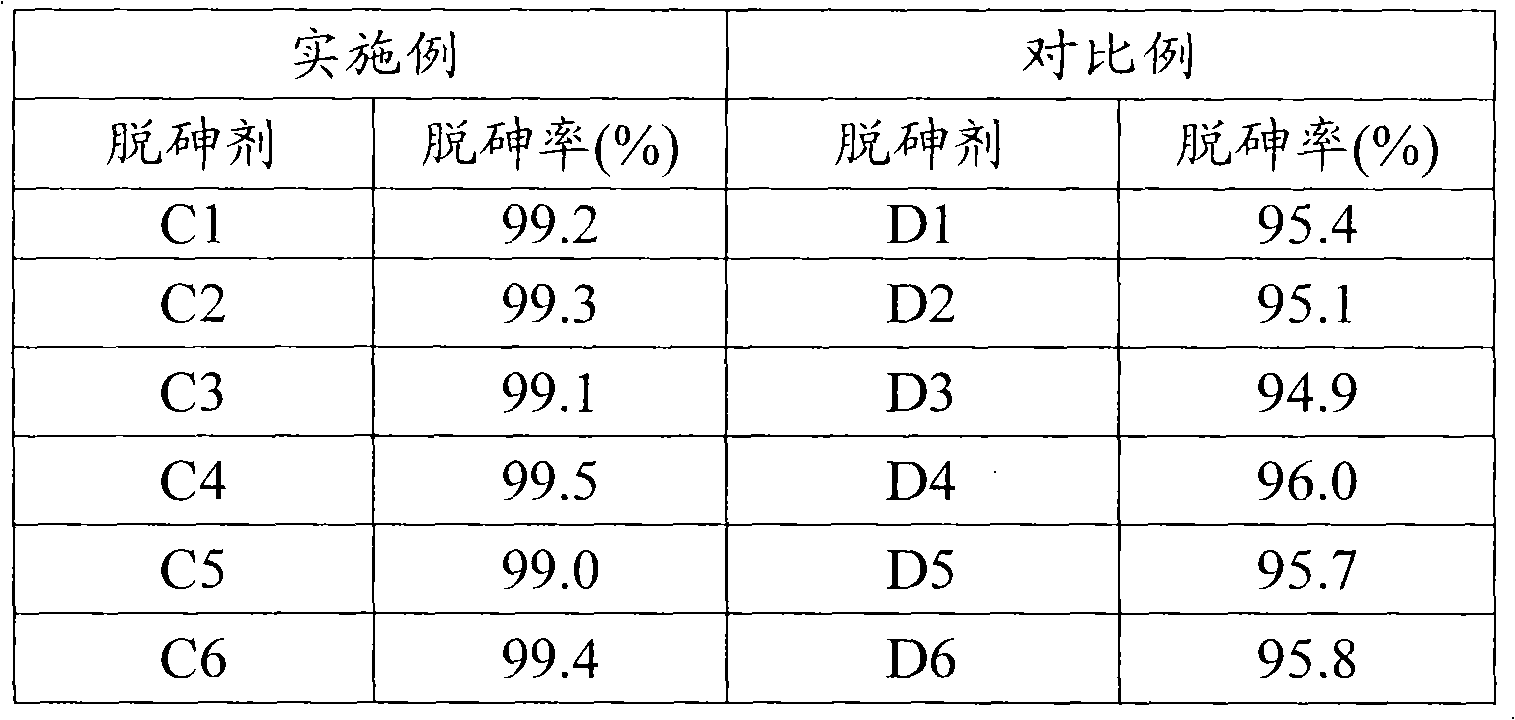

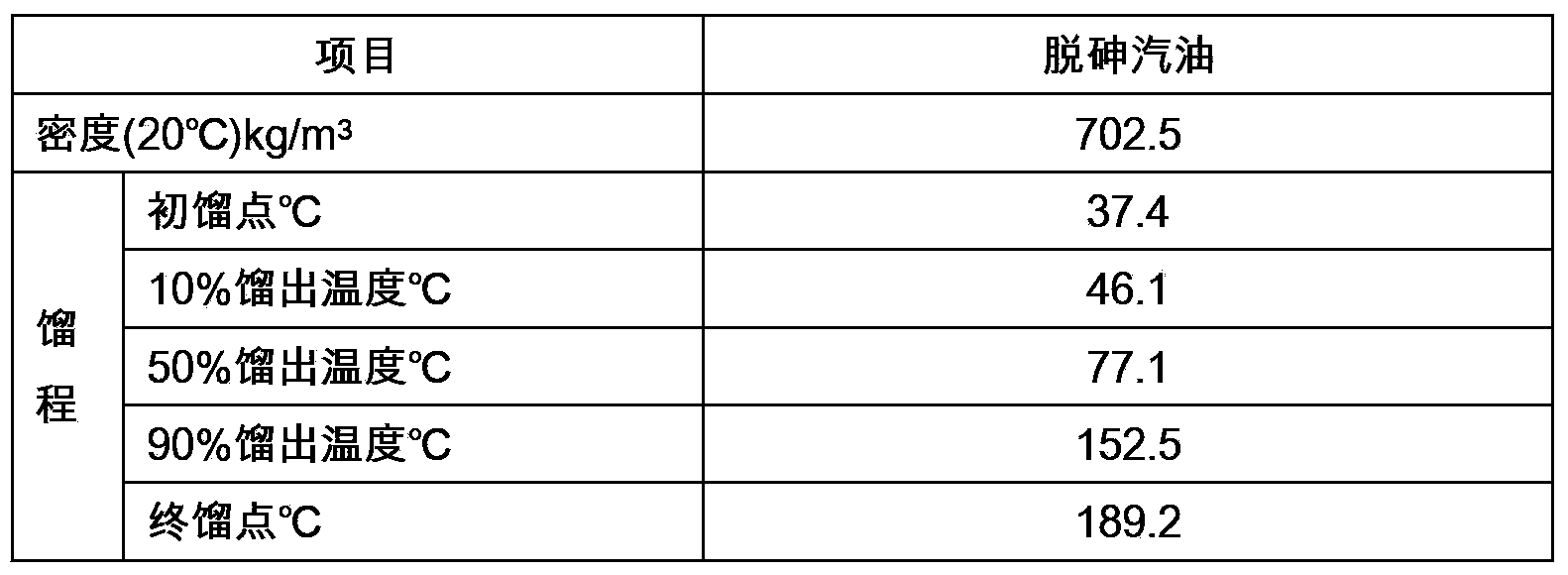

Preparation method of supported dearsenic agent and dearsenic agent prepared by same

InactiveCN101590418AGood arsenic removal effectGood effectPhysical/chemical process catalystsHydrocarbon oils refiningAqueous solutionZinc salts

The invention relates to a preparation method of supported dearsenic agent, comprising the following steps: a)) preparing water solution with soluble cupric salt and / or soluble zinc salt; b)) loading the soluble cupric salt and / or soluble zinc salt on a carrier to obtain the carrier loading active metal; c)) drying the carrier loading active metal at 50-200 DEG C for 3-20h to obtain the finished dearsenic agent. The dearsenic agent prepared by the method of the invention is composed of active constituent and carrier, the active constituent comprises soluble cupric salt and / or soluble zinc salt, and the content of the active constituent in the dearsenic agent is more than 7wt% and less than 13wt%. The dearsenic agent of the invention has the advantages of high dearsenic rate, low energy consumption and suitability for large-scale industrialized production.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Liquid-state petroleum hydrocarbon dearsenicing agent with dual medium-hole structure distribution and preparing method thereof

InactiveCN1978594AHigh arsenic capacityImprove water resistanceRefining with metal saltsLiquid stateSmall eye

The invention provides the de-arsenic agent for the liquid petroleum hydrocarbon with the double mesopore structure. The de-arsenic agent includes: 50-99% of the double mesopore molecular screen with the de-arsenic activity and the 1-50% of molding assistant material. The molecular screen is the SiO2 or Silal double mesopore molecular screen which has the average small eye of 2-20nm diameter and average big eye of 6-50nm diameter. The big eye volume is not less than the 10% of the whole eye volume which is 1.0-1.9 cu m / g, the specific area is 300-1200 sq m / g. the de-arsenic activity component is one or more of the Cu, Fe, Mn, Ni and the Ag which is 0.01-20% of the metal content. So the de-arsenic agent has the high arsenic content, good water resistance and good de-arsenic character.

Owner:SHANGHAI RES INST OF CHEM IND

Load-type dearsenic agent and preparation method

ActiveCN103394324AImprove adsorption capacityEvenly dispersedOther chemical processesActivated carbonComponent Load

The invention relates to a load-type dearsenic agent. The load-type dearsenic agent is composed of carriers and active components. The carriers are activated carbon carriers. The active components are metal oxides. When the load-type dearsenic agent is prepared, first, the activated carbon carriers are pretreated, the activated carbon carriers are subjected to surface treatment only by strong oxidizing acid liquids and then calcined in inert gases, the structural characteristics of the activated carbon carriers can be optimized, the pore volume and the specific surface area of the activated carbon carriers are increased, and the dispersion of the pore channels and the pore diameters is uniform and ordered; second, in the production method, the semi-finished product of the load-type dearsenic agent is prepared first, and then subjected to alkali treatment, and so the active metal salt components loaded on the activated carbon carriers can be decomposed into active metal oxide components at a low temperature.

Owner:SHENYANG SANJUKAITE CATALYST

Lead-based de-arsenic catalyst

InactiveCN101590409AWide range of applicationsGood arsenic removal effectHydrocarbon oils refiningMetal/metal-oxides/metal-hydroxide catalystsGaseous hydrocarbonLiquid hydrocarbons

The invention provides a lead-based de-arsenic catalyst, comprising a carrier and an active constitute. The invention is characterized in that the carrier is Al2O3, the mass percentage content is 50-80%, the pore volume is 0.4-0.6mL / g; the active constitute is one or more transition metal oxides and PbO, the mass content of PbO is 10-30%, the mass content of one or more transition metal oxides is 10-20%. The lead-based de-arsenic catalyst in the invention has the advantages that the application range is wide, the invention can be applied to the dearsenization of liquid hydrocarbon and gaseous hydrocarbon; the dearsenization effect is good, the dearsenization rate can be as high as 99.9%; when the hydrocarbon feedstock contains certain amount of sulphide, the dearsenization effect of the lead-based de-arsenic catalyst in the invention cannot be affected and the dearsenization rate is still high.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

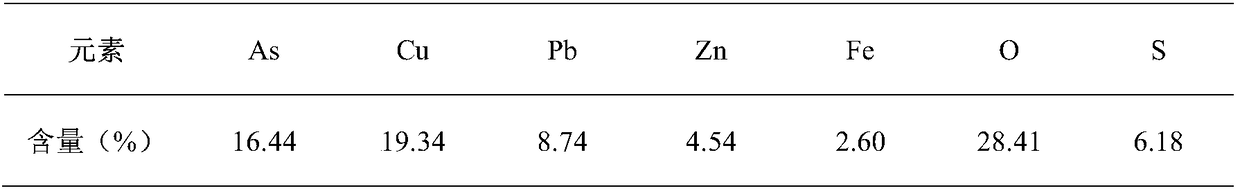

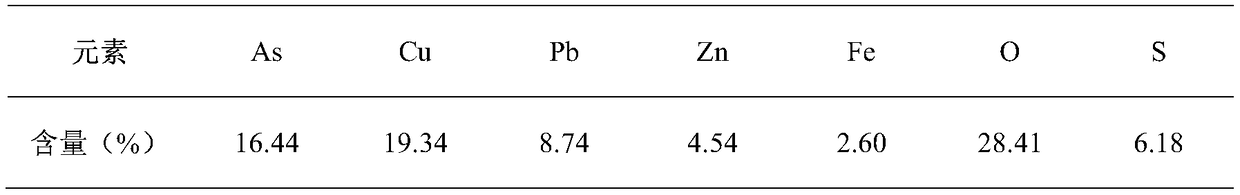

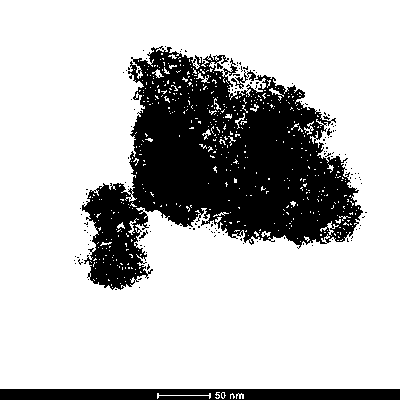

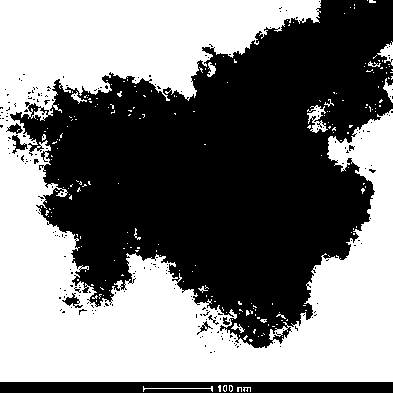

Copper smelting smoke dust arsenic removal method

ActiveCN109321755AImprove escape rateEfficient enrichmentProcess efficiency improvementIron sulfideCopper

The invention discloses a copper smelting smoke dust arsenic removal method. According to the method, copper smelting arsenious smoke dust and a material containing iron sulfide are mixed and then roasted in a protective atmosphere to remove arsenic in the copper smelting arsenious smoke dust in an arsenious oxide form. Compared with a conventional fire arsenic removal method, the method has the advantages that arsenic can be efficiently removed under a low roasting temperature, and the arsenic removal rate can reach up to 88% or above; moreover, operation is easy, the conditions are mild, energy consumption is low, and arsenic in the copper smelting smoke dust can be removed on a large scale.

Owner:CENT SOUTH UNIV

Adsorbing material for removing arsenic from water and preparation method of material

InactiveCN103272555AGood arsenic removal effectImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionFerric hydroxideCerium

The invention discloses an adsorbing material for removing arsenic from water and a preparation method of the material. The preparation method comprises the steps as follows: certain amounts of cerous salt and ferric salt are dissolved in appropriate water, hydrogen peroxide is taken as an oxidizing agent, and cerous ions are oxidized; and an alkali liquid is taken as a precipitator, a coprecipitation reaction happens, and drying is performed at a certain temperature, so that the amorphous ferric hydroxide adsorbing material loaded with nano cerium oxide is obtained. The arsenic-removing adsorbing material has a strong absorption action on arsenic ions in the water, and is simple in preparation process and low in cost; when arsenic in a water solution is processed, water is not required to be preprocessed; and the material can be applied to removing of arsenic in drinking water or industrial wastewater.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

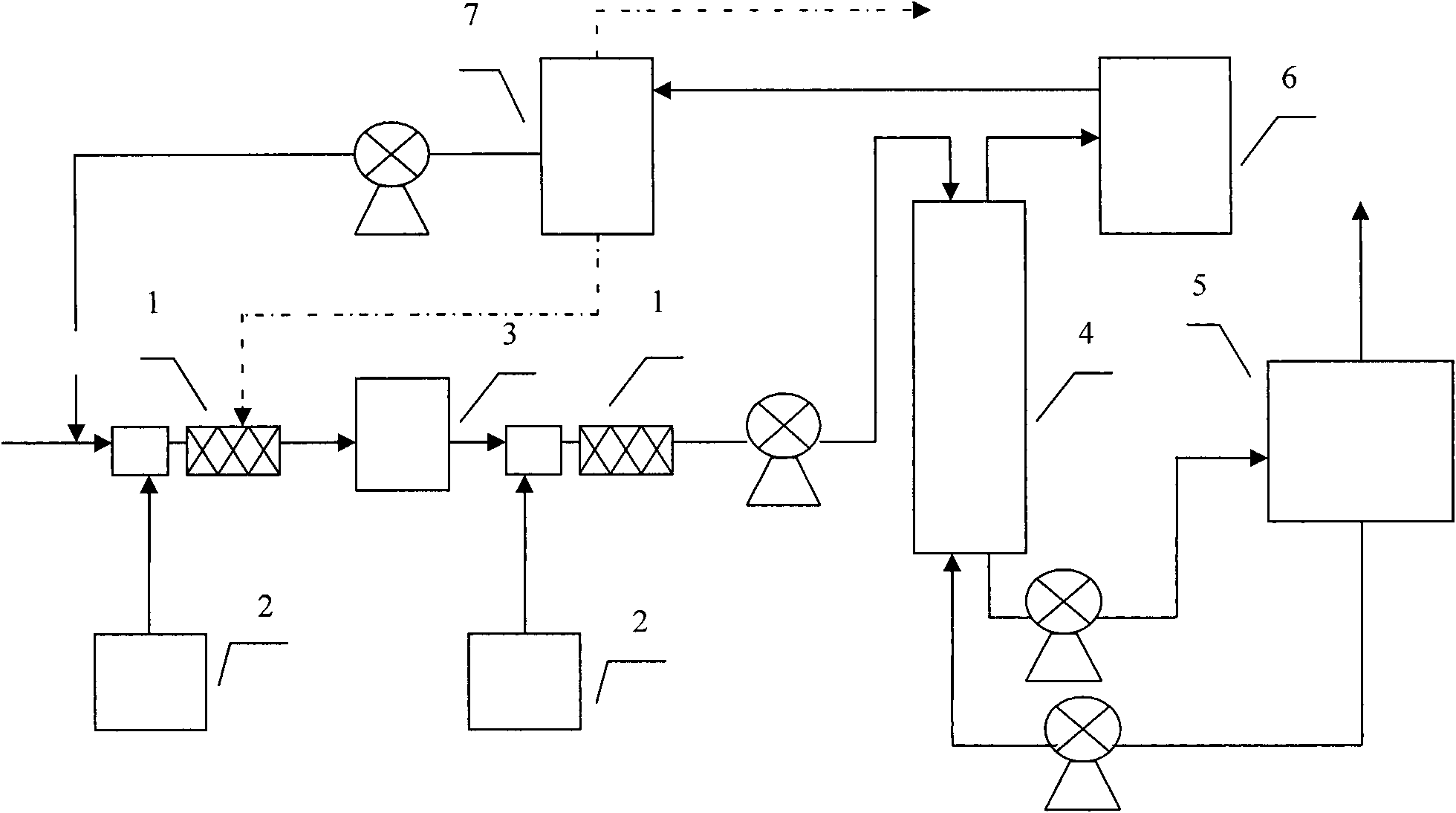

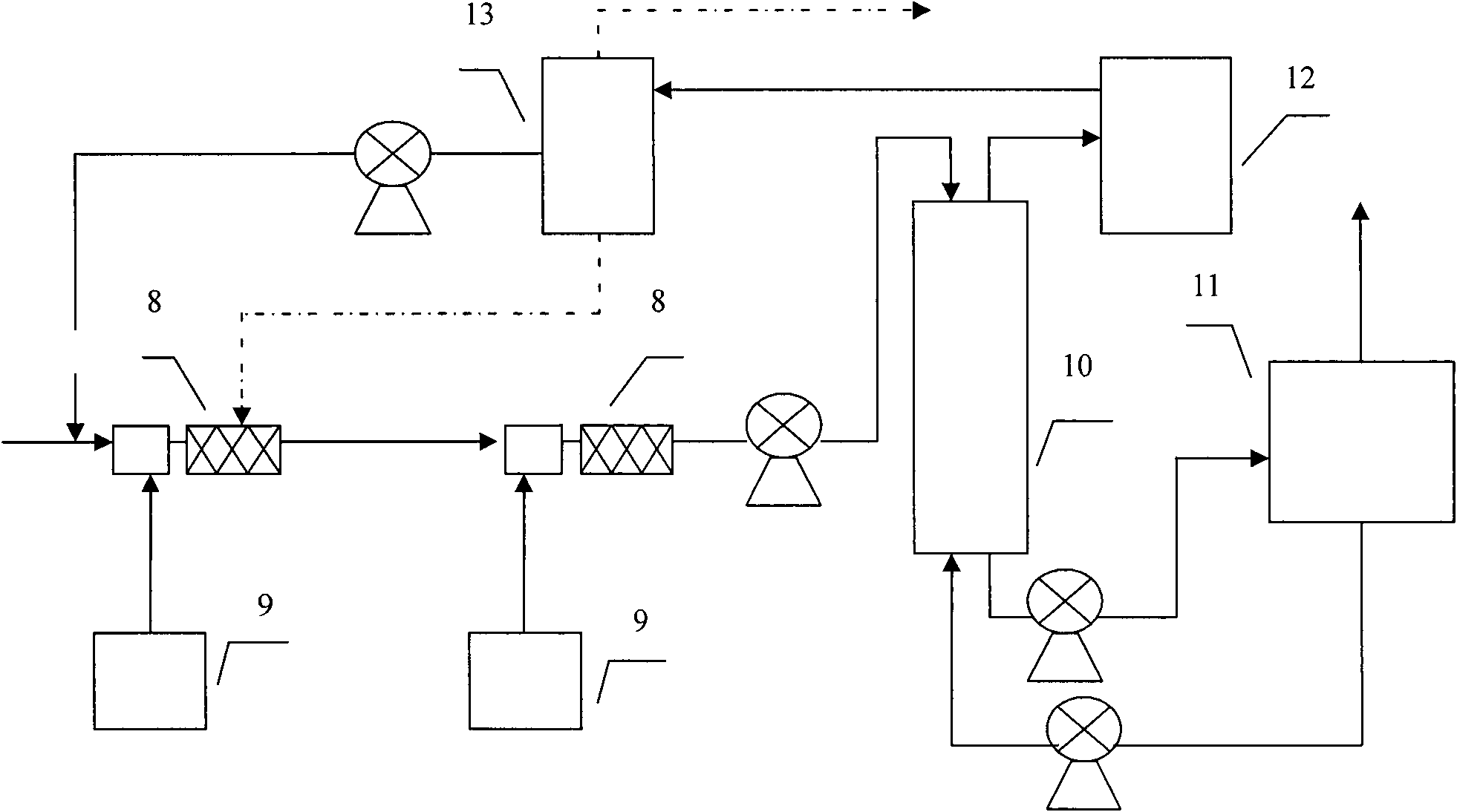

Method for removing arsenic by using Fe (II) and Mn (II) in underground water

InactiveCN102583810ASimple processSimple and fast operationMultistage water/sewage treatmentWater/sewage treatment by oxidationWater sourceWater quality

The invention discloses a method for treating underground arsenic water by using Fe (II) and Mn (II) coexisting with arsenic in underground water. The arsenic removing method comprises the steps of oxidation, micro-flocculation, contact filtration, backwashing water concentration, ferrimanganic particle FeMnOyHy and the like. In addition, an arsenic removing activity filter membrane with arsenic removing activity can be formed on the filter medium surface load of a contact filtration pond and can be used as another barrier for removing arsenic. The method is used for removing arsenic in a drinking water source, treatment water can reach the limit requirements (smaller than 10 mug / L) for arsenic in latest national Standards for Drinking Water Quality (GB5749-2006), and the indexes of ferrum, manganese, turbidity and the like can also reach the national standards. In addition, the method can be also used for removing heavy metals such as copper, chromium, cadmium, lead, antimony and the like and contaminants such as ferrum, manganese and the like in the drinking water source.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

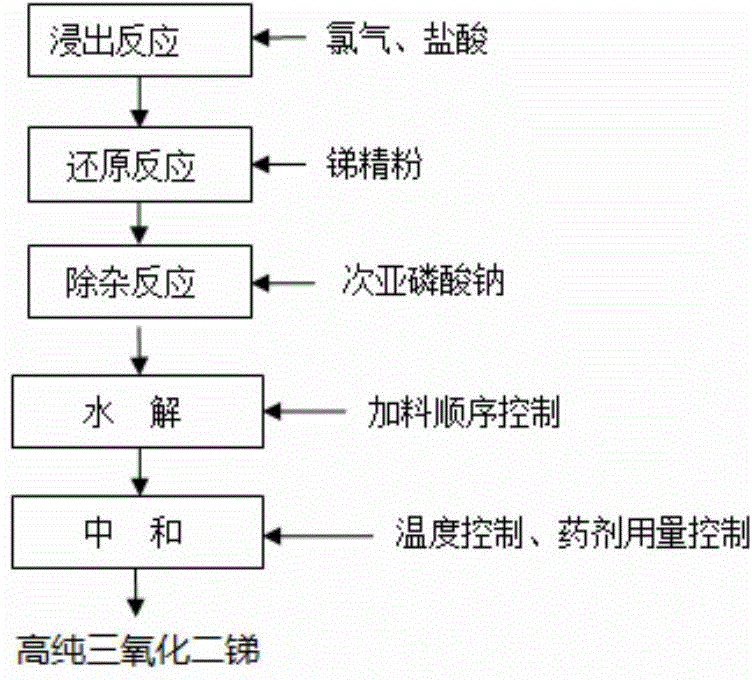

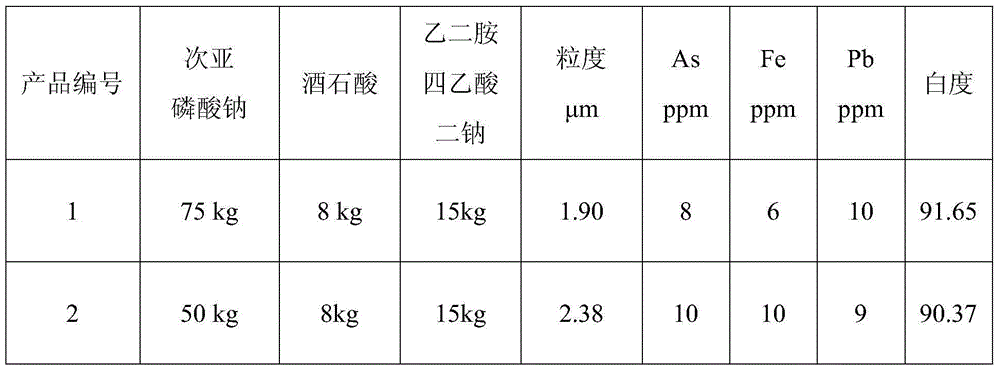

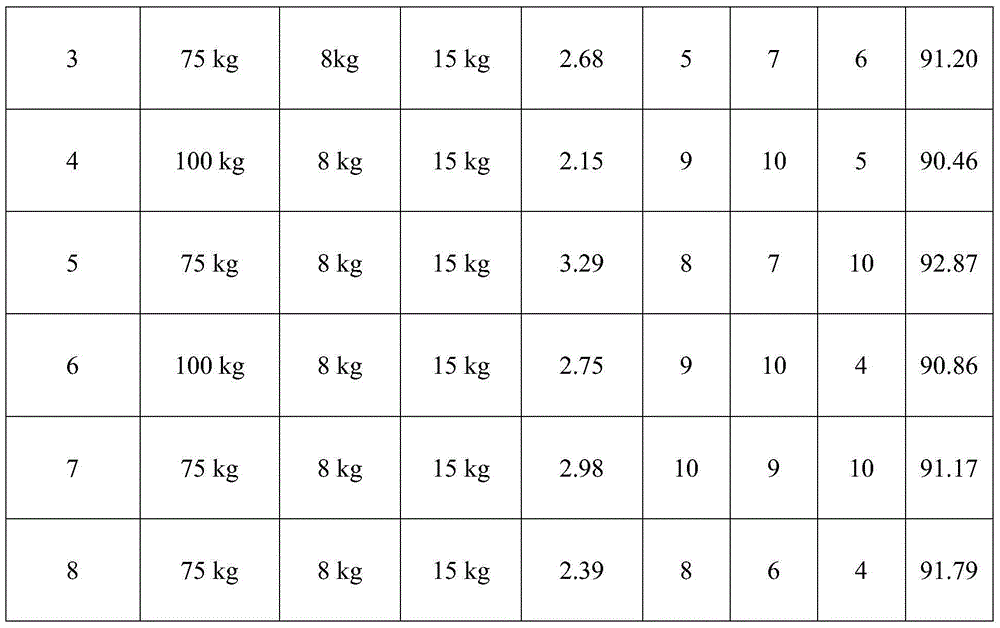

Technique for producing high-purity antimonous oxide by processing stibnite concentrate through wet method

InactiveCN104944469AHigh purityUniform particle sizeAntimony compoundsEthylene diamineAcid concentration

The invention discloses a technique for producing high-purity antimonous oxide by processing stibnite concentrate through the wet method. According to the technique, the stibnite concentrate is chloridized, a leaching agent is reduced by means of fine stibium powder, reduction liquid is selectively reduced through sodium hypophosphite under the proper temperature and proper acid concentration conditions so that arsenic is removed, iron in a solution subjected to arsenic removal is removed through hydrolysis, and lead in the solution subjected to arsenic removal is removed through ethylene diamine tetraacetic acid; meanwhile, growth of crystals is controlled by adding dihydroxysuccinic acid and controlling the neutral reaction condition, and in this way, a high-purity antimonous oxide product containing main impurities such as lead, arsenic and iron all being within 10 ppm and the average particle sizes being 2-3 microns can be produced. According to the technique, the stibium loss is small, operation is easy, production cost is low, and industrial production requirements are met.

Owner:HUNAN CHENZHOU MINING CO LTD

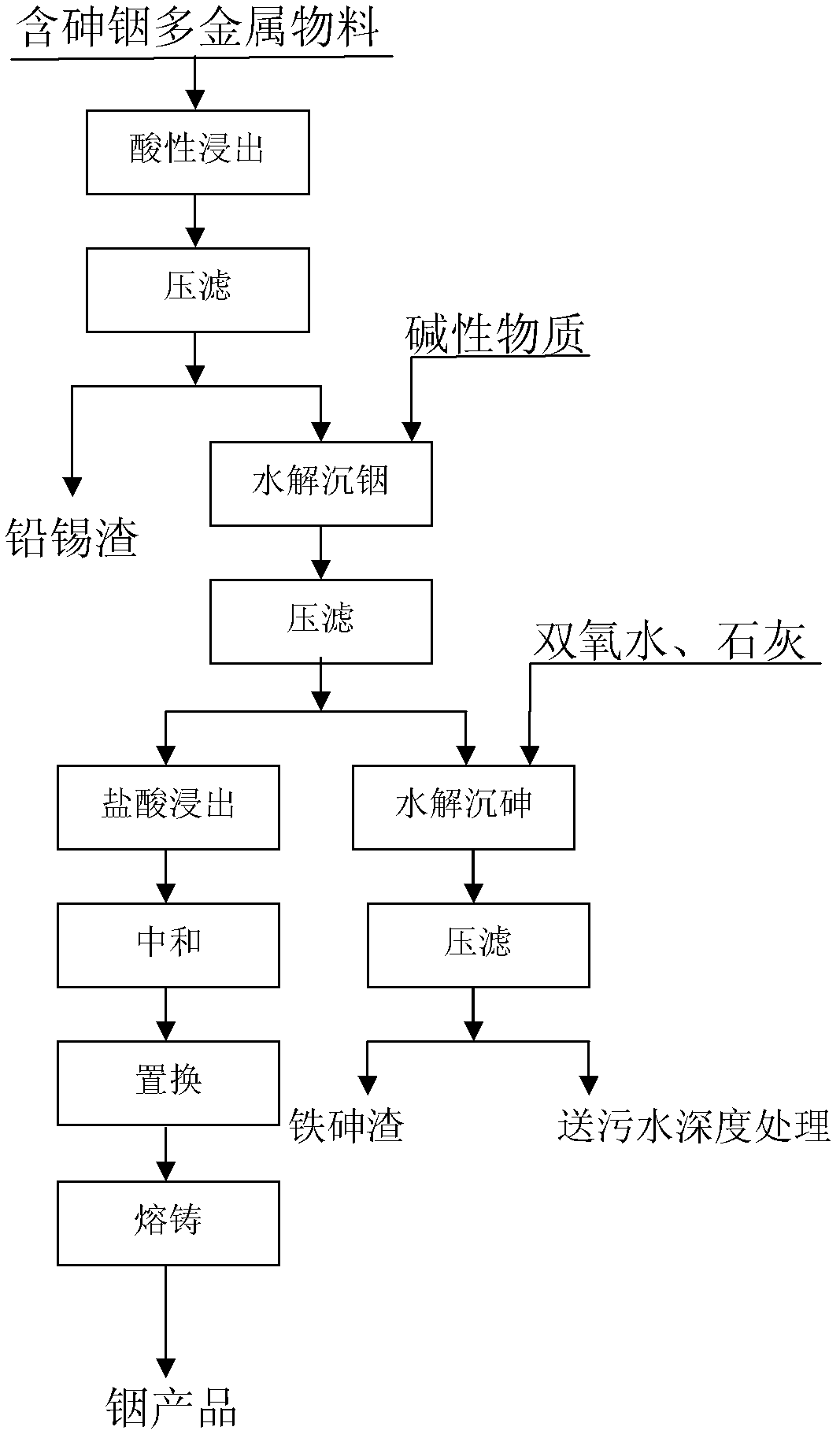

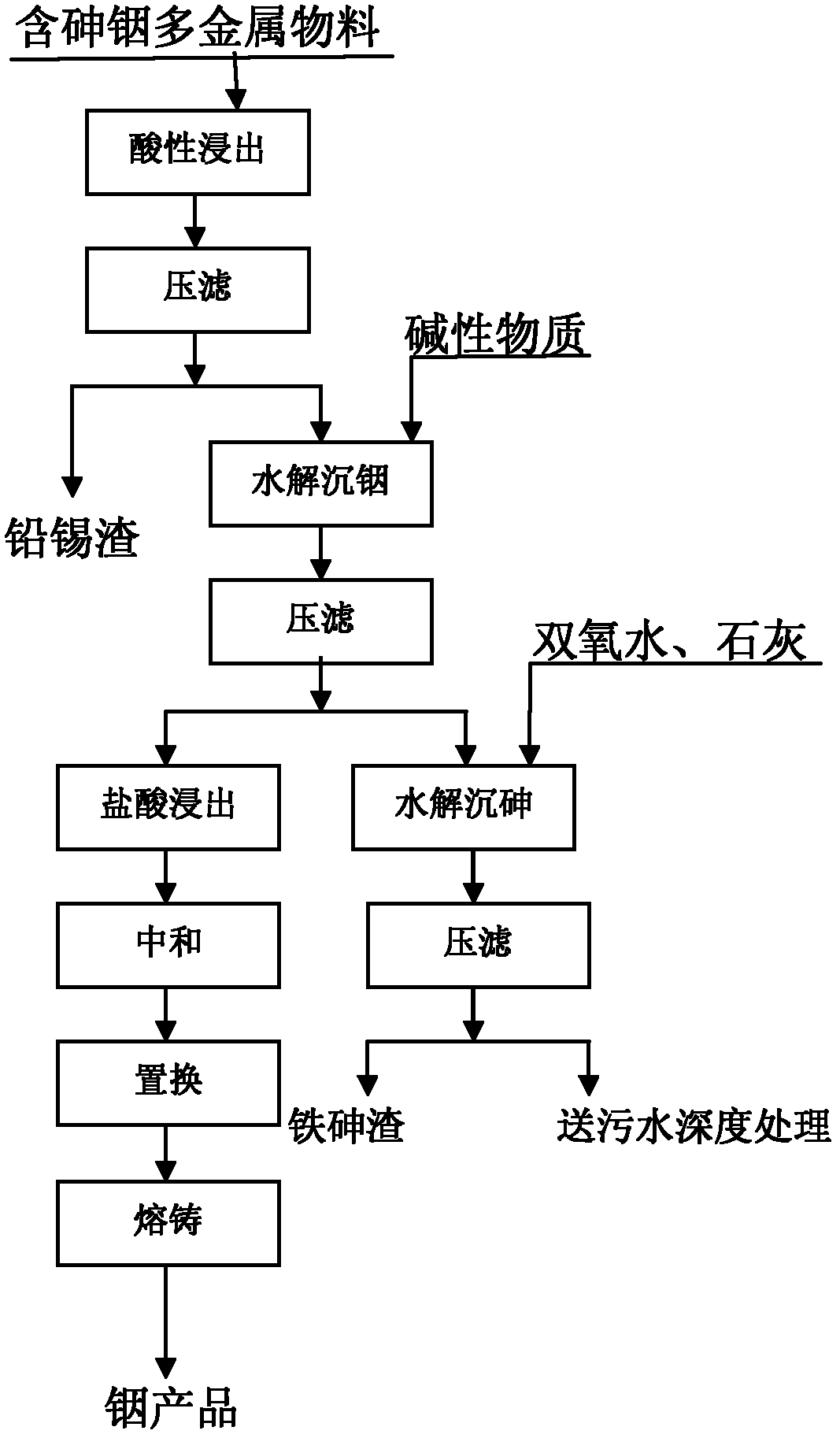

Method for utilization and harmless treatment of multi-metal material containing arsenic and indium

InactiveCN102560123AGood arsenic removal effectEasy to separatePhotography auxillary processesProcess efficiency improvementIndiumSlag

The invention discloses a method for utilization and harmless treatment of multi-metal material containing arsenic and indium, comprising the steps of: dissolving most of metals like arsenic and indium into the solution through hydrometallurgy while lead and stannum into the slag; then precipitating indium by means of hydrolysis; afterwards, leaching out the precipitated indium with hydrochloric acid to obtain indium-rich solution, and obtaining coarse indium product through replacement and smelting; finally adding alkali to the arsenic-containing solution to produce harmless ferrite. With the invention, the arsenic removal rate is greater than 93%; arsenic is well separated from the valued metals so that the arsenic content in the valued metal slag is less than 1%, which is convenient for reclamation of valued metals; moreover the arsenic slag formed is a general solid waste which is easy to dispose, and the waste water meets the requirement of first-grade discharge standard to realize comprehensive and harmless reclamation of the arsenic-containing materials.

Owner:CHENZHOU FENGYUE ENVIRONMENTAL PROTECTION TECH

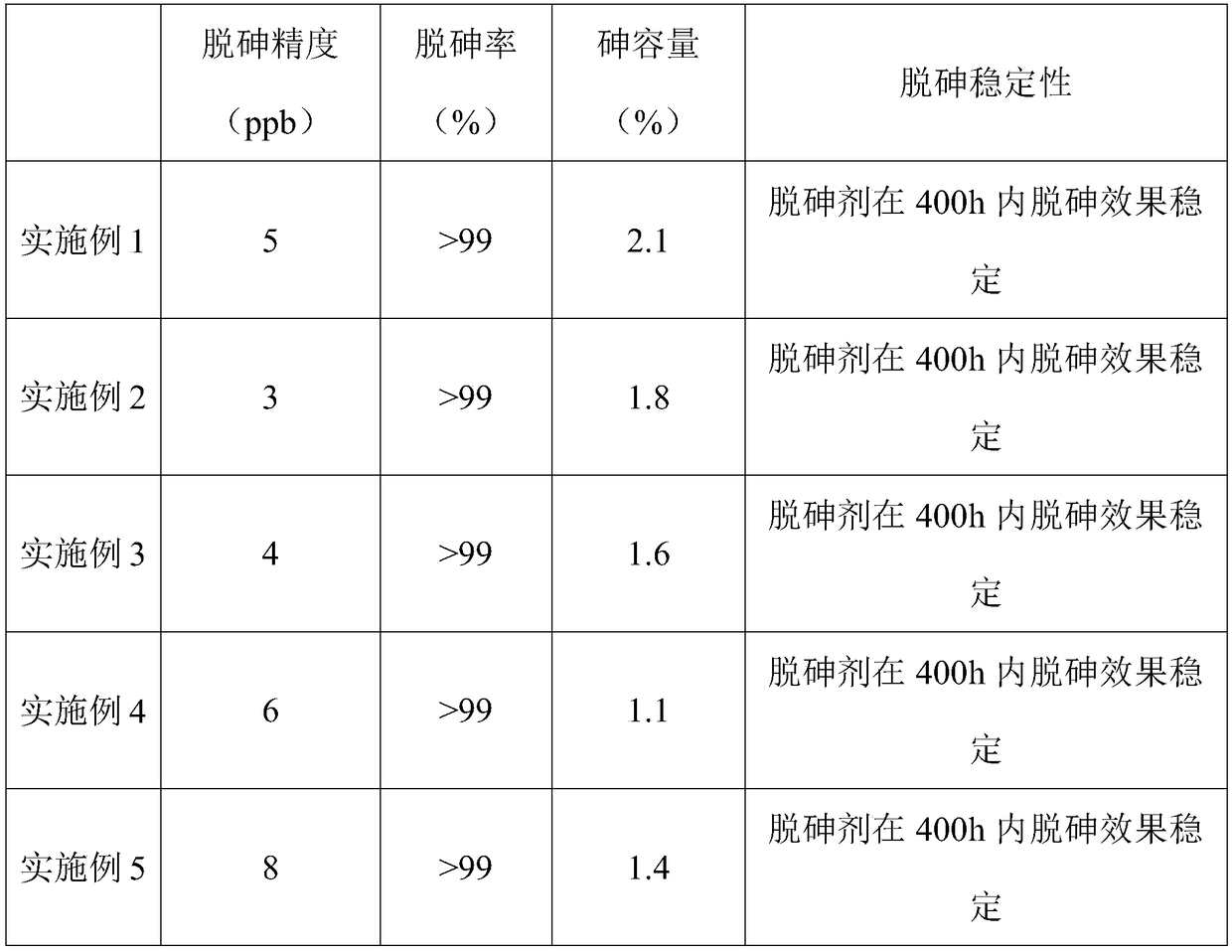

Arsenic removal agent, and preparation method and use thereof

ActiveCN109251764AHigh precision of arsenic removalImprove stabilityRefining with metal oxidesProcess efficiency improvementActivated carbonActive component

Owner:昆山市精细化工研究所有限公司

Liquid condition petroleum hydrocarbon arsenic removal catalyst, producing method and use of the same

InactiveCN101173181AHigh arsenic capacityGood water resistanceRefining with metal saltsMolecular sieveChemistry

The invention relates to a normal temperature de-arsenic agent for liquid petroleum hydrocarbons, and the preparation method and the usage of the de-arsenic agent. The de-arsenic agent comprises the following components: 55 to 59 weight account of molecular sieve comprising active arsenic removing component and provided with double middle pore-micropore structure, and 1 to 50 weight account of auxiliary materials for frame forming; the molecular sieve and the auxiliary materials for frame forming react under certain conditions to produce the de-arsenic agent; the de-arsenic agent is used for the normal temperature arsenic removal of liquid petroleum hydrocarbons. Compared with the prior art, the invention has the advantages of high arsenic capacity, good waterproof property, good arsenic removing performance and other advantages.

Owner:上海化工研究院天地科技发展有限公司 +1

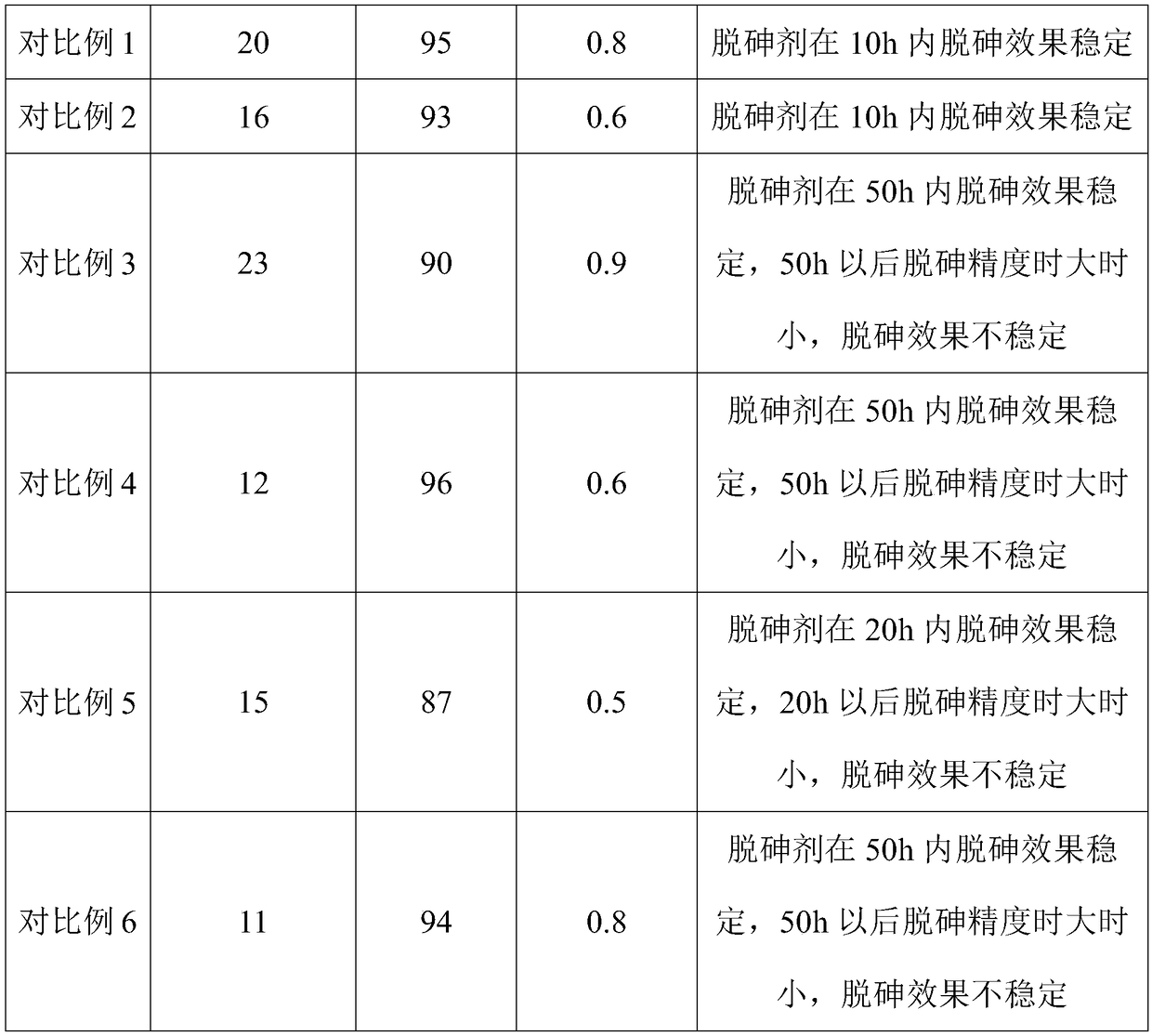

Modified resin for removing arsenic from low-concentration arsenic-containing water and preparation method thereof

InactiveCN104667887AHigh removal rateGood removal effectOther chemical processesWater/sewage treatment by sorptionIron(III) chlorideIron chloride

The invention discloses modified resin for removing arsenic from low-concentration arsenic-containing water and a preparation method of the modified resin. The modified resin is prepared as follows: resin is impregnated in aluminum chloride solution to be loaded sufficiently, and then is impregnated in ferric chloride solution to be loaded sufficiently, therefore, the modified resin is acquired; the modified rein is loaded with iron and aluminum materials with high arsenic adsorption capacity, and has greatly-improved arsenic removal ability due to the synergic effect of the iron and aluminum materials, and the arsenic removal rate can reach more than 99%, and the concentration of arsenic in water after adsorption treatment of modified resin can reach 0.001mg / L and is lower than the national newest drinking water standard 0.01mg / L. The modified resin is also suitable for treating sewage with low arsenic concentration, and the concentration of arsenic in yielding water is lower than 50ppb. The modified resin material is solid particles which can be separated, can be filled in a filter and has flexible using modes, the modified resin material can be used for static adsorption and can be used as a packed column for dynamic adsorption, has stable adsorption capability and long using period, can be regenerated and repeatedly utilized easily, and has high efficiency.

Owner:SUN YAT SEN UNIV

Method for processing arsenic polluted water body by enrichment adsorption coupling

InactiveCN101648748AImprove landscapeEasy to operateWater contaminantsSustainable biological treatmentPlant rootsHazardous substance

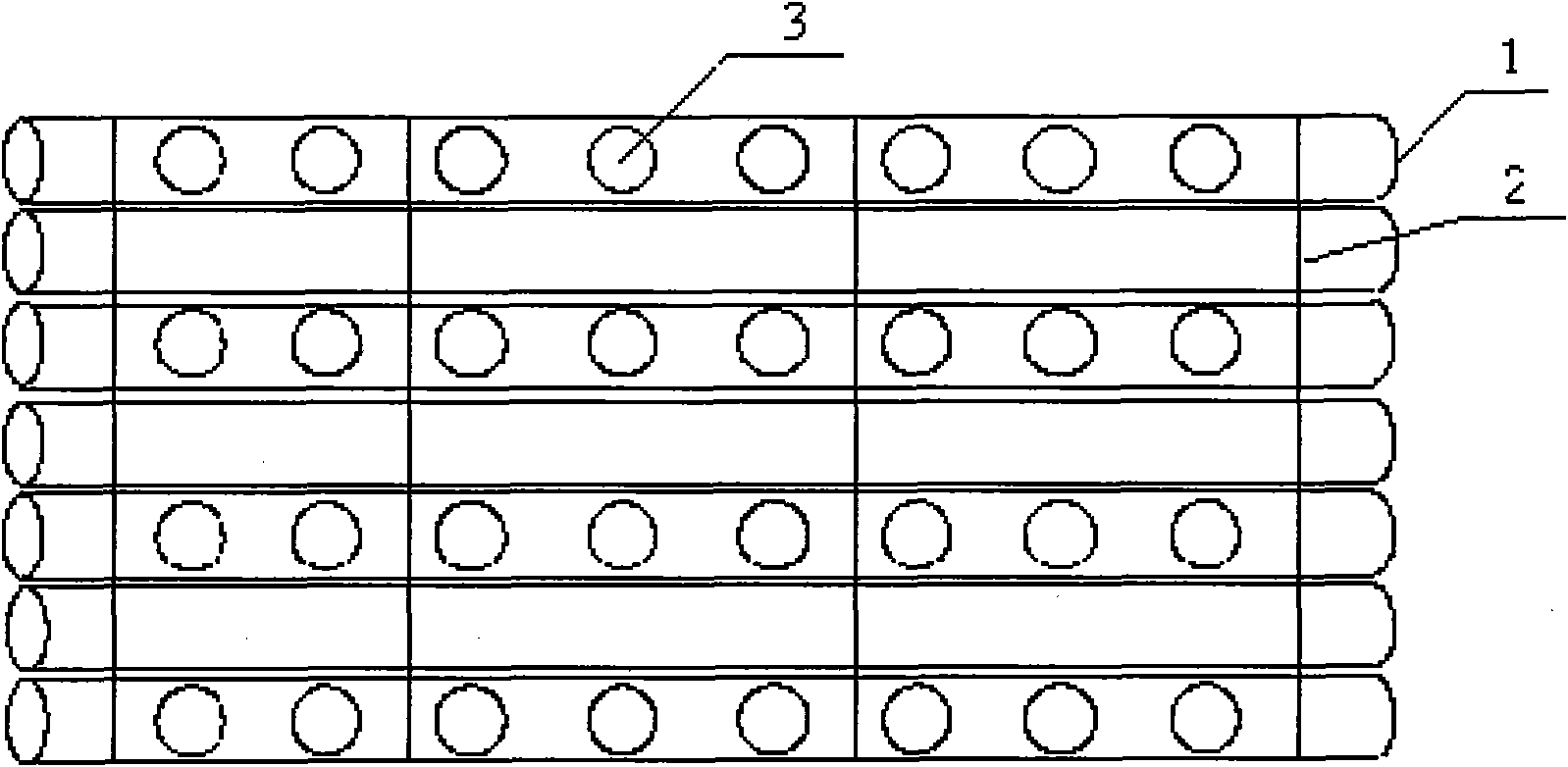

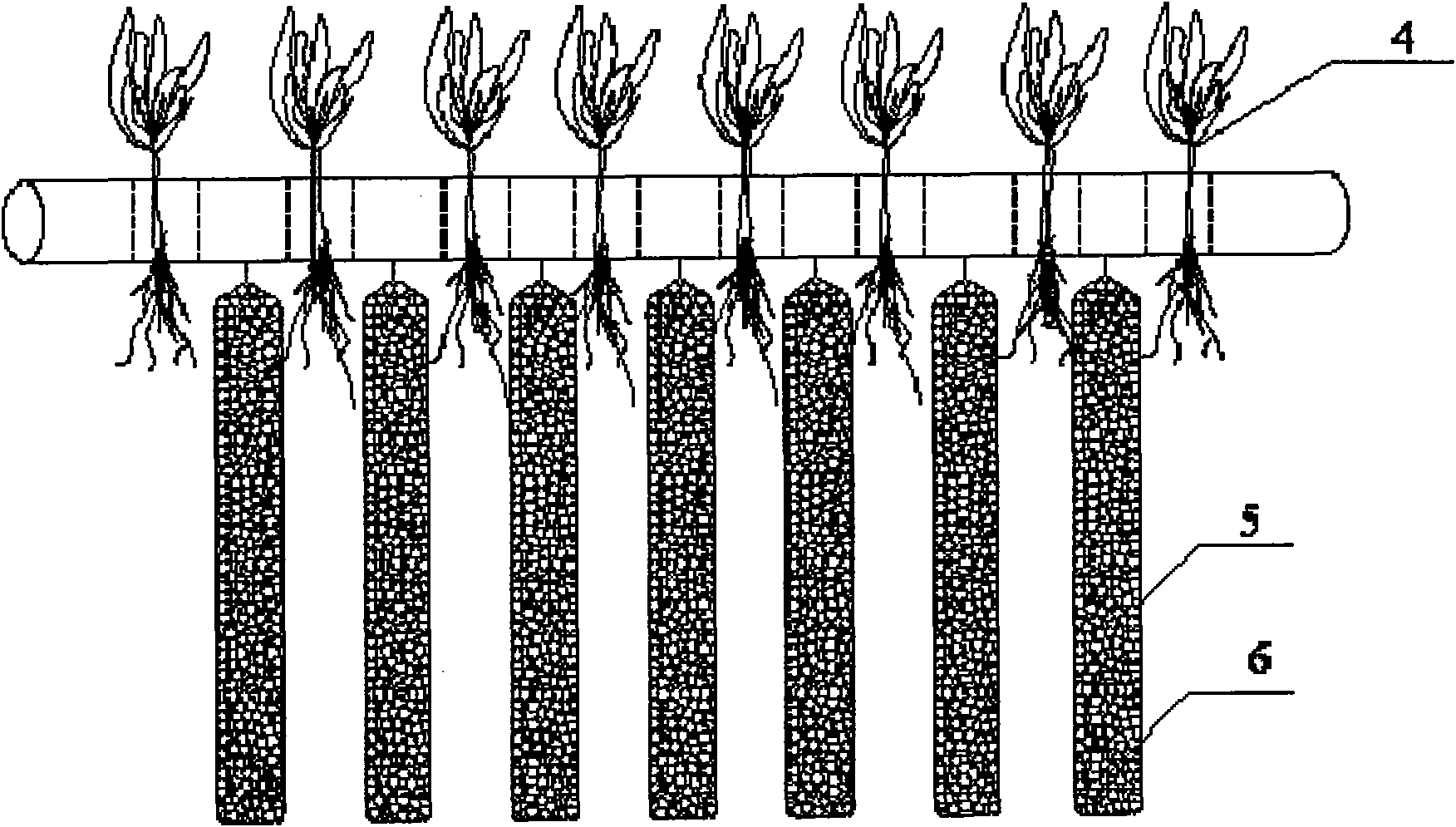

The invention provides a method for processing arsenic polluted water body by enrichment adsorption coupling, which is to place a processing unit in the polluted water body. The processing unit comprises floating bodies, plants and adsorbents; the floating bodies are bamboo rafts made of moso bamboo; the plants select emergent aquatic plants which can enrich arsenic and are fixed on the surfaces of the floating bodies to grow in a floating manner; the adsorbents are contained in an absorbing bag which is hung under the floating bodies; the absorbing bag hung under the bamboo rafts absorbs harmful substance through the adsorbents in a deep layer of the water body; the roots of the floating plants are underwater, which enrich arsenic through the action of plant roots to achieve the purpose of purifying water body. The method of the invention has simple operation, low cost, environmental protection and no pollution; the arsenic removing effect is good by combining the enrichment of plantsand absorption of the absorbents; and the introduction of the plants improves the landscape of the water body and beautifies the environment.

Owner:SHANDONG UNIV

Method for treating arsenic in waste smelting acid by using copper slag

InactiveCN109534476AIncrease management costsSusceptible to toxic leachingWater contaminantsWaste water treatment from metallurgical processSludgeImpurity

The invention discloses a method for treating arsenic in waste smelting acid by using copper slag, and belongs to the field of heavy metal pollution treatment and metallurgical solid waste utilization. The method includes firstly subjecting the copper slag to drying, ball milling and magnetic separation to obtain iron-rich copper slag and other impurities; subjecting the iron-rich copper slag to high-temperature pretreatment at 500-800 DEG C; subjecting the high-temperature iron-rich copper slag to water quenching through high-speed water blowing; then drying and grinding the copper slag afterwater quenching; adding H2O2 into waste acid and mixing to perform oxidation pretreatment at 60-80 DEG C; then adding the copper slag into the waste acid after oxidation pretreatment; performing an arsenic removing reaction at atmospheric pressure under stirring; and finally performing solid liquid separation. The method achieves arsenic removal with cheap copper slag, reduces sludge storage volume in the process of waste acid treatment when compared with a traditional arsenic removal process, and achieves an effect of treating waste with a waste material. The method has characteristics of simple process operation, a low production cost and a wide market prospect.

Owner:KUNMING UNIV OF SCI & TECH

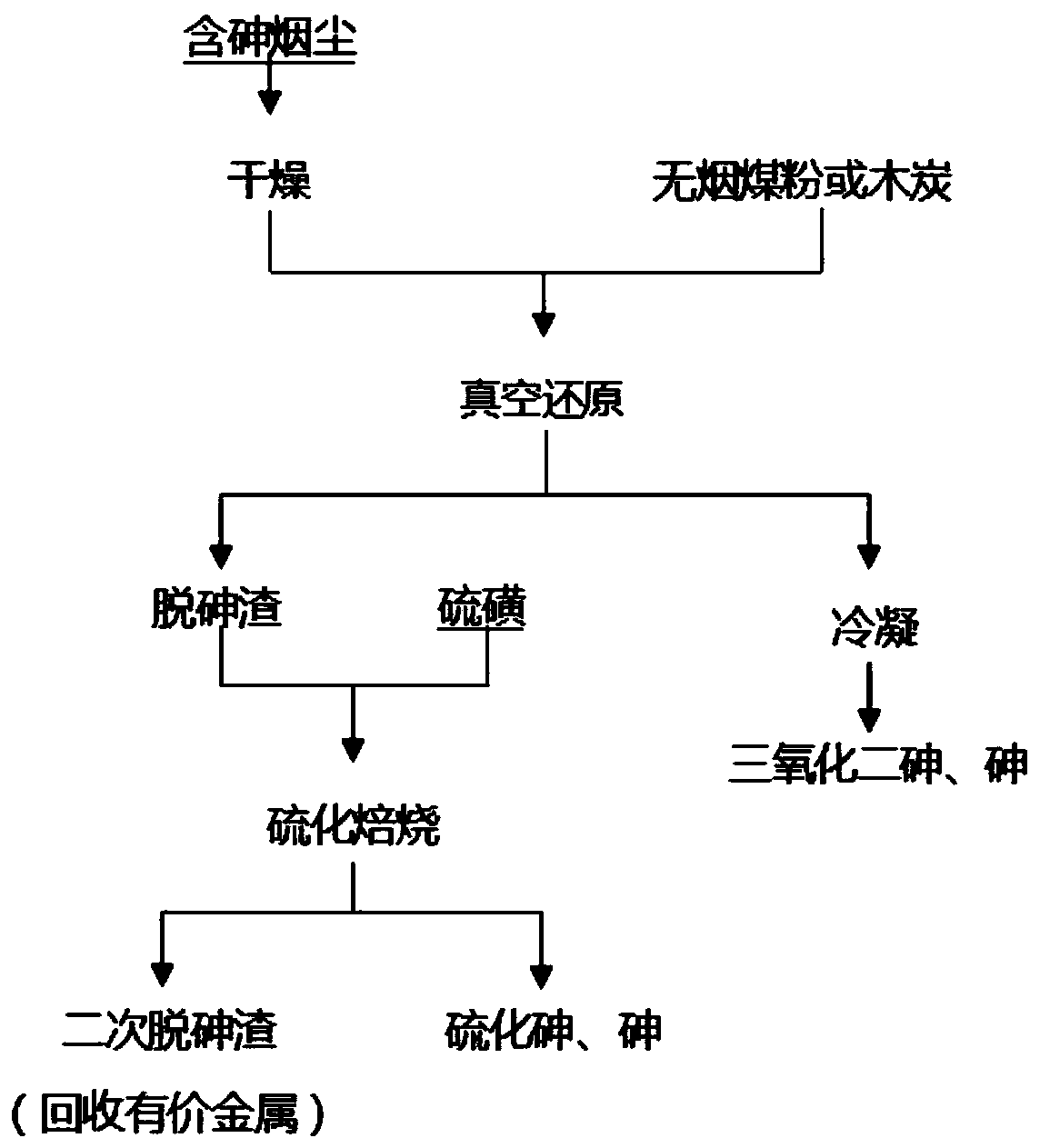

Method for desorbing arsenic from arsenic-containing soot

ActiveCN109136576ATo achieve the purpose of removing arsenicGood arsenic removal effectProcess efficiency improvementIndiumSlag

The invention provides a method for desorbing arsenic from an arsenic-containing soot, and belongs to the field of secondary resource utilization of complicated nonferrous metals. The method comprisesthe following steps: under the condition of vacuum, carrying out arsenic pre-removal treatment on the arsenic-containing soot by carbon thermal reduction reaction; and then removing arsenic slag andcarrying out sulphidizing roasting. The arsenic-containing soot which contains arsenate and an arsenic phase of which the arsenide is complicated and is difficult to treat can be treated, the arsenicremoval effect is good, the process is simple, the method is environmentally friendly, the arsenic content of the treated soot is lower than 2%, moreover, the soot is rich in valuable metals such as lead, zinc, copper and bismuth and rare metals such as indium, silver and gold, and can be directly utilized comprehensively later, a purpose of desorbing the arsenic from the arsenic-containing soot is achieved, furthermore, the valuable metals such as the lead, the zinc, the copper and the bismuth in the arsenic-containing soot can be enriched, low-toxicity treatment on hazardous wastes is carried out, and meanwhile, the additional value is increased.

Owner:KUNMING UNIV OF SCI & TECH

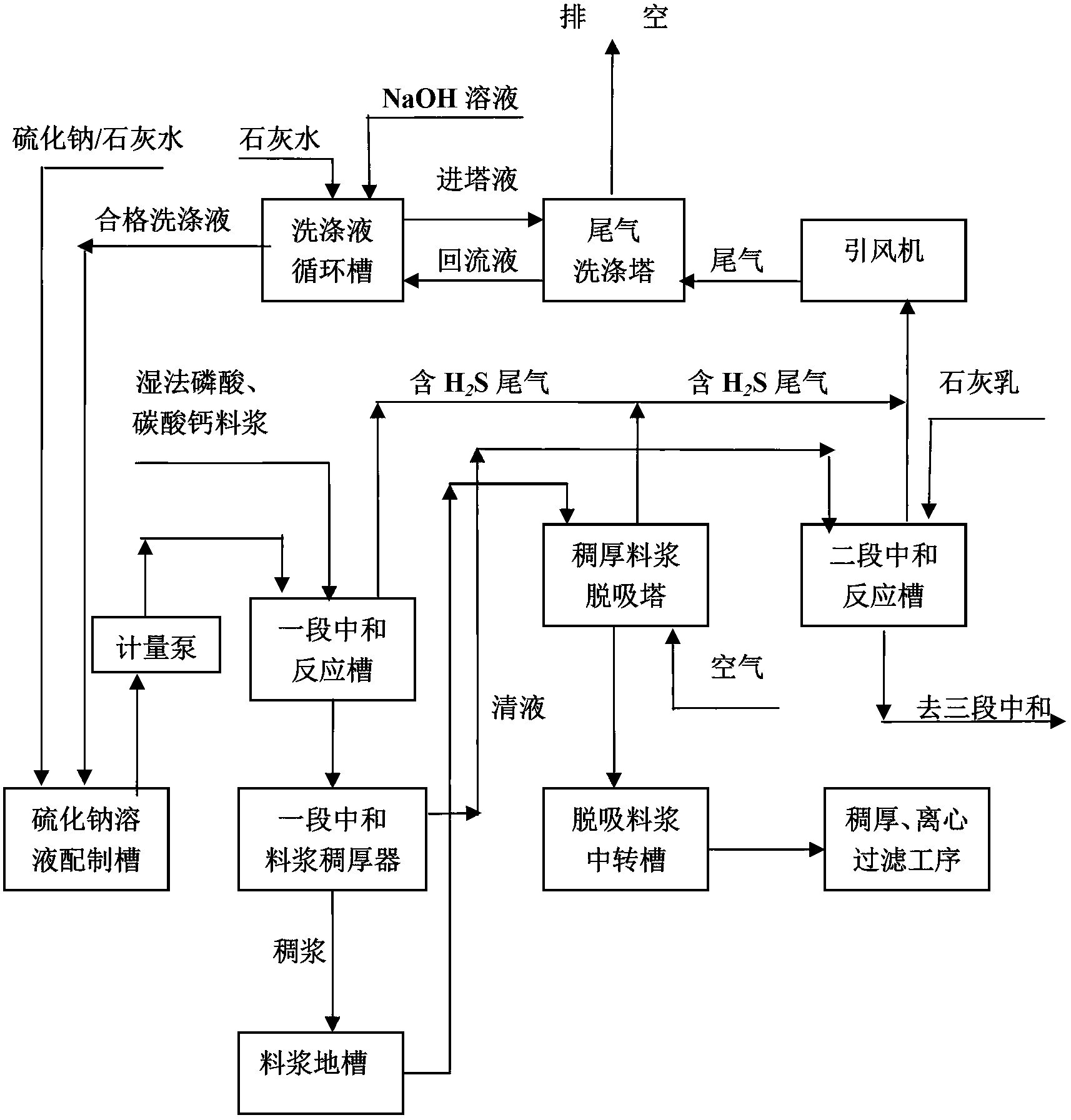

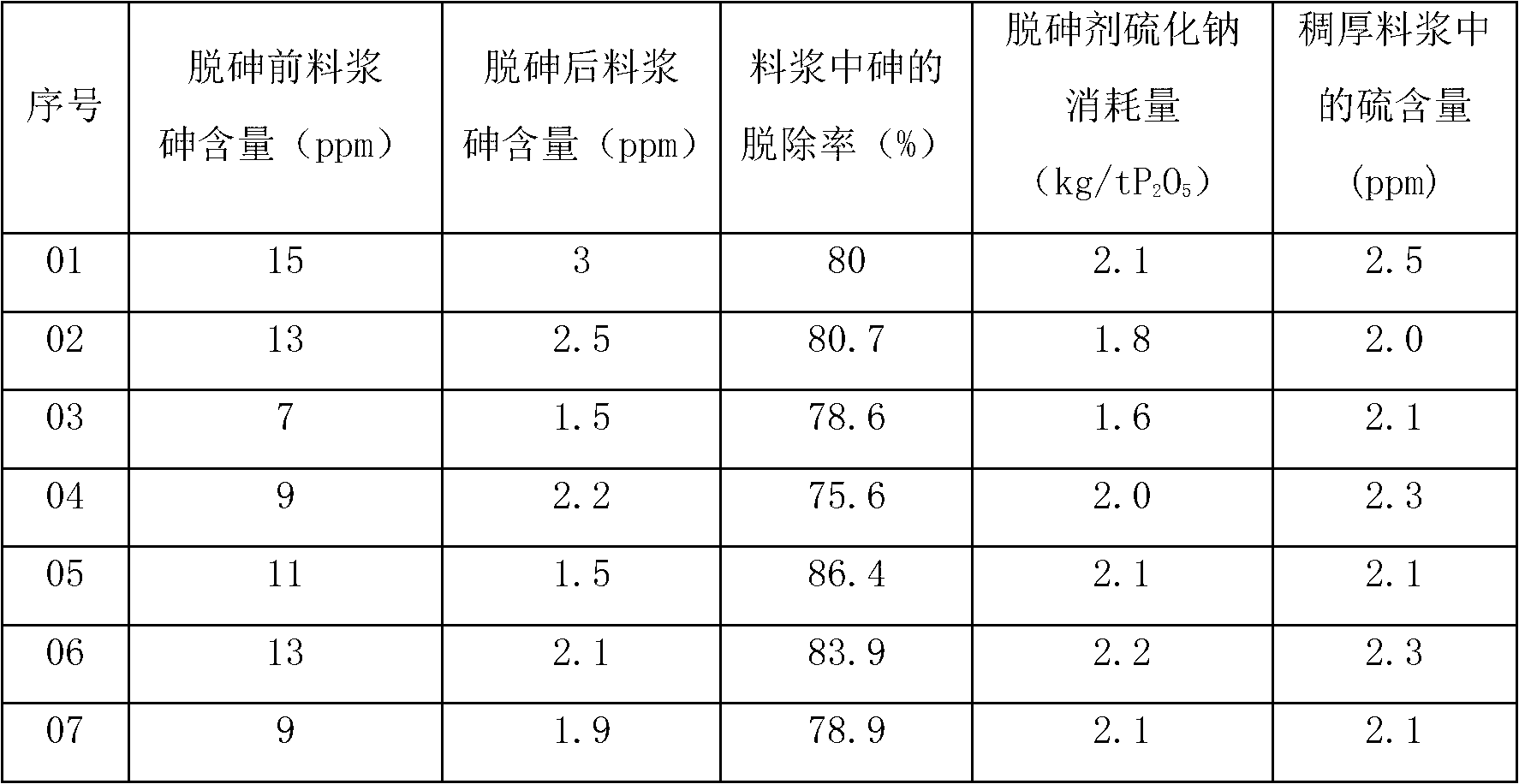

Process method for removing arsenic from feed-grade calcium hydrogen phosphate prepared from wet-process phosphoric acid

ActiveCN102701170AGood arsenic removal effectGuaranteed SolubilityDispersed particle separationPhosphorus compoundsDesorptionPhosphoric acid

The invention relates to a process method for removing arsenic from feed-grade calcium hydrogen phosphate prepared from wet-process phosphoric acid. The process method comprises the following steps of: 1) adding a sodium sulfide or calcium sulfide solution into neutralized slurry by using an adjustable pressure metering pump until the solution reaches a position which is 50cm away from the liquid level of the neutralized slurry; 2) desulfurizing by an air stripping method, namely removing hydrogen sulfide (H2S) from slurry at the bottom of a thickener by using a desorption tower; 3) recovering the H2S in tail gas to generate a mixed solution of calcium sulfide and sodium sulfide by using lime water and liquid caustic soda in a molecular ratio of Ca(OH)2 to NaOH of 1:1 as washing water of a tail gas washing tower, wherein the washing water of the tail gas washing tower is used as a raw material of an arsenic remover for the neutralized slurry in a section I and recycled after the concentration of the washing water is qualified; and 4) adding the sodium sulfide or calcium sulfide solution into the last one or two reaction tanks for one-stage neutralization of the wet-process phosphoric acid. The process method has the advantages that the content of the H2S in the slurry is reduced to about 3ppm, and the slurry does not have the odor of the H2S; and arsenic removal cost is reduced by more than half compared with that of a treatment method in which lime is not used.

Owner:KUNMING CHUAN JINNUO CHEM IND

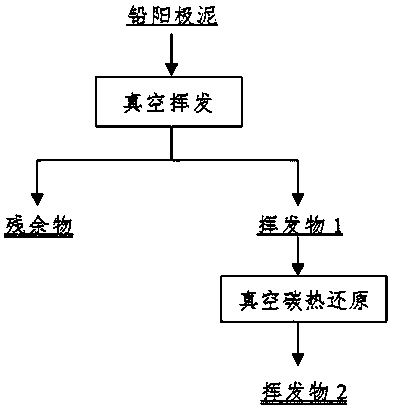

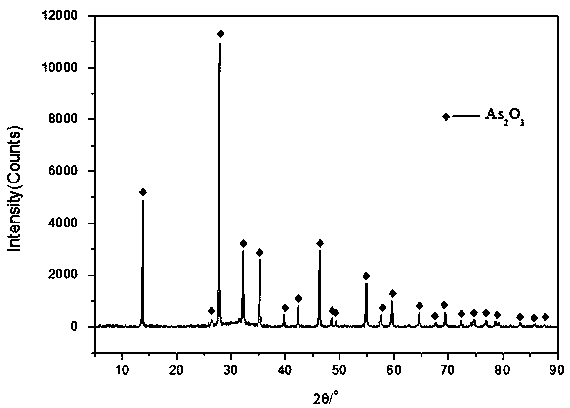

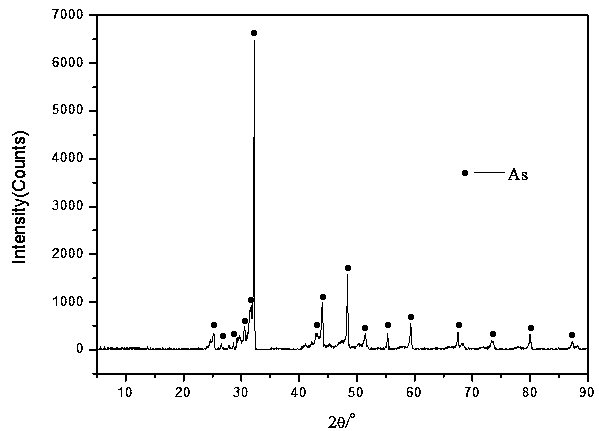

Method for removing arsenic from lead anode mud

ActiveCN109777962AEfficient recyclingAvoid harmProcess efficiency improvementArsenic compoundsCarbon layerSingle substance

The invention discloses a method for removing arsenic from lead anode mud and belongs to the technical field of thermometallurgy. According to the method, at first, the lead anode mud is dried and dehydrated, the lead anode mud is roasted and treated on the vacuum condition, arsenic oxide and simple substance arsenic in the lead anode mud are volatilized at a high temperature, and the purpose of arsenic removing is achieved; and by adding a carbon layer on the upper portion of a lead anode mud raw material, volatile toxic arsenic oxide is reduced into low-toxicity single-substance arsenic. According to the method, the flow is simple, the arsenic removing effect is remarkable, only by means of vacuum volatility, arsenic in the lead anode mud can be removed by over 90%, the direct recovery rate of other valuable metal Ag and Cu is 99%, and the direct recovery rate of Pb is 95%. The method is low in investment cost and high in economic benefit, and has a very good industrialized prospect.

Owner:KUNMING UNIV OF SCI & TECH

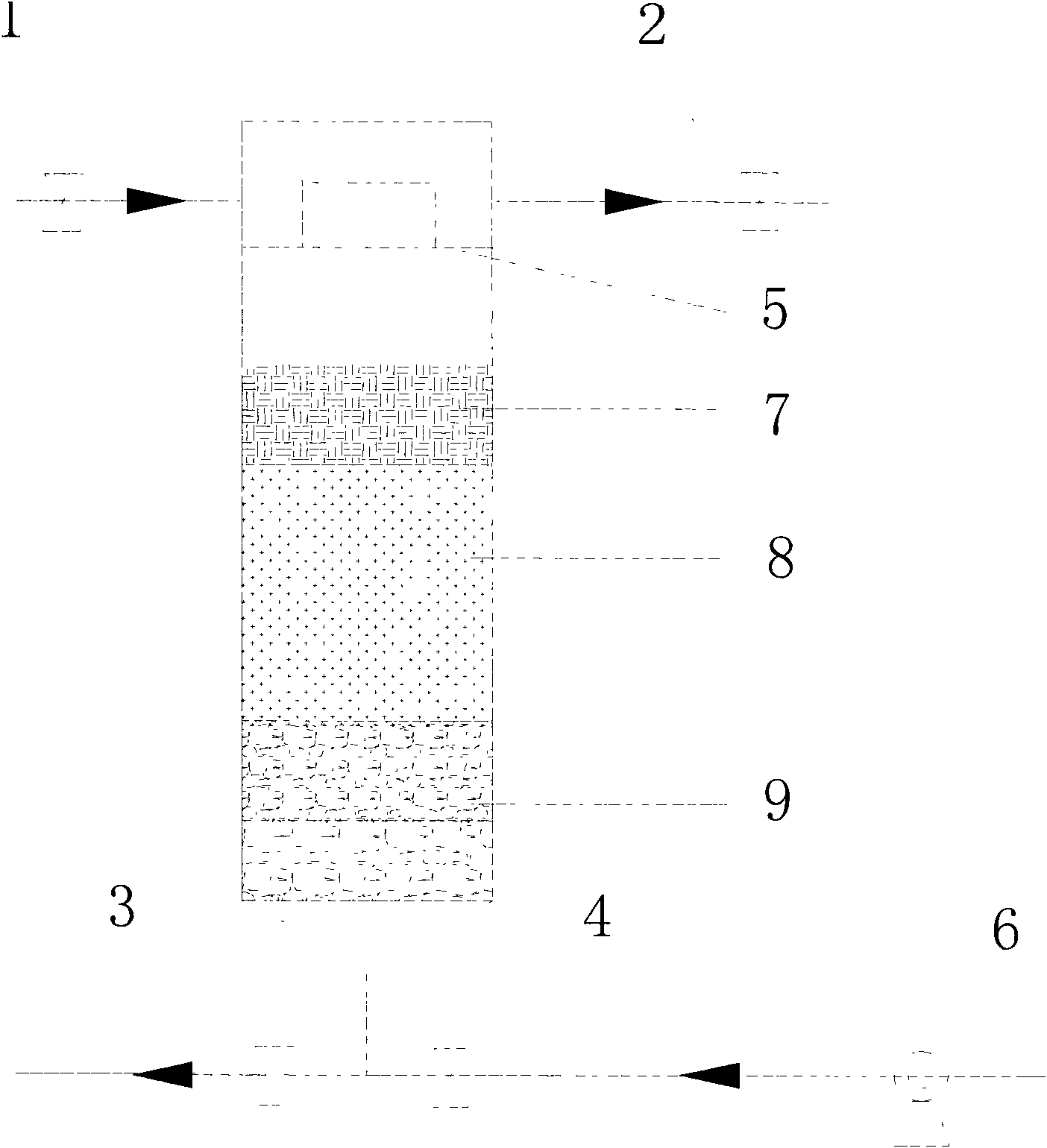

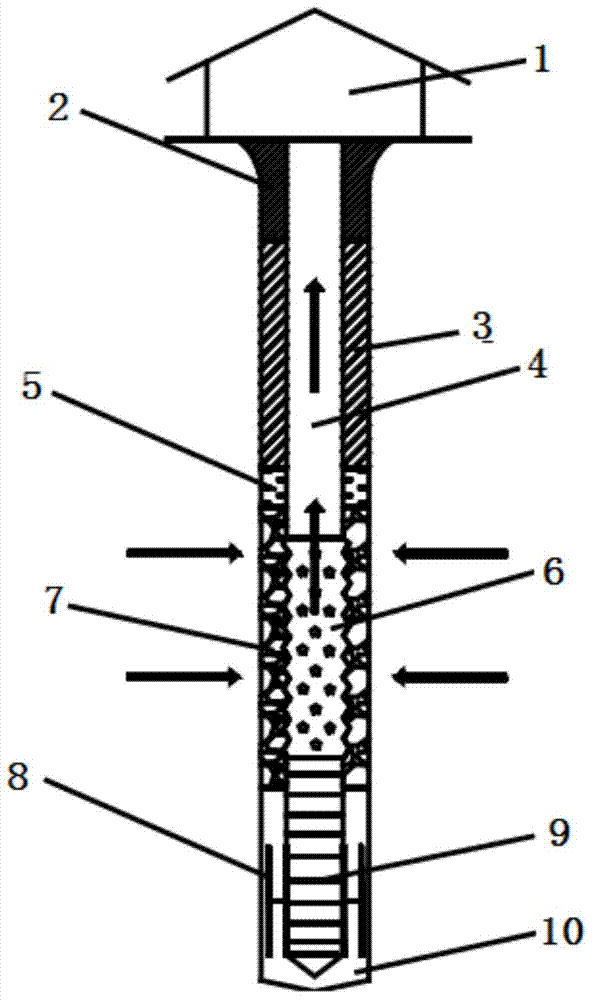

Home-position arsenic removal single well based on siderite filter materials

InactiveCN103882912ALow costGuaranteed accuracyGeneral water supply conservationDrinking water installationEngineeringWater processing

The invention provides a home-position arsenic removal single well based on siderite filter materials. The home-position arsenic removal single well at least comprises a ground pump room and a wellhole, wherein a well tube, a gauze permeable sleeve and a sediment tube are sequentially arranged in the wellhole from top to bottom, the well tube is fixed on the upper portion of the wellhole, the gauze permeable sleeve is fixed on the lower portion of the wellhole and located in the aquifer of the stratum, the sediment tube is connected to the lower portion of the gauze permeable sleeve, and the well tube is tightly connected with the gauze permeable sleeve through threads; space between the outer wall of the well tube and the well wall sequentially is filled with a concrete well fixing layer and a red soil protecting layer from top to bottom, the concrete well fixing layer is used for protecting and fixing the well tube, and space between the outer wall of the gauze permeable sleeve and the well wall is filled with a filter material layer; the bottom of the wellhole is further provided with a double-ring locator. The home-position arsenic removal single well is good in arsenic removing effect, simple in structure, capable of achieving the natural inferior underground water processing technique of underground normal-position arsenic removal, and capable of making a contribution towards resolving the problems of drinking water safety and body health of people in high-arsenic underground water areas in China, and the filter materials are cheap and easy to obtain.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Electrochemical enhanced sand filter tank arsenic removal method

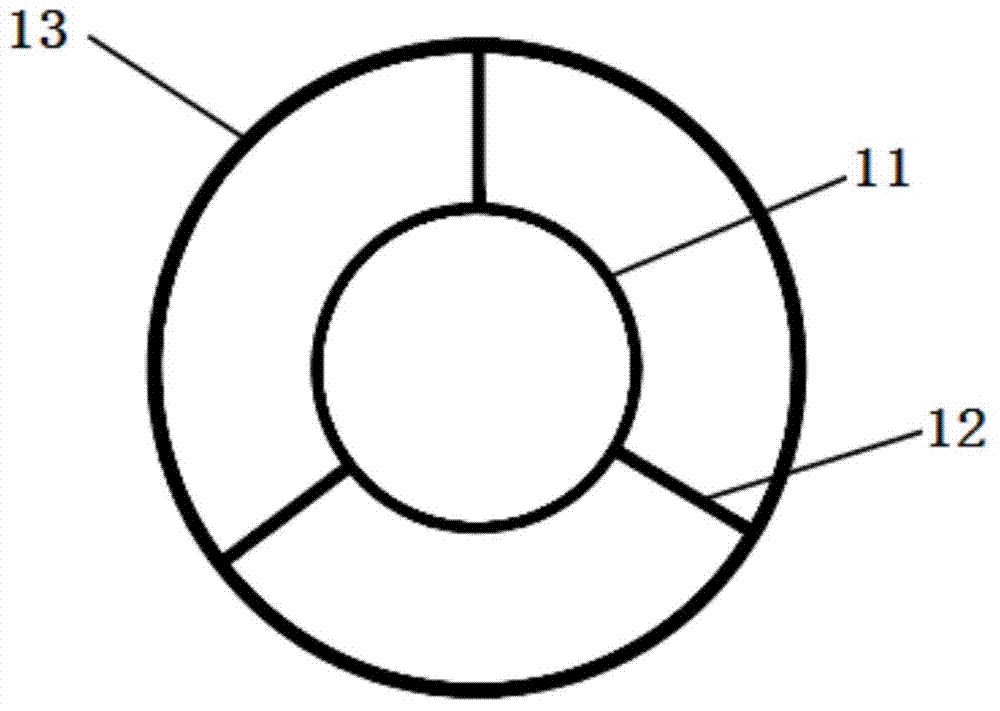

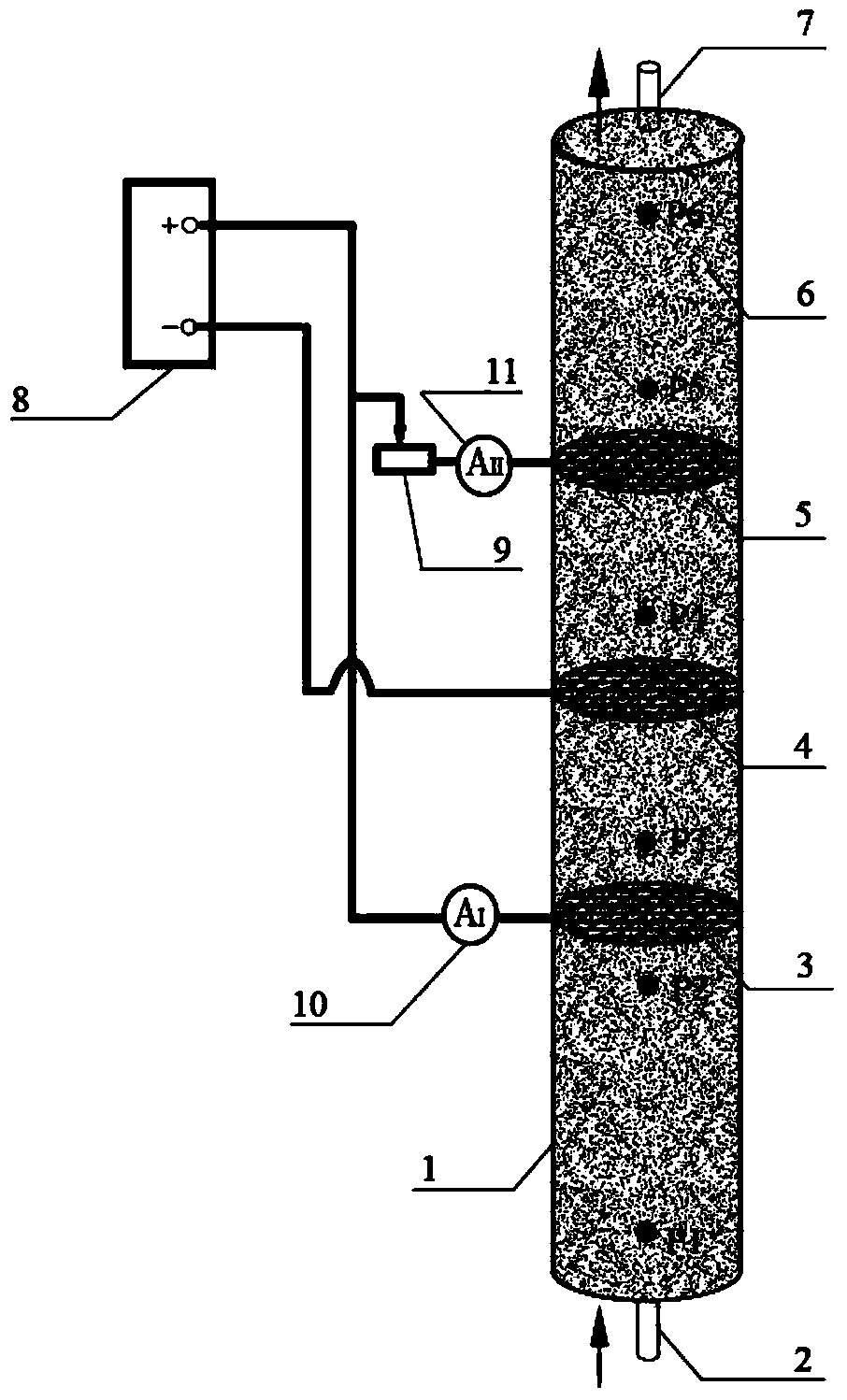

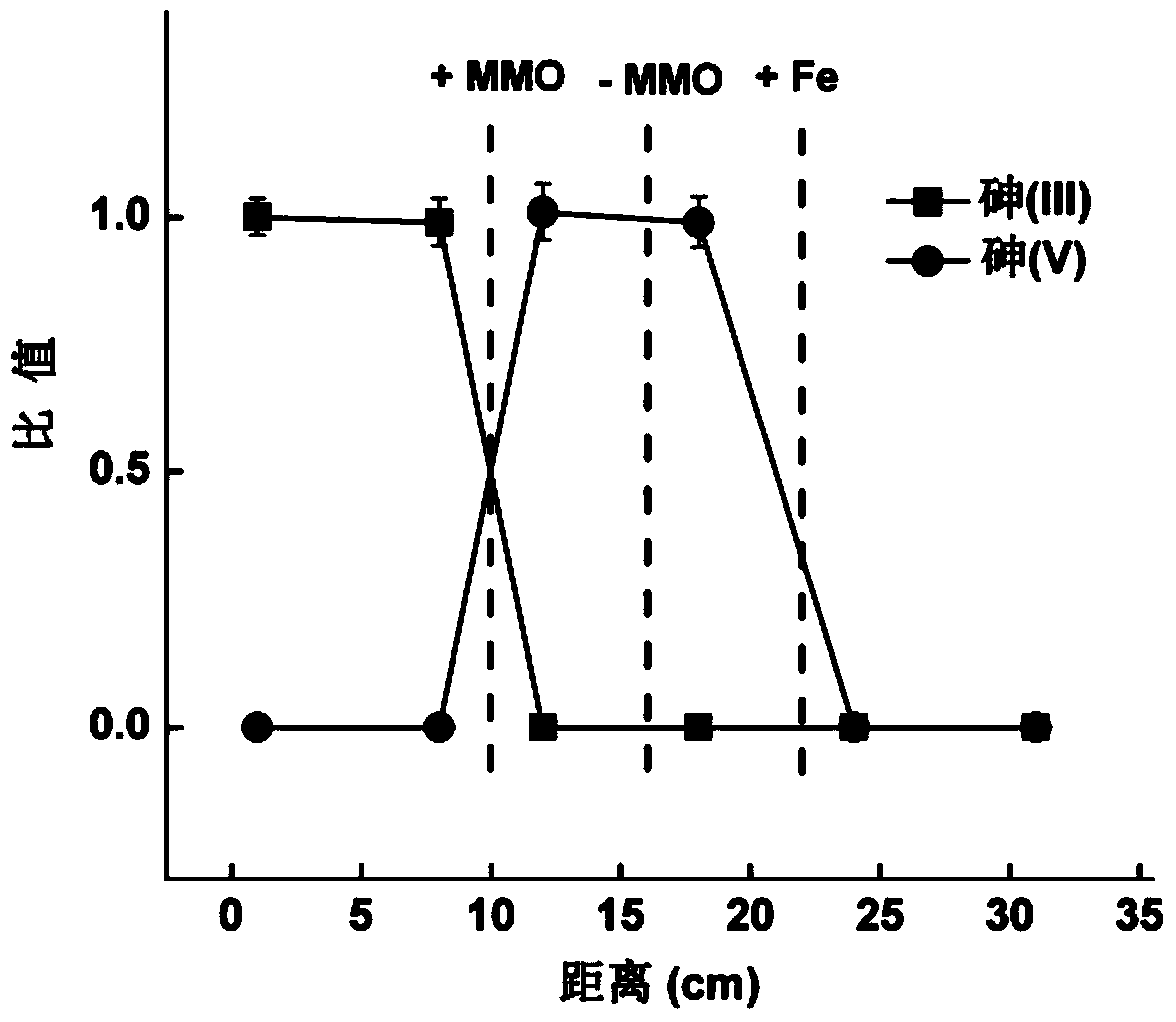

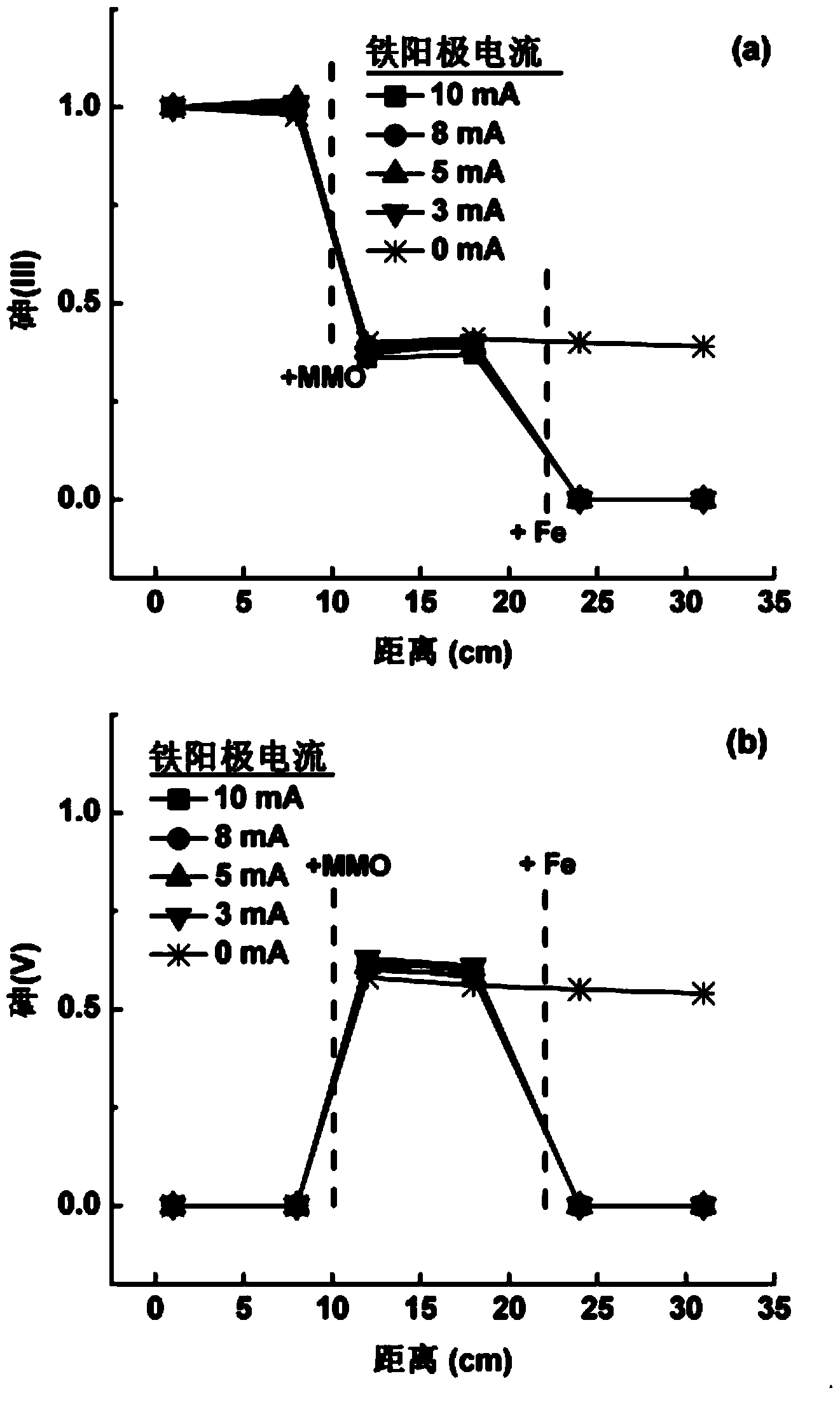

ActiveCN104030405AEasy to replaceHigh adsorption capacityWater/sewage treatment by electrochemical methodsWater/sewage treatment by sorptionEngineeringElectrochemistry

The invention relates to an electrochemical enhanced sand filter tank arsenic removal method. According to the electrochemical enhanced sand filter tank arsenic removal method, a set of arsenic removal device is adopted, an electrochemical technology is combined with a traditional sand filter tank arsenic removal technology, that is to say, iron oxide continuously produced by an electrode in the electrochemical technology is utilized for improving arsenic adsorption capacity of a sand filter tank, regular back washing is carried out when an arsenic removal device is used, the arsenic removal device can be reused after being subjected to back washing, and arsenic (III) in underground water is oxidized into arsenic (V) for a long time and the arsenic (V) is adsorbed and removed. The electrochemical enhanced sand filter tank arsenic removal method solves the problems that a traditional sand filter tank is long in service life, and sand filter materials are difficult to replace; no foreign oxidizing agent is added, and the electrochemical enhanced sand filter tank arsenic removal method has the characteristics of short treatment time, high efficiency, flexible operation, convenience in control, simple maintenance and environmental friendliness and is convenient for popularization and application.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

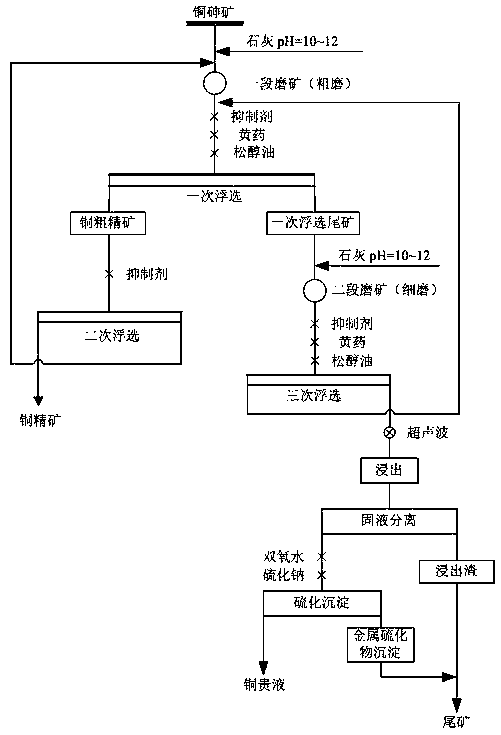

Method for removing arsenic from copper ore

ActiveCN109266842AGood arsenic removal effectAchieve recyclingFlotationProcess efficiency improvementPregnant leach solutionSlag

The invention discloses a method for removing arsenic from copper ore. The method comprises the steps of subjecting arsenic-containing copper ore to primary flotation after coarse grinding to obtain coarse copper concentrates and primary flotation tailings, subjecting the coarse copper concentrates to secondary flotation for arsenic removal to obtain copper concentrates and secondary flotation tailings, subjecting the secondary flotation tailings to coarse grinding, subjecting the primary flotation tailings to tertiary flotation after fine grinding to obtain tertiary flotation concentrates andtertiary flotation tailings, subjecting the tertiary flotation concentrates to primary floatation, leaching the tertiary flotation tailings in an ultrasonic wave radiation environment according to aleaching method to obtain leaching slags and leachate, subjecting the leachate to sulfide precipitation after oxidation to be purified, putting sediments and the leaching slags into the tailings, andtaking the precipitated filtrate as a copper pregnant solution. The method has the advantages of simplicity in process, easiness in implementation, good arsenic removal effect on the copper ore, capability of treating arsenic-containing complex copper ore containing copper sulfide and copper oxide, and wide application to copper ore arsenic removal in the industry.

Owner:KUNMING UNIV OF SCI & TECH

Method of eliminating arsenic by fluosilicic acid

ActiveCN101033067AOxidation is not requiredGood arsenic removal effectSilicon halogen compoundsHexafluorosilicic acidArsenic

This invention discloses a method for eliminating As to fluosilicic acid, which puts a fluosilicic acid solution containing 50-100mg / L As in a reactor with a beater, heats it with a vapour to 30-90deg.C and mixes it in the speed of 50-400r / m and adds an As-elimination agent steadily to the reactor in the weight of 0.1-0.6% that of fluosilicic acid solution, then reacts them for 30-200m and puts the solution into a cleaifying tank to be idled for 1-6h to be filtered to separate sulfide deposition of As to get a fluosilicic acid solution with low As.

Owner:WENGFU (GRP) CO LTD +1

Mineral material for removing arsenic and preparation method thereof

InactiveCN102078794BGood arsenic removal effectSimple preparation processOther chemical processesWater/sewage treatment by sorptionSideriteBiological activation

Owner:BEIJING UNIV OF CHEM TECH

Method for cascade disposal of arsenic-containing waste acid through copper slags

InactiveCN110171886AEasy to operateGood arsenic removal effectWater contaminantsWater/sewage treatmentArsenic pollutionCopper slag

The invention relates to a method for cascade disposal of arsenic-containing waste acid through copper slags, and belongs to the technical field of heavy metal arsenic pollution disposal and industrial solid waste comprehensive utilization. According to the method, the copper slags, the waste acid and an H2O2 solution are uniformly mixed, an arsenic precipitating reaction is carried out for 3-5 hours under a stirring condition of 70-90 DEG C to obtain a solid-liquid mixture A, and through solid-liquid separation, an arsenic-containing solid substance A and a filtrate A are obtained; the wasteacid is added into the filtrate A, air is continuously introduced under a stirring condition of 85 DEG C or above for 12-16 hours of an arsenic precipitating reaction to obtain a solid-liquid mixtureB, and solid-liquid separation is conducted to obtain an arsenic-containing solid substance B and a filtrate B; an alkaline substance is added into the filtrate B, the pH of the solution is adjusted to 7-8, and purification treatment is conducted to obtain industrial standard-reaching water. According to the method, the technological process is simple, the arsenic removal effect is significant, and the arsenic-containing solid substances are stable; the solid waste of a nonferrous metallurgy plant is comprehensively utilized for waste liquid disposal, and an efficient and low-cost method is provided for disposal of the heavy and nonferrous metallurgy smelting waste liquid.

Owner:KUNMING UNIV OF SCI & TECH

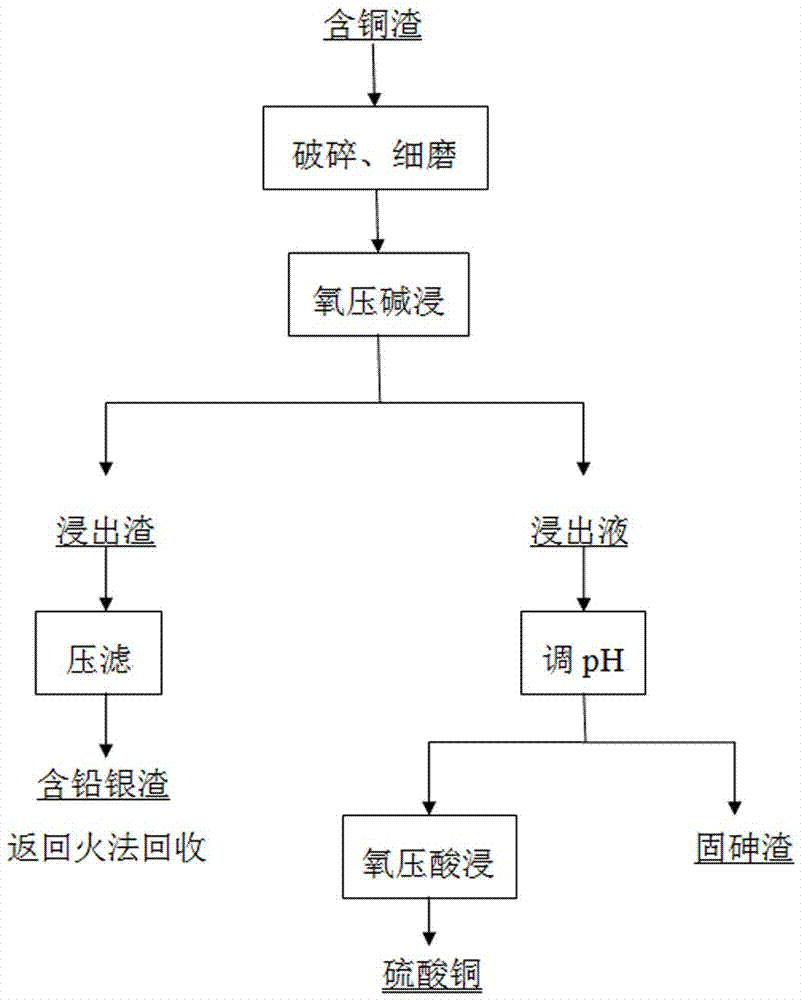

Method for efficiently cleaning and removing arsenic in copper-containing slag

InactiveCN107099669AEfficient leachingThoroughly leachedProcess efficiency improvementSlagCopper sulfate

The invention discloses a method for efficiently cleaning and removing arsenic in copper-containing slag. The method comprises steps of crushing, fine grinding, oxygen pressure alkaline leaching, pH regulation, oxygen pressure acid leaching and the like. The method sequentially comprises the following steps: efficiently cleaning and separating arsenic in the copper-containing slag as well as lead, silver and other valuable metals, and recovering copper in the copper-containing slag. The method disclosed by the invention is low in energy consumption, less in environmental pollution and high in production efficiency. The reaction process of the method is simple and rapid, and the selectivity is high. The copper in the copper-containing slag can be efficiently leached, and the metals can be completely separated. Compared with the conventional copper-containing slag treatment process technology, the arsenic is removed in a sodium arsenate precipitation form through alkaline leaching before copper leaching, so that high-efficiency cleaning and arsenic removal can be achieved, the arsenic removal effect is excellent, and the arsenic content in the leaching solution is less than 1g / L. Moreover, the copper is recovered through the oxygen pressure acid leaching, and the finally prepared copper sulfate product has the copper leaching rate of more than or equal to 96%. The arsenic in the copper-containing slag is recovered in an arsenic slag form, and secondary pollution of the arsenic is avoided. The technology has the advantages of high metal recovery rate, low production cost, high-efficiency cleaning and the like.

Owner:KUNMING METALLURGY INST

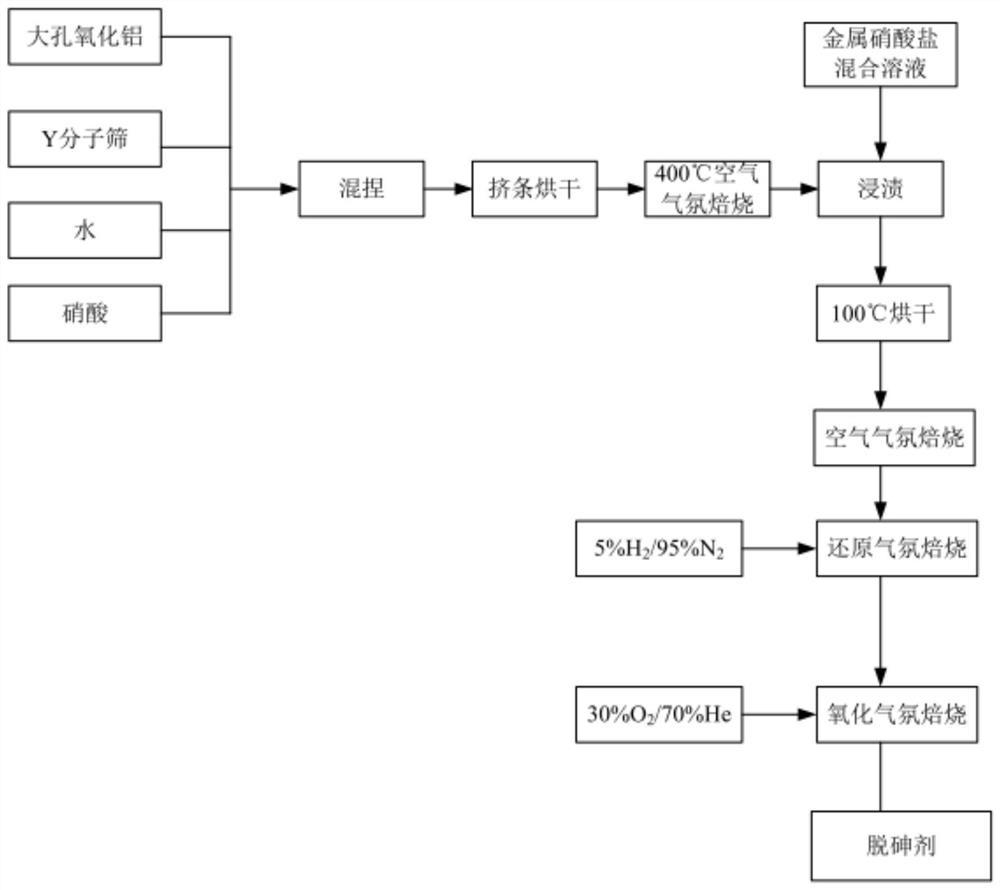

Dearsenification catalyst and preparation method thereof

ActiveCN111672533AHigh adsorption space velocityReduce use costMolecular sieve catalystsCatalyst activation/preparationAir atmosphereMolecular sieve

The invention relates to a dearsenification catalyst and a preparation method thereof. Copper oxide and nickel oxide are loaded by an impregnation method, and then are further treated to form an oxidesolid solution of copper and nickel. According to the dearsenification agent obtained after dipping-air atmosphere roasting-reducing atmosphere roasting-oxidation / helium atmosphere roasting, a metalsolid solution of CuNiO2 is formed and is uniformly dispersed on the inner surface of a molecular sieve, especially the inner surface of a macroporous Y-type molecular sieve, so that excellent dearsenification capacity is obtained. The formation of the solid solution metal oxide can give full play to the ability of complexing metal elements with arsenic elements, and the dearsenification capacityis improved by 30% compared with that of an impregnated CuONiO dearsenification agent.

Owner:BEIJING UNIV OF CHEM TECH +1

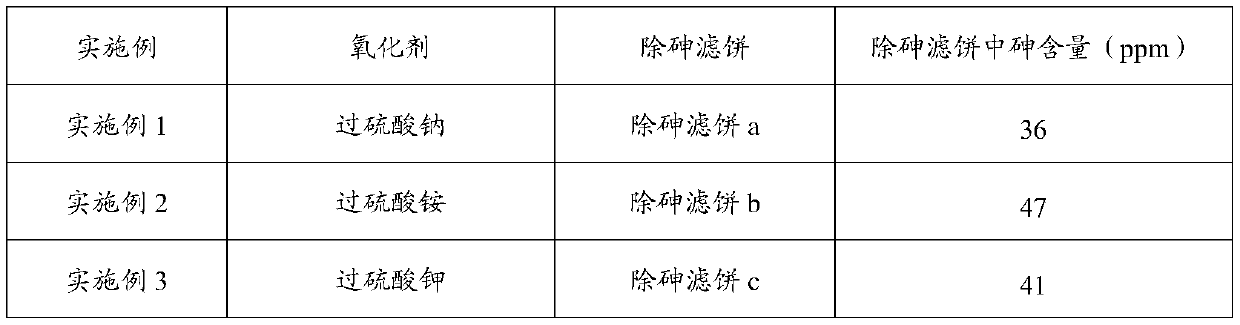

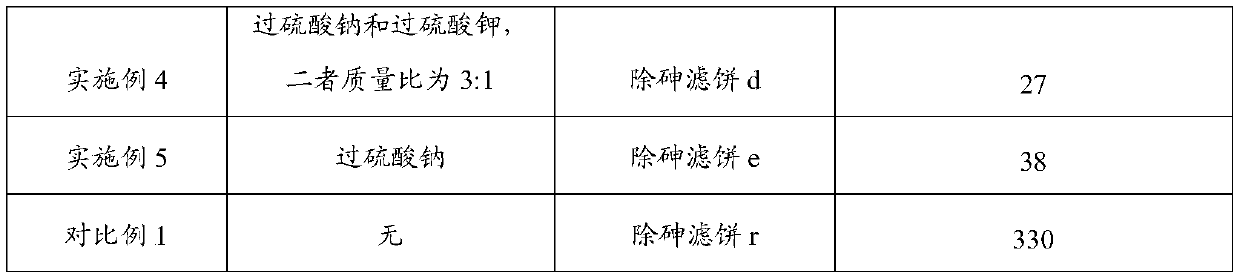

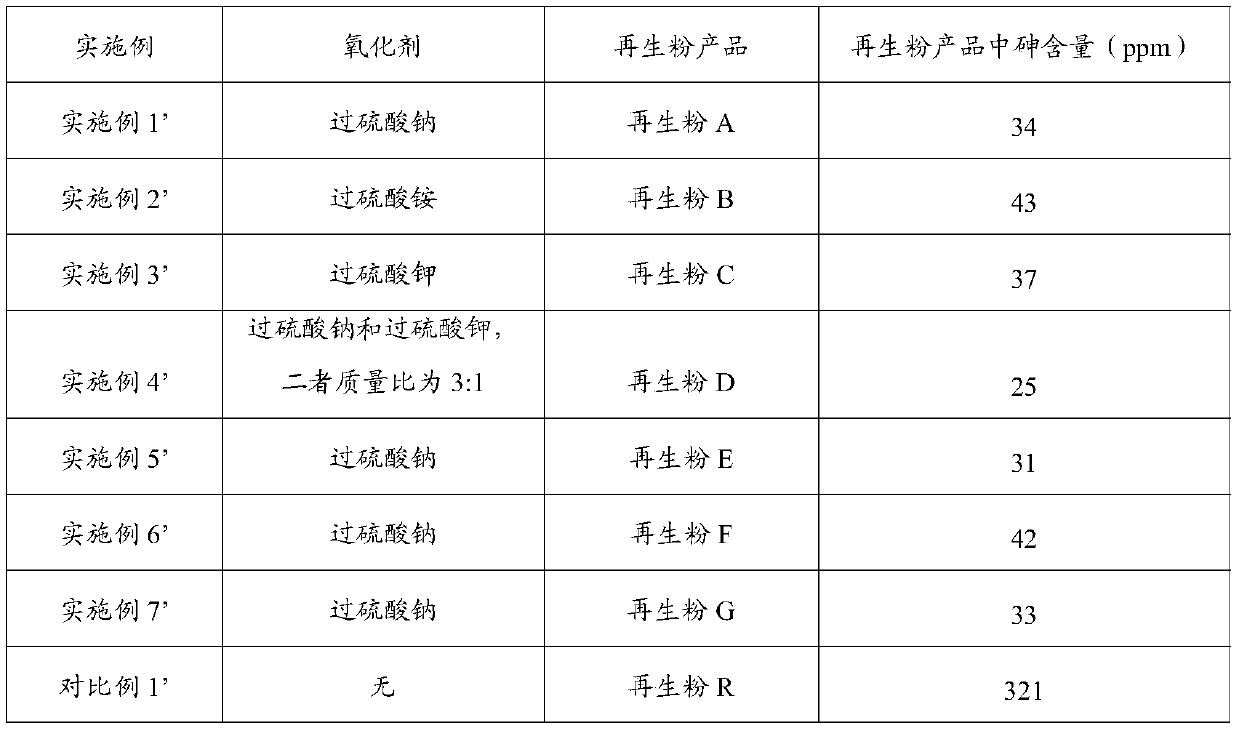

Arsenic removal method of waste SCR denitration catalyst and preparation method of regenerated powder of waste SCR denitration catalyst

PendingCN111054451AReduce arsenic levelsGood arsenic removal effectCatalyst regeneration/reactivationProcess efficiency improvementWet grindingCatalyst regeneration

The invention provides an arsenic removal method in the regeneration process of an SCR denitration catalyst, wherein the method comprises the following steps: (1) pretreatment: sequentially carrying out cleaning, crushing and wet grinding treatment on a waste SCR denitration catalyst to obtain slurry; (2) oxidation treatment: adding an oxidant solution into the slurry, and carrying out oxidation reaction to obtain oxidized slurry; (3) alkaline leaching treatment: adding a strong alkaline solution into the oxidized slurry, and carrying out alkaline leaching reaction to obtain alkaline-leached slurry; and (4) filtering and cleaning: sequentially filtering and cleaning the alkaline leached slurry to obtain an arsenic removal filter cake. The arsenic removal method is obvious in arsenic removal effect, low in energy consumption, simple to operate and low in operation cost. The invention further provides a preparation method of SCR denitration catalyst regenerated powder. The preparation method comprises the arsenic removal method. According to the preparation method, arsenic in the waste SCR denitration catalyst can be well removed, so that the arsenic content in the prepared SCR denitration catalyst regenerated powder meets the requirement.

Owner:中节能生态环境科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com