Method for efficiently cleaning and removing arsenic in copper-containing slag

A copper slag, high-efficiency technology, applied in the field of high-efficiency cleaning and arsenic removal, can solve the problems of complex process flow of iron salt method, easy introduction of other impurities, difficult solid-liquid separation, etc. Arsenic works well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

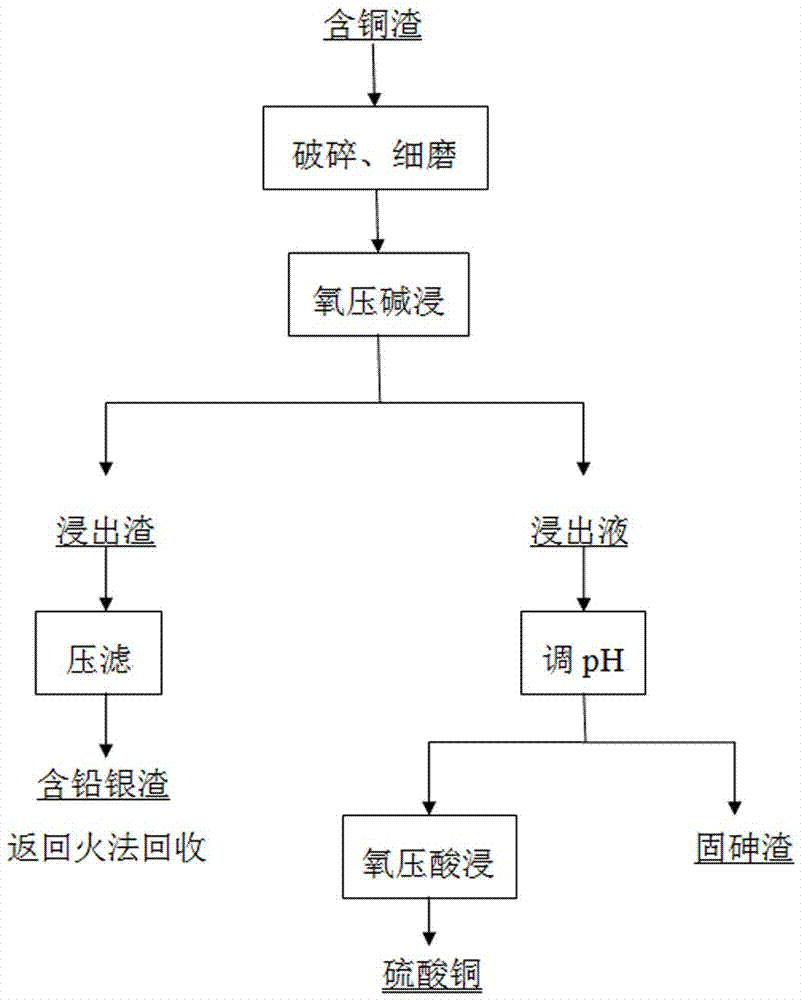

Image

Examples

Embodiment 1

[0034] The copper-containing slag is crushed and finely ground to obtain copper-containing slag powder, and then according to the liquid-solid ratio of 5:1, a sodium hydroxide solution with a concentration of 30g / L is added to form a mixed material; the mixed material is added to the autoclave, and oxygen is introduced , under the conditions of controlling the oxygen pressure to 0.8MPa, the leaching temperature to 100°C, the leaching time to 1h, and the stirring speed to 200r / min, the pressurized oxidation alkaline leaching reaction was carried out. After the leaching reaction time is reached, the ore pulp after the pressurized oxidation alkali leaching is filtered to obtain the leach residue and leach solution containing lead and silver; the obtained leach residue is returned to the fire method to recover the lead, silver, antimony, etc. valence metals. Add sodium hydroxide solution to the obtained leaching solution to adjust the pH to 9, and obtain the filtrate and arsenic-f...

Embodiment 2

[0036] The copper-containing slag is crushed and finely ground to obtain copper-containing slag powder, and then according to the liquid-solid ratio of 5:1, a sodium hydroxide solution with a concentration of 25g / L is added to form a mixed material; the mixed material is added to the autoclave, and oxygen is introduced , under the conditions of controlling the oxygen pressure to 1.0MPa, the leaching temperature to 80°C, the leaching time to 1h, and the stirring speed to 400r / min, the pressurized oxidation alkaline leaching reaction was carried out. After the leaching reaction time is reached, the ore pulp after the pressurized oxidation alkali leaching is filtered to obtain the leach residue and leach solution containing lead and silver; the obtained leach residue is returned to the fire method to recover the lead, silver, antimony, etc. valence metals. Add sodium hydroxide solution to the obtained leachate to adjust the pH to 9, and obtain the filtrate and arsenic-fixed slag ...

Embodiment 3

[0038] The copper-containing slag is crushed and finely ground to obtain copper-containing slag powder, and then according to the liquid-solid ratio of 5:1, a sodium hydroxide solution with a concentration of 40g / L is added to form a mixed material; the mixed material is added to the autoclave, and oxygen is introduced , under the conditions of controlling the oxygen pressure to 1.0MPa, the leaching temperature to 100°C, the leaching time to 2h, and the stirring speed to 600r / min, the pressurized oxidation alkaline leaching reaction was carried out. After the leaching reaction time is reached, the ore pulp after the pressurized oxidation alkali leaching is filtered to obtain the leach residue and leach solution containing lead and silver; the obtained leach residue is returned to the fire method to recover the lead, silver, antimony, etc. valence metals. Add sodium hydroxide solution to the obtained leachate to adjust the pH to 9, and obtain the filtrate and arsenic-fixed slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com