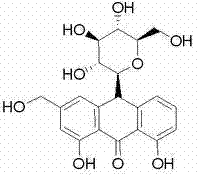

Method for removing pigment and barbaloin in aloe barbadensis juice

A technology of aloe vera juice and aloe vera glycosides, applied in the application, food preparation, food science and other directions, can solve the problems of high removal cost and large pollution of aloe vera glycosides, and achieve the effects of improving color, reducing production costs and short contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A. Wash 35 tons of aloe leaves with water to remove the residual sediment on the aloe leaves, then disinfect and clean the surface of the aloe leaves with a concentration of 20ppm chlorine dioxide disinfectant to control the growth of microorganisms, disinfect and clean, and then use pure water Wash the aloe leaves to remove the residual disinfectant, then remove the edge thorns and skins, and then crush and extract the juice. Sterilize them at 80°C for 6 seconds to obtain 15 tons of aloe juice;

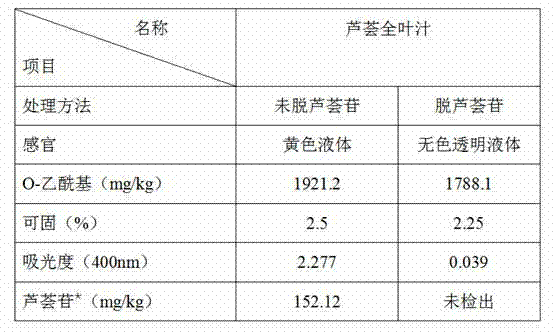

[0023] B. Add 750ml of pectinase to the aloe juice obtained in step A, enzymatically react at 50°C for 60 minutes, filter, sterilize at 120°C for 6 seconds, and cool to room temperature to obtain crude aloe juice; Detect the content of aloin, O-acetyl and solid content;

[0024] C. According to the volume ratio of crude aloe vera juice: macroporous anion resin = 12:1, pass the crude aloe juice obtained in step B through a commercially available industrial-grade macroporous anion re...

Embodiment 2

[0028] A. Wash 30 tons of aloe leaves with water to remove the residual sediment on the aloe leaves, and then disinfect and clean the surface of the aloe leaves with a concentration of 30ppm chlorine dioxide disinfectant to control the growth of microorganisms, disinfect and clean, and then use pure water Wash the aloe leaves to remove the residual disinfectant, then remove the edge thorns, and then crush and squeeze the juice. Sterilize at 95°C for 4 seconds to obtain 22 tons of aloe juice;

[0029] B. Add 2200ml of pectinase to the aloe juice obtained in step A, enzymatically react at 55°C for 40 minutes, filter, sterilize at 125°C for 4 seconds, and cool to room temperature to obtain crude aloe juice; Detect the content of aloin, O-acetyl and solid content;

[0030] C. According to the volume ratio of crude aloe vera juice: macroporous anion resin = 10:1, pass the crude aloe juice obtained in step B through a commercially available industrial-grade macroporous anion resin, and t...

Embodiment 3

[0035] A. Wash 35 tons of aloe leaves with water to remove the residual sediment on the aloe leaves, and then use a chlorine dioxide disinfectant with a concentration of 40ppm to disinfect and clean the surface of the aloe leaves to control the growth of microorganisms, disinfect and clean, and then use pure water Wash the aloe leaves to remove the residual disinfectant, then remove the edge thorns, then crush and squeeze the juice. Sterilize the leaves at 90°C for 5 seconds to obtain 22 tons of aloe juice;

[0036] B. Add 1650ml of pectinase to the aloe juice obtained in step A, enzymatically react at 52°C for 50 minutes, filter, sterilize at 122°C for 5 seconds, and cool to room temperature to obtain crude aloe juice;

[0037] C. According to the volume ratio of crude aloe vera juice: macroporous anion resin = 15:1, pass the crude aloe juice obtained in step B through a commercially available industrial-grade macroporous anion resin, and control the contact time between the crude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com