Method for removing arsenic from lead anode mud

A lead anode slime and removal technology, which is applied in chemical instruments and methods, arsenic compounds, and process efficiency improvement, can solve the problems of low production cost, large arsenic-containing wastewater, etc. Harmful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

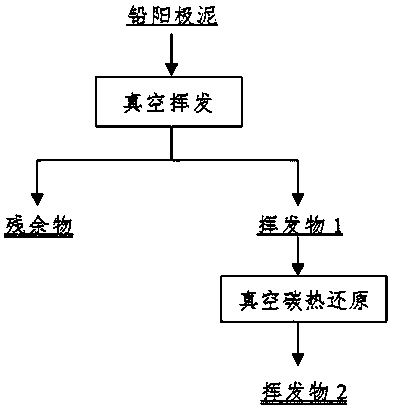

Image

Examples

Embodiment 1

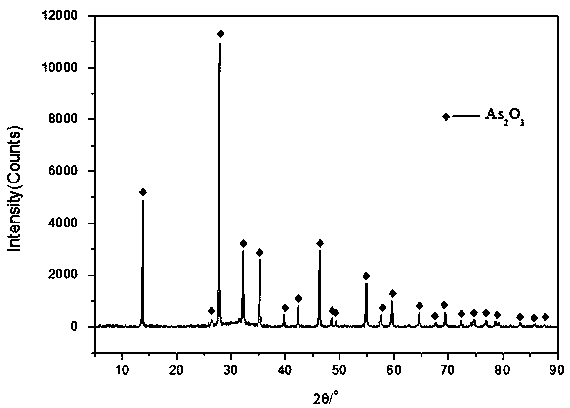

[0016] Take 200g of lead anode slime and put it into an electric blast drying oven, dry it at 105°C for 5 hours, and the weight loss is 25.05%; take 30g of dried lead anode slime and grind it evenly, put it into a crucible, and put it into a tubular resistance furnace; vacuumize , when the pressure in the furnace is stabilized at 5Pa, control the resistance furnace to heat up to 600°C at a heating rate of 17°C / min, and keep it warm for 3 hours. During the heat preservation process, the pressure in the reactor fluctuates within the range of 1-500Pa; product and condensate, the obtained residue contains 3.83% arsenic, the arsenic removal rate is 98.04%, and the condensate is diarsenic trioxide (such as figure 2 shown), the direct recovery rate of silver and copper is >99%, the direct recovery rate of antimony is 55.66%, and the direct recovery rate of lead is 98.22%.

Embodiment 2

[0018] Take 500g of lead anode slime and put it into an electric blast drying oven, dry it at 120°C for 20 hours, and the weight loss is 28.18%; take 30g of dried lead anode slime and grind it evenly, put it into a crucible, and put it into a tubular resistance furnace; vacuumize , when the pressure in the furnace is stabilized at 10000Pa, control the resistance furnace to raise the temperature to 800℃ at 22℃ / min, and keep it warm for 2h. , the obtained residue contains 8.16% arsenic, and the arsenic removal rate is 91.81%. 91.21%.

Embodiment 3

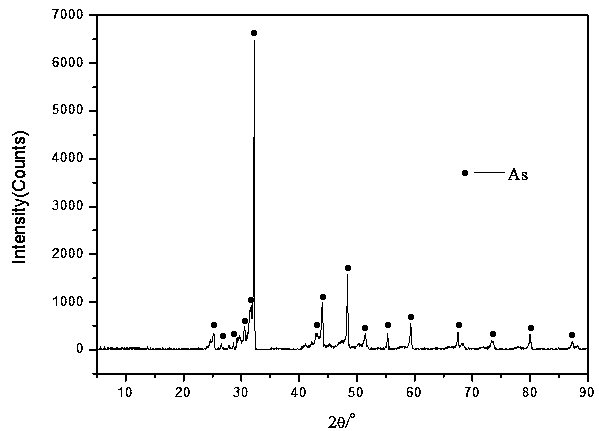

[0020] Put 500g of lead anode slime into an electric blast drying oven, dry at 150°C for 10h, and lose 27.43% of its weight; take 30g of dried lead anode slime and grind it evenly, put it into a crucible, place a wood carbon layer on the upper 8cm of the crucible, and put Put it into a tubular resistance furnace; pump vacuum, and when the pressure in the furnace is stable at 100Pa, control the temperature of the resistance furnace to rise to 700°C at 18°C / min and keep it warm for 4 hours. During the heat preservation process, the pressure in the reactor fluctuates within the range of 1~500Pa; After the reaction, the residue and condensate were collected, and the residue contained 8.52% arsenic, and the arsenic removal rate was 92.80%. The condensate was mainly elemental arsenic (such as image 3 shown), the direct recovery rate of copper and silver is >99%, the direct recovery rate of antimony is 57.86%, and the direct recovery rate of lead is 93.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com