Preparation of iron-managanese compounded oxide/diatomite adsorbant, its using and regenerating method

A composite oxide, diatomite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of small arsenic adsorption capacity, high cost, and restricting the popularization and application of arsenic removal adsorption materials. , to achieve the effect of fast adsorption speed, low cost and excellent water purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

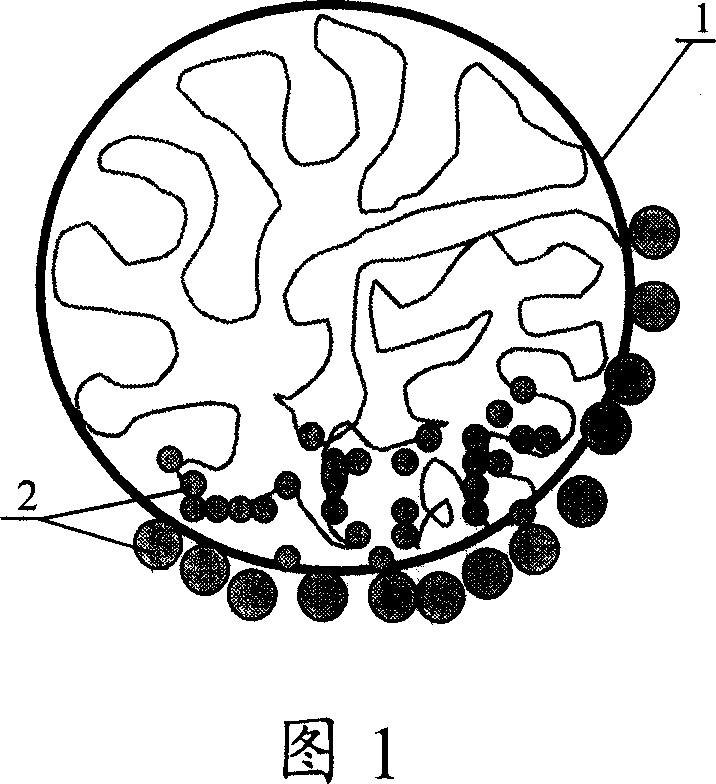

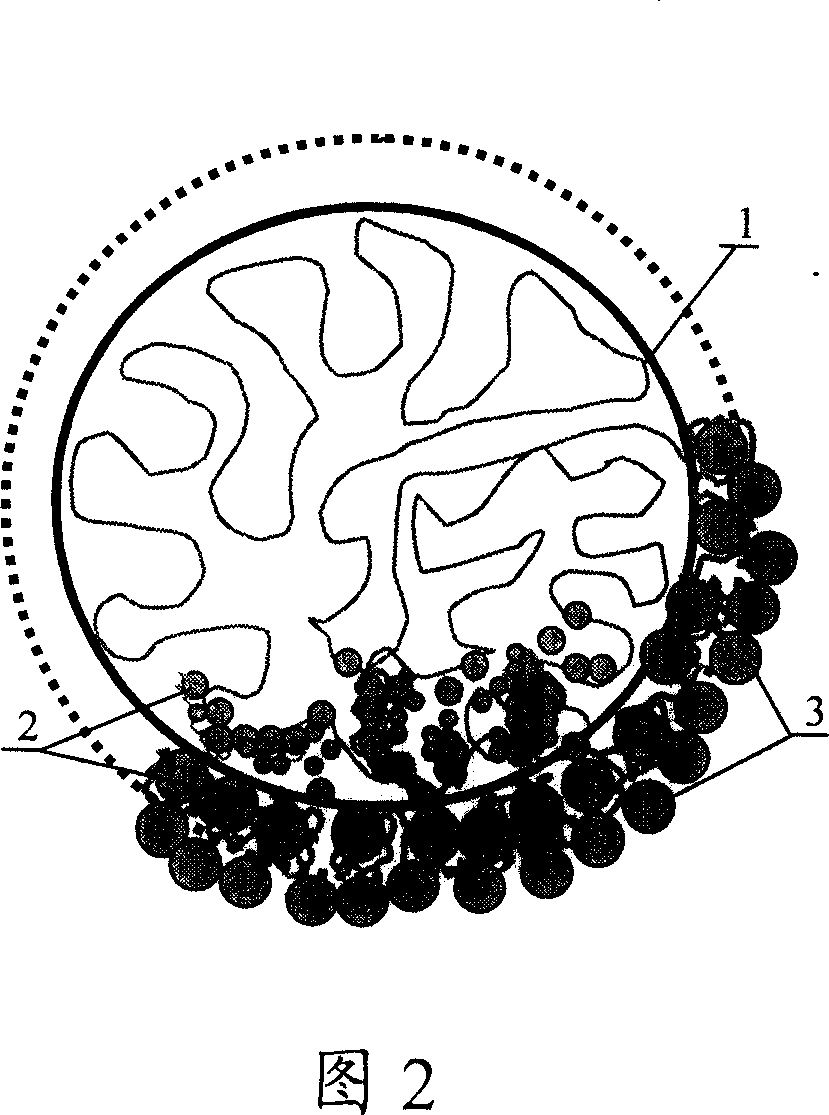

[0023] Embodiment 1 Preparation of iron-manganese composite oxide / diatomaceous earth adsorbent: weigh 1.248g FeSO 4 7H2O and 0.237g KMnO 4 , were dissolved in 60ml of water. Add 2.4ml 1mol / LNaOH solution in potassium permanganate solution, then add ferrous sulfate solution, stir 60g diatomite (BET 3m 2 / g, 65 mesh or more) was added to the mixture, continued to stir for 30 minutes, then stood still and aged at room temperature for 16 hours. After aging, skim off the supernatant, then add a small amount of dilute sodium hydroxide solution to neutralize to neutrality, then add 200ml deionized water, stir and wash for 10 minutes, filter for solid-liquid separation, and continue to add solid adsorbent Wash with deionized water for 3-4 times, separate the adsorbent, put it in an oven and bake it at 50-55°C for 2 hours, raise the temperature to 105°C and keep it for 8 hours to obtain the iron-manganese composite oxide / diatomite Adsorbent.

Embodiment 2

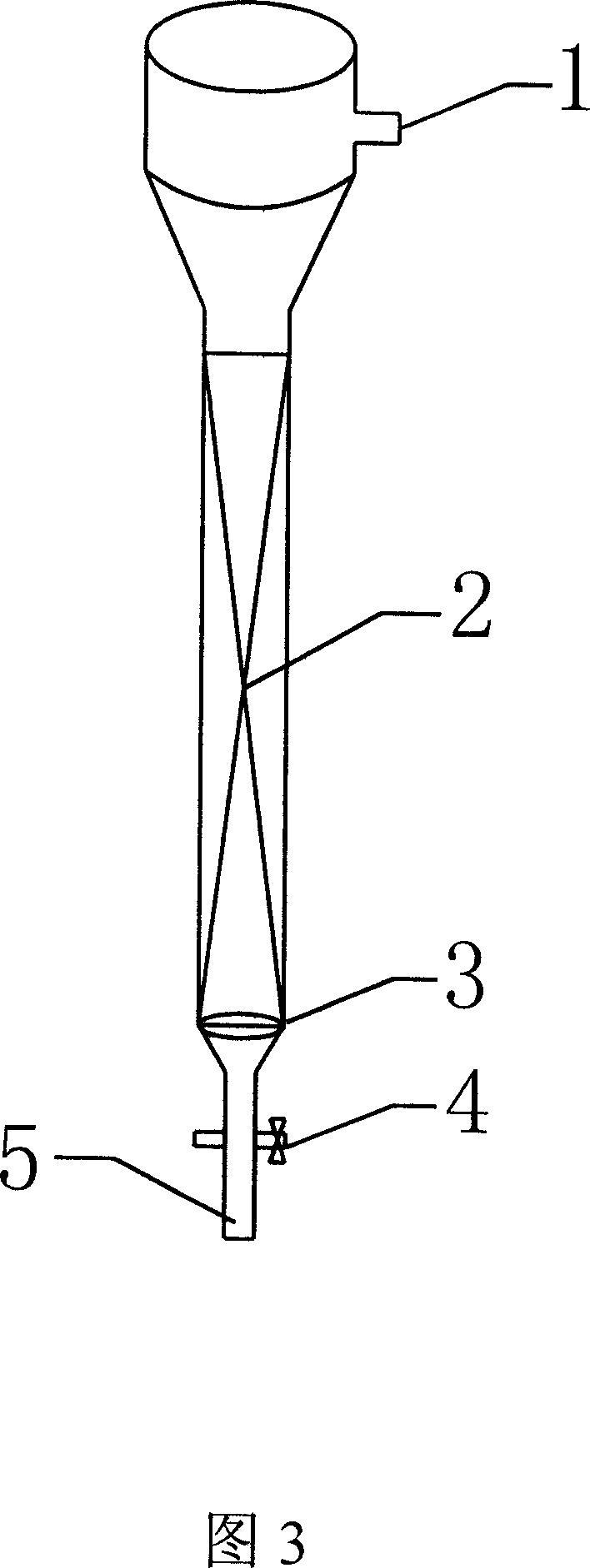

[0024] Example 2 Application of iron-manganese composite oxide / diatomite adsorbent in the treatment of arsenic-containing wastewater: the reactor used in the present invention is a glass packed column filled with prepared iron-manganese oxide / diatomite adsorbent Particles, the column height is about 0.5m, the diameter is 3.4cm, and the filling volume is 415cm 3 . A certain arsenic-containing wastewater, the concentration of trivalent arsenic As(III) is 1 mg / l, and the pH is 6.7. Water is fed from the bottom of the packed column, and water is discharged from the upper end, with a flow rate of 40ml / min, and the concentration of arsenic in the discharged water is regularly measured. After flowing through 170 times the filling volume, the concentration of arsenic in the effluent was higher than 10 μg / l.

Embodiment 3

[0025] Example 3 In-situ regeneration of iron manganese oxide / diatomite adsorbent: When the concentration of arsenic in the effluent water of the packed column is higher than the water quality requirement, stop the water inflow, and after emptying the water in the column, slowly pump the arsenic from the bottom of the packed column. 100ml 0.03mol / L KMnO with lye 4 solution, and then slowly add 100ml of 0.09mol / L ferrous sulfate solution from the top of the packed column at a flow rate of 1ml / min. After the addition is completed, it is statically aged for 4 hours, and then the water phase is released, and the packed column is washed with deionized water until the concentration of soluble iron and manganese ions in the effluent is lower than the water quality requirement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com