Refining method of raw material gas containing ethene in process of preparing ethylbenzene from ethene

A refining method and raw gas technology, applied in the direction of liquid carbon-containing fuel, chemical instruments and methods, fuel, etc., can solve the problems of waste of resources, discontinuity, high investment, etc., and achieve the effect of increasing production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

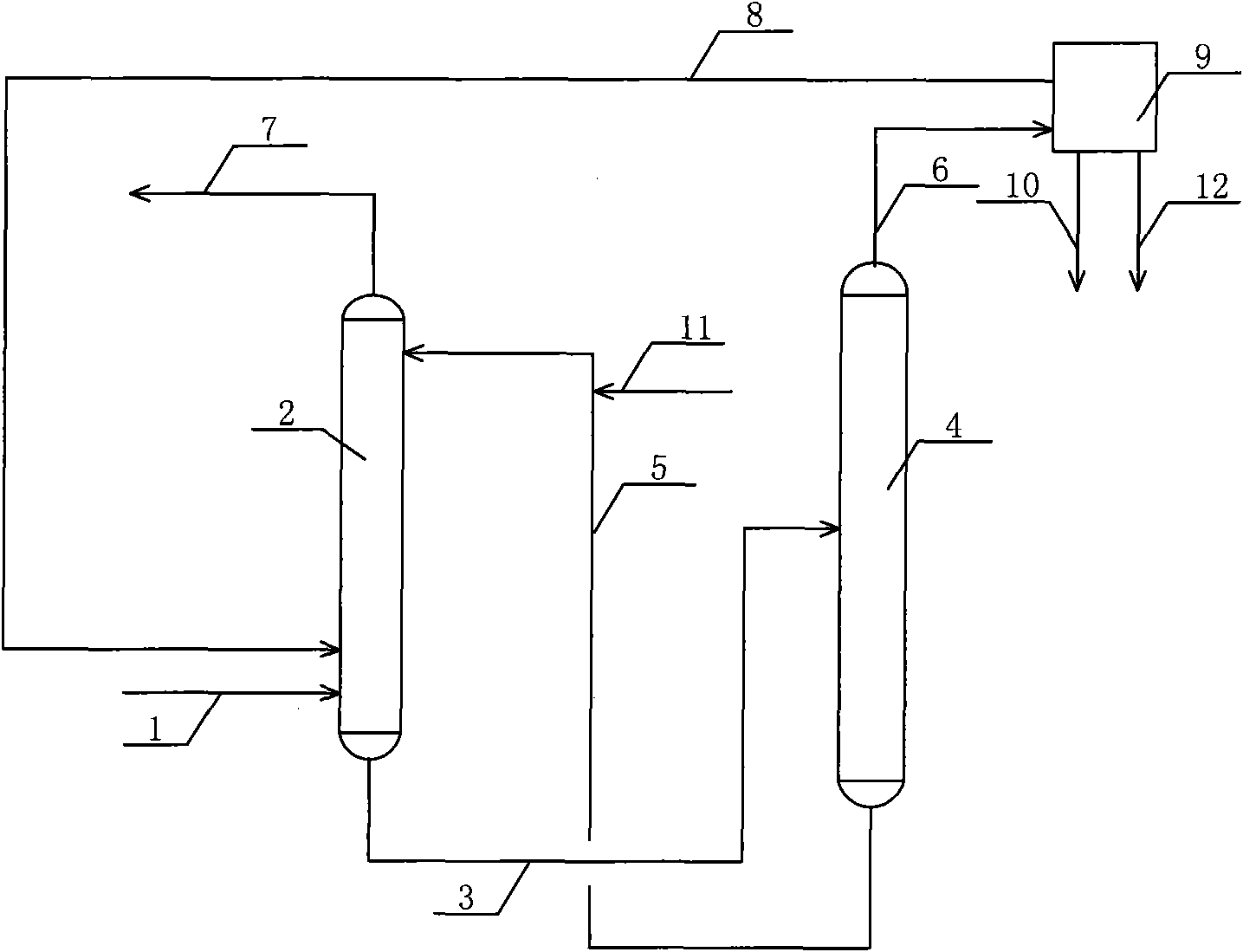

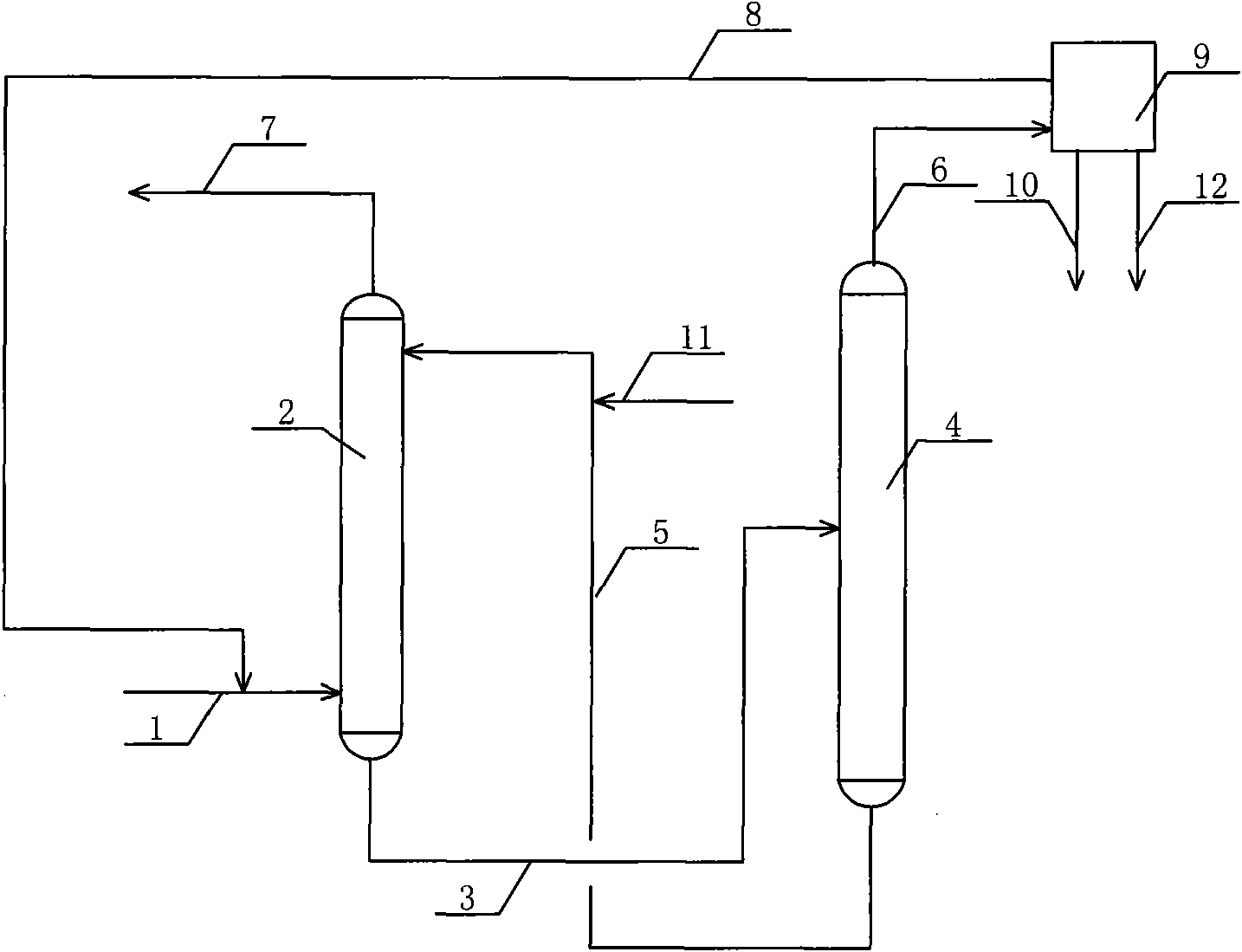

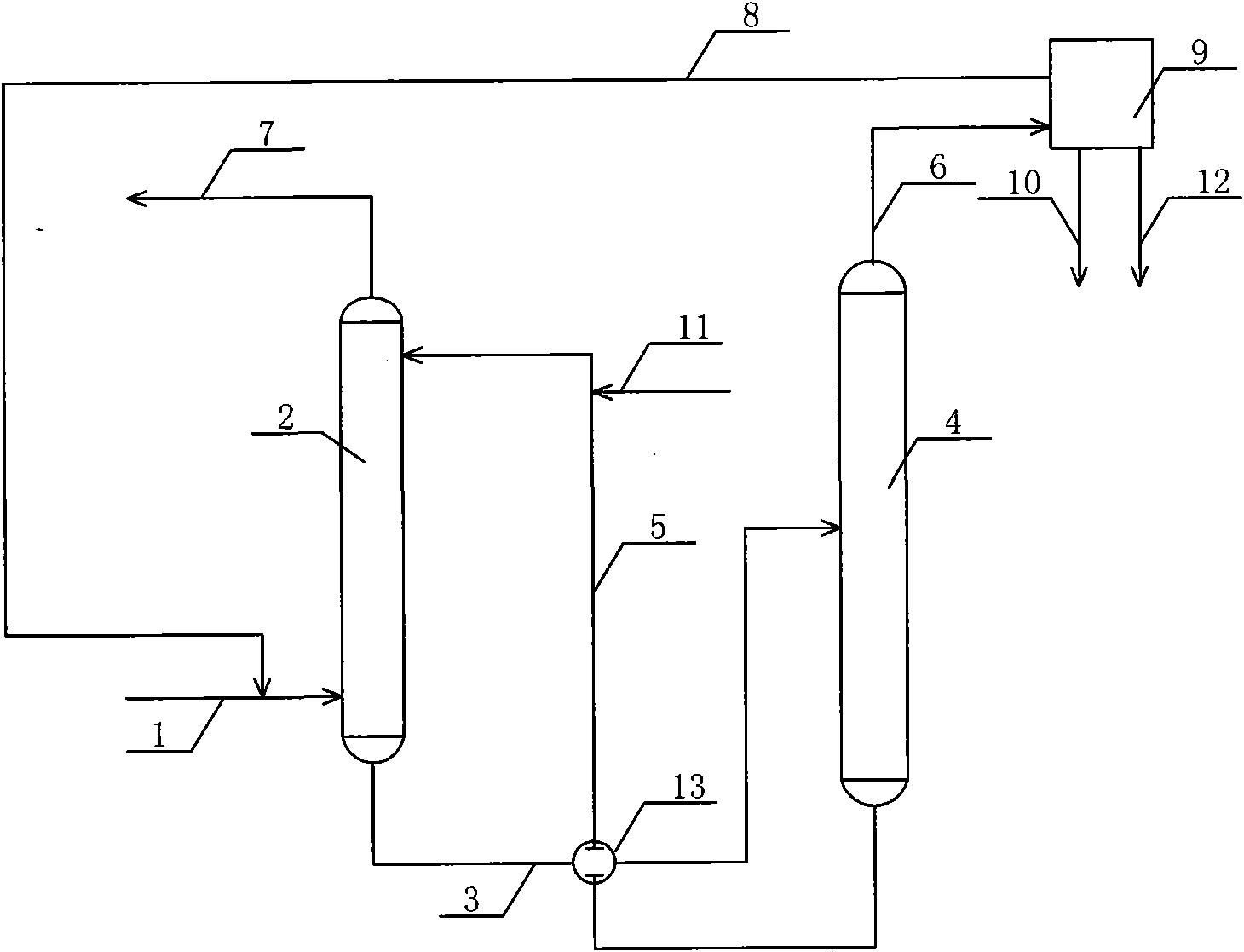

[0039] A specific embodiment of the present invention is as figure 1 As shown, the ethylene-containing raw material gas 1 and the dilute ethylene gas 8 returned by the catalytic cracking or catalytic cracking unit enter from the lower end of the absorption device 2 respectively, and the desorbed absorbent 5 is mixed with the supplementary absorbent 11 and enters from the upper end of the absorption device 2. Under the condition that the temperature is -20°C-40°C, the pressure is 0.1-5.0MpaG, and the volume ratio of the absorbent to the total amount of raw gas is 0.001-1, most of the propylene in the raw gas is removed, and the purification after absorption by the absorbent The raw material gas 7 enters the reaction part of the ethylbenzene plant; the saturated absorbent 3 enters the middle section of the desorption device 4 for desorption, the pressure is 0.001-4.0MPaG, the temperature is 10-300°C, and the absorbent 5 after desorption at the bottom of the tower is mixed with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| escape rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com