Preparation method of supported dearsenic agent and dearsenic agent prepared by same

A supported, arsenic removal technology, applied in chemical instruments and methods, refined hydrocarbon oil, physical/chemical process catalysts, etc., can solve the problems of low arsenic removal rate, low production capacity and low production energy consumption of arsenic removers , to achieve the effect of reducing energy consumption, excellent effect and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the arsenic removal agent of the present invention can be divided into three steps: a step of preparing a solution, a step of loading an active component, and a drying step. These three steps are illustrated and described respectively below.

[0020] Preparation of solution steps

[0021] Dissolve one or more of copper sulfate, copper nitrate and copper nitrite and / or one or more of zinc sulfate, zinc nitrate and zinc nitrite in water to prepare an aqueous solution with a concentration of 5% to the saturation concentration of the solute in the solution at normal temperature and pressure.

[0022] Loading active ingredient step

[0023] The prepared solution containing the active metal salt is loaded on the carrier by impregnation or spraying. In the present invention, it is preferred to load the soluble copper salt and / or zinc salt on the carrier by equal-volume spray-dipping or equal-volume impregnation, mainly to avoid waste of active c...

Embodiment 1

[0027] Example 1 Preparation of modified arsenic removal agent C1

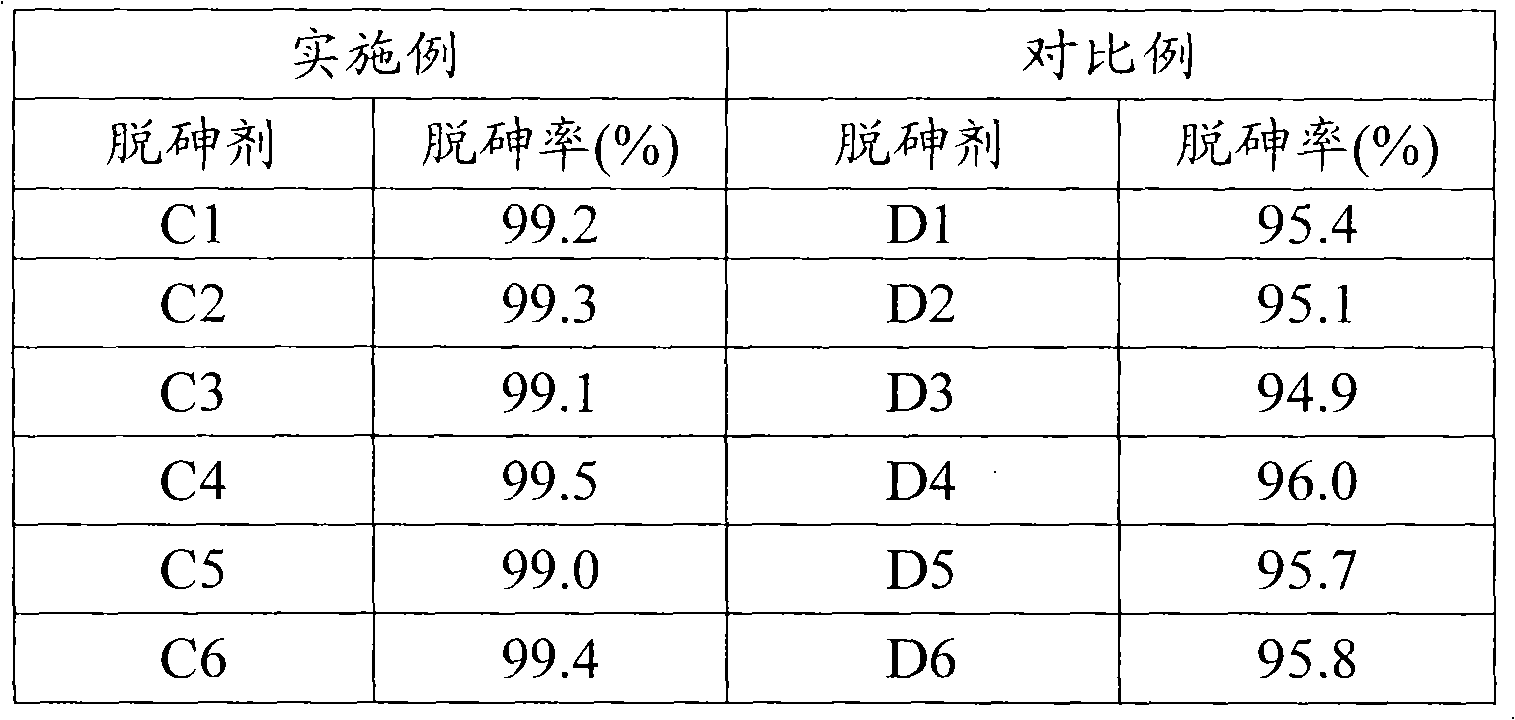

[0028] Prepare a solution of copper nitrite and copper sulfate with a concentration of 15%. Then the equal volume of the prepared solution was sprayed and impregnated onto the spherical carrier of 200g alumina. After drying at 200°C for 3 hours, the finished arsenic removal agent C1 was obtained, wherein the total content of copper nitrite and copper sulfate in C1 was 12.9 wt%. Its arsenic removal performance is shown in Table 1.

Embodiment 2

[0029] Example 2 Preparation of modified arsenic removal agent C2

[0030] Prepare a mixed solution of copper sulfate and zinc sulfate with a concentration of 13%. Then, 200 g of activated carbon and silica mixture spherical carrier were immersed in the prepared mixed solution. After drying at 50°C for 20 hours, the finished arsenic removal agent C2 was obtained, wherein the total content of copper sulfate and zinc sulfate in C2 was 12wt%. Its arsenic removal performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com