Method for removing arsenic from copper ore

A technology for copper ore and arsenic copper ore, which is applied to the improvement of process efficiency, flotation, solid separation, etc., can solve the problems of poor dearsenic effect of copper ore, and achieve good arsenic removal effect, strong inhibitory effect, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

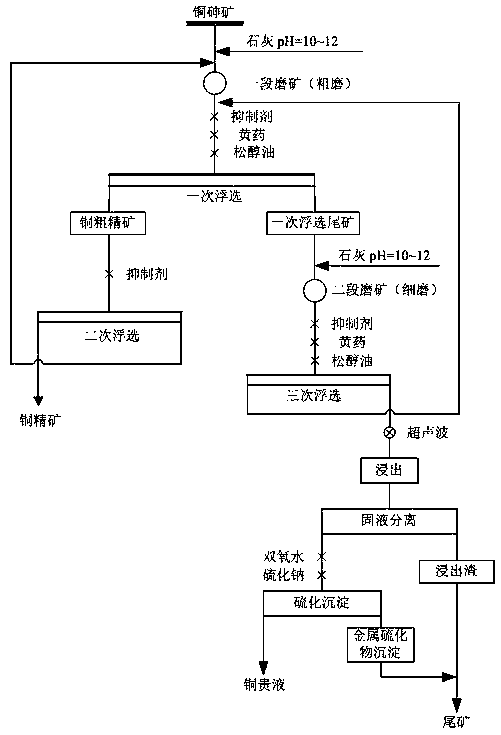

[0024] Such as figure 1 As shown, the Cu grade of a copper mine in Yunnan is 0.68%, and the As grade is 4.80%. The specific steps are as follows:

[0025] (1) Roughly grind arsenic-containing copper ore to a fineness of -0.074mm, accounting for 50%. When grinding, add lime to make the slurry pH=10. After the first flotation of the slurry, the crude copper concentrate and the first flotation tail are obtained. Mine, flotation agents and their order of addition are inhibitors (10% ammonium chloride, 10% aluminum sulfate, 80% sodium thiosulfate) 300g / t, xanthate 10g / t and pinitol oil 15g / t, The slurry concentration is 20%;

[0026] (2) After the second flotation of the copper coarse concentrate, the copper concentrate and the second flotation tailings are obtained respectively, and the second flotation tailings are returned to the coarse grinding operation, and the flotation inhibitor (chlorinated Ammonium 10%, aluminum sulfate 10%, sodium thiosulfate 80%) dosage is 250g / t, flotatio...

Embodiment 2

[0031] Such as figure 1 As shown, the Cu grade of a copper mine in Jiangxi is 2.08%, and the As grade is 6.43%. The specific steps are as follows:

[0032] (1) Roughly grind arsenic-containing copper ore to a fineness of -0.074mm, accounting for 60%. When grinding, add lime to make the slurry pH=11. After the first flotation of the slurry, the copper concentrate and the first flotation tail are obtained. Mine, flotation agents and their order of addition are inhibitors (10% ammonium chloride, 80% aluminum sulfate, 10% sodium thiosulfate) 1000g / t, xanthate 100g / t and pinitol oil 50g / t, The slurry concentration is 30%;

[0033] (2) After the second flotation of the copper coarse concentrate, the copper concentrate and the second flotation tailings are obtained respectively, and the second flotation tailings are returned to the coarse grinding operation, and the flotation inhibitor (chlorinated Ammonium 10%, aluminum sulfate 80%, sodium thiosulfate 10%) The dosage is 500g / t, and the...

Embodiment 3

[0038] Such as figure 1 As shown, the Cu grade of a copper flotation concentrate in Sichuan is 14.08% and the As grade is 2.61%. The steps are as follows:

[0039] (1) Roughly grind arsenic-containing copper ore to a fineness of -0.074mm, accounting for 70%. When grinding, add lime to make the slurry pH=12. After the first flotation of the slurry, a crude copper concentrate and a flotation tail are obtained. Mine, flotation agents and their order of addition are inhibitors (40% ammonium chloride, 30% aluminum sulfate, 30% sodium thiosulfate) 1500g / t, xanthate 150g / t and pinitol oil 75g / t, The slurry concentration is 45%;

[0040] (2) After the second flotation of the copper coarse concentrate, the copper concentrate and the second flotation tailings are obtained respectively, and the second flotation tailings are returned to the rough grinding operation, and the flotation inhibitor (chlorinated Ammonium 40%, aluminum sulfate 30%, sodium thiosulfate 30%) The dosage is 1000g / t, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com