Recycling separation process of electrode component materials of used lithium batteries

A lithium battery and recycling technology, applied in the field of recycling separation process, can solve the problem of low comprehensive utilization rate, and achieve the effects of efficient removal, easy control, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

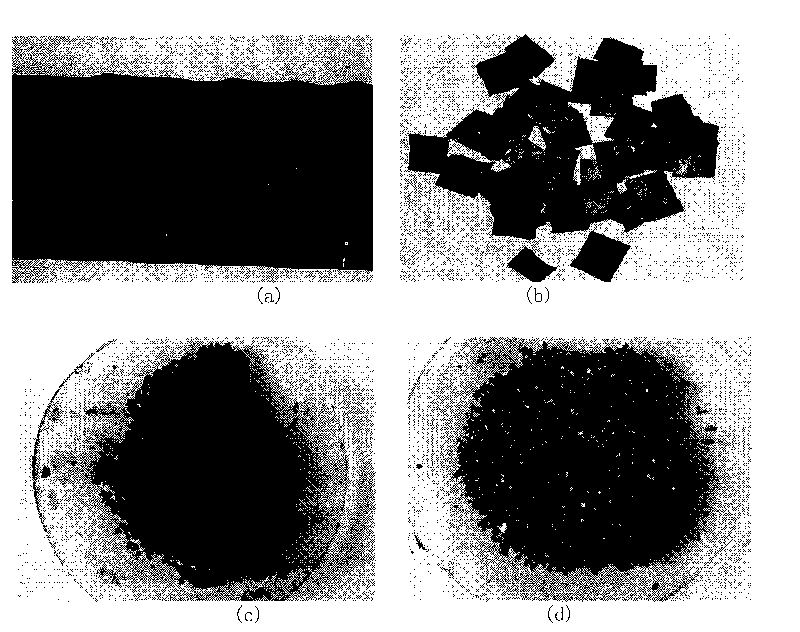

[0026] Example 1: A 10-mesh sieve plate is set at the lower part of the rotor of an ordinary hammer crusher, and the negative electrode of the waste lithium battery is hammered and stripped with it, and the resulting broken particles can be sieved by subsequent vibration to achieve metal copper and negative electrode carbon powder and acetylene black powder. High-efficiency separation, the separation effect can be seen figure 1 shown. Among them, the size of copper particles is between 10 mesh and 30 mesh, the grade is greater than 95%, and the recovery rate is greater than 93%.

Embodiment 2

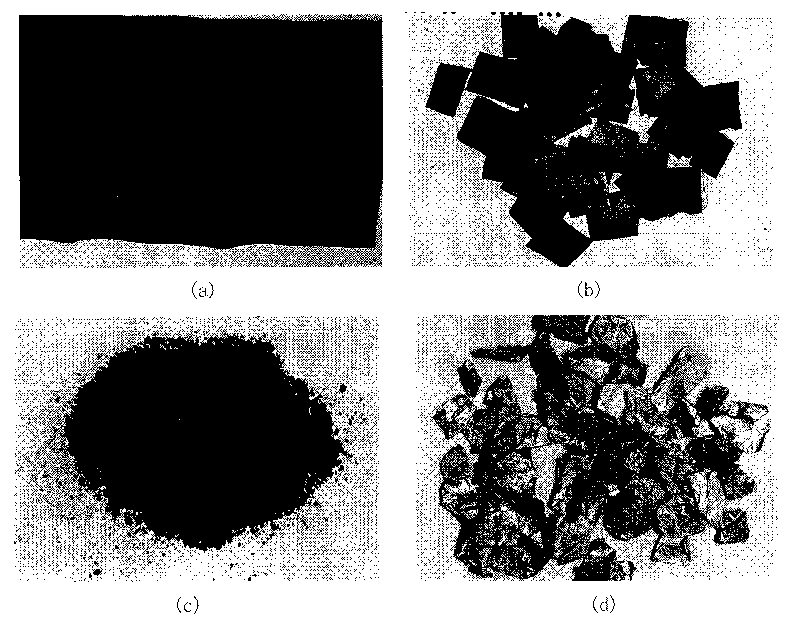

[0027] Example 2: Under the condition of normal pressure and temperature of 450°C, the sheet-shaped positive electrode was treated for 45 minutes, and then the mixture of aluminum foil, lithium cobaltate and acetylene black was vibrated and impacted, and the separation effect was shown in figure 2 As shown, wherein the recovery rate of lithium cobaltate and acetylene black mixture is as high as 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com