Patents

Literature

167results about How to "Improve escape rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

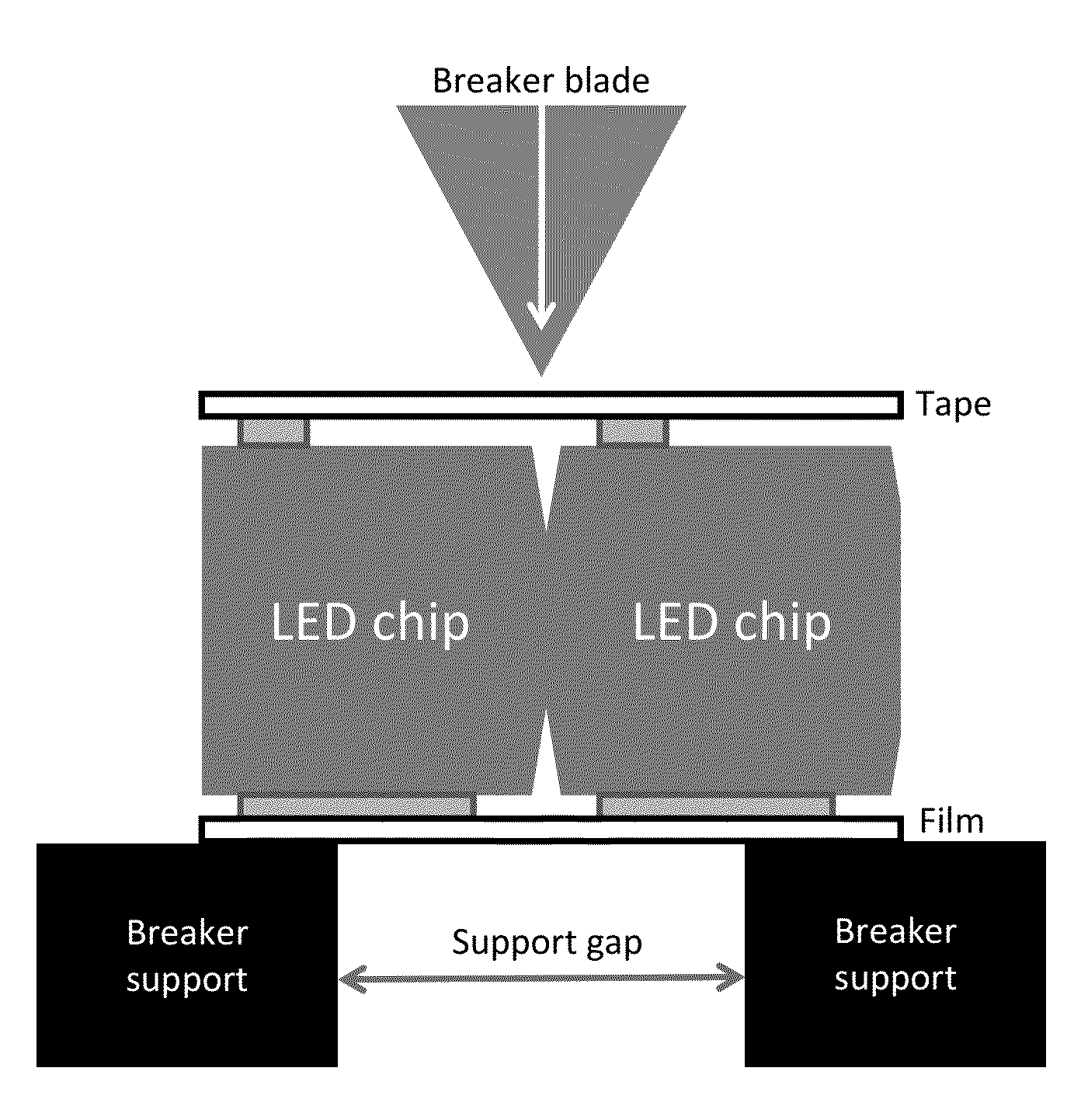

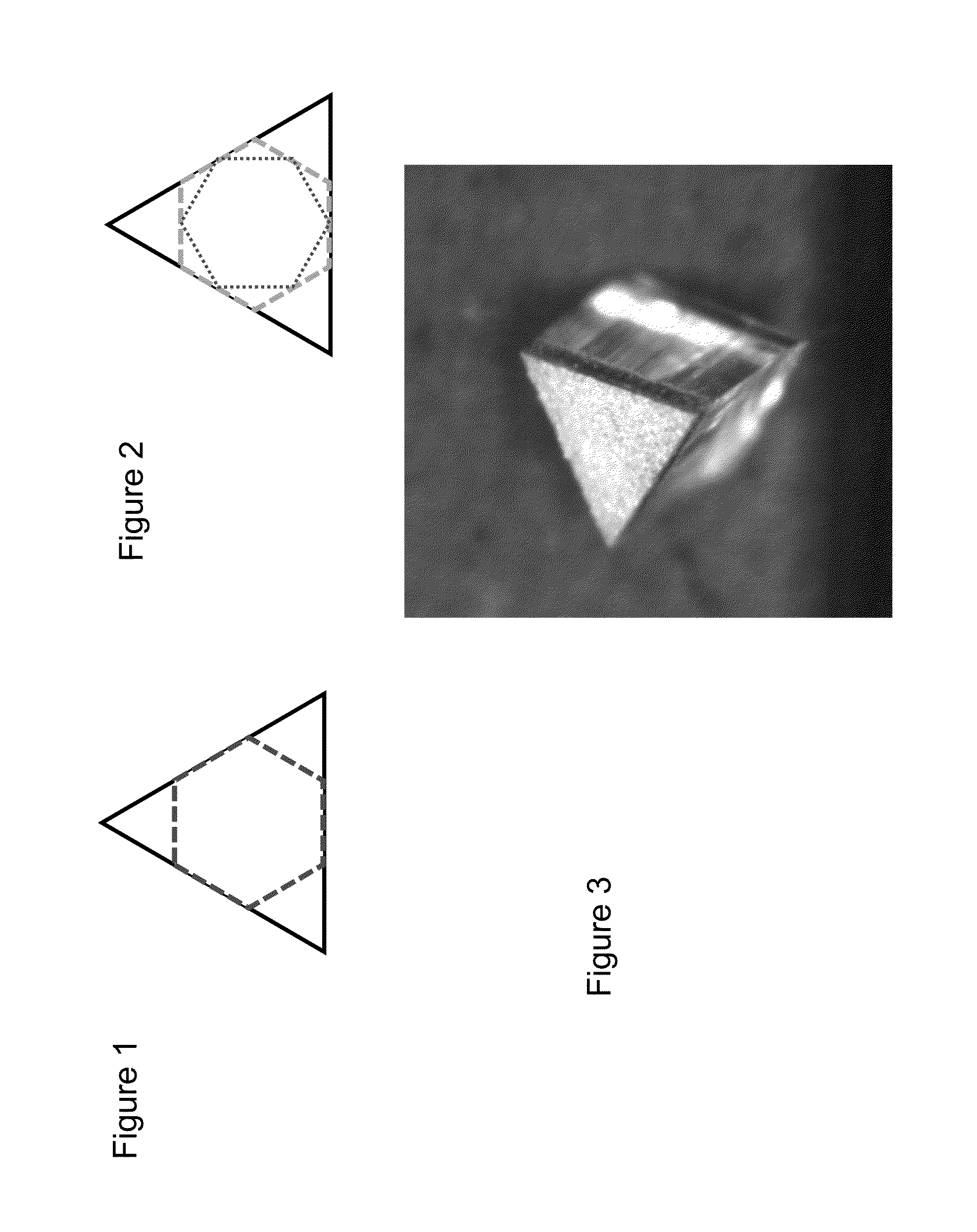

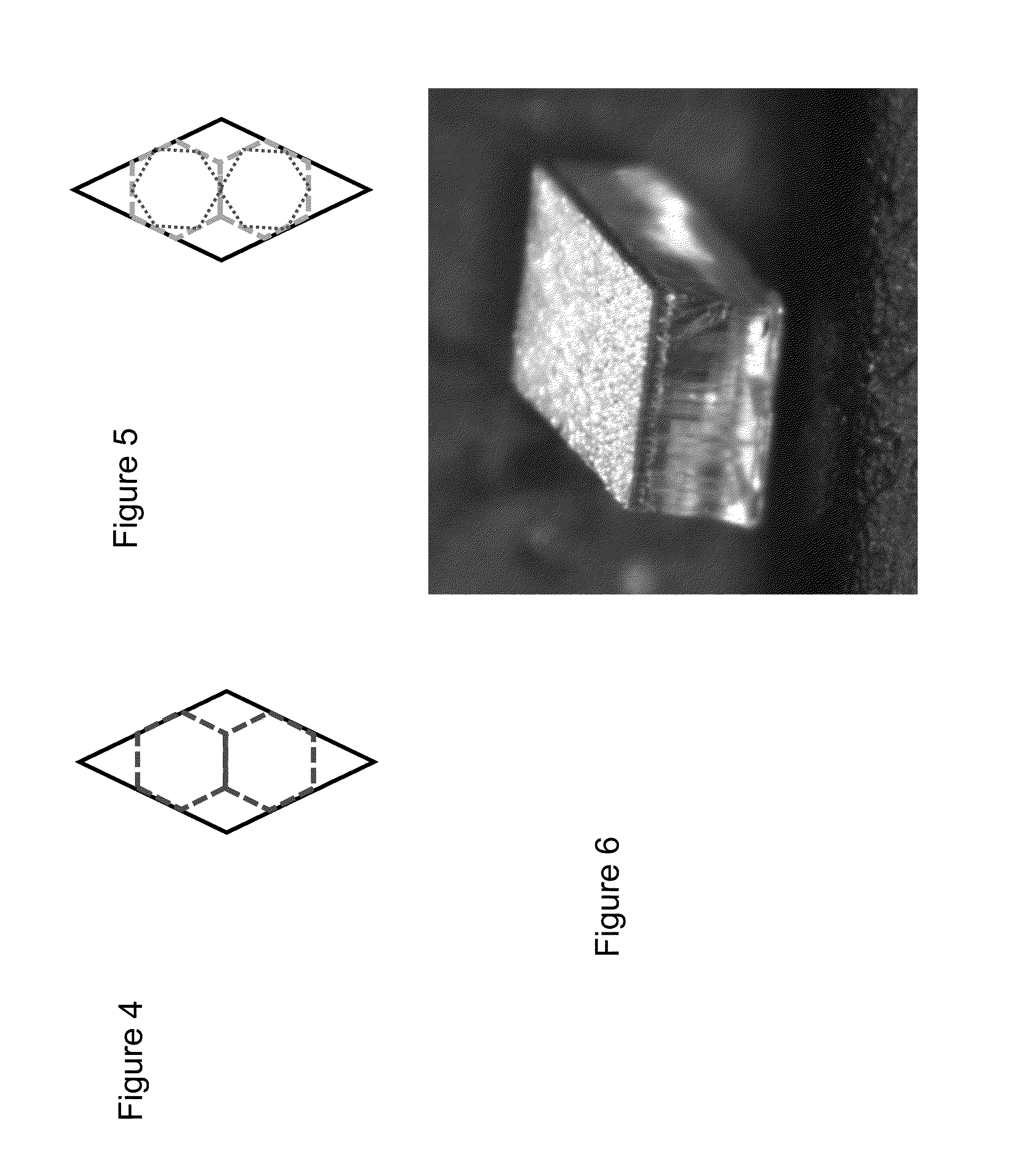

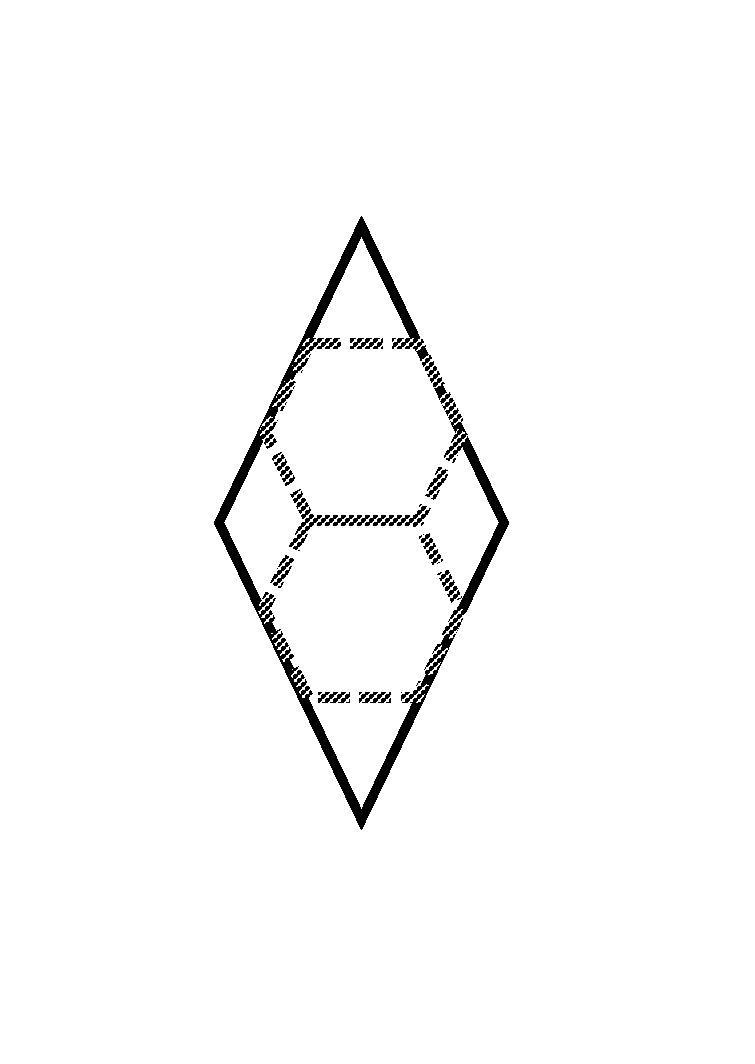

Gallium and Nitrogen Containing Triangular or Diamond-Shaped Configuration for Optical Devices

ActiveUS20130026483A1Easy to cutHigh yieldSemiconductor/solid-state device manufacturingSemiconductor devicesNitrogenOptoelectronics

Owner:KORRUS INC

Gallium and nitrogen containing triangular or diamond-shaped configuration for optical devices

ActiveUS8293551B2Easy to cutHigh yieldSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingNitrogenOptoelectronics

Owner:KORRUS INC

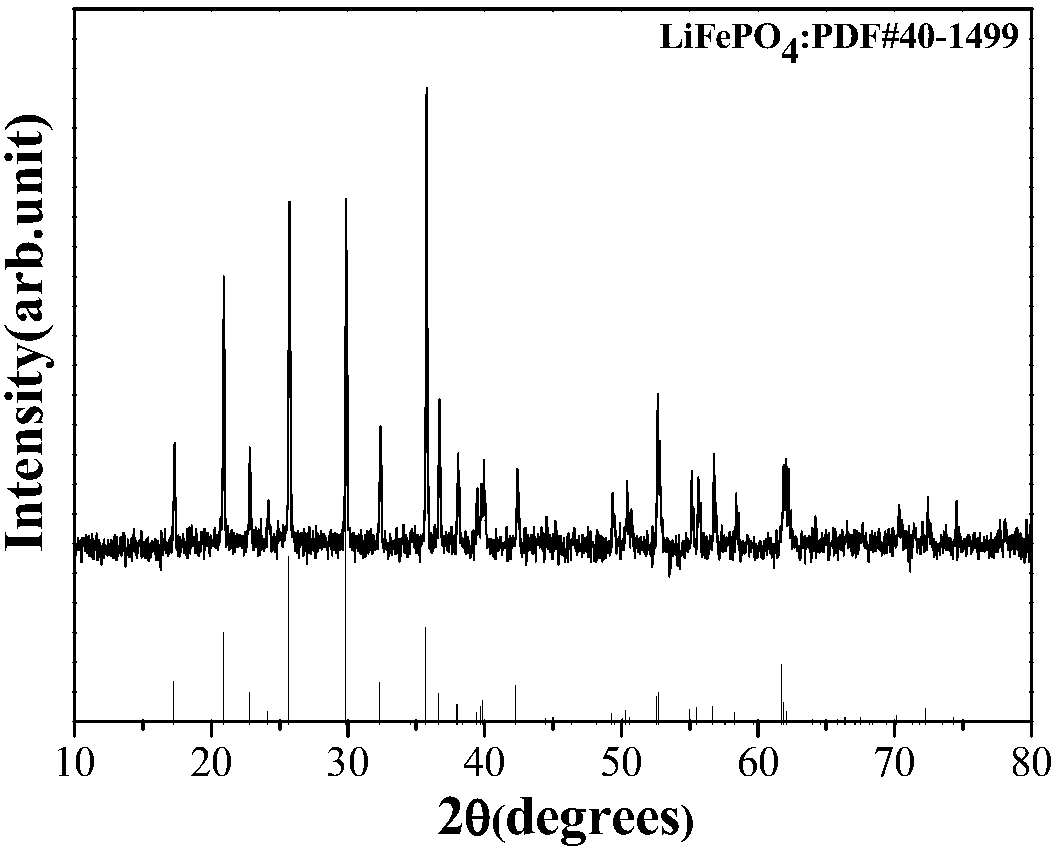

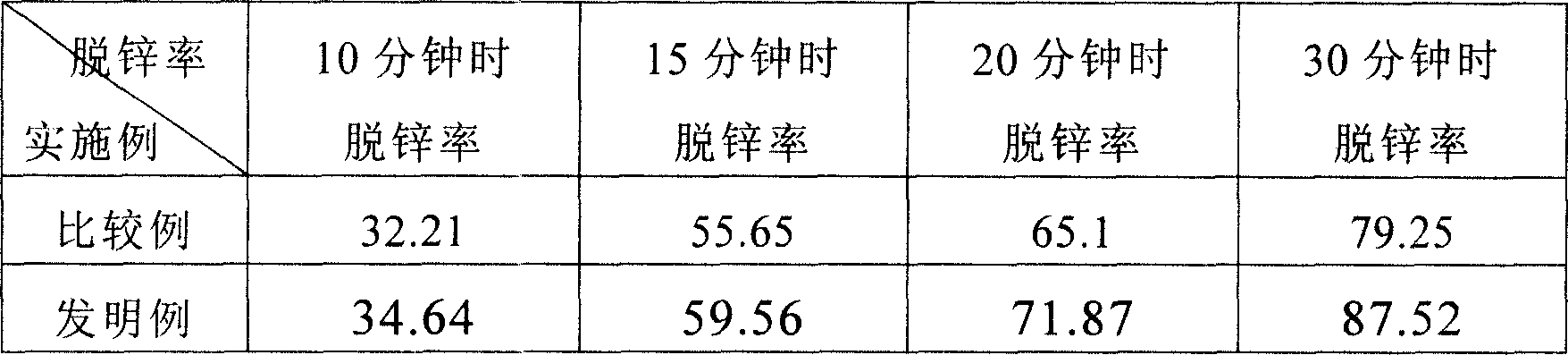

Recycling method of retired lithium iron phosphate battery positive-electrode materials

InactiveCN108417923ASimple processImprove escape rateWaste accumulators reclaimingBattery recyclingElectrolysisPhosphoric acid

The invention discloses a recycling method of retired lithium iron phosphate battery positive-electrode materials. The method includes the steps: soaking and dissolving binding agents in an N-methylpyrrolidone solvent by the aid of the N-methylpyrrolidone solvent to strip LiFePO4 positive-electrode materials and aluminum foil fluid collectors; mixing the stripped waste LiFePO4 positive-electrode materials and binding agents; coating a carbon fabric or titanium mesh with mixture of the waste LiFePO4 positive-electrode materials and the binding agents to serve as a positive electrode; taking a graphite electrode as a negative electrode; building an electrolytic tank in electrolyte solution; driving lithium removal by the aid of a direct-current electric field to collectively recycle lithiumions and lithium removal product iron phosphate. According to the method, lithium removal is driven and adjusted by the direct-current electric field, lithium can be basically completely removed, subsequent treatment of the electrode materials after lithium removal is performed, so that treated electrode materials can be converted into the iron phosphate, and the iron phosphate can be used for preparing lithium iron phosphate positive-electrode materials and is good in electrochemical performance. The method is simple and convenient in operation process, controllable in condition, high in recycling rate and environmentally friendly, and popularization and application are facilitated.

Owner:HEFEI UNIV OF TECH

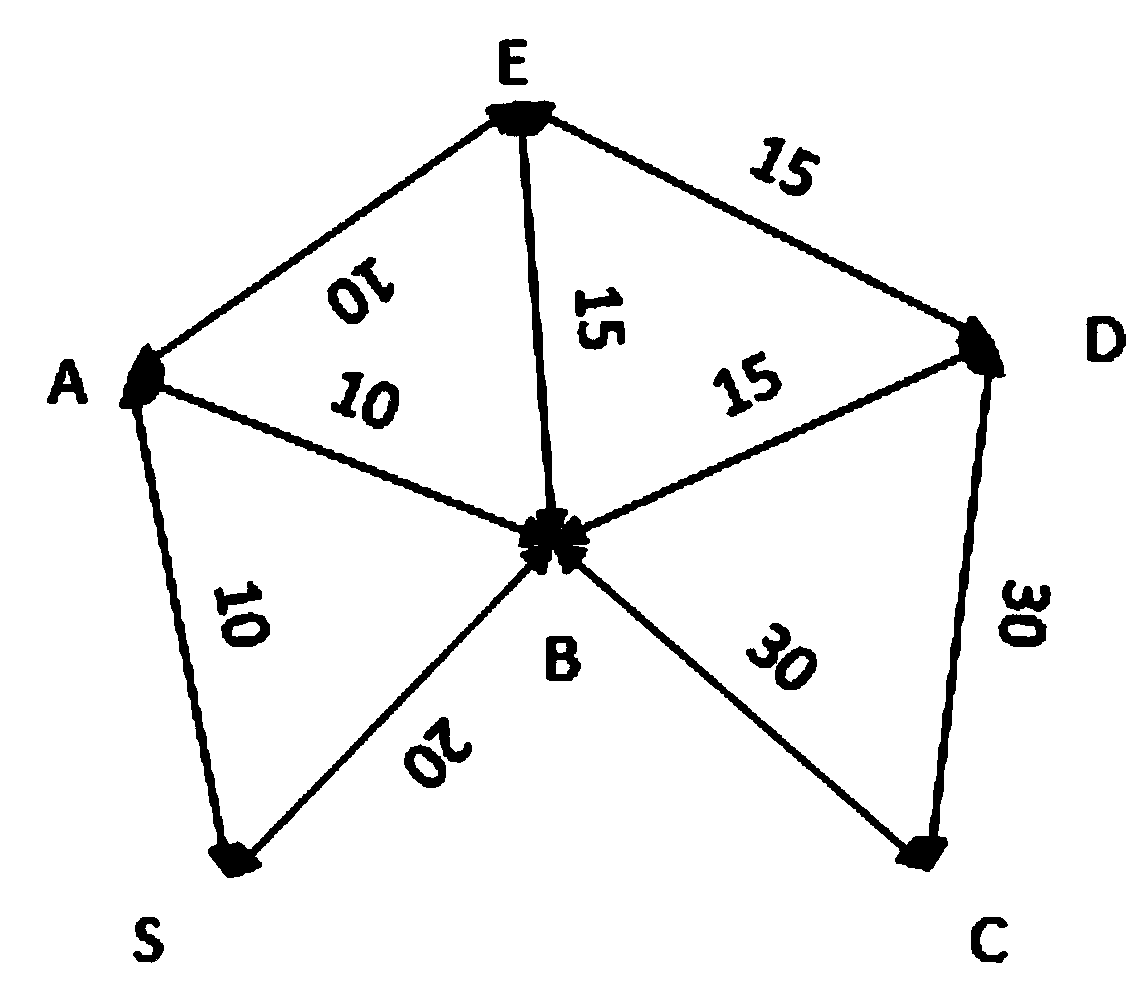

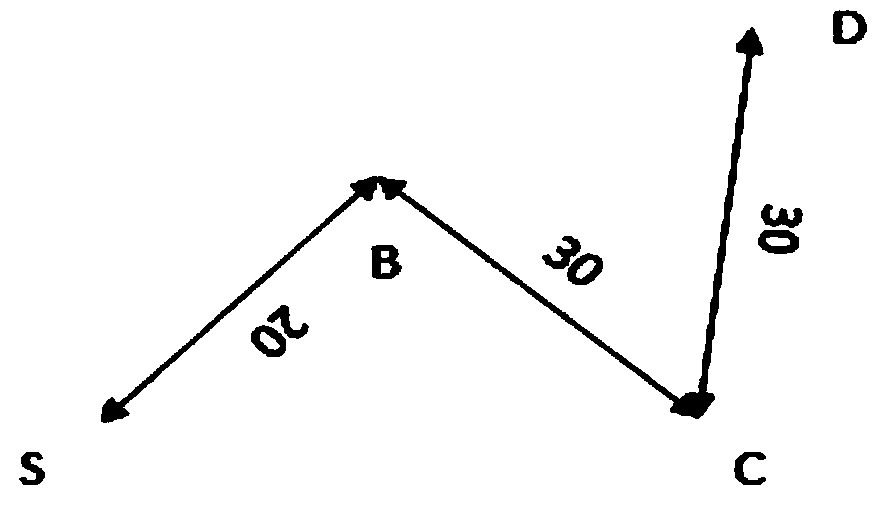

Personnel characteristic-based fire evacuation path navigation method

ActiveCN103776452AEscaped smoothlyImprove escape rateNavigational calculation instrumentsFire detectorFire evacuation

The invention discloses a personnel characteristic-based fire evacuation path navigation method which comprises the following steps: 1, obtaining fire behavior information through a fire detector, calculating an effective time range capable of being used for escape of each path; 2, reading personnel label information by using an RFID (Radio Frequency Identification) reader-writer, locating personal position information, performing personnel evacuating speed classifying according to the obtained personnel label information and the obtained personnel position information; 3, for personnel with different speeds, calculating evacuating path information by using a shortest path precedence algorithm, wherein the evacuating path information comprises a shortest path length value from an initial position to an outlet node D and all nodes on the path; and 4, sending the shortest path length value and all nodes on the path to personnel to be evacuated. According to the personnel characteristic-based fire evacuation path navigation method, the utilization rate of the path can be effectively increased.

Owner:HUAZHONG UNIV OF SCI & TECH

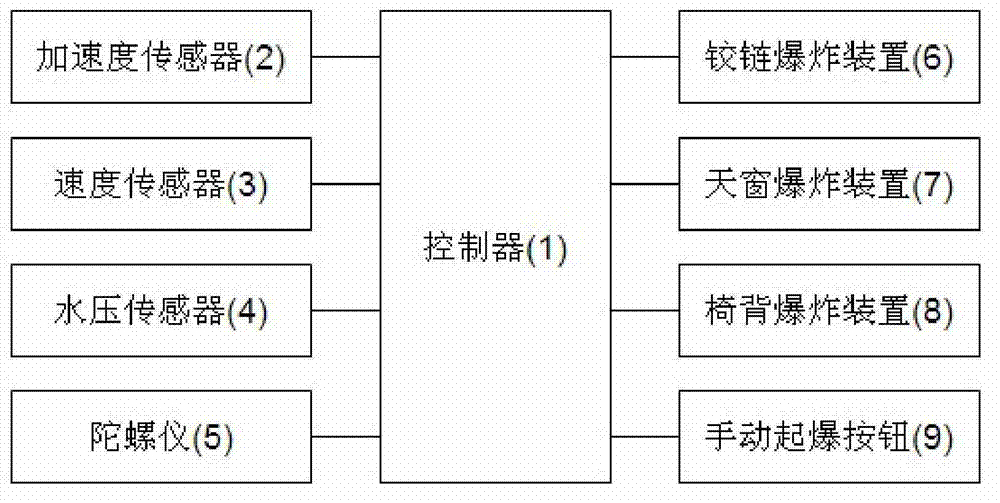

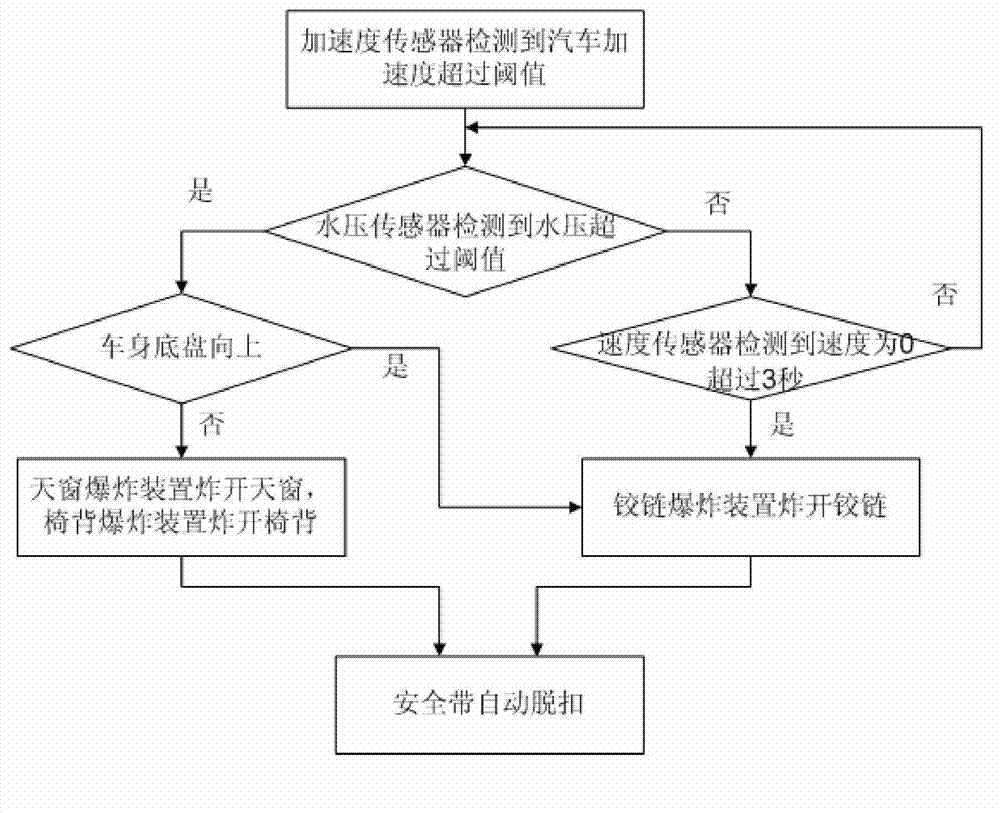

Escape way opening method and system after crash

ActiveCN103192786AImprove escape ratePedestrian/occupant safety arrangementAcceleration UnitCar door

The invention discloses an escape way opening method and an escape way opening system after crash. The system comprises a controller as well as an acceleration sensor, a speed sensor and a hinge explosion device which are respectively connected with the controller, wherein the acceleration sensor is a triaxial acceleration sensor; and the hinge explosion device is arranged at the automobile door hinge. The controller judges whether crash happens or not through the acceleration sensor, and judges whether the automobile body is static or not through the speed sensor if the crash happens, and the automobile door hinge can be exploded through the hinge explosion device and the automobile doors can be pushed away from the automobile body through the force of explosion if the automobile body is static, so that personnel inside the automobile can escape. The escape way opening method and the escape way opening system can be suitable for all automobiles.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

Novel technology for recycling fluorinated surfactant in water

ActiveCN106000355AReduce consumptionIncrease added valueOther chemical processesWater contaminantsPolyethylene glycolPolymer

The invention relates to the technical field of water treatment, in particular to a novel technology for recycling a fluorinated surfactant in water. The technology comprises the steps that firstly, ferromagnetic particles are synthesized or selected, then, the surface of a magnetic material is coated with an inert material layer, and then, the surface of the magnetic material is coated with a large number of reaction species; then, polyethylene glycol and fluorocarbon with the tail end capable of reacting with the reaction species is added, and polyoxyethylene chains and fluorocarbon chains are linked to the surfaces of the particles; the particles with the surfaces covered with the polyoxyethylene chains and fluorocarbon chains are dispersed into raw water containing a fluorinated surfactant; when adsorption is saturated, a high magnetic field is utilized for extracting the particles from water, and therefore the fluorinated surfactant in water can be removed, and the treated clean water can be directly discharged. The novel technology has the advantages that the method is simple and reliable, energy consumption is low, the magnetic particles can be recycled, and the novel technology can be used for recycling fluorinated surfactant in fluorine-containing polymer production and treating wastewater of the fluorinated surfactant.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

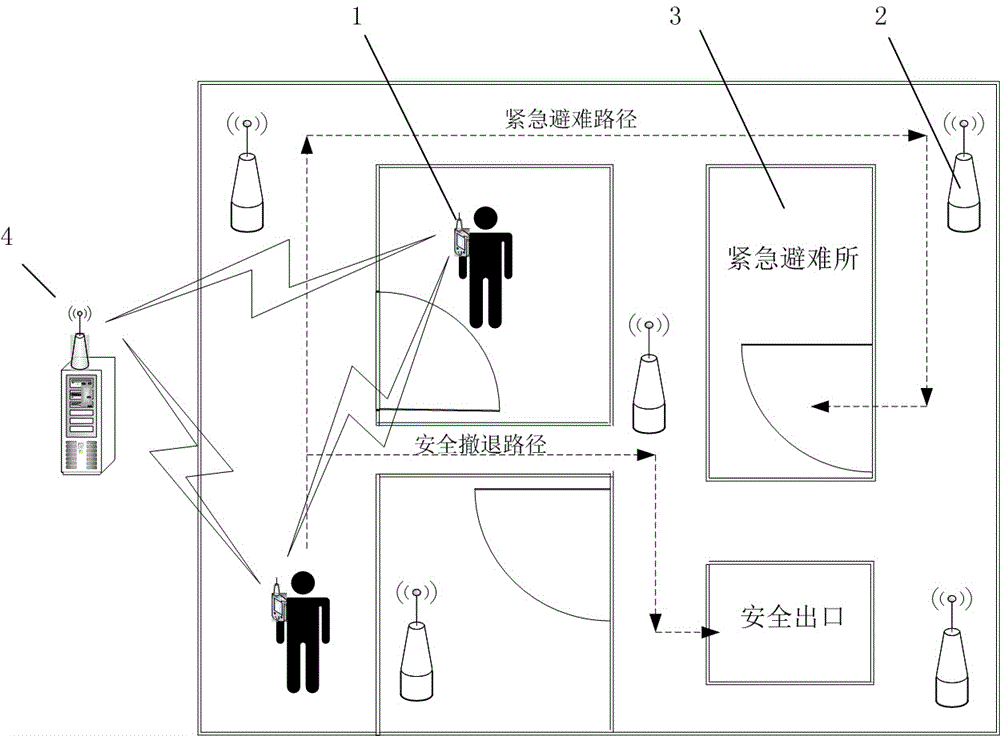

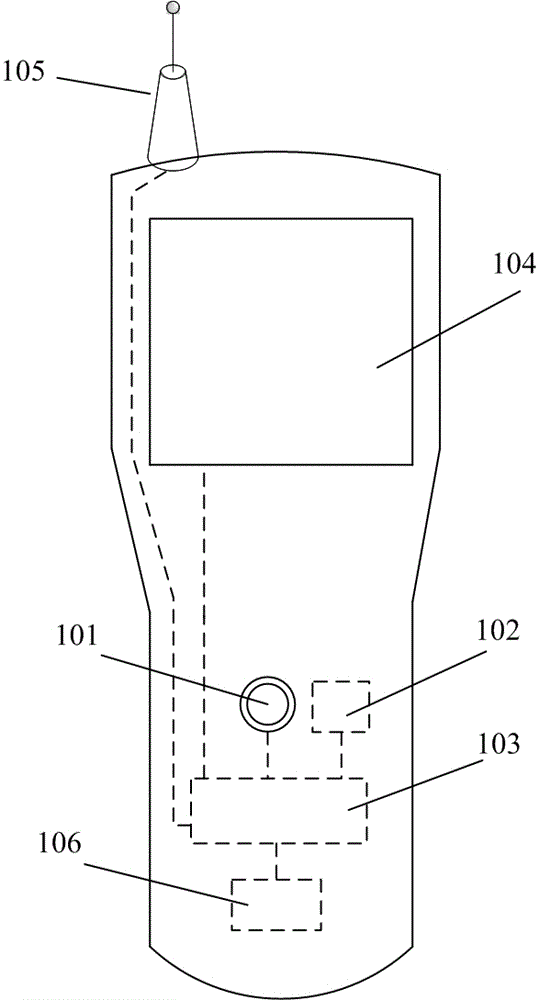

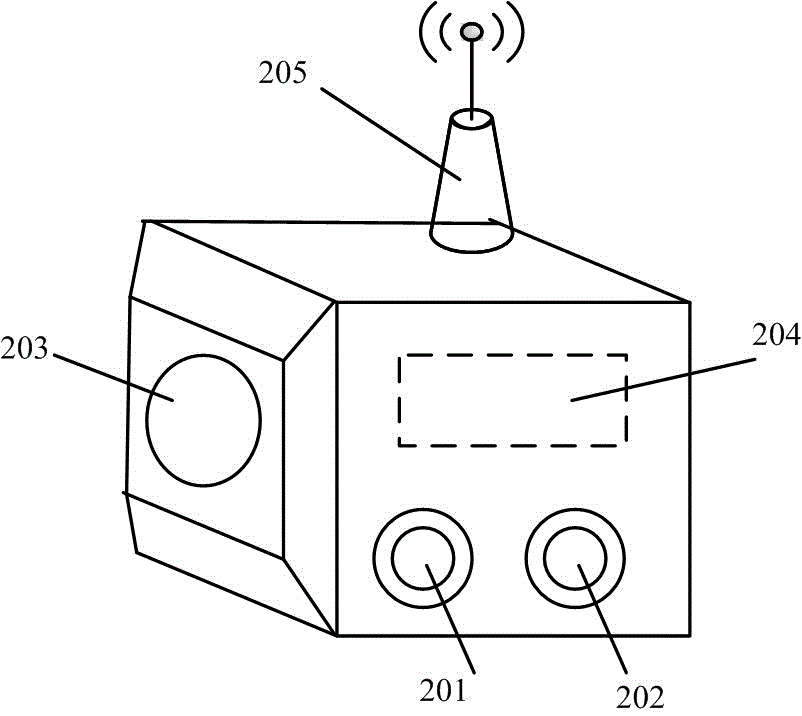

Nuclear emergency system of nuclear power plant

InactiveCN106024083AFacilitate normal inspection arrangementsKeep abreast of the radiation situationPower plant safety arrangementChecking time patrolsNuclear powerCommand system

The invention provides a nuclear emergency system of a nuclear power plant, and belongs to the technical field of nuclear power plant emergency planning and preparing. The system comprises portable individual emergency devices, a fixed nuclear radiation monitoring device, an emergency refuge and a control center. The portable individual emergency device and the fixed nuclear radiation monitoring device can position and measure current radiation data and send the data to the control center. The control center judges whether leakage happens or not, confirms the accident location and radiation range, and plans the retreating and emergency refuge route according to positions of all workers through summarization and analysis, and sends the information to the corresponding portable individual emergency devices to be displayed on a map through display modules, and safe retreating of the workers is ensured. The system is simple in structure, complete in function, rapid, efficient and high in safety coefficient, greatly improves nuclear emergency reaction capacity and increases the survival rate of the workers on site, and meanwhile can be used as a nuclear emergency command system of the nuclear power plant.

Owner:HARBIN UNIV OF SCI & TECH +1

Refining method of raw material gas containing ethene in process of preparing ethylbenzene from ethene

InactiveCN101659590AEasy to implementSimple processGaseous fuelsLiquid carbonaceous fuelsEthyleneChemistry

The invention discloses a refining method of raw material gas containing ethene in the process of preparing ethylbenzene from ethene, comprising the steps: raw material gas containing ethene and dilute ethene gas returned by a catalytic cracking or splitting device are mixed or respectively enter from the lower part of an absorbing device, are contacted with an absorbent entering from the upper part of the absorbing device for refining, the refined raw material gas enters a reaction part of an ethylbenzene device to react with benzene to prepare the ethylbenzene, the saturated absorbent is desorbed and then recycled, and desorbed gas enters a catalytic cracking or catalytic splitting device. The method has simple flow, low investment and favorable refining effect, and ensures that the unreacted rate of propylene is as high as 98.1-99.9 percent.

Owner:CHINA PETROCHEMICAL CORP +1

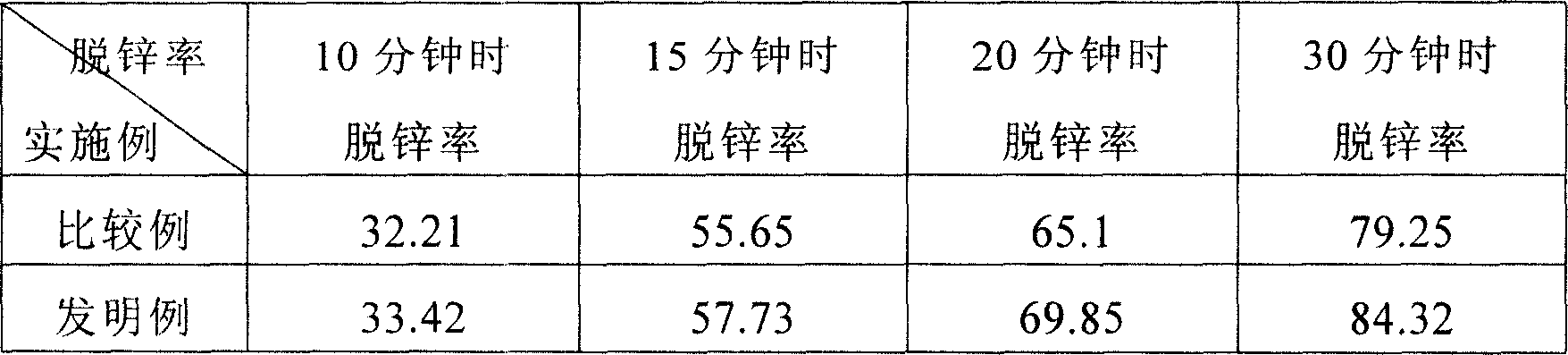

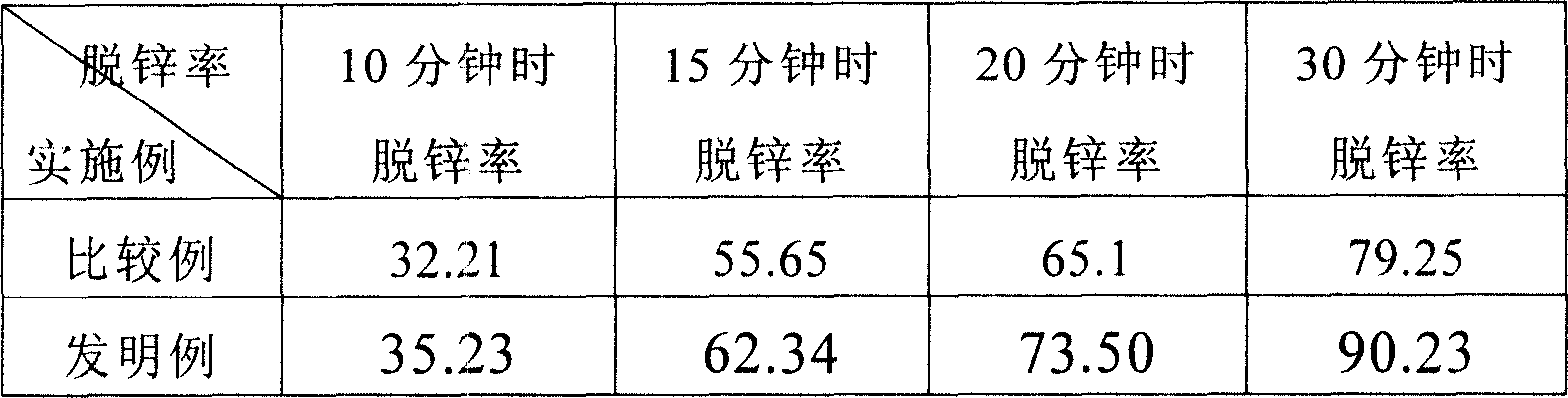

High-heat direct reduction dezincing method for zinc-containing dust carbon-bearing briquette

The direct high temperature reduction process to eliminate zinc from zinc containing dust pellet includes the following steps: 1. analysis to determine the CaO, MgO, SiO2 and Al2O3 contents in zinc containing dust with zinc content lower than 5 wt% and calculate ternary (CaO+MgO) / (SiO2+Al2O3) alkalinity value; 2. adding one or several of slaked lime, lime limestone, dolomite powder and alkaline steel slag powder to zinc dust to control the alkalinity value in 1.3-2.6; 3. adding coal powder, coke powder, petroleum powder and / or graphite powder, mixing and rolling or pressing into pellet; and 4. heating the pellet at 1100-1350 deg.c for over 10 min to reduce zinc while reducing ferric iron into metal iron. The process has high zinc eliminating rate and no increased loss.

Owner:BAOSHAN IRON & STEEL CO LTD

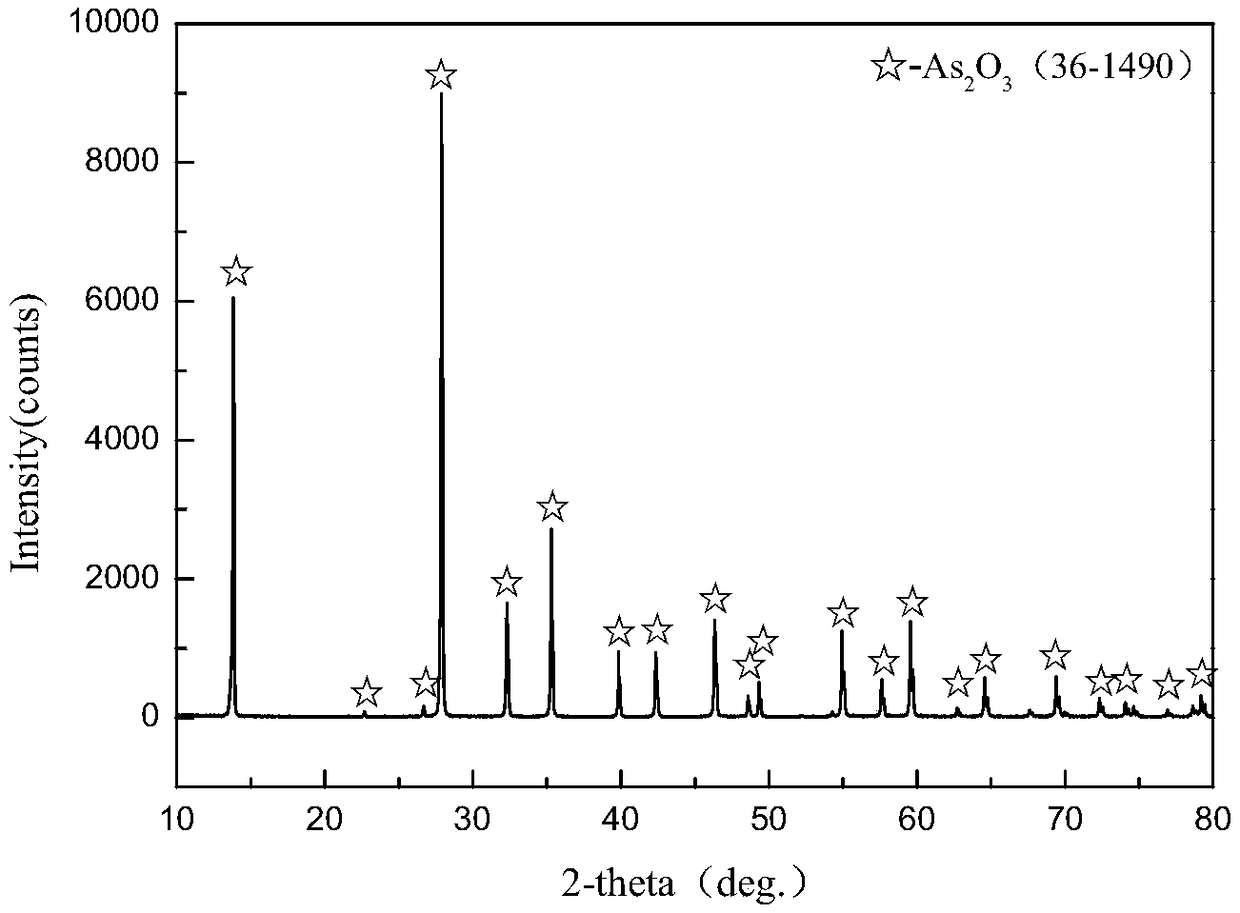

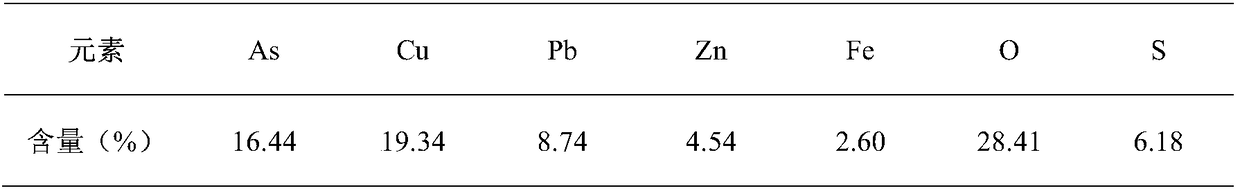

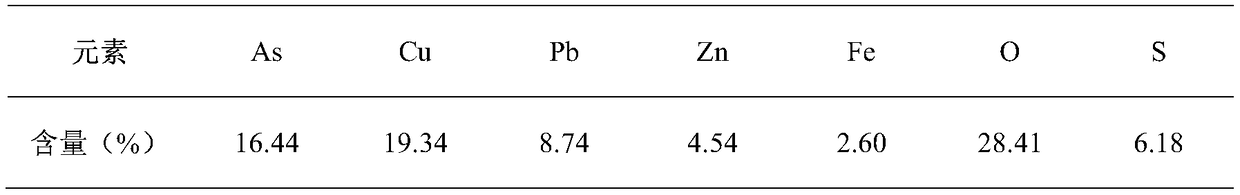

Copper smelting smoke dust arsenic removal method

ActiveCN109321755AImprove escape rateEfficient enrichmentProcess efficiency improvementIron sulfideCopper

The invention discloses a copper smelting smoke dust arsenic removal method. According to the method, copper smelting arsenious smoke dust and a material containing iron sulfide are mixed and then roasted in a protective atmosphere to remove arsenic in the copper smelting arsenious smoke dust in an arsenious oxide form. Compared with a conventional fire arsenic removal method, the method has the advantages that arsenic can be efficiently removed under a low roasting temperature, and the arsenic removal rate can reach up to 88% or above; moreover, operation is easy, the conditions are mild, energy consumption is low, and arsenic in the copper smelting smoke dust can be removed on a large scale.

Owner:CENT SOUTH UNIV

Production process of decaffeination tea

InactiveCN101785517ANon-destructive propertiesEffective protectionTea alkaloid content reductionDecaffeinationPolyphenol

The invention discloses a production process of decaffeination tea, which is characterized in that a supercritical carbon dioxide extraction method is utilized for producing the decaffeination tea, water is added into the supercritical carbon dioxide for preparing entrainers, 90 percent of caffeine in the tea can be extracted in a short time at a low temperature, the fragrance and tea polyphenol in the tea can be effectively protected, and the invention has the characteristics of high emersion rate, short extraction period, pure natural effect, no pollution and the like.

Owner:GUIZHOU TAIBO BIO TECH

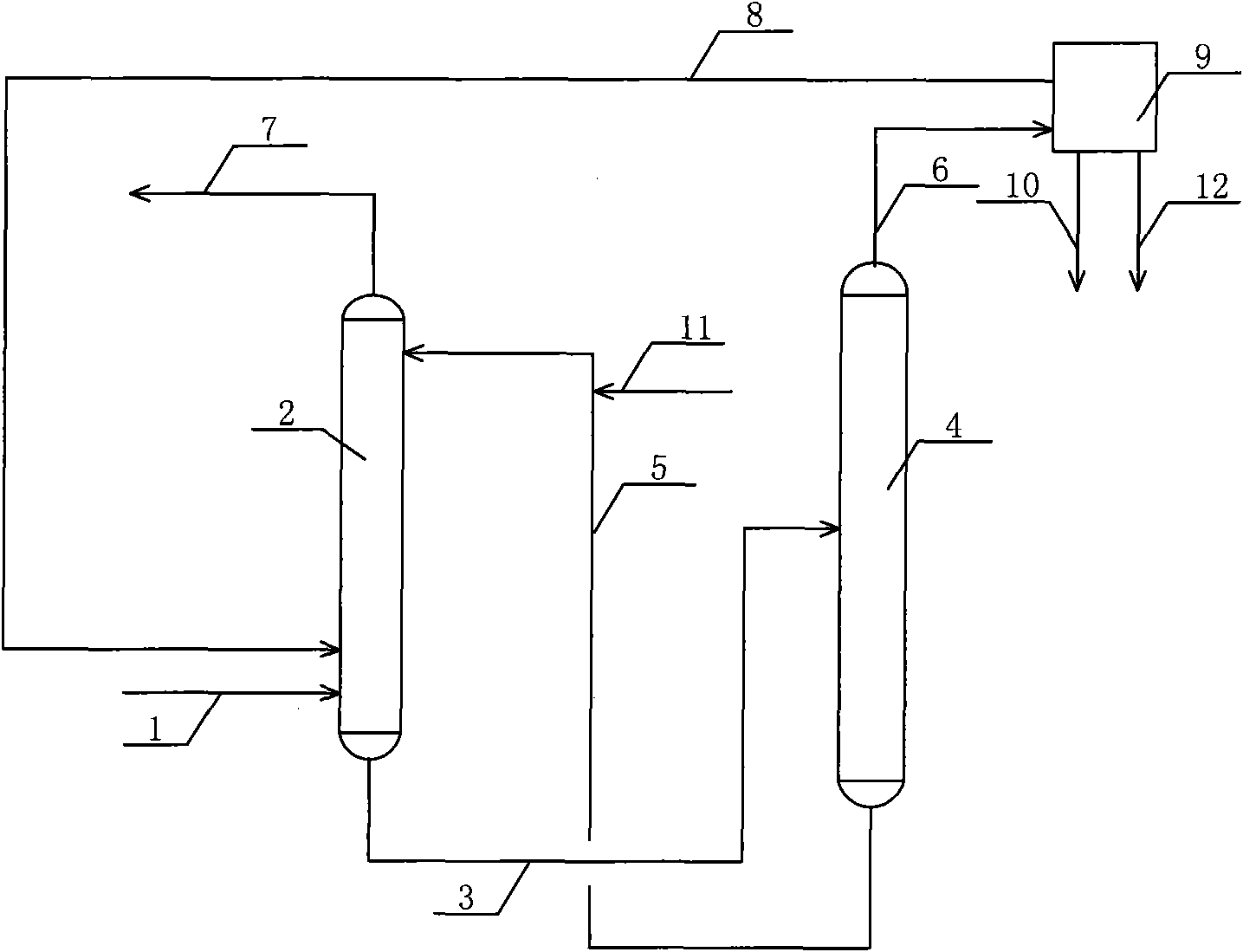

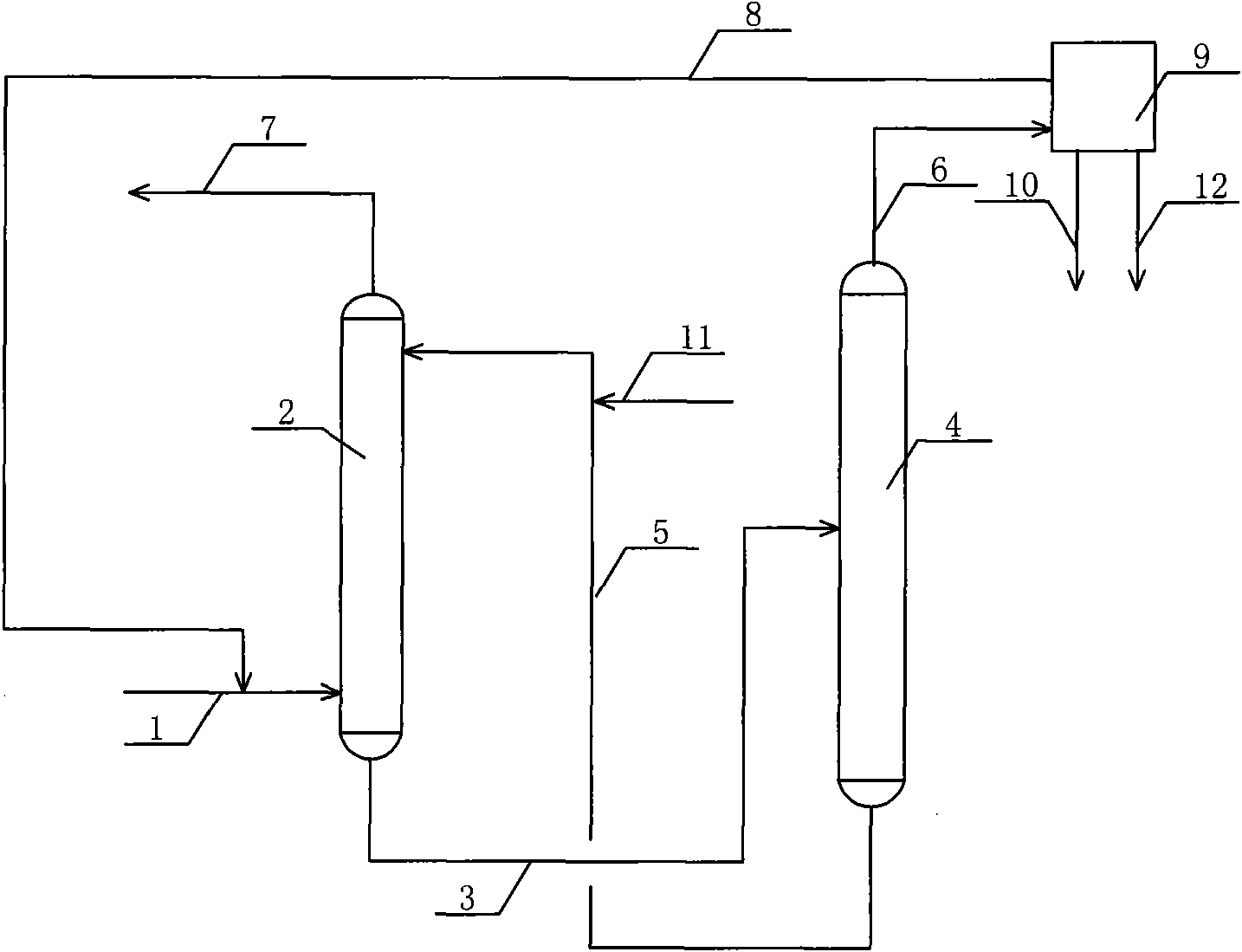

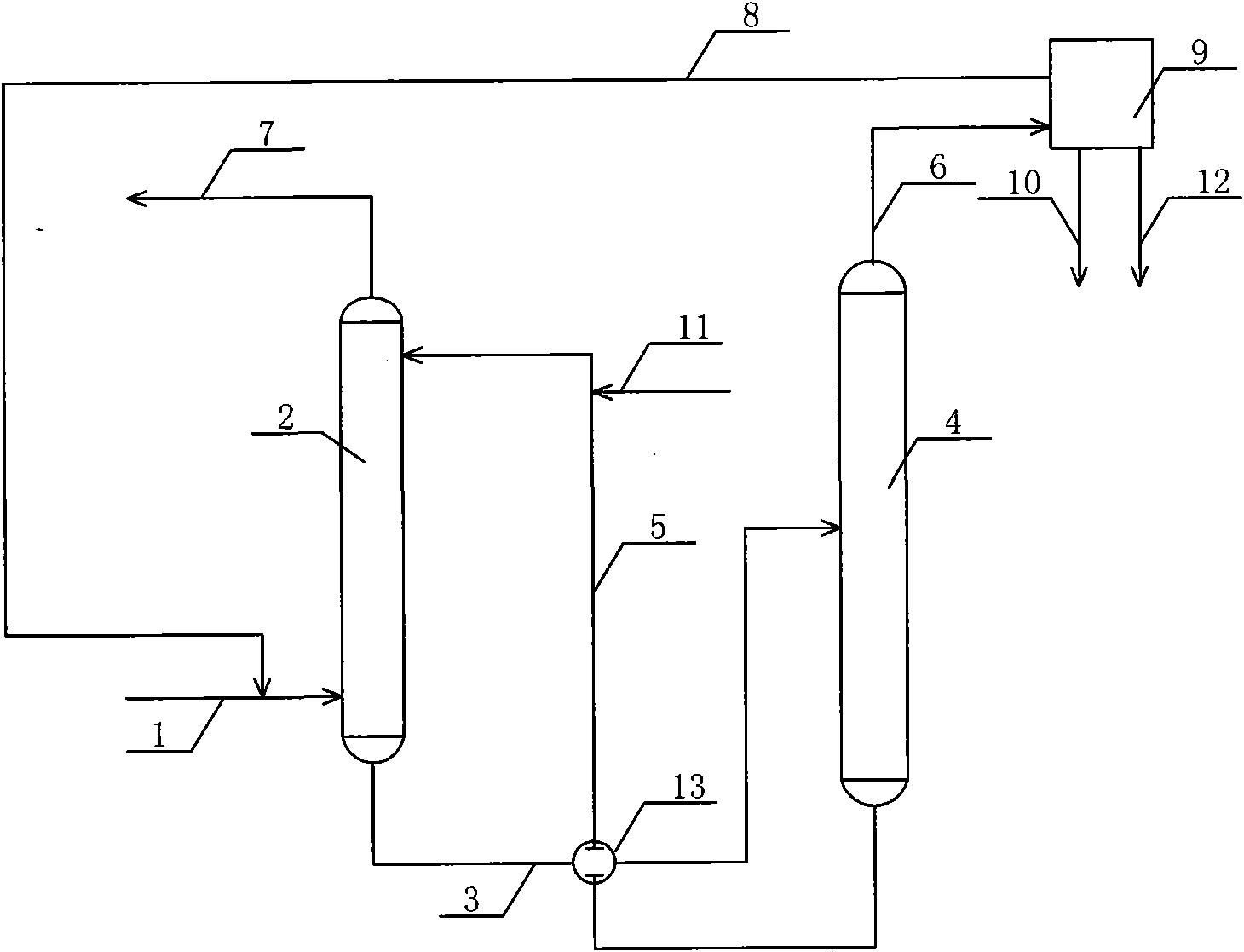

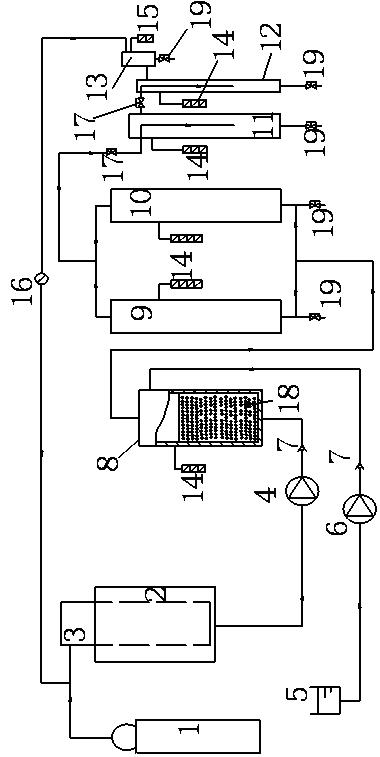

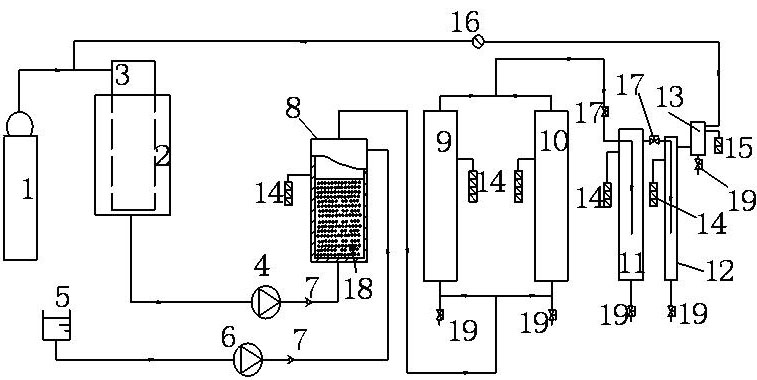

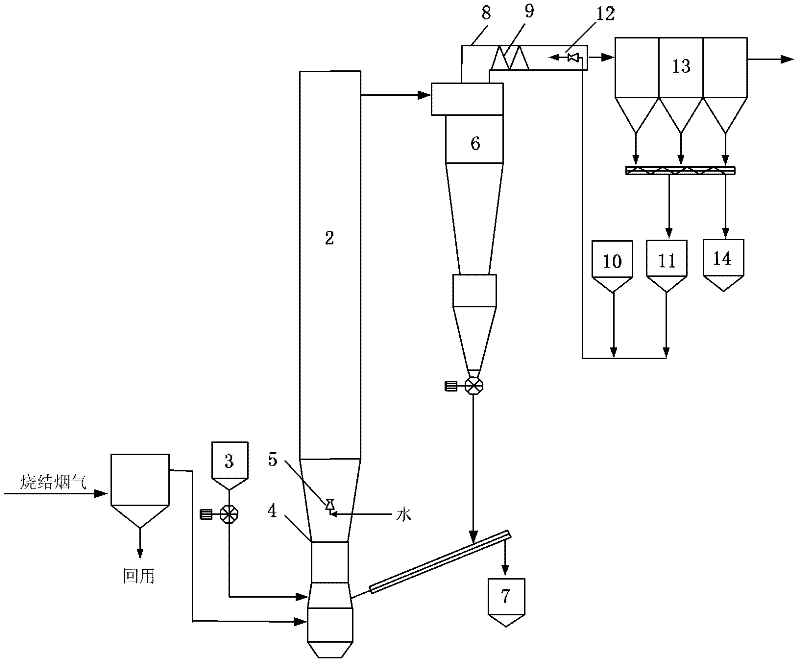

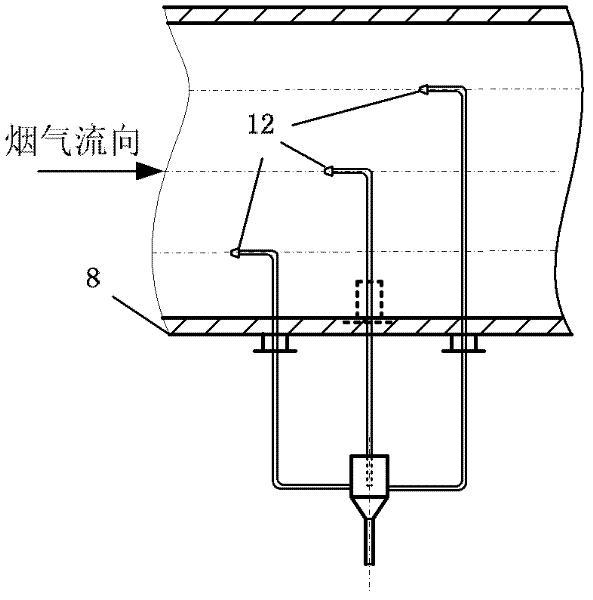

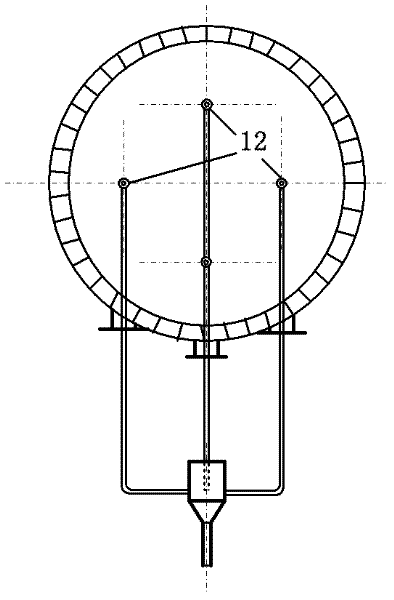

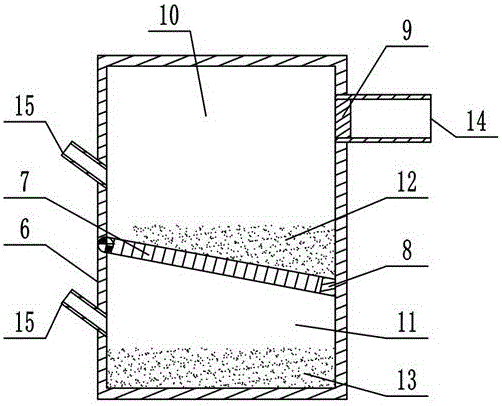

Device and method for removing sulphur dioxide and dioxin from sintering flue gas

InactiveCN102366704AAchieve removalRemove changeDispersed particle separationActivated carbonGas solid

The invention relates to a device and method for removing sulphur dioxide and dioxin from sintering flue gas. The device comprises a circulating fluid bed adsorption tower (2) and a bag-type dust collector (13), wherein a desulphurizer bin (3) and a water spray nozzle are arranged at the bottom of the circulating fluid bed adsorption tower (2); a cyclone separator (6) and a flue duct (8) are sequentially arranged between the top of the circulating fluid bed adsorption tower (2) and the top of the bag-type dust collector (13) along the flowing direction of flue gas; and a plurality of activated carbon spray nozzles (12) are arranged at one end of the flue duct (8) adjacent to the bag-type dust collector (13) in the direction opposite to the flowing direction of the flue gas, and are communicated with an activated carbon bin (10). The device and method for removing sulphur dioxide and dioxin from sintering flue gas, provided by the invention, have the advantages that the sulphur dioxide and the dioxin are separately removed, the influence of the sulphur dioxide on absorption of the dioxin by activated carbon in the flue gas is reduced, and the efficiency of removing the dioxin is increased; and due to the adoption of spiral fins (9) in the flue duct, gas-solid mass transfer of the flue gas and the activated carbon is strengthened, and the efficiency of removing the dioxin from the flue gas can be obviously improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

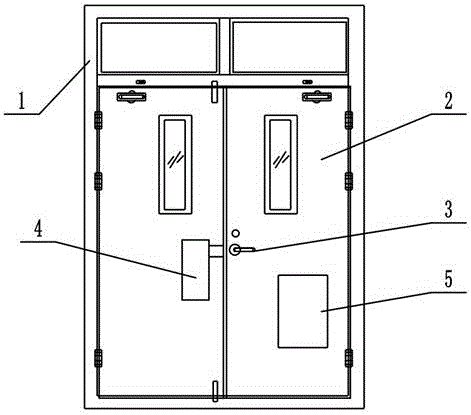

Novel fire-proofing escape door with cooling effect

The invention belongs to the field of windows and doors of fixed constructions, and particularly discloses a novel fire-proofing escape door with a cooling effect. The novel fire-proofing escape door comprises a door frame and a door body, which are made of fire-proofing core plates, wherein a door handle is respectively arranged on indoor side and outdoor side of the door body; a fire-extinguishing and cooling device is arranged on one side of each door handle, and comprises a cylinder body; a separator is arranged in each cylinder body, one end of each separator is hinged in the respective cylinder body, the other end of each separator is adhered with glue, and each separator is adhered to the inner wall of the respective cylinder body through the first glue; each cylinder body is separated into a first chamber and a second chamber by virtue of the respective separator, each first chamber is filled with aluminum sulfate, and each second chamber is filled with sodium bicarbonate; a nozzle is formed in the side wall of the top of each cylinder body, and is filled with second glue for sealing; the melting point of the second glue is higher than that of the first glue; and the nozzle is just aligned to each door handle. By adopting the scheme, the temperature of the door handles can be reduced when a fire disaster happens, so that the escape rate of people can be improved.

Owner:重庆金华兴门业有限公司

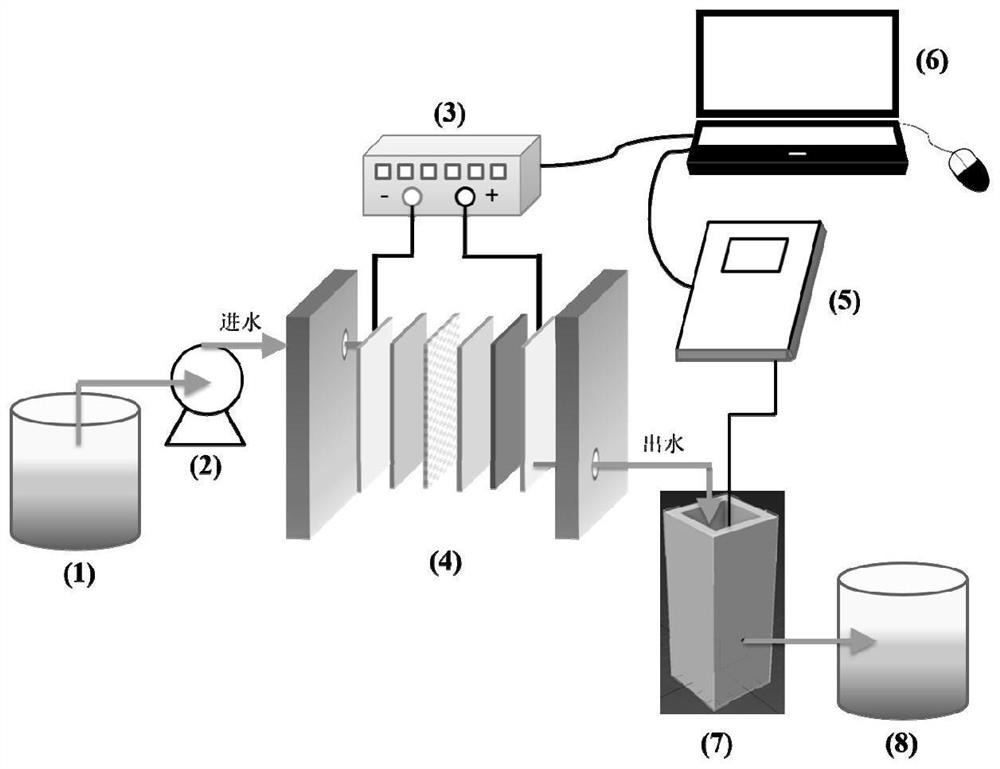

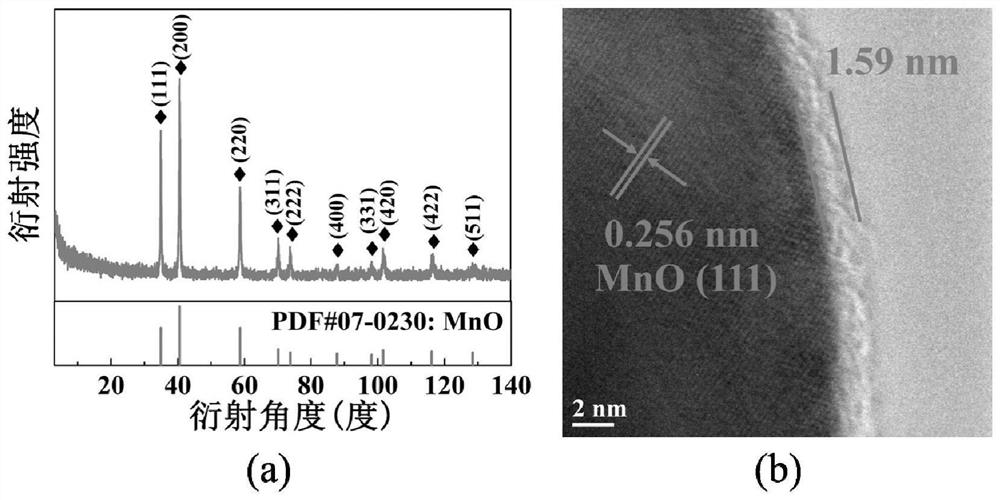

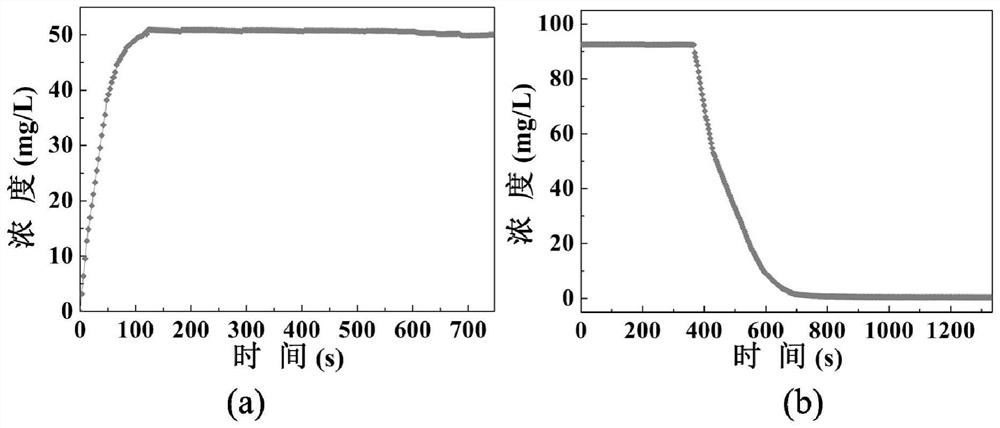

Membrane electrode material, preparation method and application of membrane electrode material adsorption-electrochemical lithium method to extract lithium

ActiveCN111647746AEfficient separationIncrease capacityMaterial nanotechnologyMembranesCarbon coatingAdsorptive membrane

Owner:BEIJING UNIV OF CHEM TECH

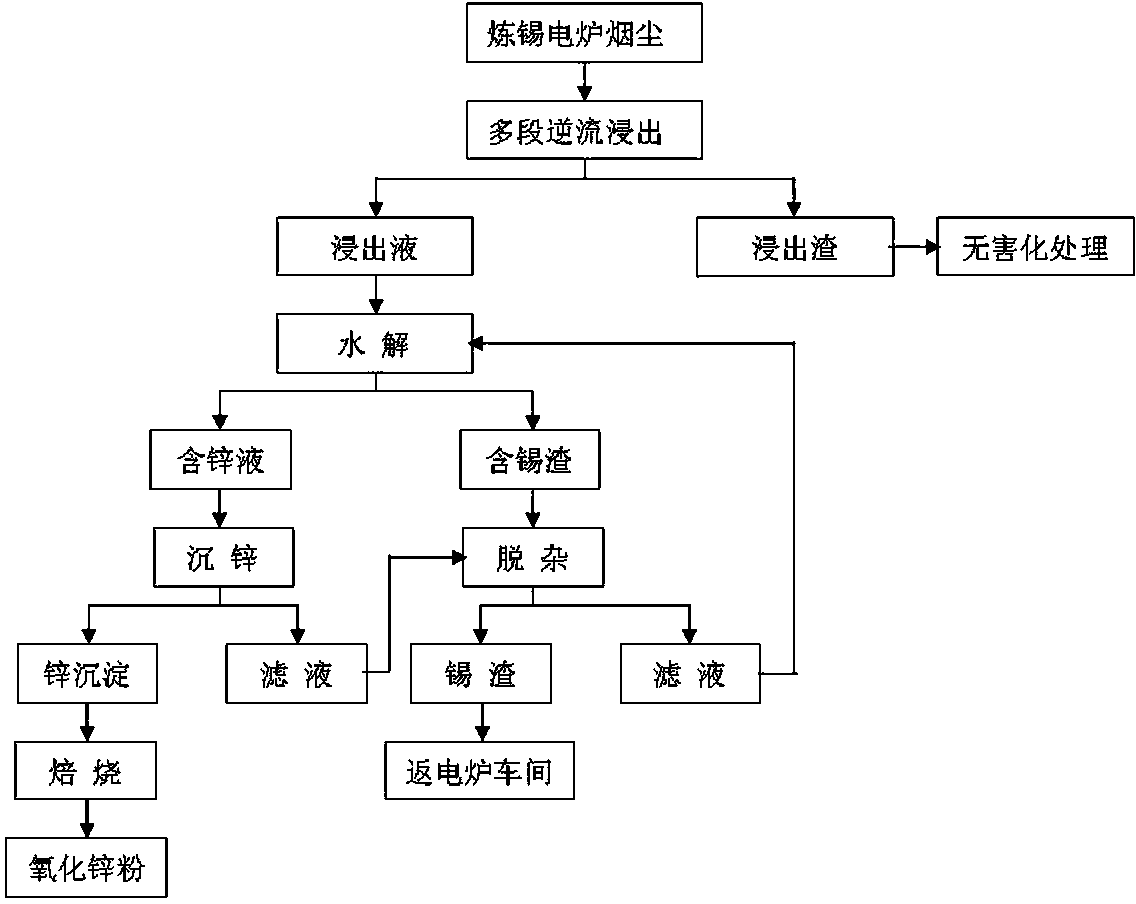

Process for recovering zinc from tin-smelting electric furnace smoke

The invention discloses a process for recovering zinc from tin-smelting electric furnace smoke. The process comprises the steps of multi-stage countercurrent extraction, hydrolysis, zinc deposition, roasting and impurity removal, and particularly comprises the following steps: collecting zinc-containing smoke, adding water and acid, leaching, and filtrating; performing hydrolysis on zinc-containing liquid obtained through leaching to enable impurities such as zinc to generate precipitation, separating, and roasting to obtain zinc oxide powder; obtaining precipitation through a hydrolysis procedure, performing impurity removal, leaching out impurity elements by acid, separating, returning slag with rich tin to an electric furnace shop after filtration, mixing with a zinc-containing material fed into an electric furnace, and recovering zinc through smelting in the electric furnace. According to the process, the multi-stage countercurrent extraction is adopted in the tin-smelting electric furnace smoke, so that the leaching rate of zinc in the smoke is improved, the consumption of acid is reduced, the zinc oxide powder is obtained, and all metallic elements in the smoke are comprehensively recovered; during metal recovering, waste gas and waste water cannot be produced, the smoke emission pollution is reduced while the comprehensive recovery of wastes is realized, the environment is protected, and the economic efficiency is improved.

Owner:YUNNAN CHENGFENG NON FERROUS METALS

Modularized ejection seat and escaping airplane comprising same

ActiveCN106335643AIncrease escape speedImprove escape rateSupports/holding devicesAircraft ejection meansJet aeroplaneEjection Seats

The invention provides a modularized ejection seat and an escaping airplane comprising same, and relates to an escaping apparatus. The invention aims at providing a modularized ejection seat capable of helping passengers to rapidly escape from a compartment and an escaping airplane comprising the modularized ejection seat. The modularized ejection seat comprises a seat body and an ejection apparatus, wherein the seat body is fit to an ejection end of the ejection apparatus and can be separated from the ejection apparatus under the ejection effect of the ejection apparatus. The escaping airplane comprises an airplane body, an escaping window and the modularized ejection seat, wherein the escaping window is arranged on the airplane body; the ejection apparatus is fixedly arranged relative to the escaping window; and the seat body is opposite to the escaping window, and the seat body is completely separated from the airplane body by virtue of the escaping window under the ejection effect of the ejection apparatus.

Owner:刘继军

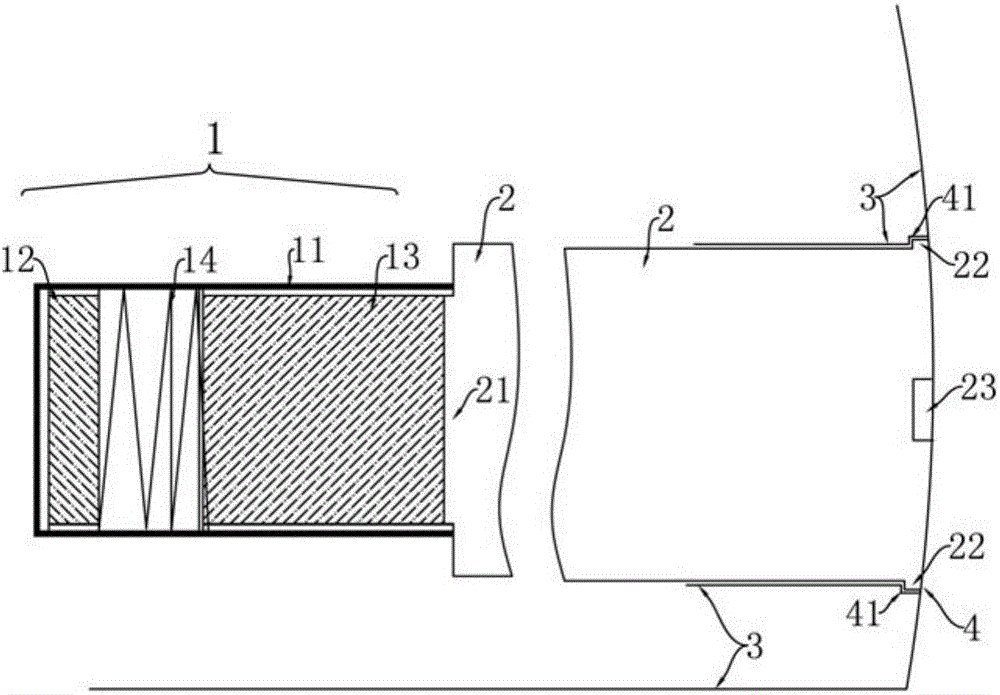

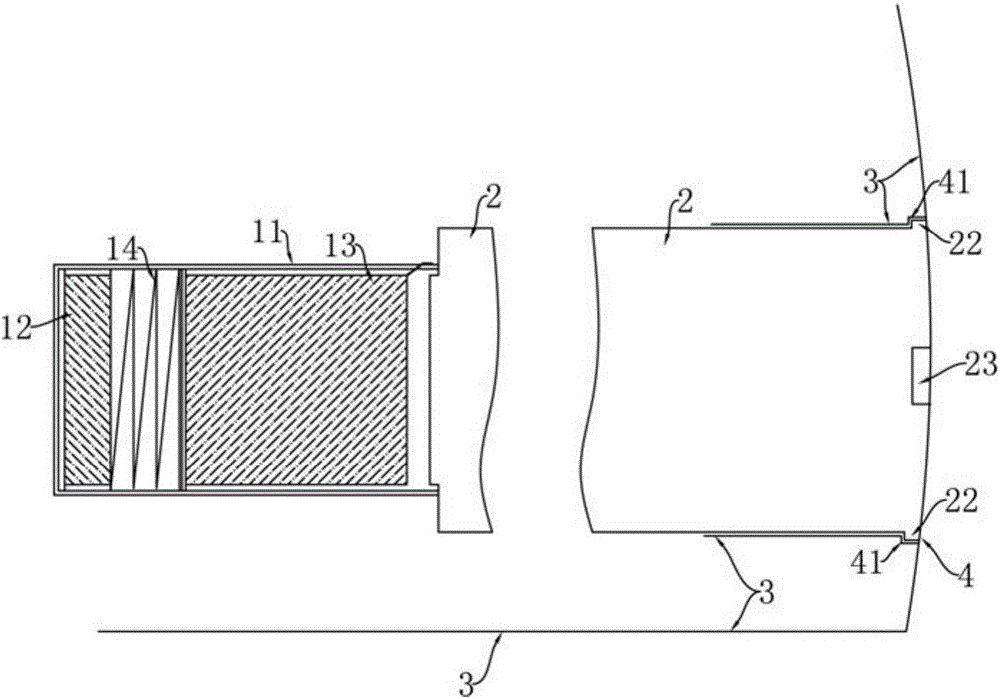

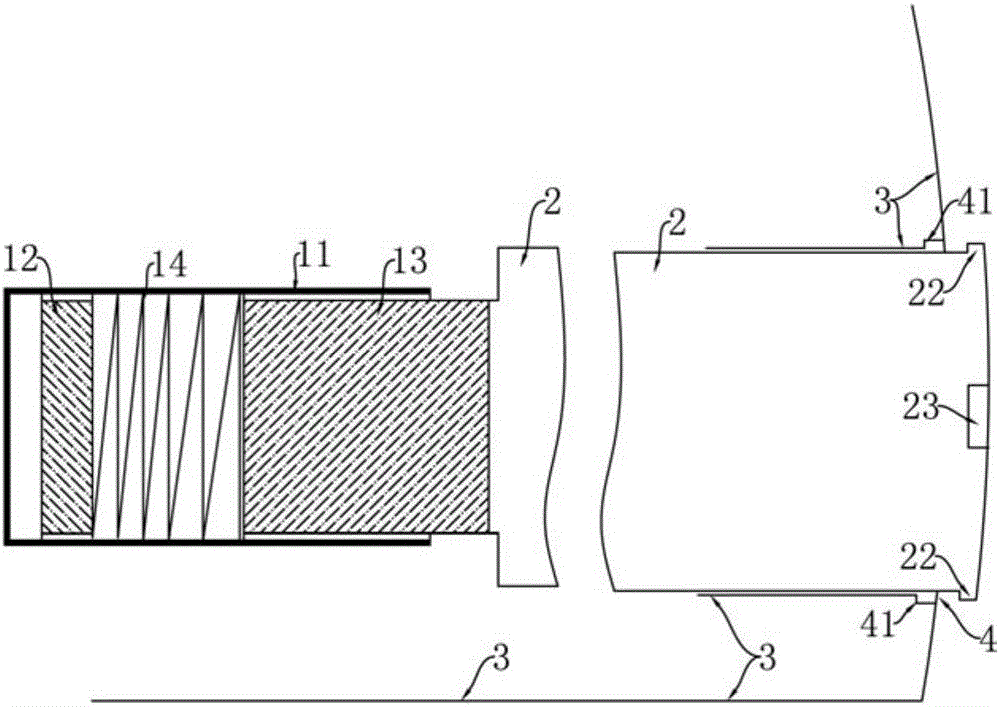

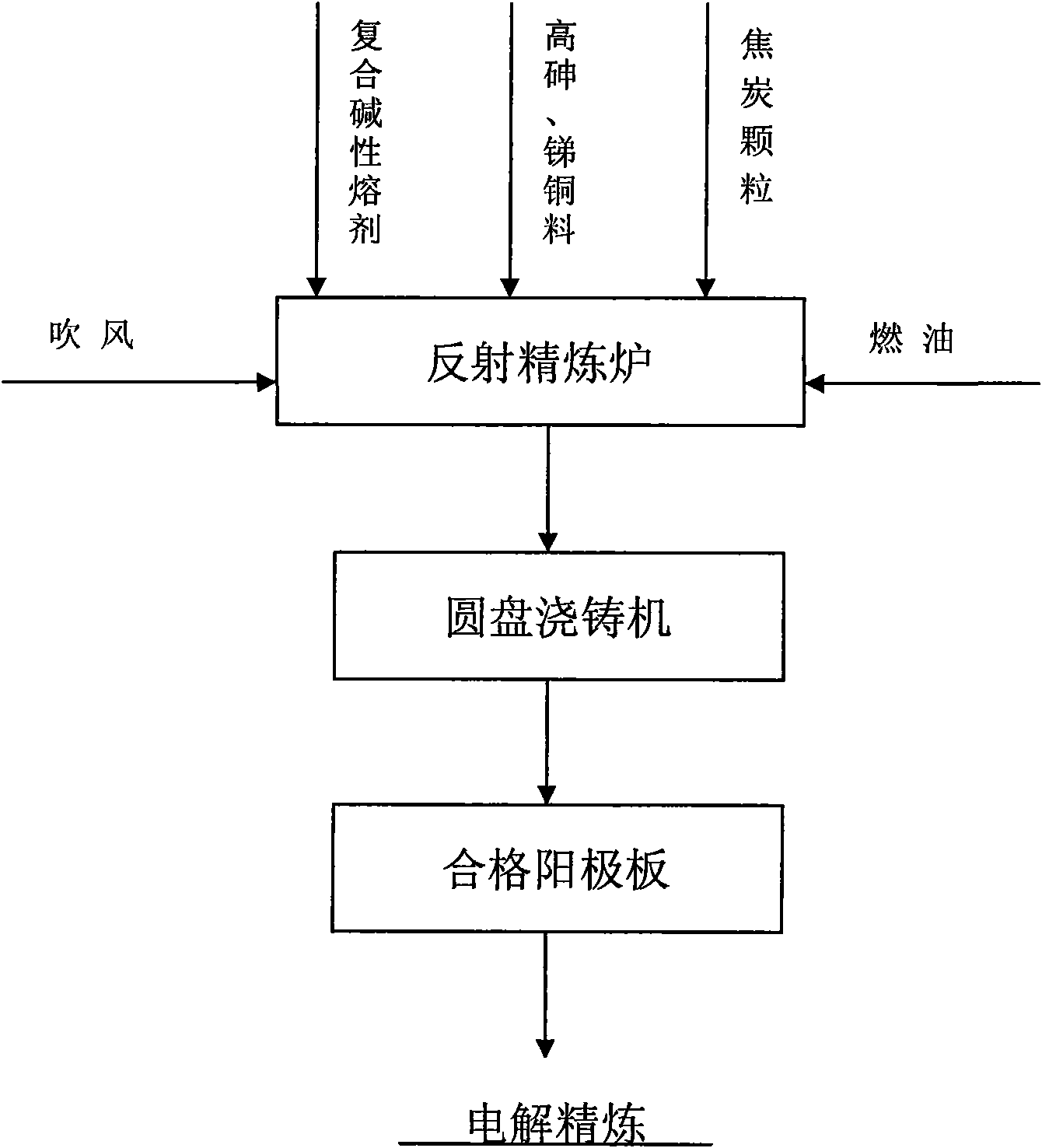

Reverberatory furnace pyrorefining method of crude copper with high arsenic and antimony

InactiveCN101654744ABroaden source channelsAlleviate resource constraintsReverberatory furnaceRedoxReverberatory furnace

The invention relates to a reverberatory furnace pyrorefining method of crude copper with high arsenic and antimony which is a pyrorefining method combining melting, redox volatilizing and composite alkaline fusing agent slagging together. When refining the crude copper with high content of arsenic, antimony and other impurities in the reverberatory furnace, the process comprises the following steps: firstly performing fusion volatilization and redox volatilization and slagging with composite alkaline fusing agent to realize multiple stage purification. The invention has the advantage of simple process, high production efficiency and the like.

Owner:DONGYING FANGYUAN NONFERROUS METALS

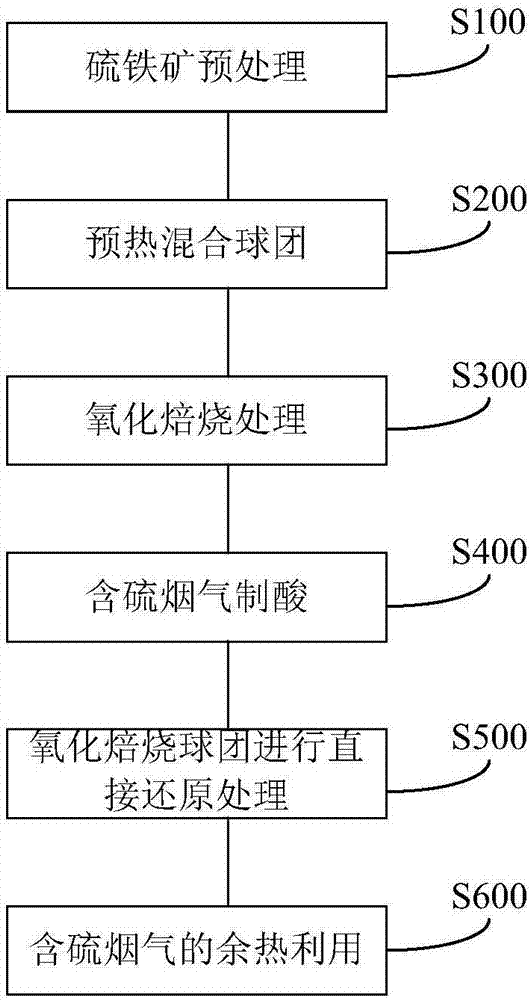

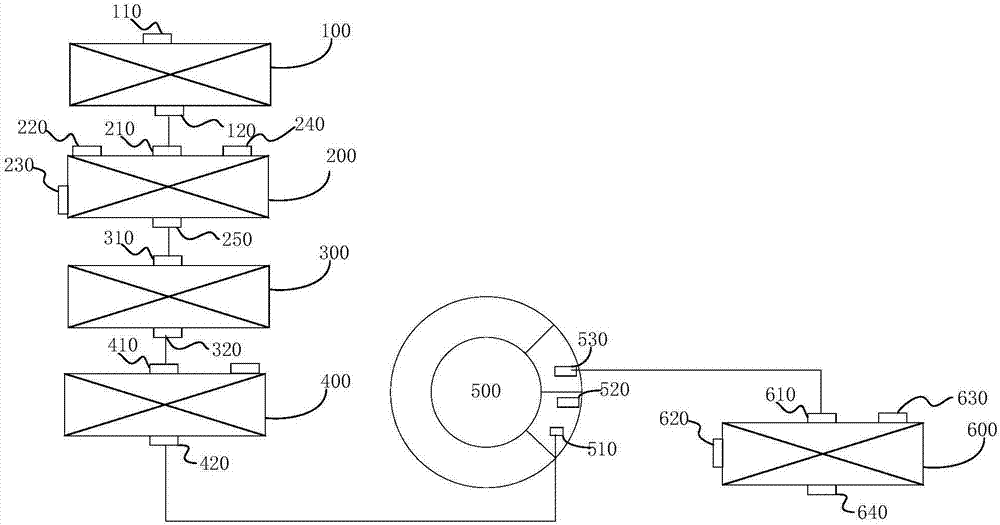

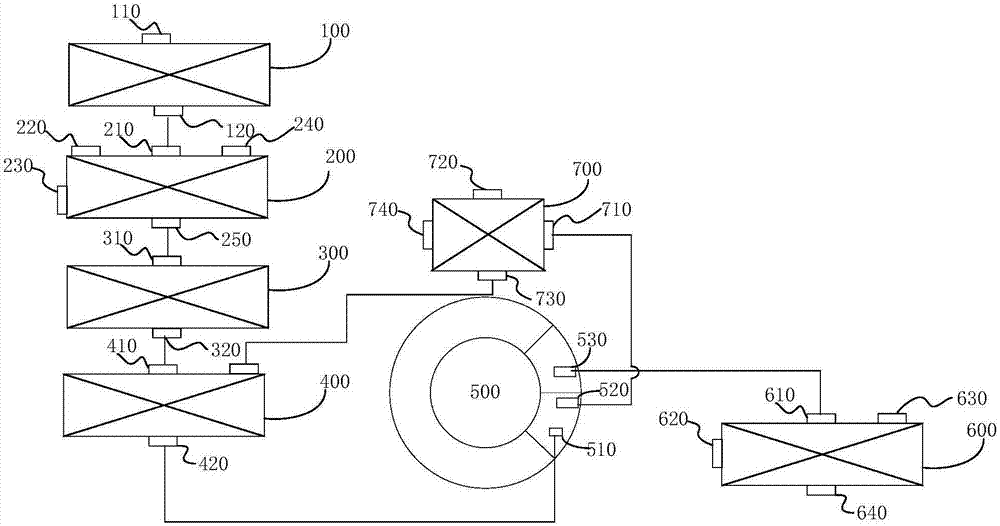

Method and system for preparing sulfuric acid and direct reduction iron from pyrite

PendingCN108004362AImprove escape rateReduce contentSulfur compoundsShaft furnaceReduction treatmentResource utilization

The invention discloses a method and system for preparing sulfuric acid and direct reduction iron from pyrite. The method comprises the following steps of (1) carrying out fine grinding treatment on the pyrite so as to obtain pyrite powder; (2) carrying out mixing forming treatment on the pyrite powder, water, a binder and an additive so as to form mixed pellets; (3) feeding the mixed pellets to achain grate machine for drying, first preheating and second preheating so as to obtain preheated pellets; (4) feeding the preheated pellets to a rotary kiln for oxidation roasting treatment so as toobtain oxidation-roasted pellets and sulfur-contained flue gas; (5) preparing acid by utilizing the sulfur-contained flue gas so as to obtain the sulfuric acid and acid-removed flue gas; and (6) feeding the oxidation-roasted pellets to a the gas-based shaft furnace for direct reduction treatment with reducing gas so as to obtain zinc-contained flue gas and a direct reduction iron product. According to the method, the sulfur recovery rate in the pyrite can be effectively increased, the process flow can be shortened, the high-quality direct reduction iron can be effectively produced by using theroasted oxidized pellets, the utilization rate of resources can be increased, and a high-quality raw material can be provided for producing high-end castings and high-grade steel.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

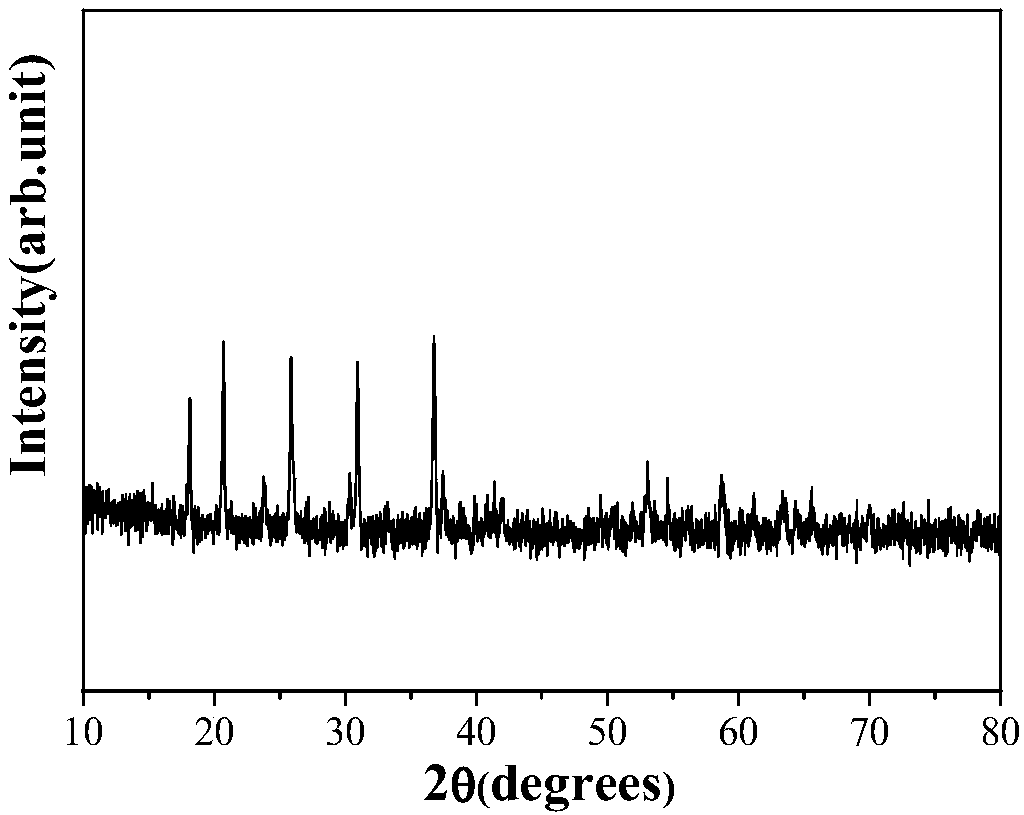

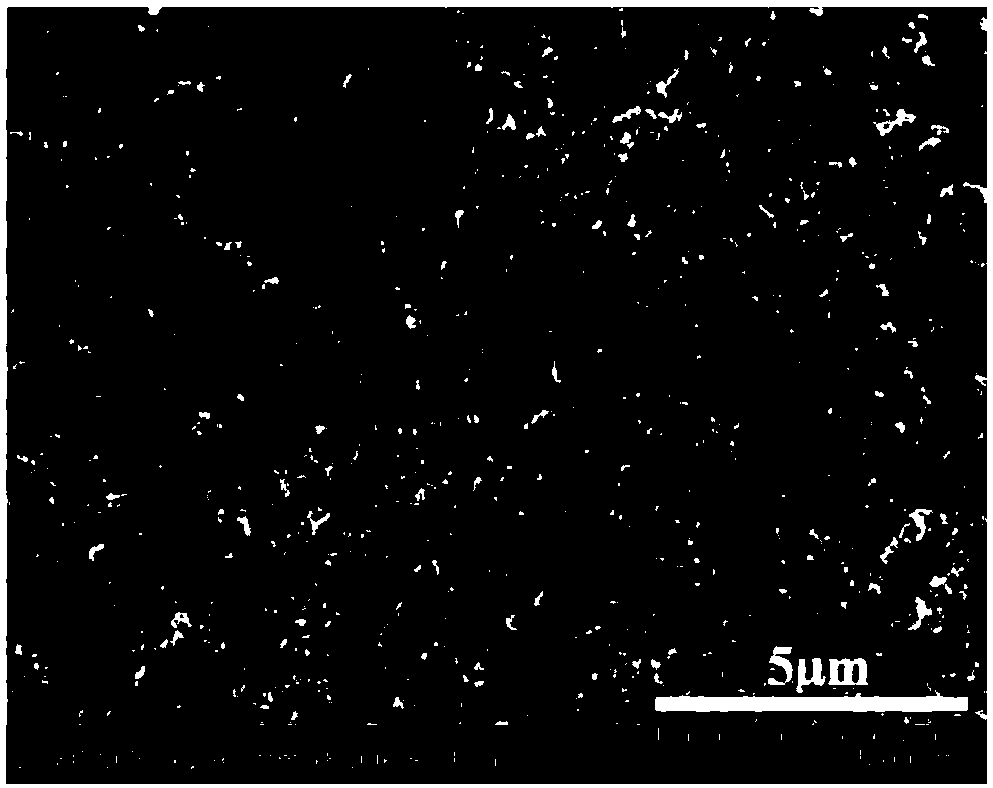

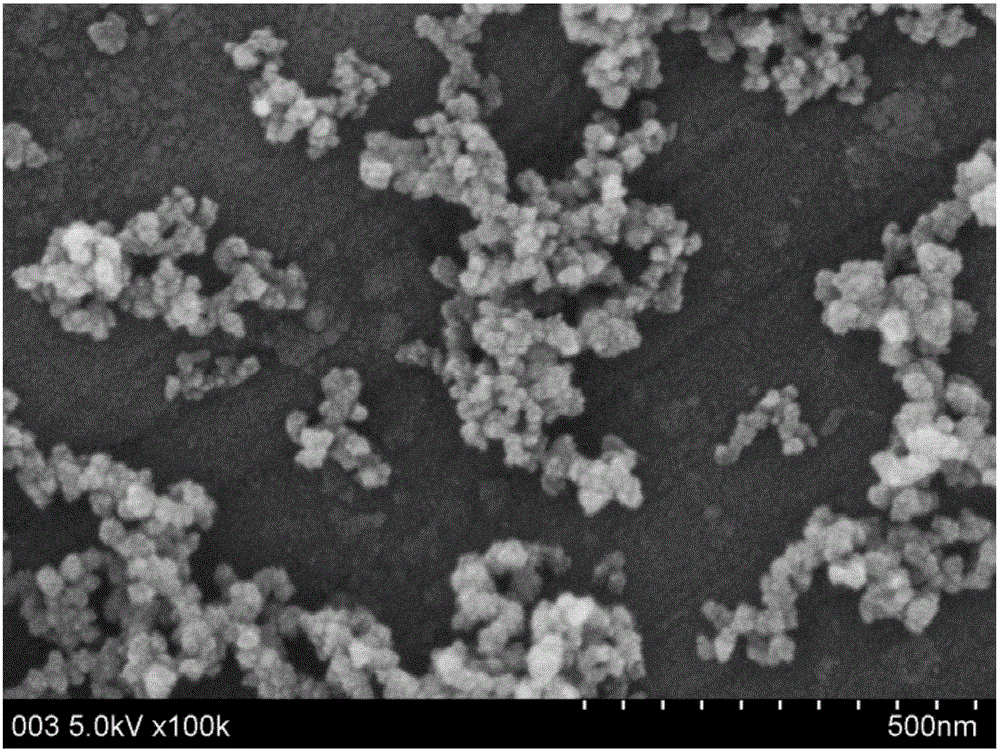

Silicon monoxide nano material and preparation method thereof

InactiveCN106744985ASolve pollutionLarge specific surface areaNanotechnologySilicon oxidesSilicon monoxideSilicon oxygen

The invention discloses a silicon monoxide nano material and a preparation method thereof. The material provided by the invention is prepared from the following raw materials in parts by weight: 90 to 120 parts of diamond wire cut silicon powder, 20 to 30 parts of millimeter-sized polycrystalline silicon powder and 0 to 90 parts of silicon-oxygen compound. The method provided by the invention comprises the following steps of uniformly mixing the raw materials according to a proportion through a wet method or a dry method, putting a dry mixed material into a crucible, uniformly covering the mixed material with a layer of the millimeter-sized polycrystalline silicon powder, and sending an obtained mixture into a vacuum furnace; starting a vacuum pump, raising a temperature to 400 to 700 DEG C, carrying out heat preservation for a certain time under negative pressure, and controlling a vacuum degree to be 500pa to 1,000pa; starting an argon tank, maintaining the negative pressure and the vacuum degree, quickly raising the temperature, maintaining the temperature at 1,300 to 1,400 DEG C, controlling an argon flow rate to be 0.5L / min to 10L / min, starting a condensation collecting tank, and keeping the temperature at 100 to 200 DEG C; decreasing the temperature after the reaction is finished, closing a vacuum, and when the vacuum degrees of the vacuum furnace and the condensation collecting tank reach normal pressure, closing the argon tank, so as to obtain the silicon monoxide nano material, wherein a particle size is 30nm to 100nm.

Owner:TIANJIN HUILI TECH CO LTD

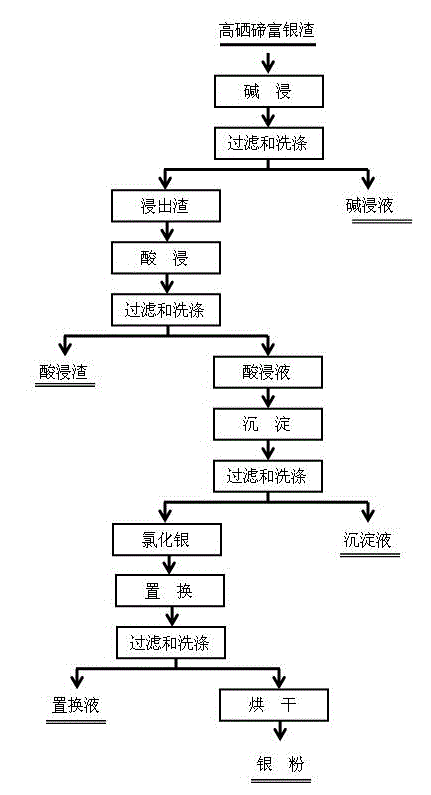

Method for preparing high-purity silver powder from silver-rich residue containing high selenium and tellurium

InactiveCN105886785AImprove escape rateEasy to operateProcess efficiency improvementIonEnvironmentally friendly

The invention discloses a method for preparing high-purity silver powder from silver-rich residue containing high selenium and tellurium. The method comprises the steps that the silver-rich residue containing the high selenium and tellurium is mixed with alkali at a certain liquid-solid ratio and placed in a titanium reaction kettle to be leached, and after leaching is completed and filtering and washing are conducted, leaching liquid containing the selenium and the tellurium and alkali leaching residue containing the selenium and the tellurium are obtained, so that preliminary removing of the selenium and the tellurium is achieved, silver is enriched, and the selenium and the tellurium which exist in sulfides need to be further removed; the alkali leaching residue is added with nitric acid and placed in the titanium reaction kettle to be leached, and after leaching is completed and filtering and washing are conducted, acid leaching residue and acid leaching liquid are obtained; the leaching liquid is added with a precipitating agent to selectively form a silver chloride precipitation, and after filtering and washing are conducted, pure silver chloride is obtained, so that the selenium and the tellurium are completely removed; and the silver chloride precipitation is added with a displacer and subjected to displacement to obtain silver powder, and the silver powder is washed through deionized water and protected and dried through nitrogen, so that the high-purity silver powder is obtained. The method for preparing the high-purity silver powder from the silver-rich residue containing the high selenium and tellurium is simple in process, easy to operate and industrialize, environmentally friendly, low in production cost, high in selenium and tellurium removing rate and product purity and good in industrialization application prospect.

Owner:KUNMING METALLURGY COLLEGE

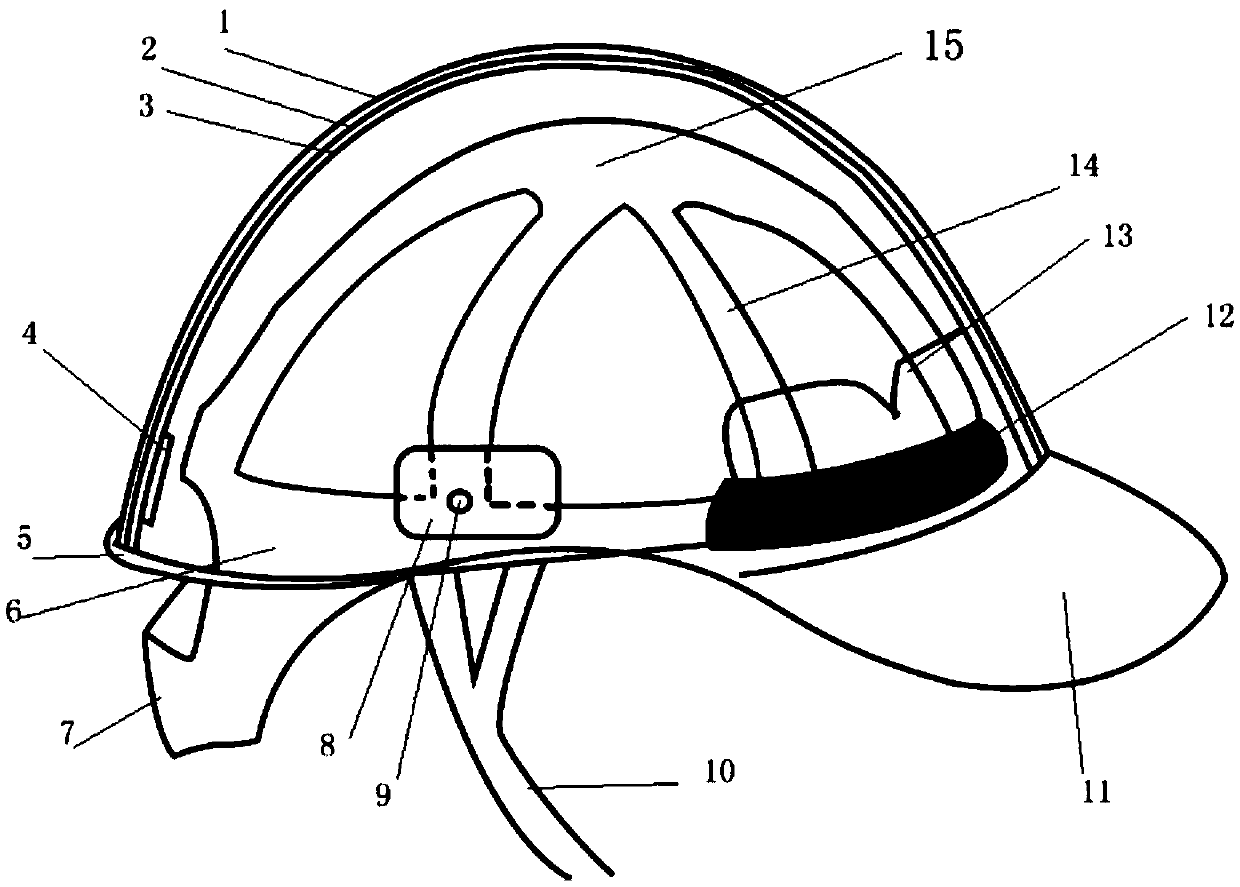

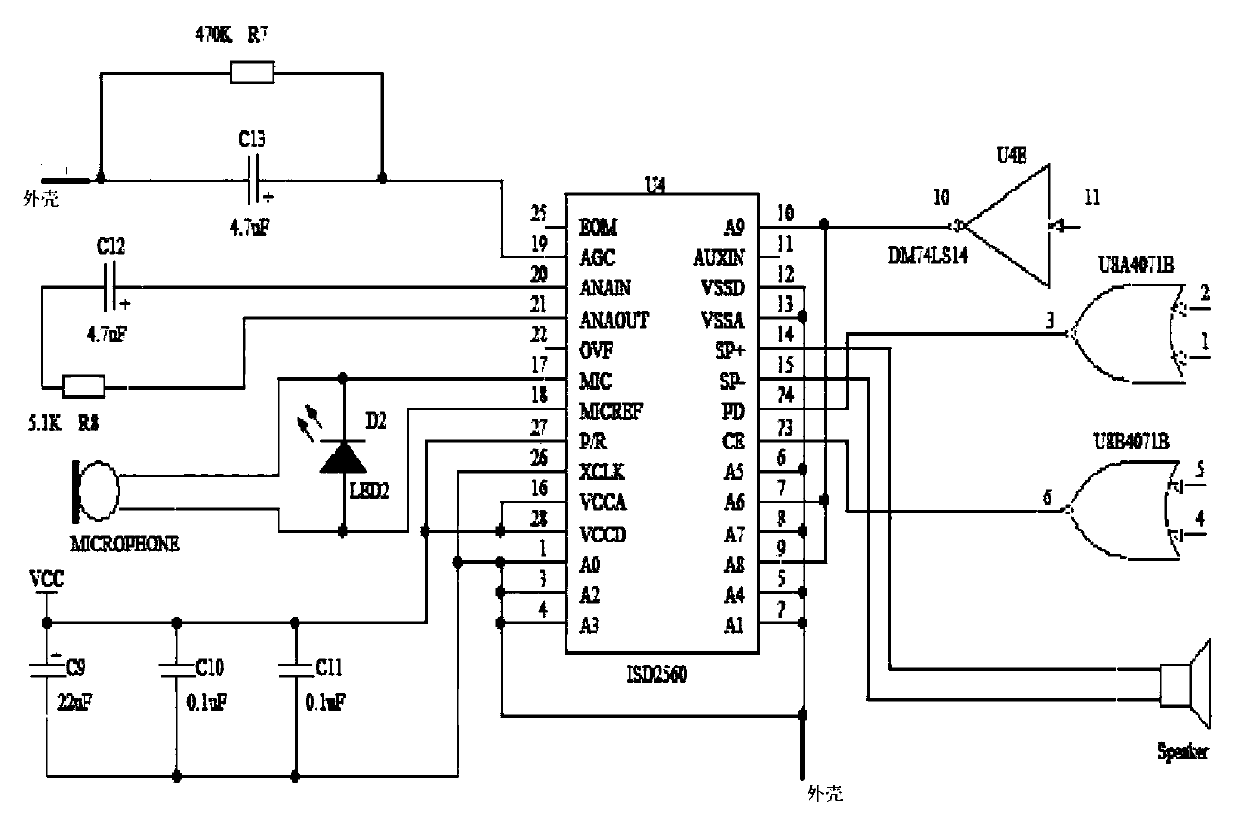

Intelligent safety helmet

InactiveCN109619741AReduce shockImprove resistance to damageHatsHeadwear capsStrain sensorGas generator

The invention discloses an intelligent safety helmet. The intelligent safety helmet comprises a helmet shell and a safety air sac control system, wherein the safety air sac control system comprises anair sac layer (2) arranged in the helmet shell, a crash sensor, a resistance strain sensor, a gas generator and a microprocessor; the signal output end of the crash sensor is connected with the signal input end of the resistance strain sensor, the signal output end of the resistance strain sensor is connected with the signal input end of the microprocessor, the signal output end of the microprocessor is connected to the gas generator, and gas generated by the gas generator is introduced into the air sac layer (2). According to the intelligent safety helmet, weight impact is sensed through thesafety air sac control system, the safety air sac control system is combined with the air sac layer to expand outwards and has the buffering effect, the buffering effect is resistant to impact forceof object impact, one part of impact is reduced, the injury resistance capacity of the safety helmet is improved, and the head and neck safety of a wearer is protected.

Owner:HENAN UNIV OF URBAN CONSTR

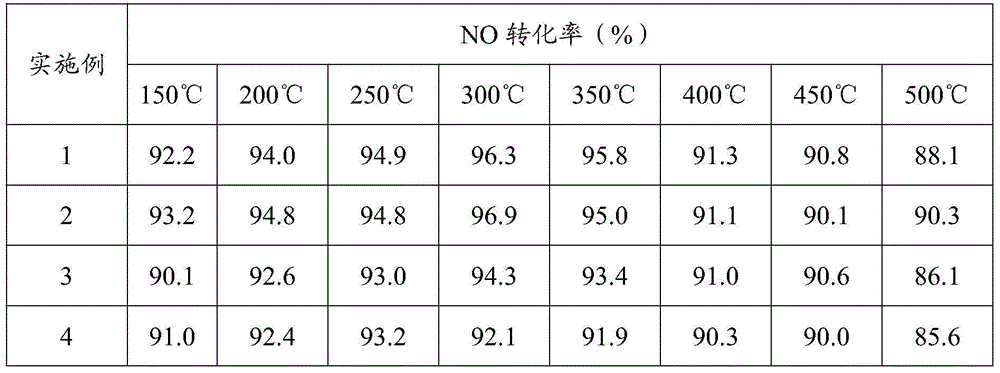

Wide temperature range type phosphorus-containing cerium-based denitration catalyst and preparation method thereof

ActiveCN105214698ALarge temperature rangeImprove escape ratePhysical/chemical process catalystsDispersed particle separationCerium phosphateNitrogen oxide

The invention relates to a wide temperature range type phosphorus-containing cerium-based denitration catalyst and a preparation method thereof. The catalyst is mainly prepared from cerium phosphate (CePO4) and manganese oxide Mn2O3 according to the molar ratio of 1:0.5-3. The wide temperature range type phosphorus-containing cerium-based denitration catalyst has the nitrogen oxide removal temperature interval of 150-500 DEG C and has high denitration stability and N2 selectivity. In particular, the nitrogen oxide removal effects of the phosphorus-containing cerium-based denitration catalyst in low-medium temperature intervals (150-350 DEG C) are good, and the nitrogen oxide conversion rates are both above 90%.

Owner:THE NORTHWEST RES INST OF CHEM IND

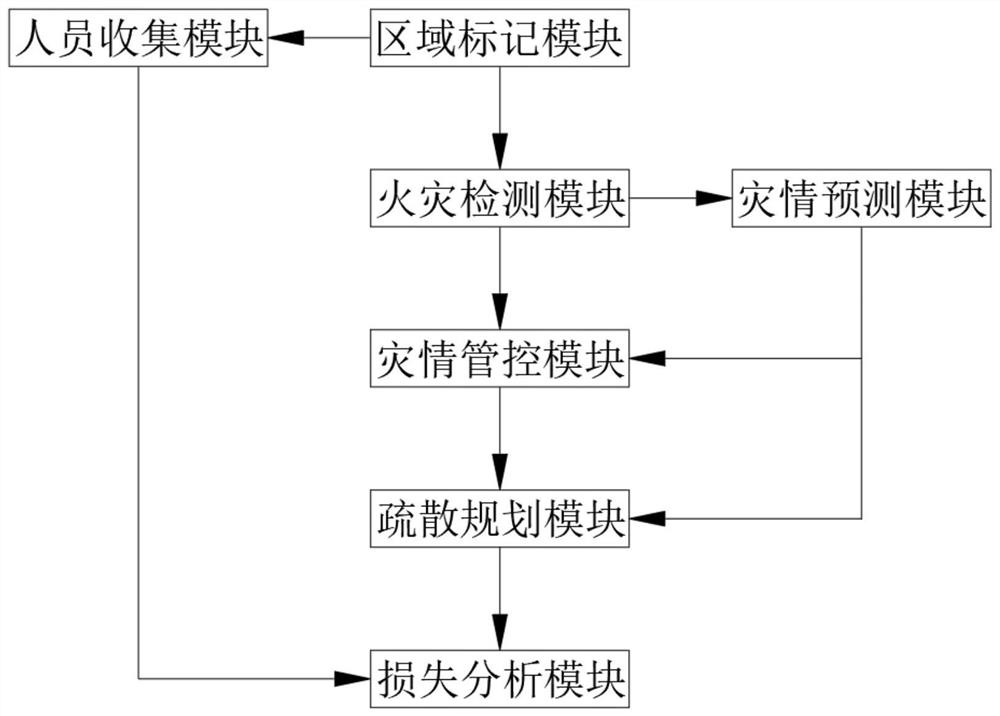

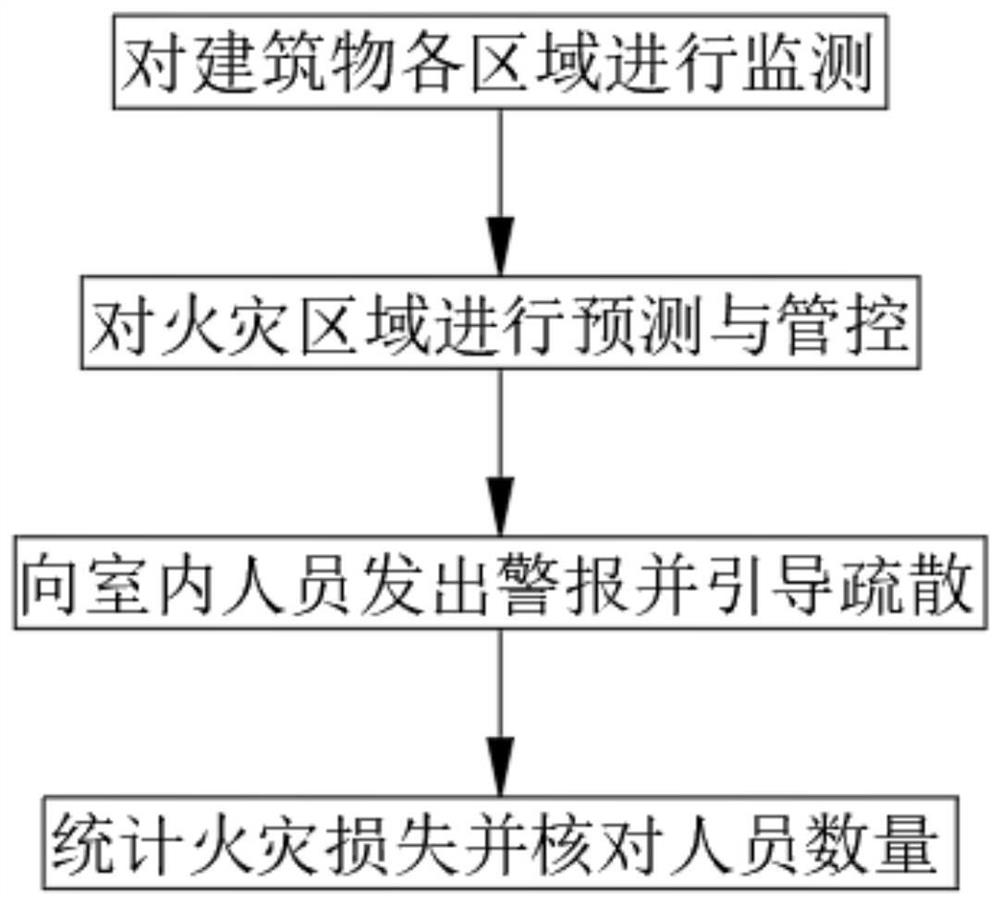

Urban large-scale building fire emergency evacuation system and method

PendingCN114445984AReduce the probability of congestion and stampedeQuick guideClimate change adaptationSignalling system detailsEvacuation planFire - disasters

The invention discloses an urban large building fire fighting emergency evacuation system and method, and belongs to the field of building fire fighting safety, and the system comprises a region marking module, a personnel collection module, a fire detection module, a disaster situation prediction module, a disaster situation management and control module, an evacuation planning module and a loss analysis module, the area marking module is used for carrying out data marking on the building; according to the invention, evacuation personnel can be rapidly and accurately guided, the probability that the personnel are jammed and trampled in a single channel is greatly reduced, the safety of the evacuation personnel in the evacuation process is ensured, a response can be made in time when a fire occurs, corresponding fire extinguishing management and control processing is carried out on the fire, the fire spreading speed is effectively restrained, and the safety of the evacuation personnel is ensured. And the personnel escape rate is improved.

Owner:深圳正中云有限公司

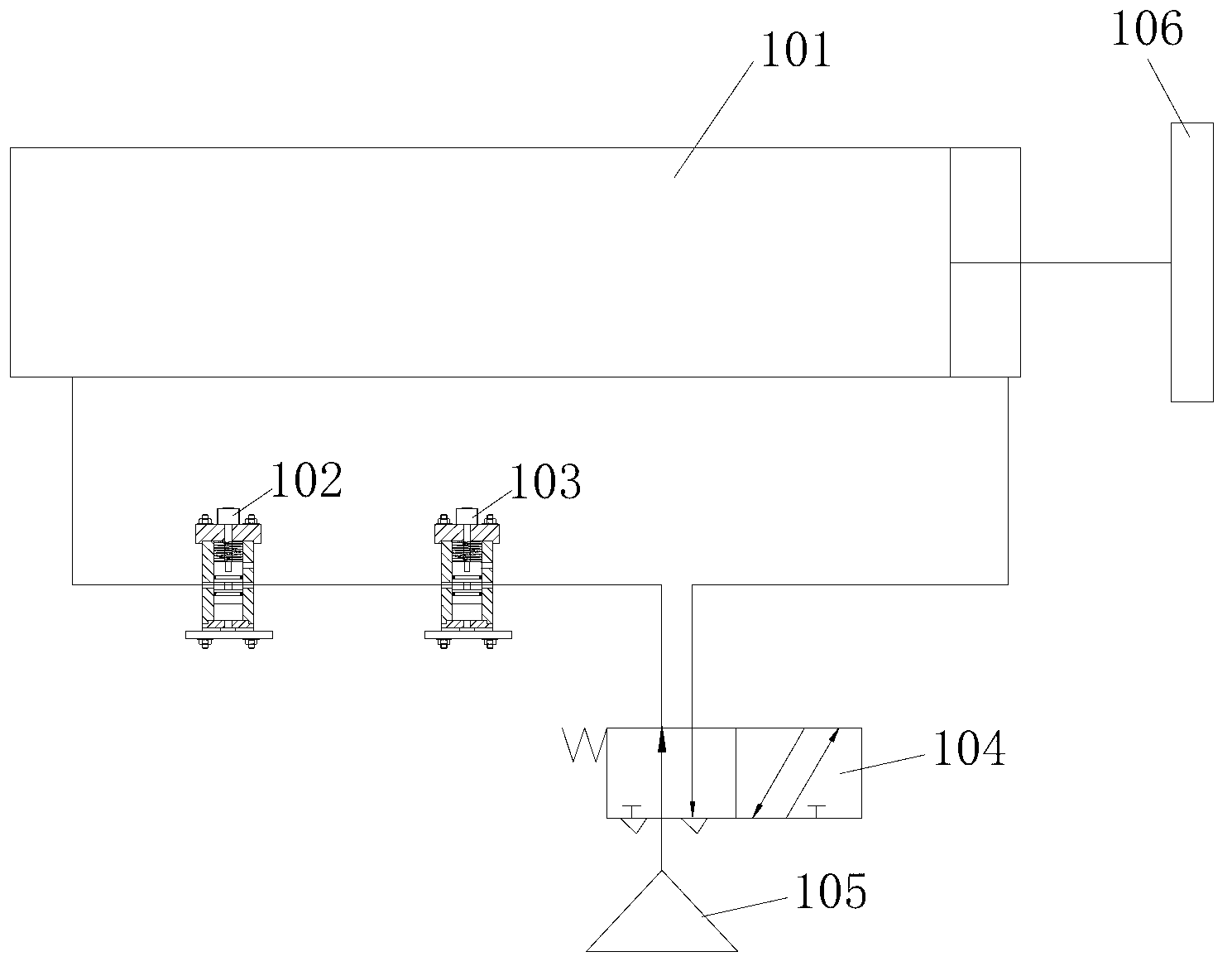

Emergency escape hand-control device and emergency escape hand-control system for pneumatic-control bus door of bus

InactiveCN102700494AAvoid misuseSimple structurePedestrian/occupant safety arrangementEmbedded systemCar door

The invention relates to an emergency escape hand-control device and an emergency escape hand-control system for a pneumatic-control bus door of a bus. The system is provided with two hand-control devices (pop safety valves) which are connected in series, wherein the hand-control devices are respectively arranged at the bus door and a navigation bridge, can be respectively operated by a driver and passengers and can operate by virtue of manual control on any position; with reference to the hand-control devices, by virtue of rotating an operating handle for 90 degrees clockwise, an air path for connecting an air pump with the cylinder of the bus door can be rapidly cut off; and meanwhile, the pressure air in the cylinder of the bus door is rapidly discharged, so that the bus door can be easily pushed away by hand, and thus the passengers can escape. The system provided by the invention has the advantages of being simple in structure, safe and reliable in use and convenient and labor-saving in operation, being capable of realizing the rapid opening of the bus door, ensuring that the two hand-control devices are mutually independent and have no interference, and greatly increasing the escape probability of the passengers in the bus under emergency conditions.

Owner:SHANGHAI DIANJI UNIV

Technology and device for producing defluorinated phosphoric acid

PendingCN110980674AIncreased surface reaction areaIncreased fluorine release ratePhosphorus compoundsO-Phosphoric AcidPhysical chemistry

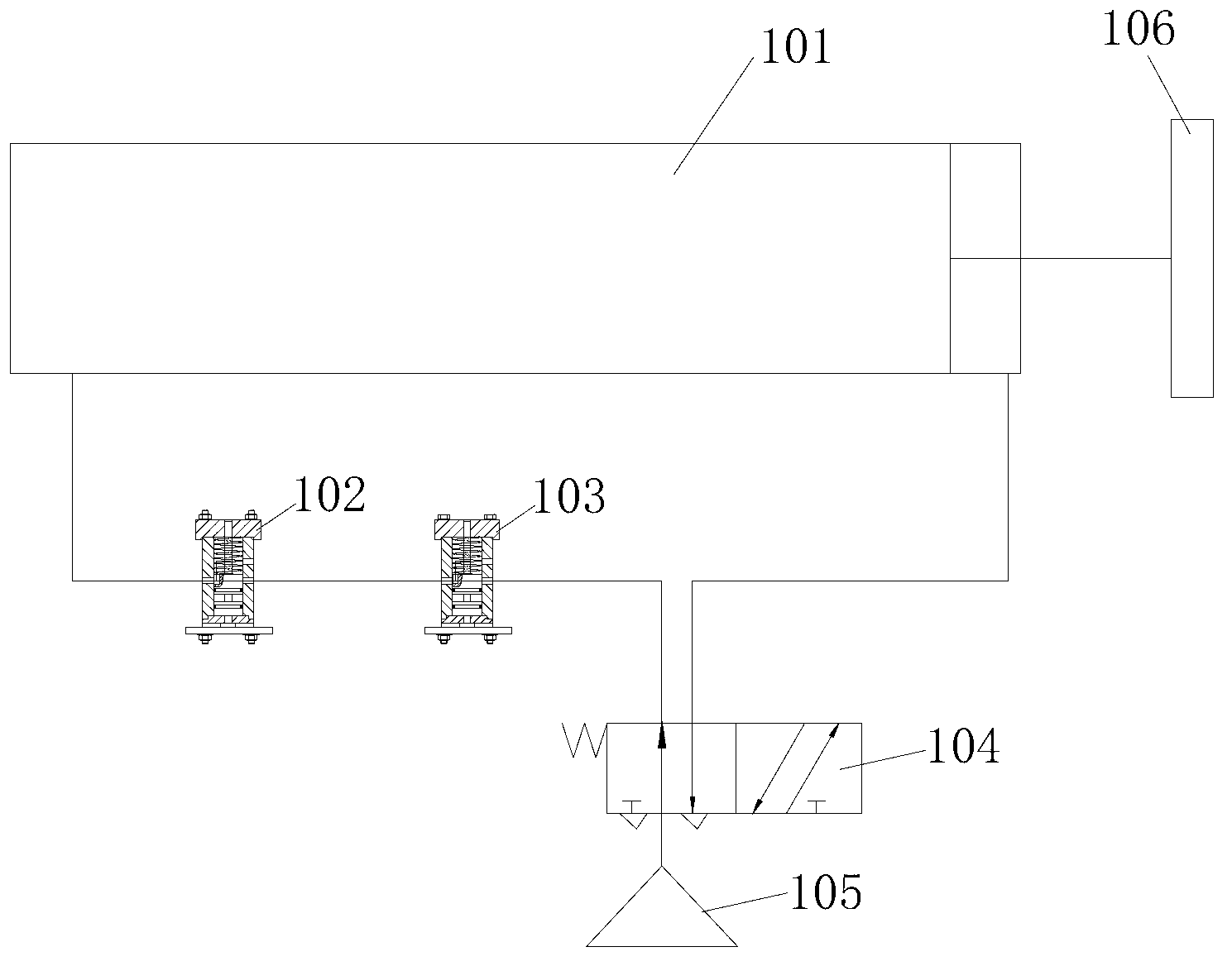

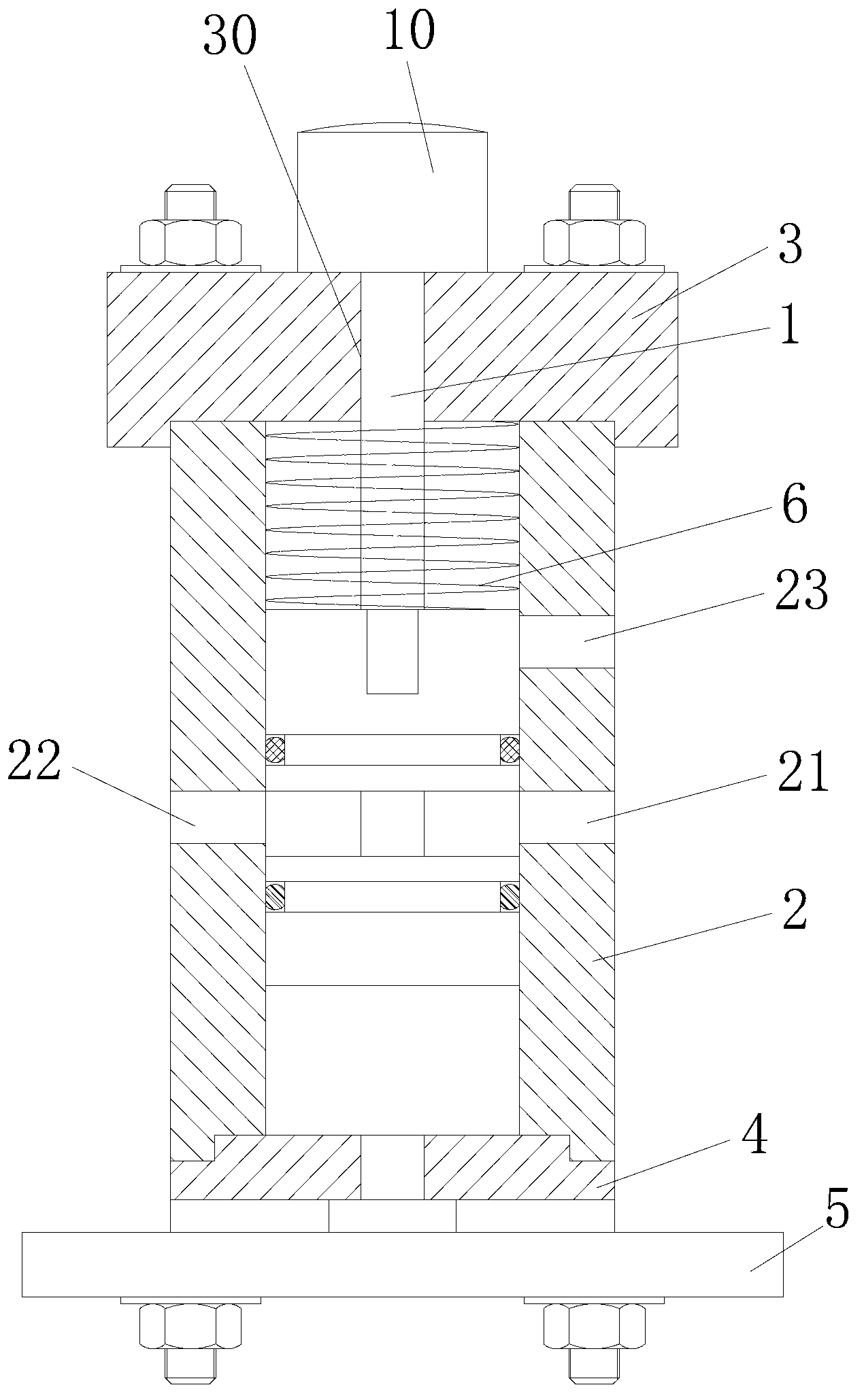

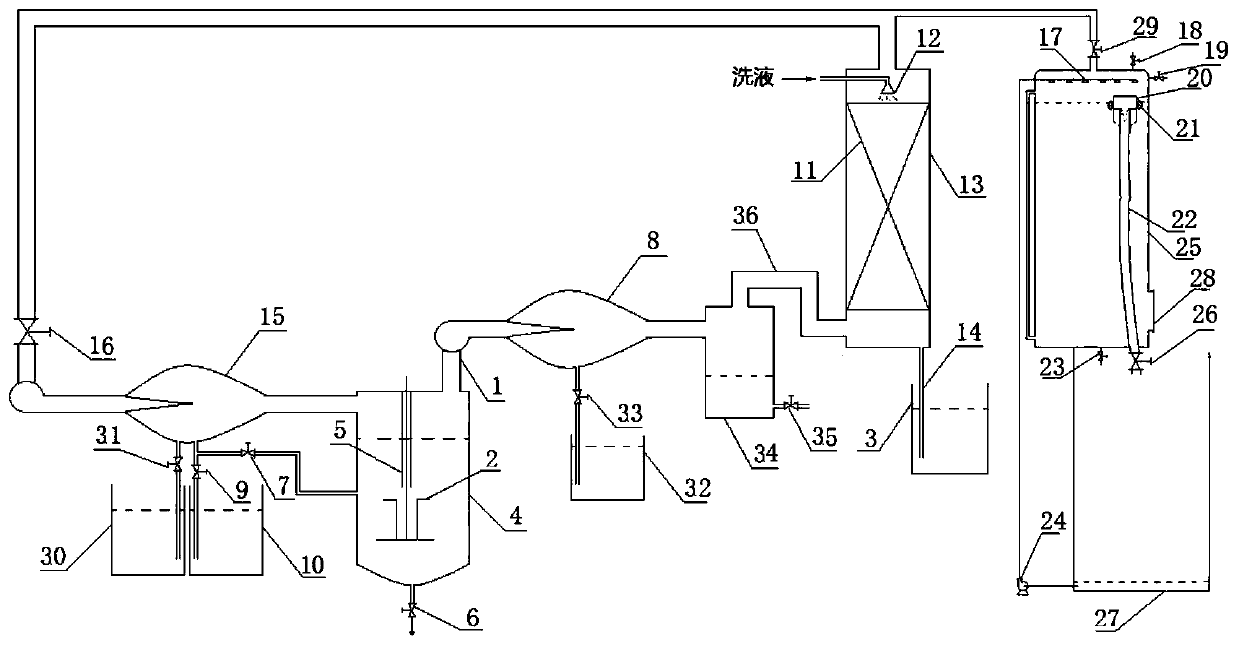

A technology for producing defluorinated phosphoric acid is characterized in that fluorine-containing phosphoric acid produced from wet-process phosphoric acid is divided into two parts, one part is used as a returned acid, and the other part is used as crude phosphoric acid; an injection pump A, a reaction kettle, an injection pump B, a gas-liquid separator and an absorption tower are sequentially connected through pipelines to form a circulating closed pipeline system which is in a micro-negative pressure state; the injection pump A and the injection pump B enable a gas in the system to circularly flow at a high speed, and the injection pump A sucks and mixes the returned acid and sulfuric acid, then sucks a reaction liquid and sulfuric acid in the reaction kettle, mixes the reaction liquid and sulfuric acid with gas flow and sprays the obtained mixture onto the liquid level of the reaction kettle; vacuum generated by the injection pump B makes the crude phosphoric acid and low-fluorine hot steam emitted from the reaction kettle be sucked and mixed and then enter the gas-liquid separator, a liquid led out from the gas-liquid separator is refined product defluorinated phosphoric acid, the gas is sent to the bottom of the absorption tower, and a defluorination tail gas led out from the top of the absorption tower enters the injection pump A and circularly flows; and a washing liquid is sprayed from the top of the absorption tower, and fluosilicic acid liquid is led out from the bottom of the absorption tower. The invention further discloses a device for producing defluorinated phosphoric acid.

Owner:HUANGGANG NORMAL UNIV +1

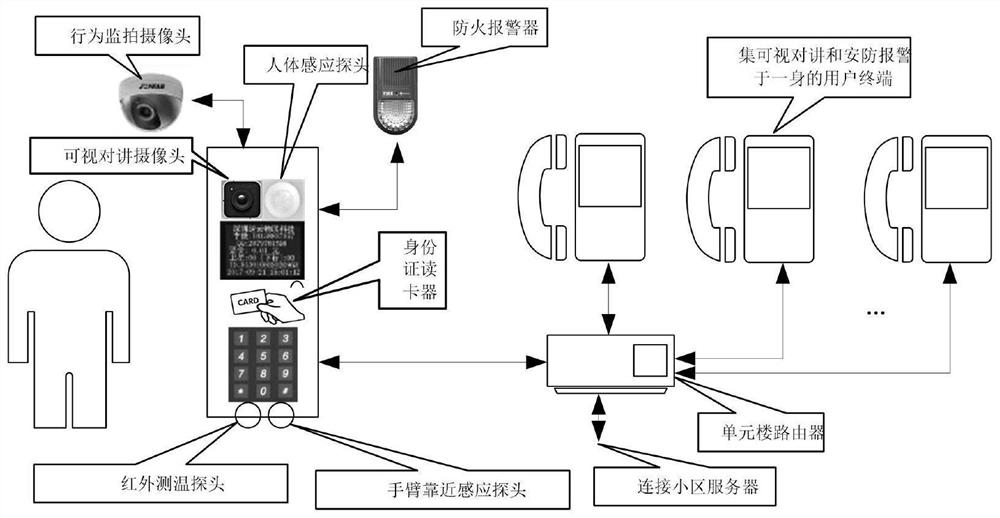

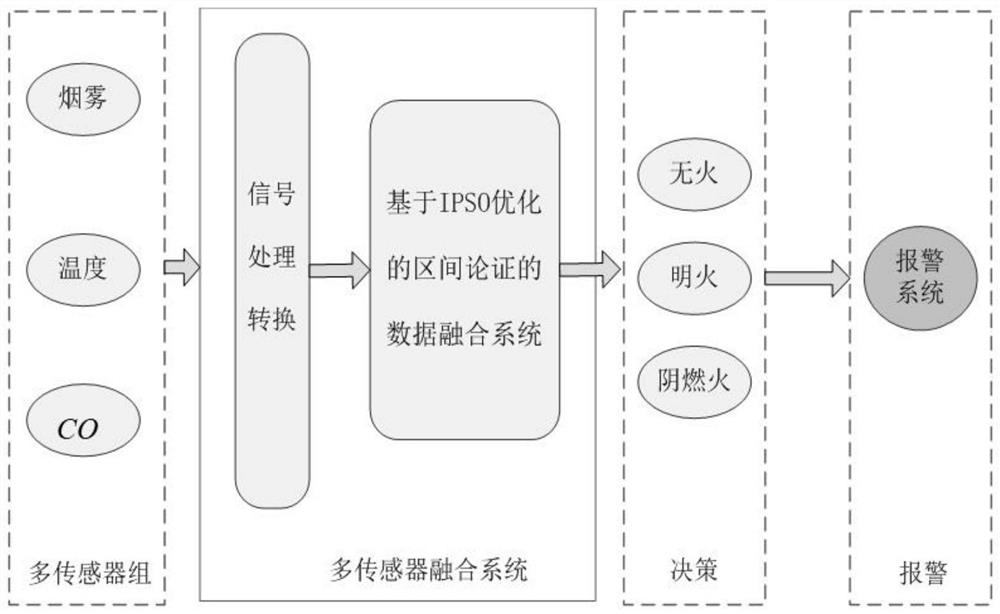

Disaster cellular alarm linkage system based on interval argumentation multi-sensor fusion of particle swarm optimization

ActiveCN113053053ARealize one-key alarmKnow the fire situation in timeData processing applicationsEpidemiological alert systemsFire alarm systemFire - disasters

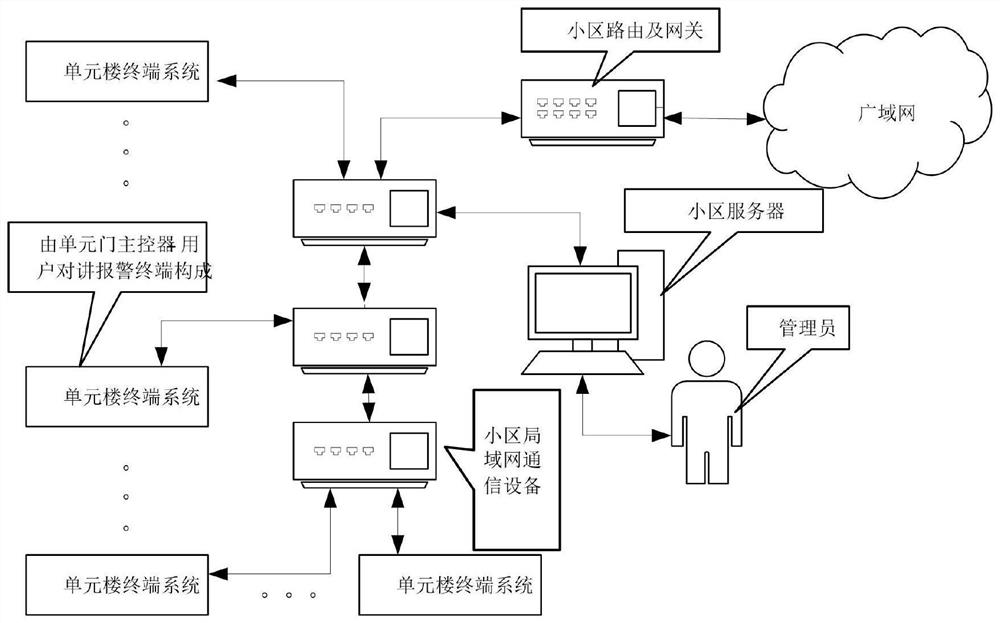

The invention discloses a disaster cellular alarm linkage system based on interval argumentation multi-sensor fusion of particle swarm optimization. The system comprises a fire monitoring alarm linkage system, a public fire alarm system and a property management platform, and is characterized in that the fire monitoring alarm linkage system comprises access control terminals of building doors of all units of a community and cellular user terminals, and emergency alarm switches are arranged on both a real estate management platform and the fire monitoring alarm linkage system; the public fire alarm system comprises a CO sensor, a smoke sensor, a temperature sensor and an alarm controller which are arranged in a resident of a community, and a fire judgment data fusion algorithm based on IPSO optimization interval demonstration multi-sensor fusion is arranged in the alarm controller. According to the present invention, the fire monitoring and alarming linkage system is matched with the public fire alarming system to work, the automatic fire alarming and the manual fire alarming are integrated, and the uncertainty of the sensor measurement data is eliminated based on the fire judgment data fusion algorithm based on IPSO optimization interval demonstration multi-sensor fusion.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

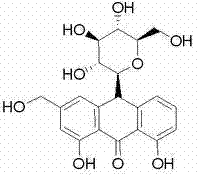

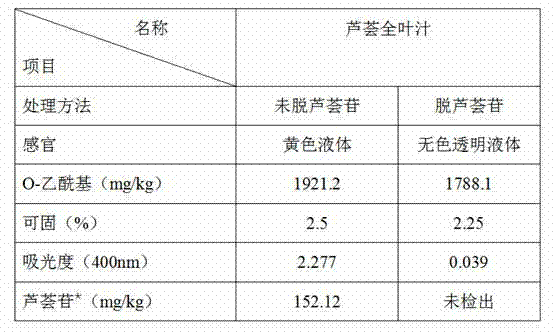

Method for removing pigment and barbaloin in aloe barbadensis juice

The invention provides a method for removing pigment and barbaloin in aloe barbadensis juice, wherein the clean aloe barbadensis leaves are peeled, ground to squeeze juice, and sterilized for 4-6 seconds at the temperature of 80-95 DEG C to obtain the aloe barbadensis juice, pectinase is added into the aloe barbadensis juice for enzymolysis for 40-60 minutes at the temperature of 50-55 DEG C, the aloe barbadensis juice is filtered, sterilized for 4-6 seconds at the temperature of 120-125 DEG C, and cooled to the room temperature, the aloe barbadensis crude juice passes through macroporous anion resin, the contact time of the aloe barbadensis crude juice and the macroporous anion resin is controlled between 20-25 minutes, so the aloe barbadensis juice which is removed with the pigment and the barbaloin is obtained. The method has the advantages of easiness for control, high removing rate, improved aloe barbadensis juice color and absorbance; the adopted resin can be recycled, so the environmental pollution is reduced, and the production cost is lowered; and the contact time is short, the nutritional ingredients of an aloe barbadensis product are not influenced, and the product quality can be improved.

Owner:云南万绿生物股份有限公司

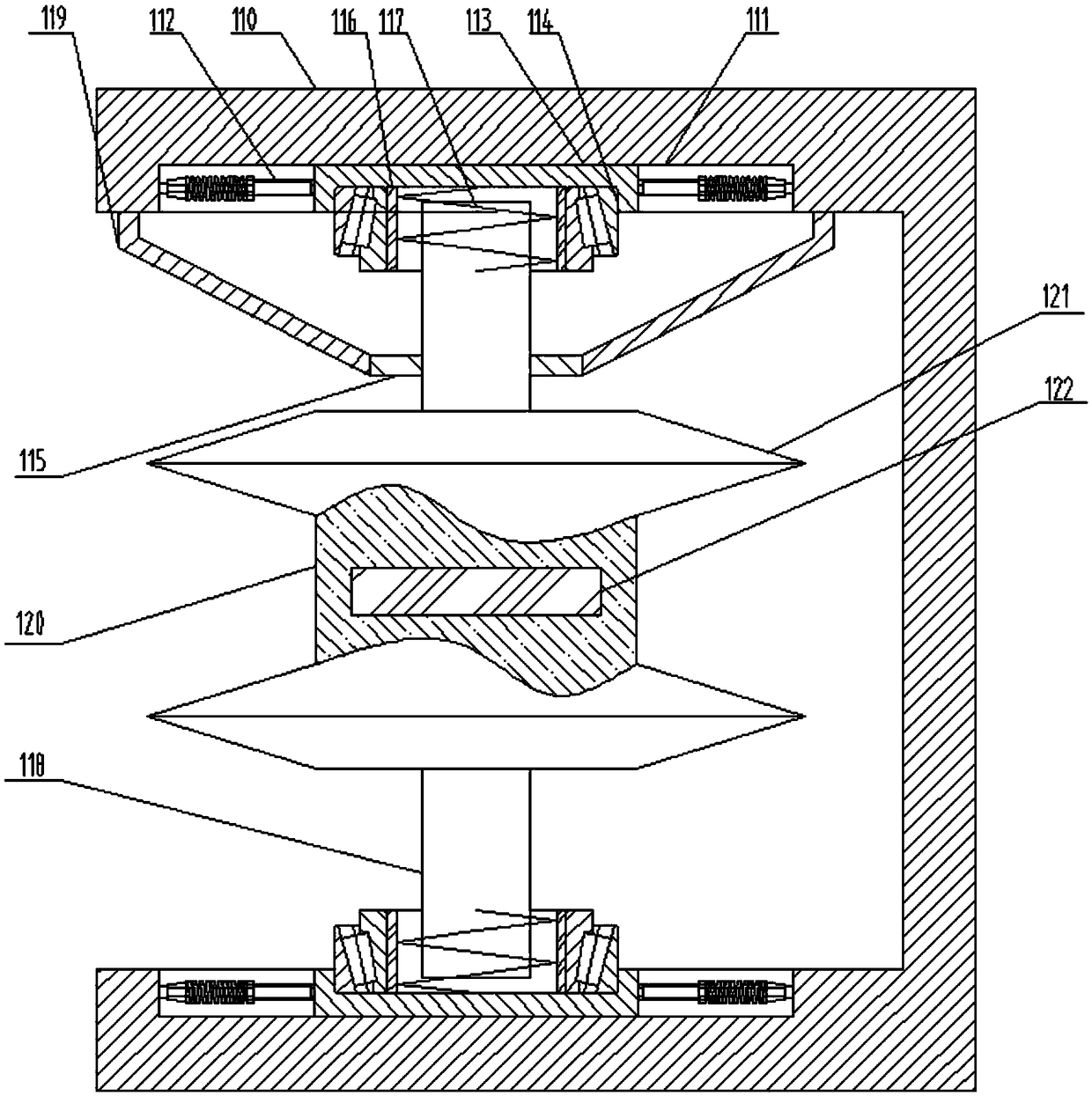

Microspherical catalyst as well as preparation method and application thereof

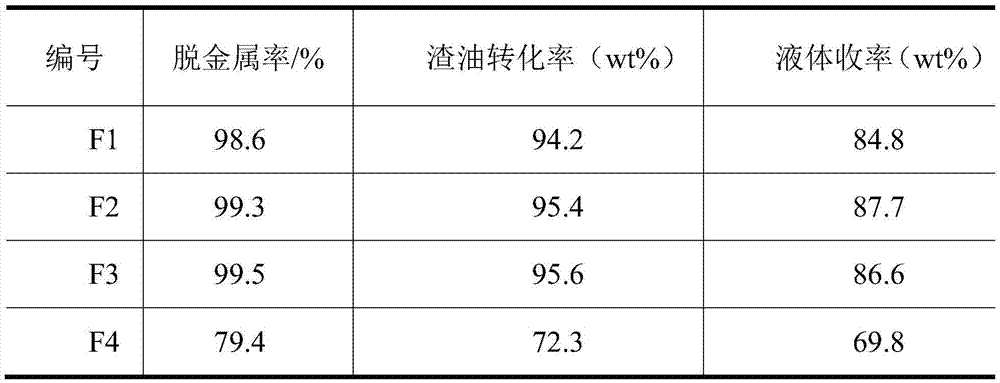

ActiveCN105435831AGood hydrogenation activityHigh yieldMolecular sieve catalystsHydrocarbon oils refiningDeoxygenationChemistry

The invention discloses a microspherical catalyst as well as a preparation method and an application thereof. The preparation method comprises the following steps: 1) mixing and stirring zeolite powder and ethyl alcohol so as to obtain slurry; 2) sequentially drying, forming, setting and sintering the slurry obtained in the step 1), thereby obtaining zeolite catalyst microspheres; and 3) impregnating the zeolite catalyst microspheres obtained in the step 2) into a metal impregnation liquid, and then drying the impregnated zeolite catalyst microspheres so as to obtain the microspherical catalyst. The preparation method is simple and convenient to operate; the prepared microspherical catalyst has high cracking performance, high desulfuration, denitrification and deoxygenation performance, high hydrogenation performance, high demetalization performance and high coke adsorption performance, and can be widely applied to heavy oil slurry bed hydrocracking process.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

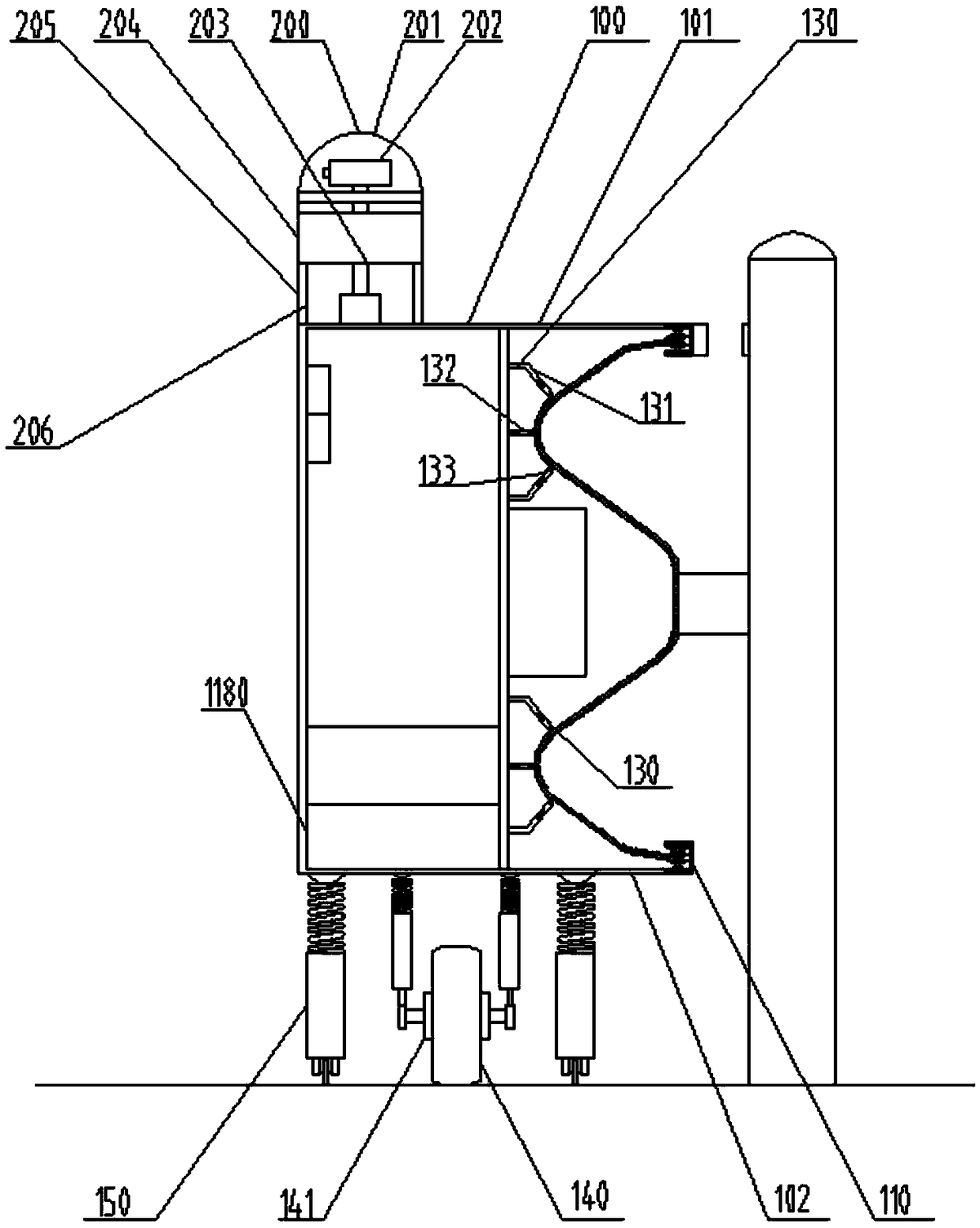

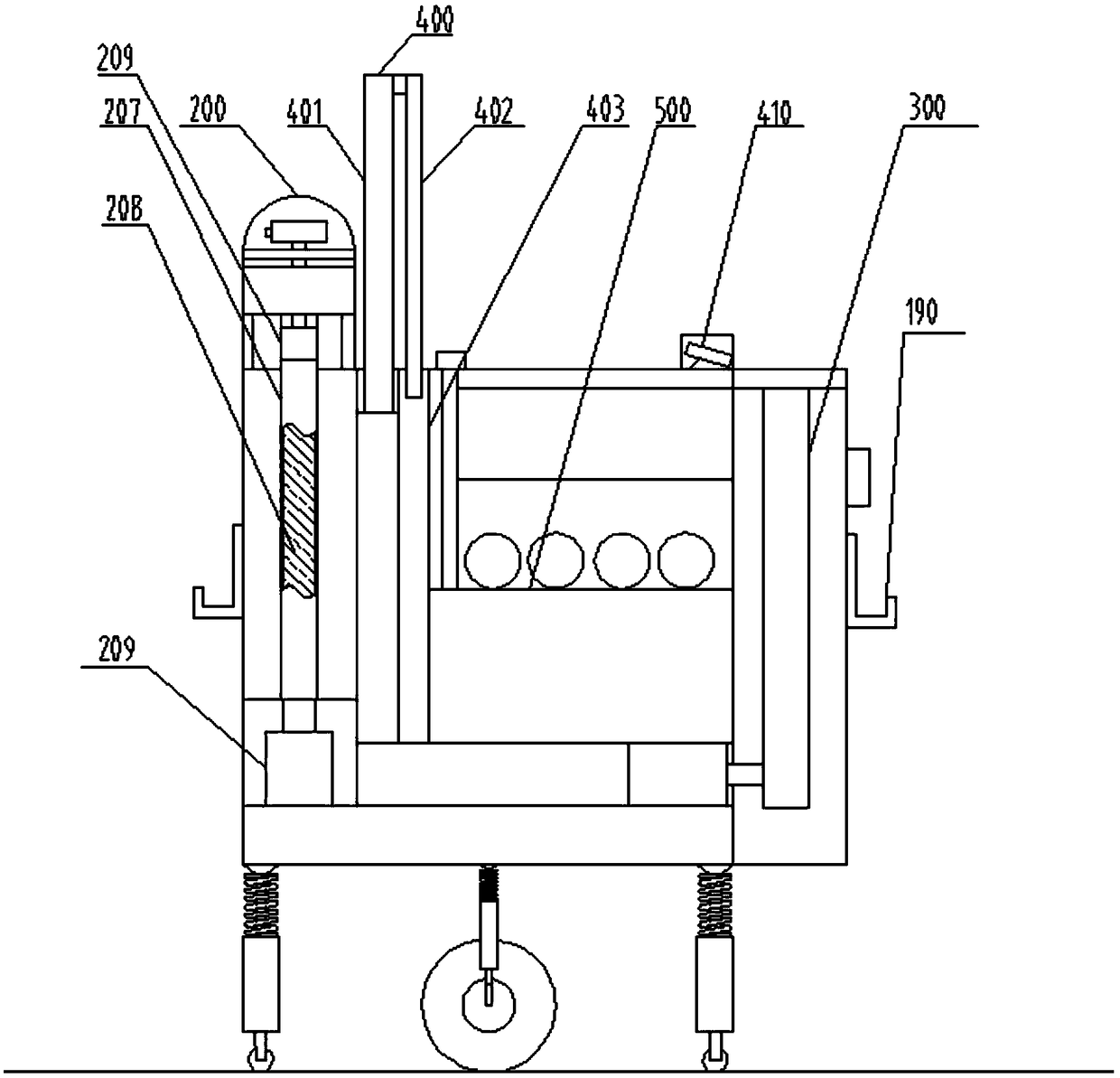

Expressway police robot

InactiveCN108898837AImprove efficiencyIntensify patrollingTelevision system detailsDetection of traffic movementDrive wheelRadar

The invention discloses an expressway police robot which comprises a box body, wherein the bottom surface of the box body is a plane, not less than four auxiliary wheels are fixed to the bottom surface of the box body, the auxiliary wheels are distributed at the periphery of the bottom surface of the box body, a driving wheel is fixed to the central position of the auxiliary wheels, an advancing motor is fixed to the hub axis of the driving wheel, an upper location plate and a lower location plate which outwards extend in parallel are fixed to one side in the axial direction of the driving wheel of the box body, and a plurality of fence location devices are fixed to the sides of the spare ends of the upper location plate and the lower location plate. The expressway police robot further comprises a camera, a radar speed measuring module and a control module. The robot can remarkably improve work efficiency of traffic police.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

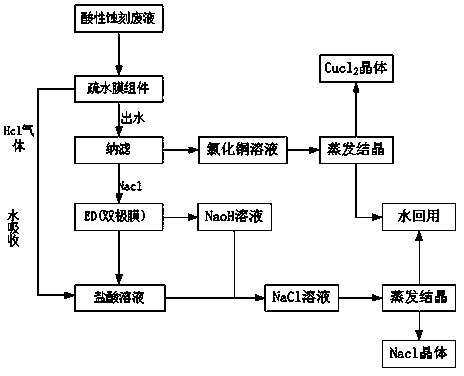

Recovery treatment method of acidic etching waste liquor

ActiveCN104176871ARealize recycling of resourcesImprove escape rateMultistage water/sewage treatmentPhysical chemistryEngineering

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com