Recovery treatment method of acidic etching waste liquor

A treatment method and resource-based technology, applied in the field of advanced treatment of wastewater in the chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

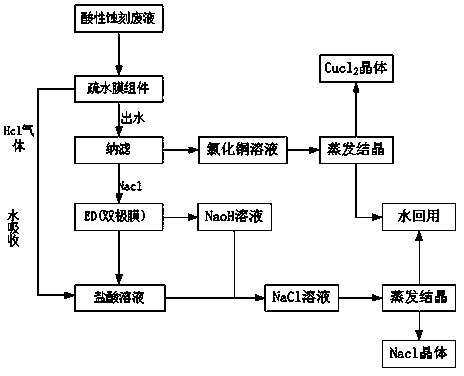

Image

Examples

Embodiment 1

[0042] A kind of acidic etching waste liquid, wherein CuCl 2 The content is 160g / L, the NaCl content is 100g / L, the HCl content is 10g / L, the solution pH=0.52, and the water inflow is 5m 3 / h.

[0043] Firstly, the acidic etching waste liquid is heated to 45°C, then filtered through the security filter and then enters from the bottom of the hollow fiber hydrophobic membrane module, and the other side of the membrane is fed with deionized water, and the hydrogen chloride gas passing through the hydrophobic membrane is absorbed by the deionized water to obtain Dilute hydrochloric acid solution and flow into the middle tank of hydrochloric acid. In this process, the hydrogen chloride removal rate of the single-stage membrane is 60%, the number of membrane stages is 5, and each stage is 10 membranes. The hydrochloric acid content in the effluent is 150mg / L, and the hydrogen chloride gas removal rate reaches 97%. % dilute hydrochloric acid solution. In addition, the pressure ...

Embodiment 2

[0046] A kind of acidic etching waste liquid, wherein CuCl 2 The content is 160g / L, the NaCl content is 100g / L, the hydrochloric acid HCl content is 10g / L, the solution pH=0.52, and the water inflow is 5m 3 / h.

[0047] Firstly, the acidic etching waste liquid is heated to 46°C, then filtered through the security filter and enters from the bottom of the hollow fiber hydrophobic membrane module, and the other side of the membrane is fed with deionized water to absorb the hydrogen chloride gas passing through the hydrophobic membrane to obtain a dilute hydrochloric acid solution and flow it into hydrochloric acid middle slot. The removal rate of the single-stage membrane selected for the hydrophobic membrane module is 60%, the number of membrane stages is set to 6, and each stage is also 10 membranes. The pressure on the etching liquid side is greater than that on the absorbing liquid side. It is 180mg / L, and at the same time, a 0.3% dilute hydrochloric acid solution is obtain...

Embodiment 3

[0050] A kind of acidic etching waste liquid, wherein CuCl 2 The content is 160g / L, the NaCl content is 100g / L, the hydrochloric acid HCl content is 10g / L, the solution pH=0.52, and the water inflow is 5m 3 / h.

[0051] Firstly, the acidic etching waste liquid is heated to 48°C, then filtered through the security filter and enters from the bottom of the hollow fiber hydrophobic membrane module, and the other side of the membrane is fed with deionized water to absorb the hydrogen chloride gas passing through the hydrophobic membrane to obtain a dilute hydrochloric acid solution and flow it into hydrochloric acid middle slot. The hydrogen chloride removal rate of the single-stage membrane used in the hydrophobic membrane module is 60%. The number of membrane stages is 7, and each stage also has 10 membranes. The pressure on the side of the etching waste liquid is greater than that of the side of the absorption liquid. MPa. The HCl content in the effluent is 210mg / L, and a 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com