Electrochemical enhanced sand filter tank arsenic removal method

A sand filter tank, electrochemical technology, applied in the field of arsenic-contaminated groundwater remediation, can solve the problems of automatic generation and removal, reduce the risk of secondary pollution, facilitate replacement, and enhance the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

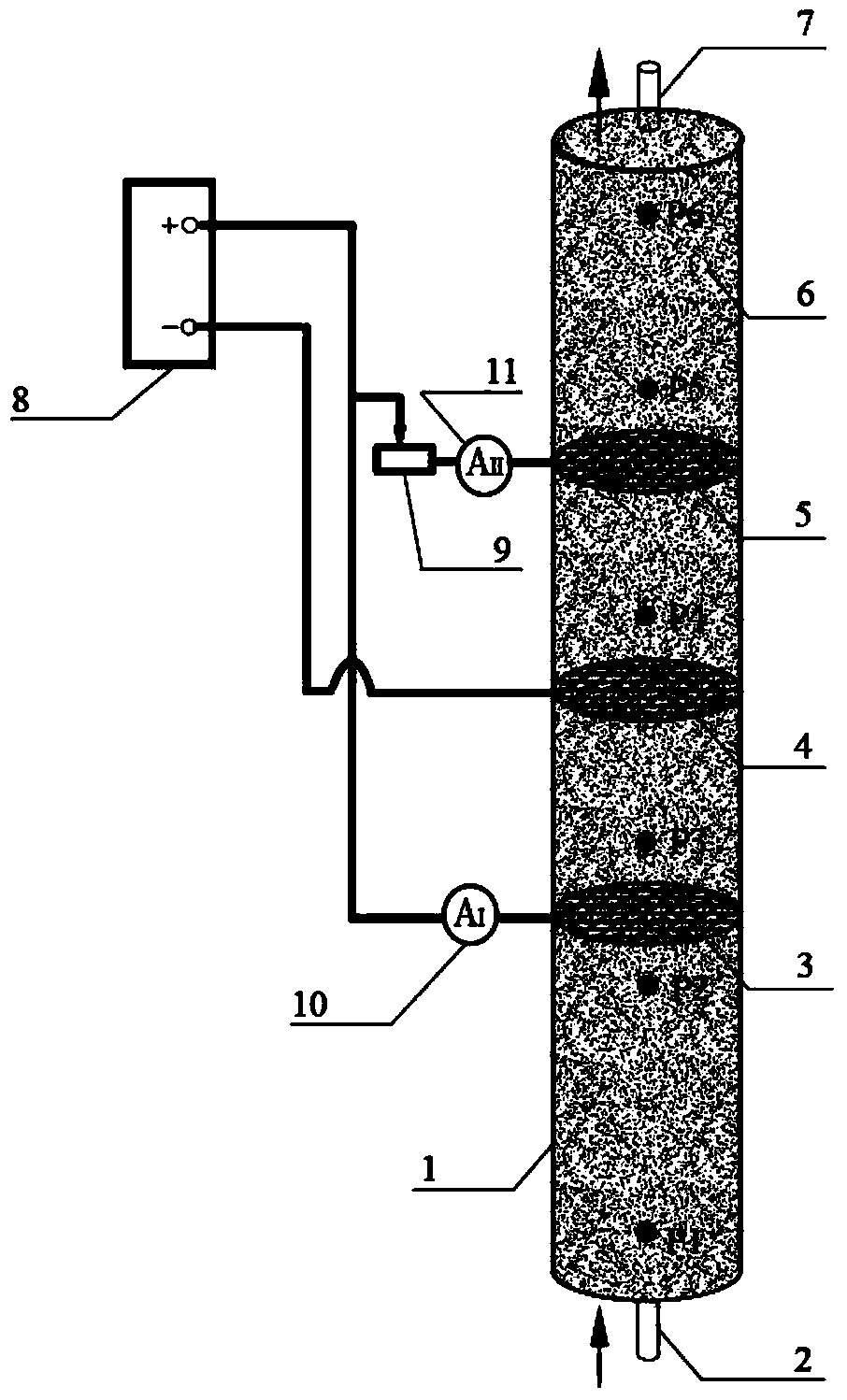

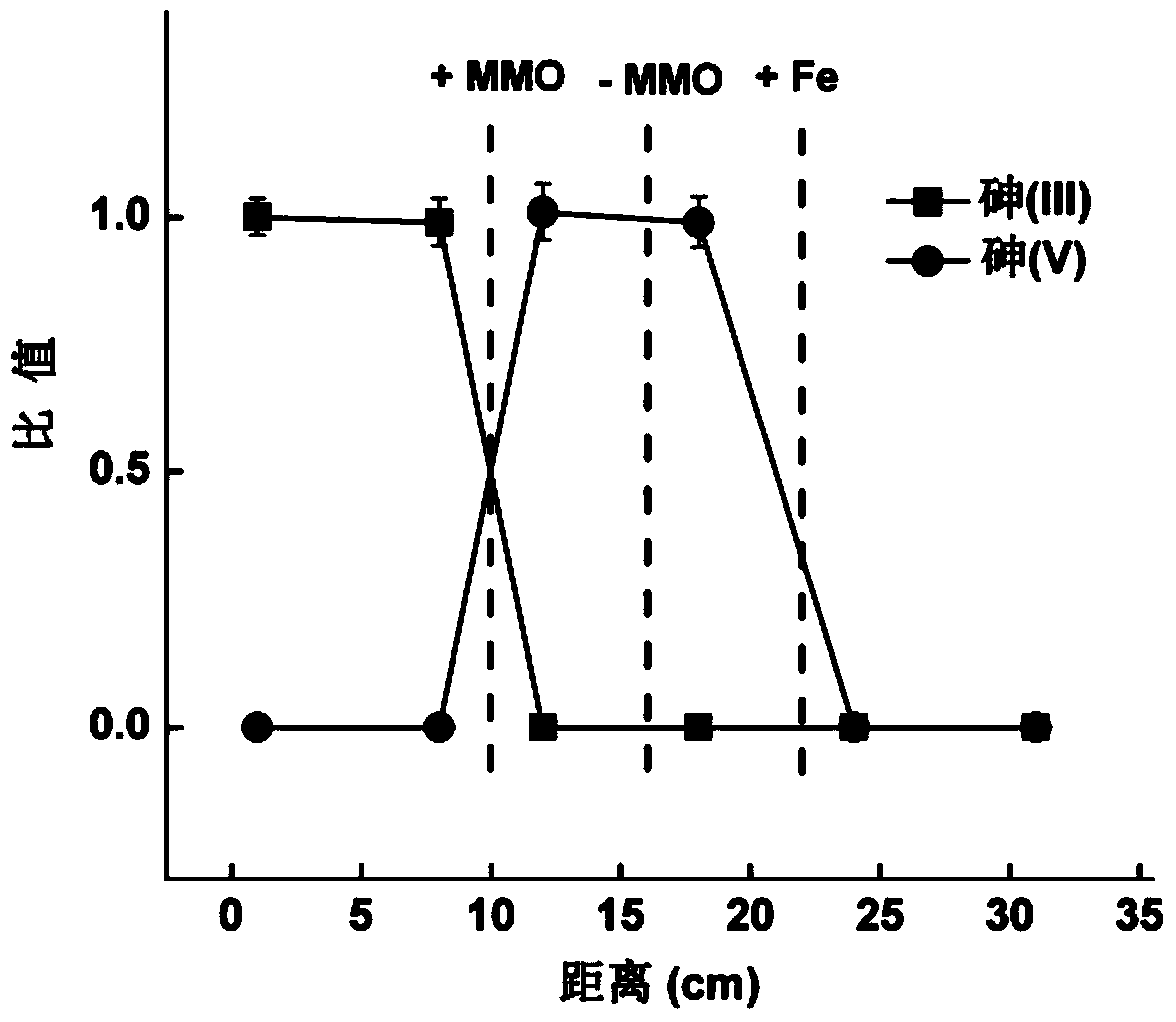

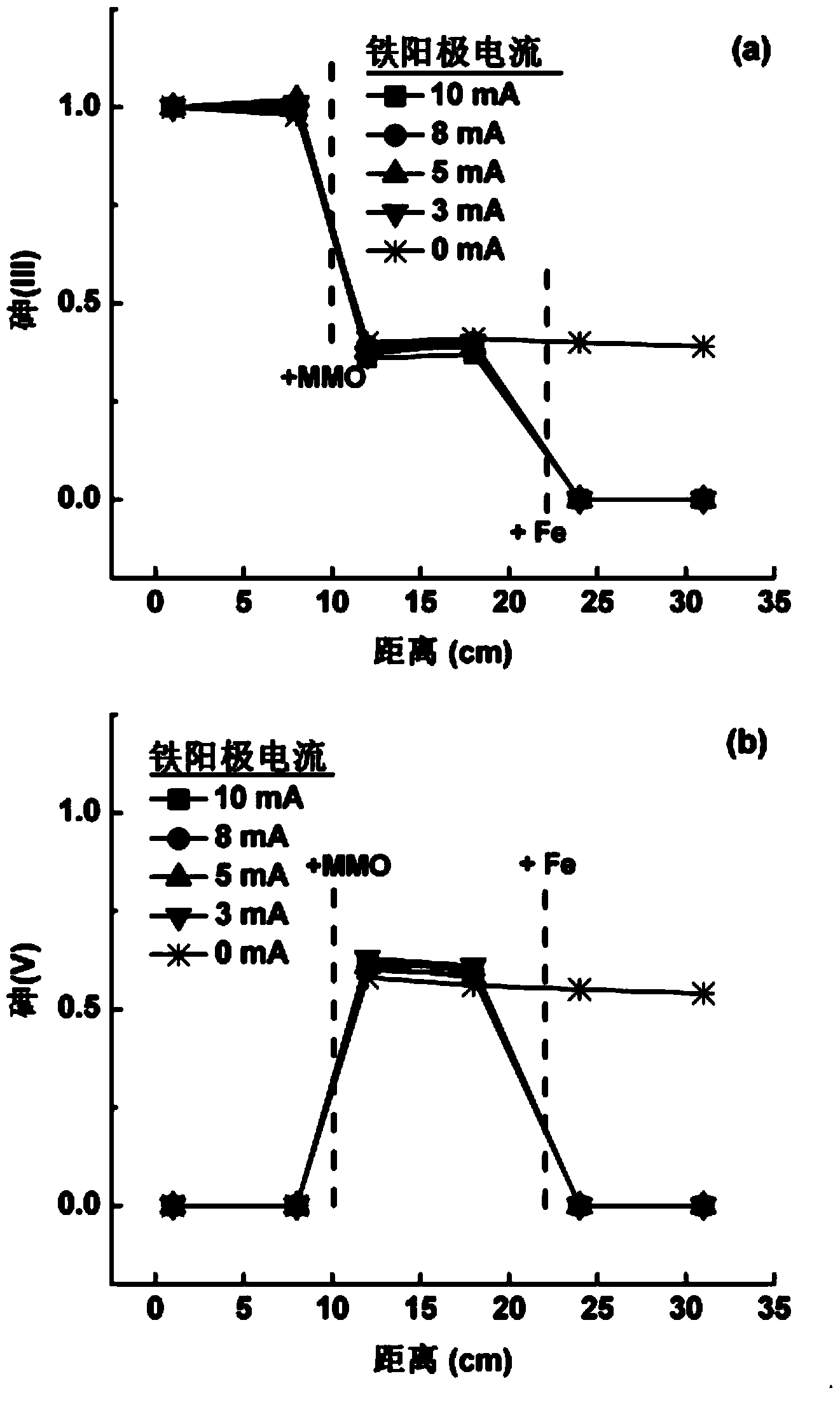

[0030] Embodiment 1: The present invention provides a method for removing arsenic by simulating an electrochemically enhanced sand filter tank in a laboratory. First, a small vertical electrochemically enhanced sand filter tank device is constructed in the laboratory. Its structure is as follows figure 1 As shown, the sand filter tank 1 is made into a cylinder with an inner diameter of 5 cm and a height of 32 cm. The sand filter tank 1 is provided with a water inlet 2 and a purified water outlet 7. The inner wall of the sand filter tank 1 is equipped with negative and positive electrodes. The remaining space is filled with quartz sand filter material 6, and sampling holes P1 to P6 are set in the wall of the sand filter tank 1, so as to sample and detect the concentration of arsenic (III) and arsenic (V) in the water at 6 water levels in the sand filter tank; Set DC power supply 8, rheostat 9, ammeter I 10, ammeter II 11 and replace water pump 12 with a peristaltic pump outside ...

Embodiment 2

[0039] Embodiment 2: The present invention provides a method for removing arsenic from electrochemically enhanced sand filter tanks. This method needs to build an electrochemically enhanced arsenic removal device from sand filter tanks. The device in this embodiment is suitable for home use. Its structure is as follows: Figure 5 As shown, the device includes a sand filter tank 1 with an inner diameter of 30 cm and a height of 100 cm. The sand filter tank 1 is provided with a water inlet 2 and a purified water outlet 7. The inner wall of the sand filter tank 1 is equipped with electrodes, and the remaining space in the sand filter tank 1 is Fill the quartz sand filter material 6 with a particle size of 0.5-1 cm, the total volume of the sand filter tank 1 and the void volume (PV) between the quartz sand are 70L and 35L respectively, and the porosity is 0.5. Set DC power supply 8, rheostat 9, ammeter 10, ammeter 11 and water pump 12 outside the sand filter tank 1; then operate as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com