Method and system for preparing sulfuric acid and direct reduction iron from pyrite

A technology of pyrite and reduced iron, which is applied in the field of pyrite to prepare sulfuric acid and direct reduction of iron, which can solve the problems of limiting the application range and quantity of sulfuric acid slag, and the amount of sulfuric acid slag added cannot exceed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

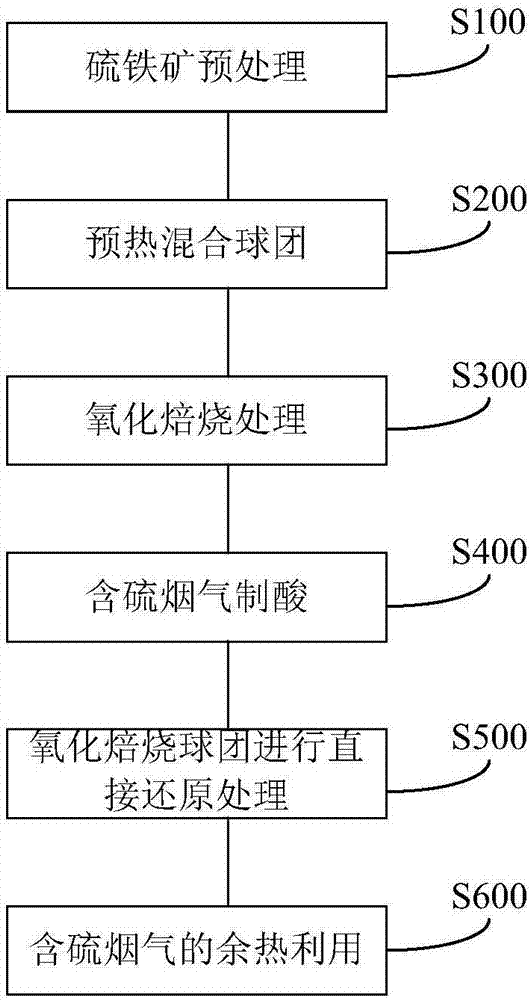

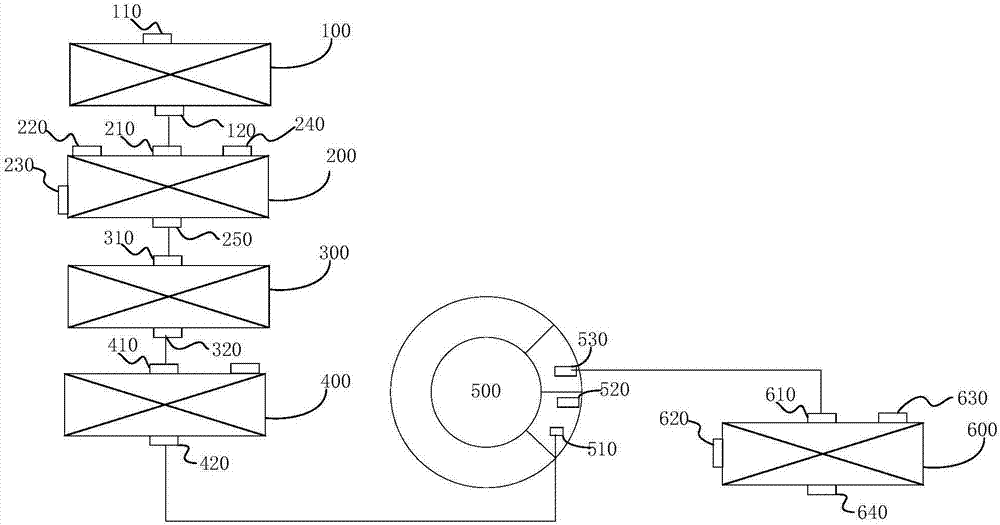

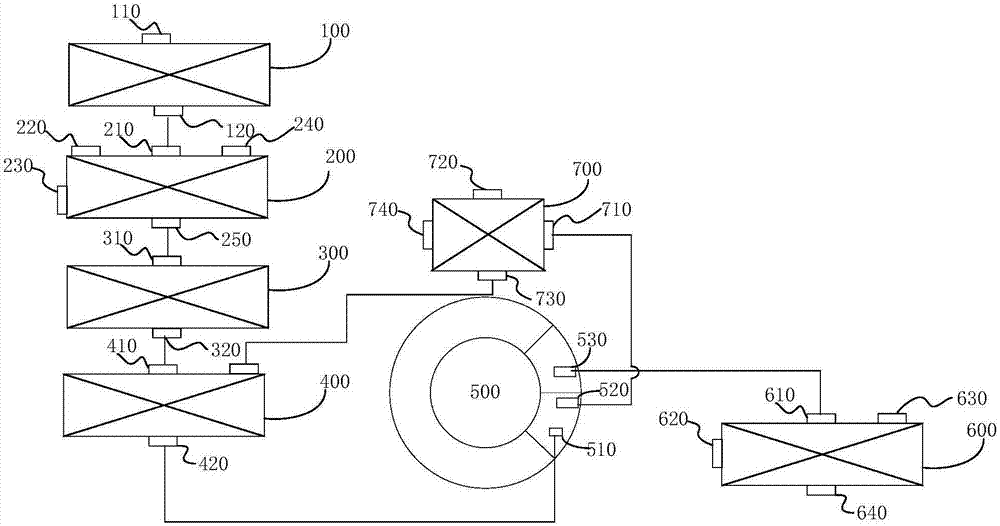

[0043] According to one aspect of the present invention, the present invention proposes a method for preparing sulfuric acid and direct reduction iron from pyrite. According to a specific embodiment of the present invention, the method includes: (1) finely grinding the pyrite, so that Obtain pyrite powder; (2) carry out mixed molding process with pyrite powder and water, binding agent and additive, so that obtain mixed pellet; (3) supply mixed pellet to chain grate machine and carry out drying, the second First preheating and second preheating, in order to obtain preheated pellets; (4) supply the preheated pellets to the rotary kiln for oxidation roasting treatment, in order to obtain oxidation roasted pellets and sulfur-containing flue gas; (5) use Sulfur flue gas is used to make acid to obtain sulfuric acid and acid-removing flue gas; (6) Supply the oxidized and roasted pellets to the air-based shaft furnace for direct reduction treatment with reducing gas to obtain zinc-cont...

Embodiment 1

[0098] Finely grind the selected pyrite to -200 mesh, accounting for more than 60%, and mix the finely ground pyrite, water, binder bentonite, and additive calcium oxide at a mass ratio of 100:8:0.83:0.77 to make pellets , the particle size of the pellets is 10-18mm, accounting for 90%. After the pellets are screened, they are transported to the grate machine-rotary kiln, dried at 250°C for 8 minutes, preheated at 400-600°C for 5 minutes, and preheated at 600-1200°C. Heat for 4 minutes, oxidize and roast at 1200-1250°C for 8 minutes, principle of oxidation and roast: FeS 2 +O 2 =Fe 2 o 3 +SO 2 , ZnS+O 2 =ZnO+SO 2 ↑ Roasting produces flue gas and solid oxidized pellets, SO 2 Acid production is recovered from the flue gas, and the oxidized pellets are sent to the gas-based shaft furnace for direct reduction. The main component of the reduced gas is H 2 +CO content is 80%, the temperature of the reducing gas is heated to 950°C, the temperature in the reduction section of t...

Embodiment 2

[0106] Finely grind the selected pyrite to -200 mesh, accounting for more than 60%, and mix the finely ground pyrite, water, binder bentonite, and additive calcium fluoride at a mass ratio of 100:6:0.62:0.98 to make Balls, pellets with a particle size of 10-18mm account for 90%. After screening, the finished pellets are transported to the grate machine-rotary kiln, baked at 250°C for 3 minutes, preheated at 400-600°C for 4 minutes, and preheated at 600-1200°C. Heat for 4 minutes, oxidize and roast at 1200-1250°C for 5 minutes, principle of oxidation and roast: FeS 2 +O 2 =Fe 2 o 3 +SO 2 , ZnS+O 2 =ZnO+SO 2 ↑ Roasting produces flue gas and solid oxidized pellets, SO 2 Acid production is recovered from the flue gas, and the oxidized pellets are sent to the gas-based shaft furnace for direct reduction. The main component of the reduced gas is H 2 The +CO content is above 85%, the temperature of the reducing gas is heated to 850°C, the temperature in the reduction section o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com